HVAC Tips

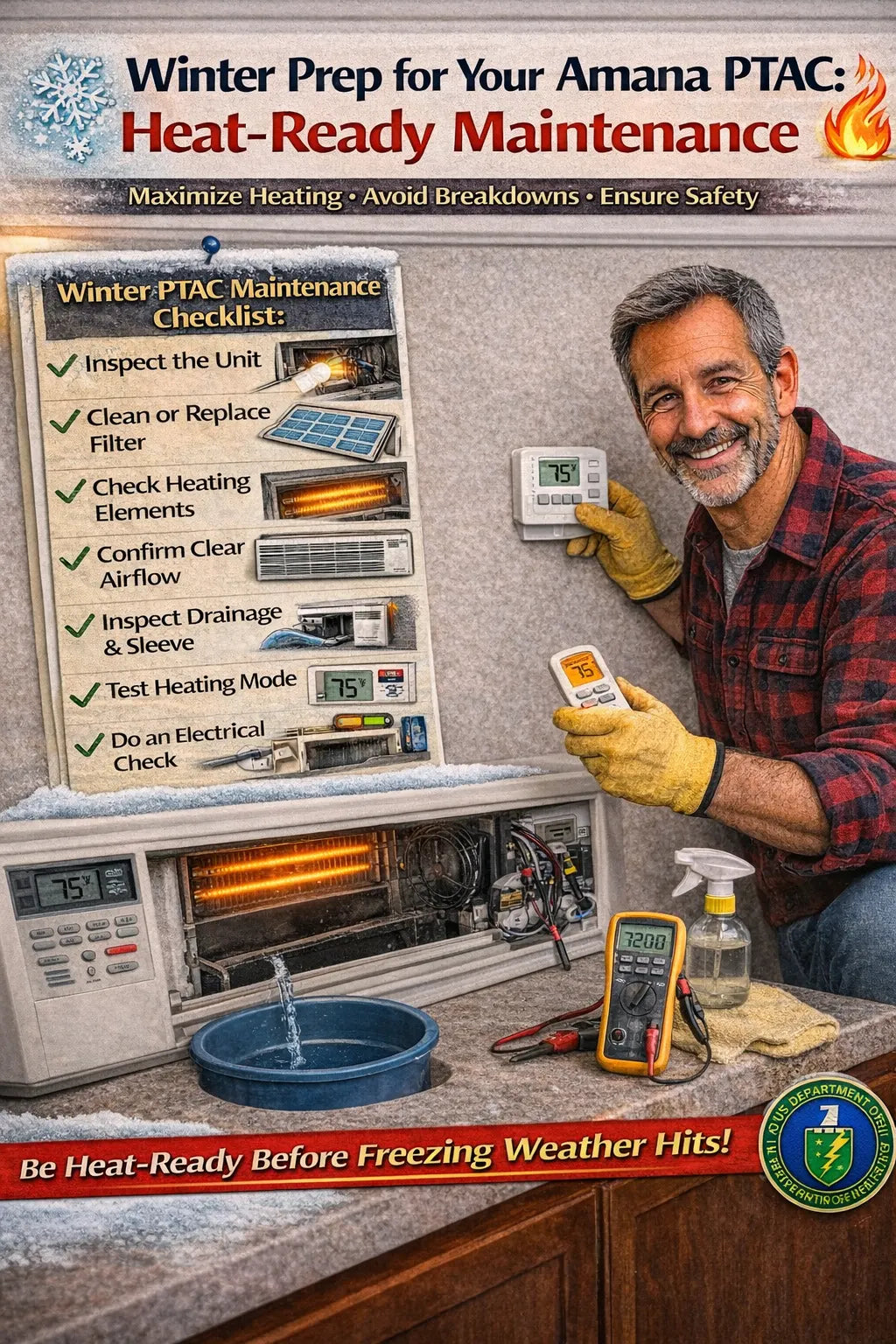

Winter Prep for Your Amana PTAC: Heat-Ready Maintenance

PTAC units don’t get a “break” when winter rolls in—they just switch jobs. Instead of dumping heat outside, your Amana PTAC is suddenly pulling ser...

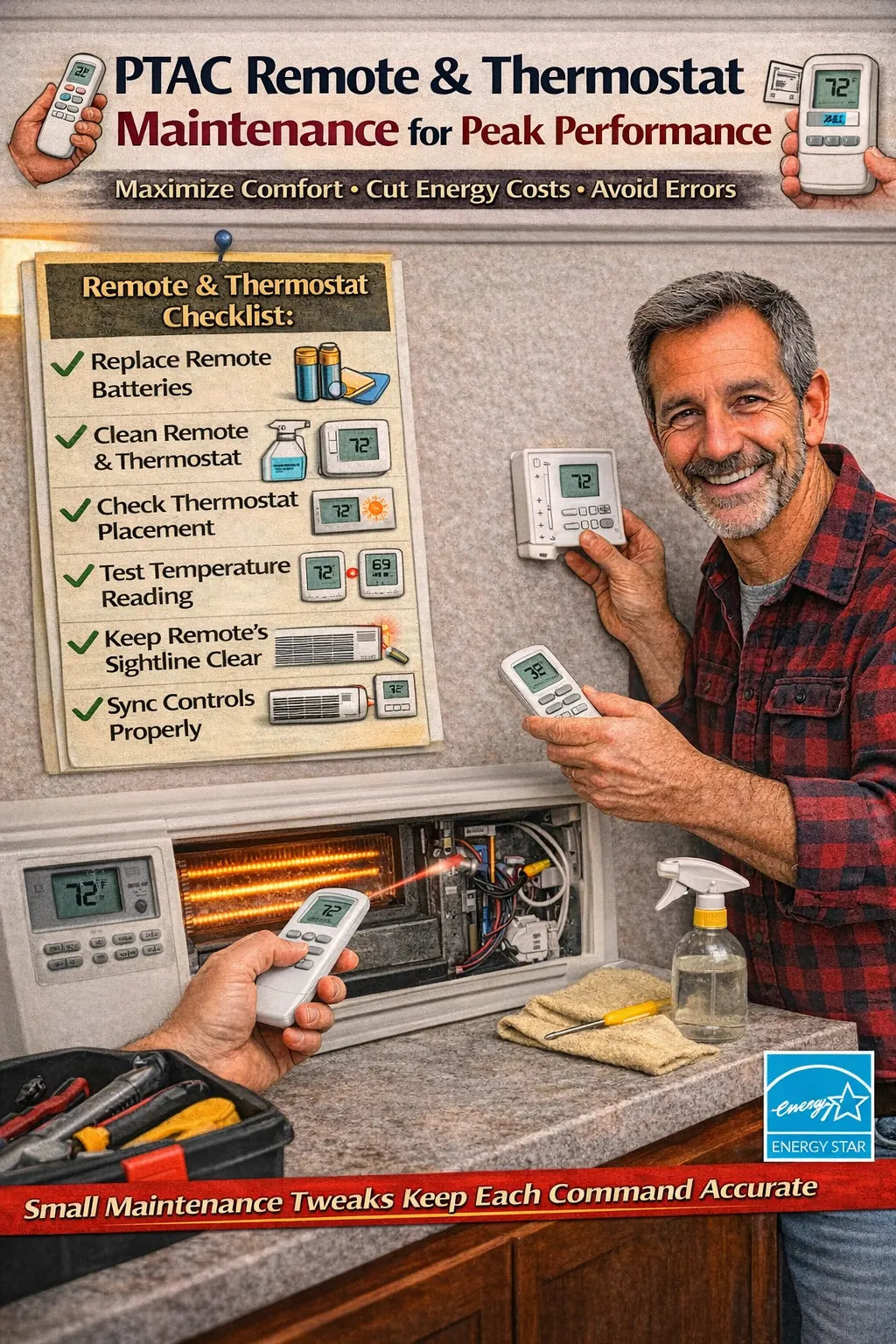

PTAC Remote & Thermostat Maintenance for Peak Performance

When a PTAC doesn’t heat or cool the way you expect, most people blame the unit itself. But more often than not, the real problem is sitting right ...

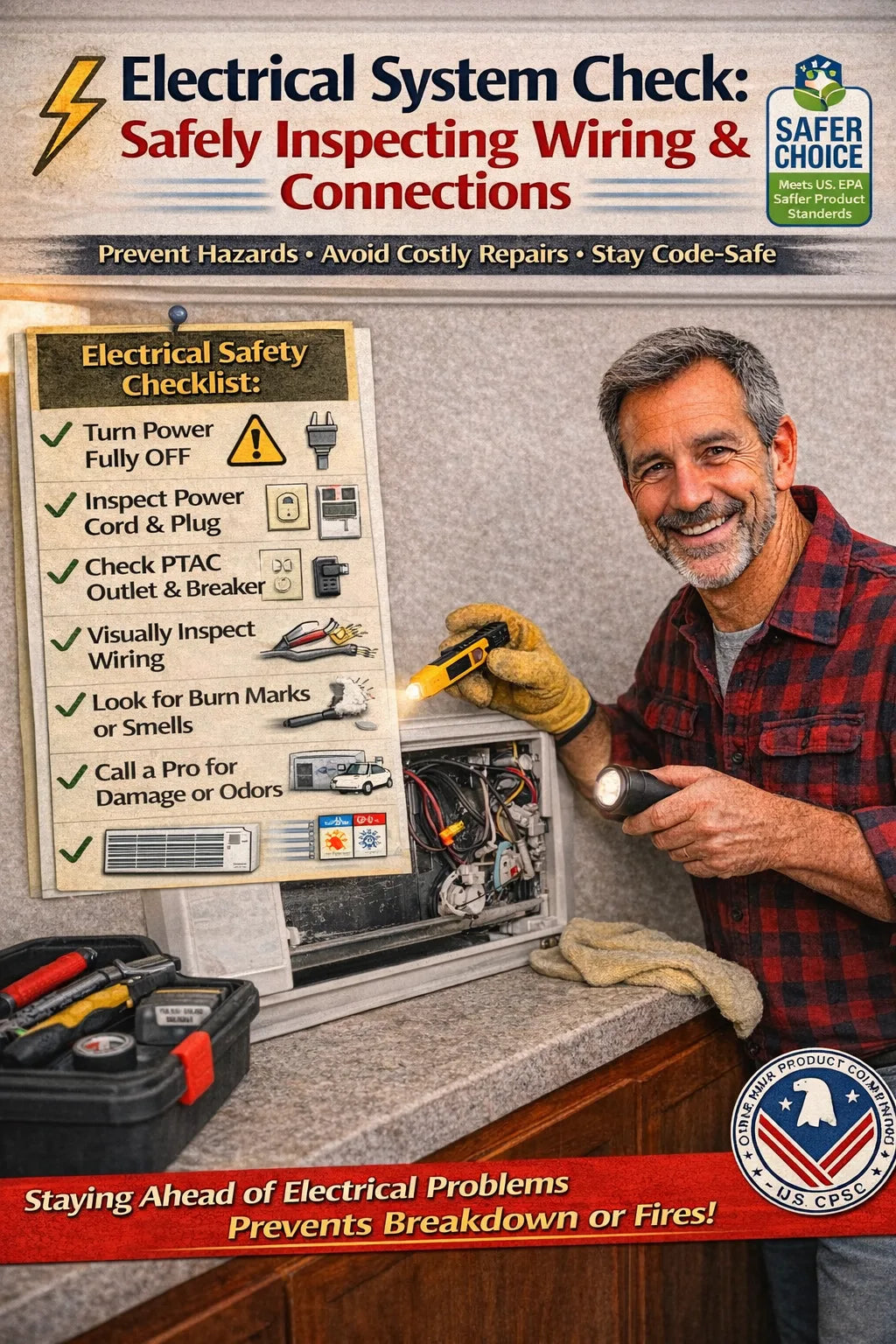

Electrical System Check: Safely Inspecting Wiring & Connections

When a PTAC unit fails unexpectedly, the root cause is often electrical—not mechanical. Loose connections, worn cords, or overheating components ca...

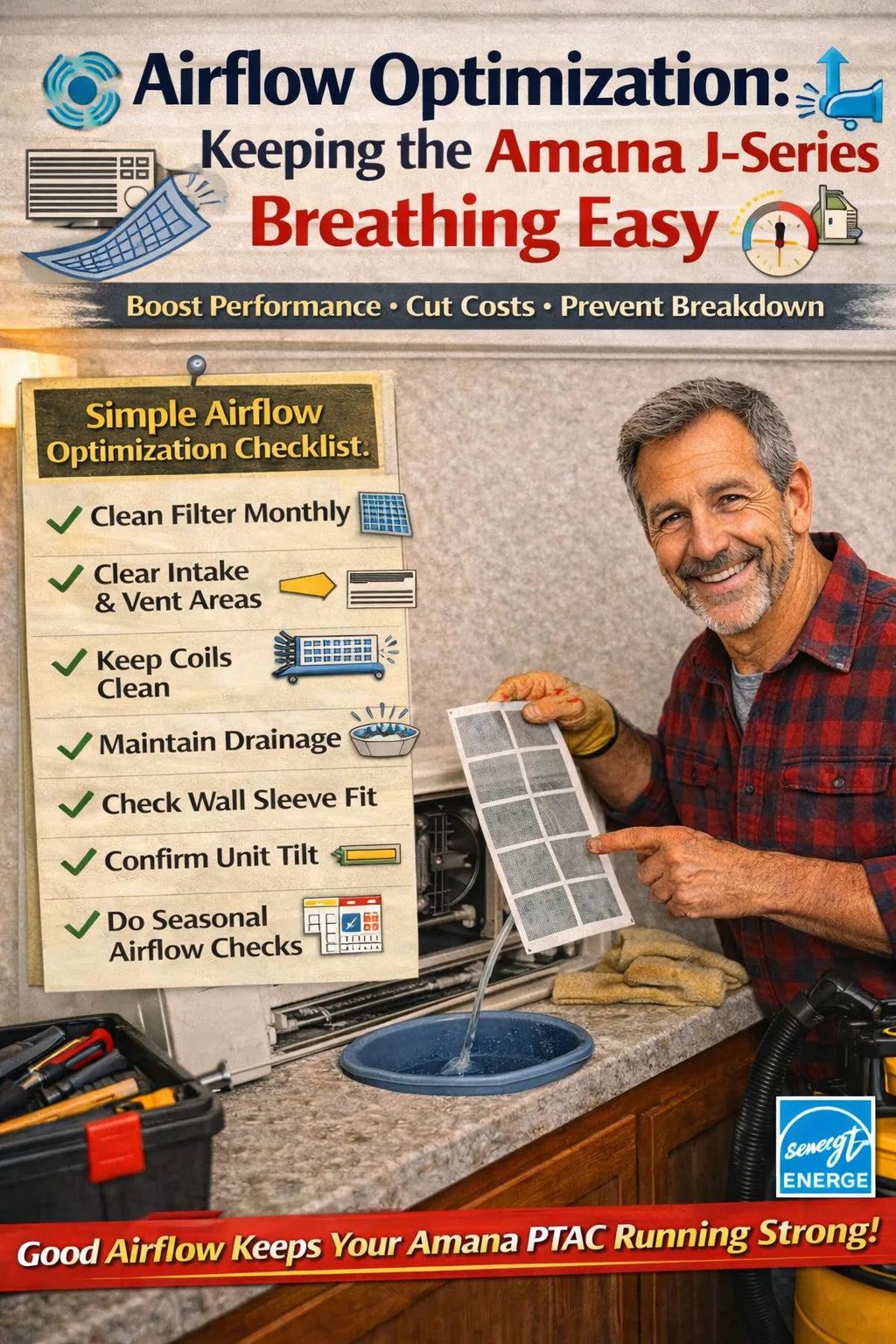

Airflow Optimization: Keeping the Amana J-Series Breathing Easy

If your Amana J-Series PTAC isn’t heating or cooling the way it used to, chances are the problem isn’t the compressor, the heater, or some expensiv...

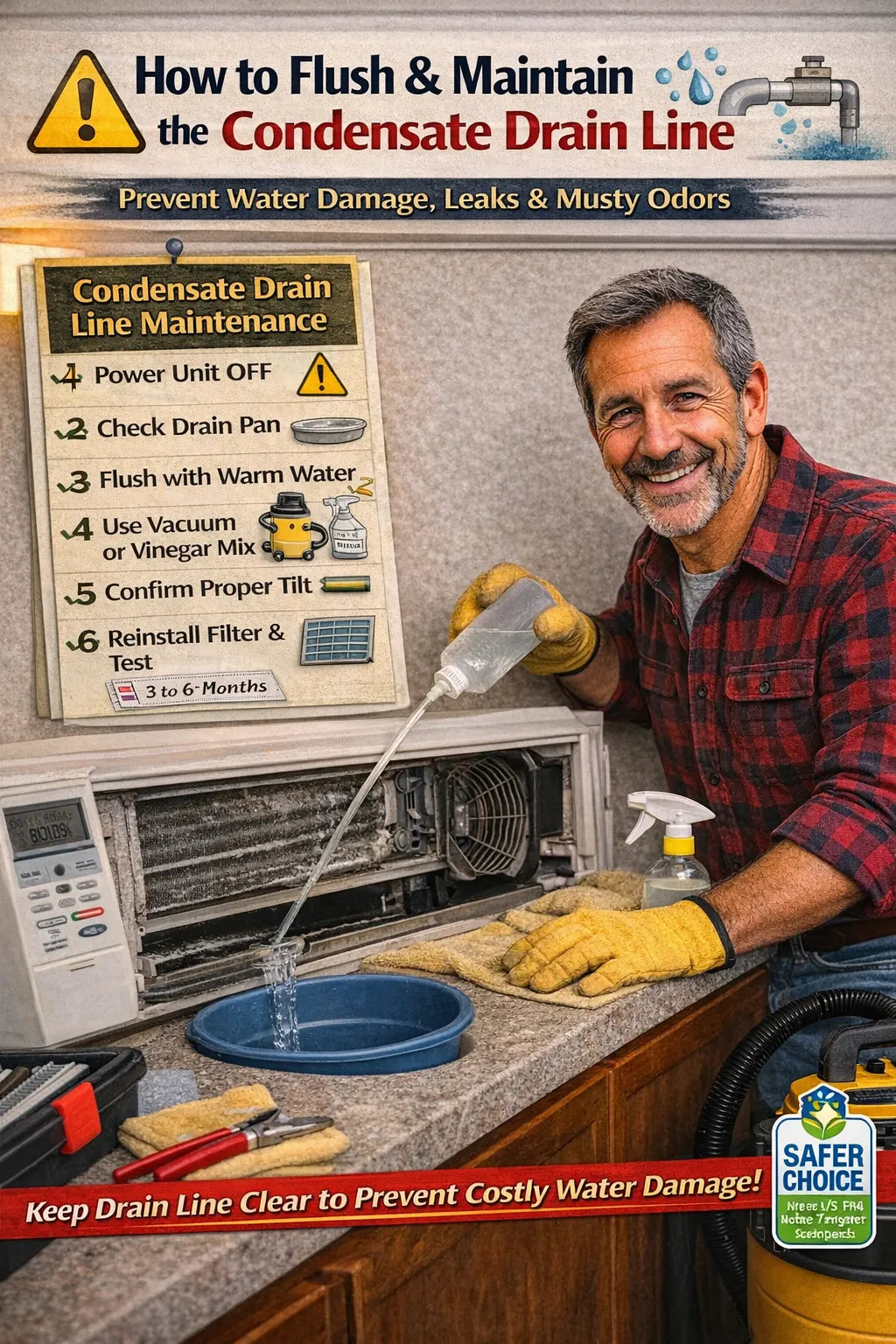

How to Flush & Maintain the Condensate Drain Line

If there’s one PTAC maintenance task that gets ignored the most—and causes the most unnecessary damage—it’s the condensate drain line.

I’ve seen pe...

Best Practices for Maintaining PTAC Heating Elements

PTAC heating elements don’t get the respect they deserve—until something goes wrong. Most people focus on cooling performance, then act surprised w...

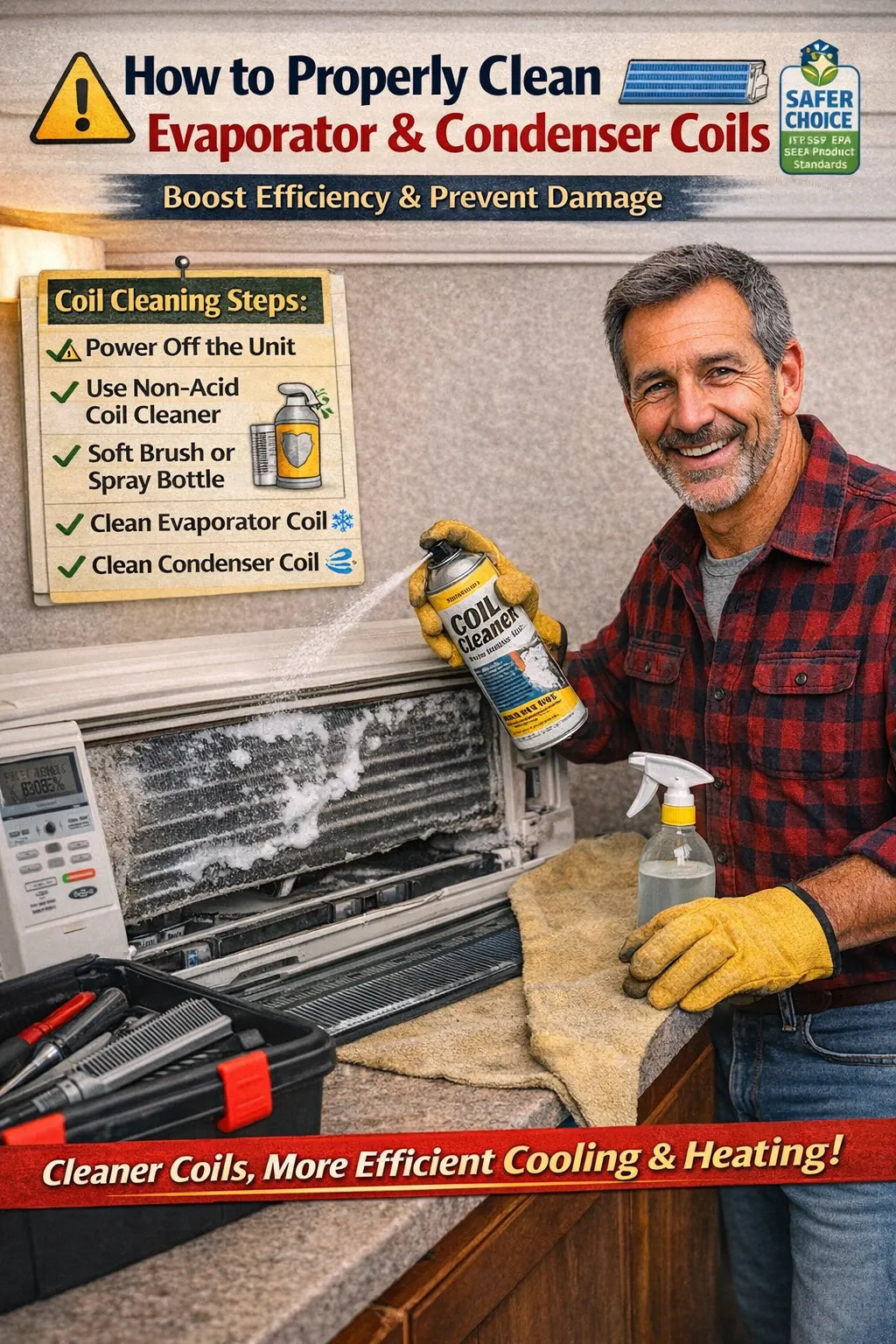

How to Properly Clean Evaporator & Condenser Coils

Dirty coils don’t just make your system work harder—they quietly drain efficiency, shorten component life, and cause performance problems that look...

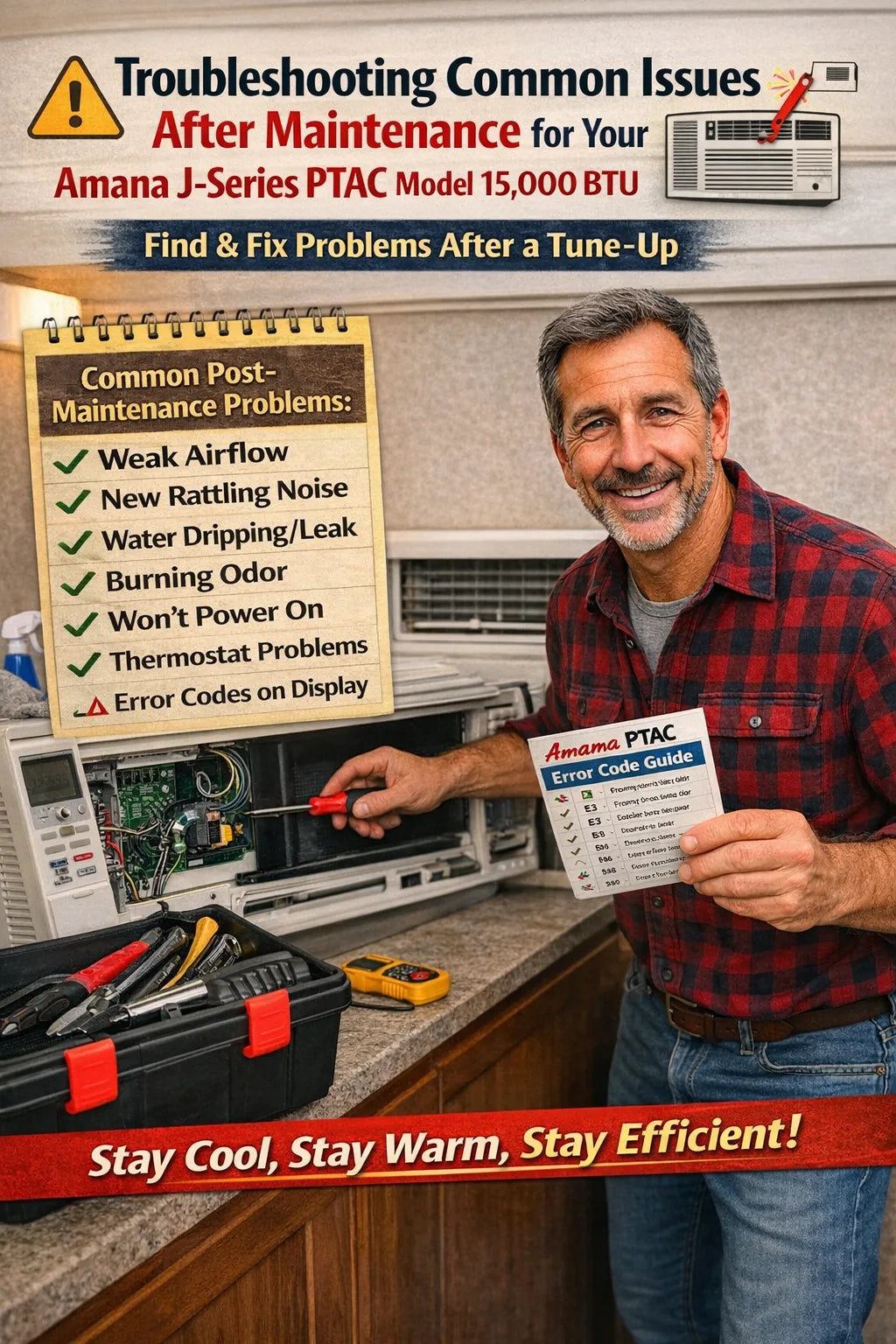

Troubleshooting Common Issues After Maintenance for your Amana J-Series PTAC Model 15,000 BTU

You just cleaned the filter, wiped things down, maybe flushed the drain—and now the unit isn’t acting right. Don’t panic. This happens more often t...

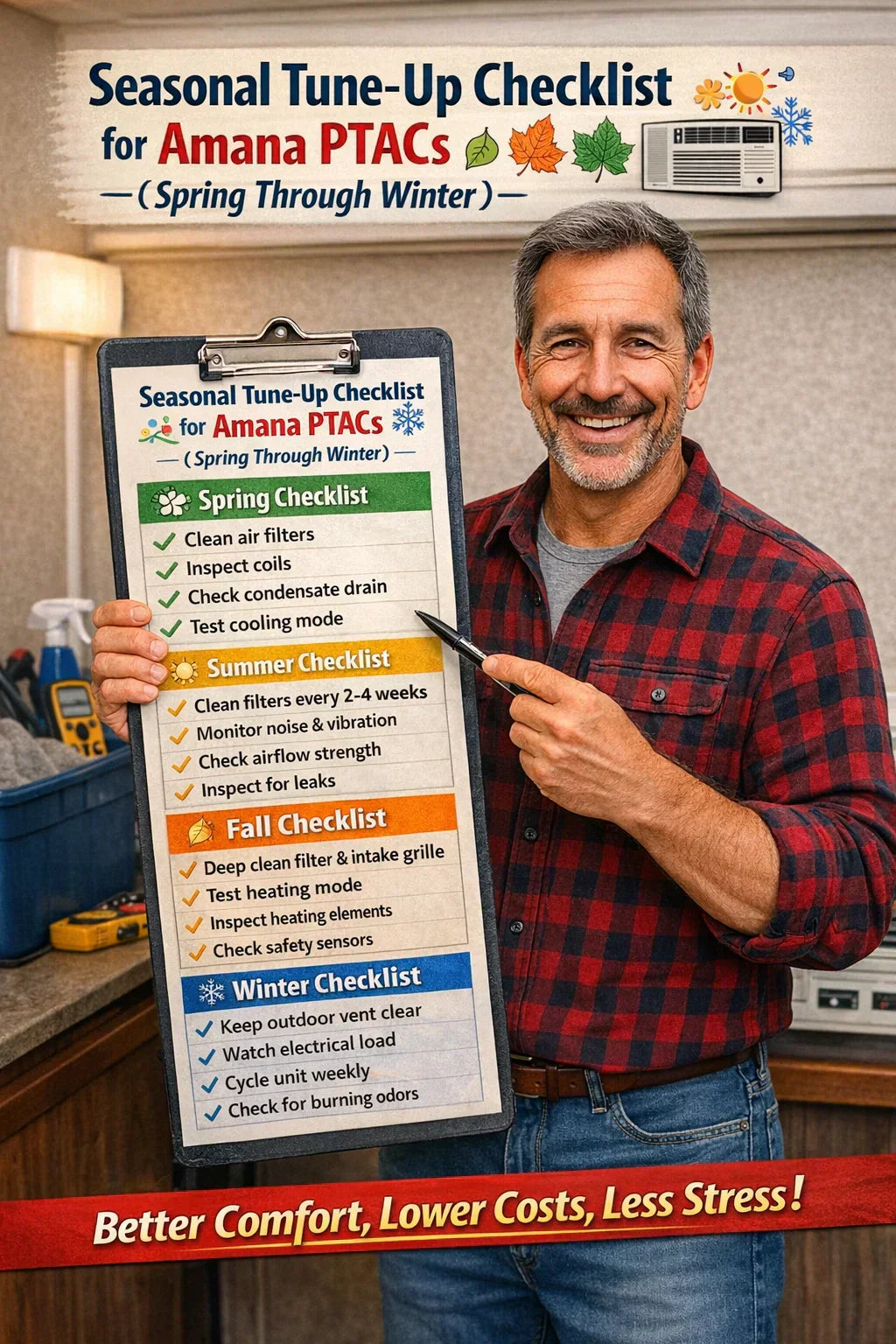

Seasonal Tune-Up Checklist for Amana PTACs: Spring Through Winter

If you want your Amana PTAC to last, run efficiently, and avoid surprise breakdowns, seasonal tune-ups aren’t optional — they’re essential. PTAC un...

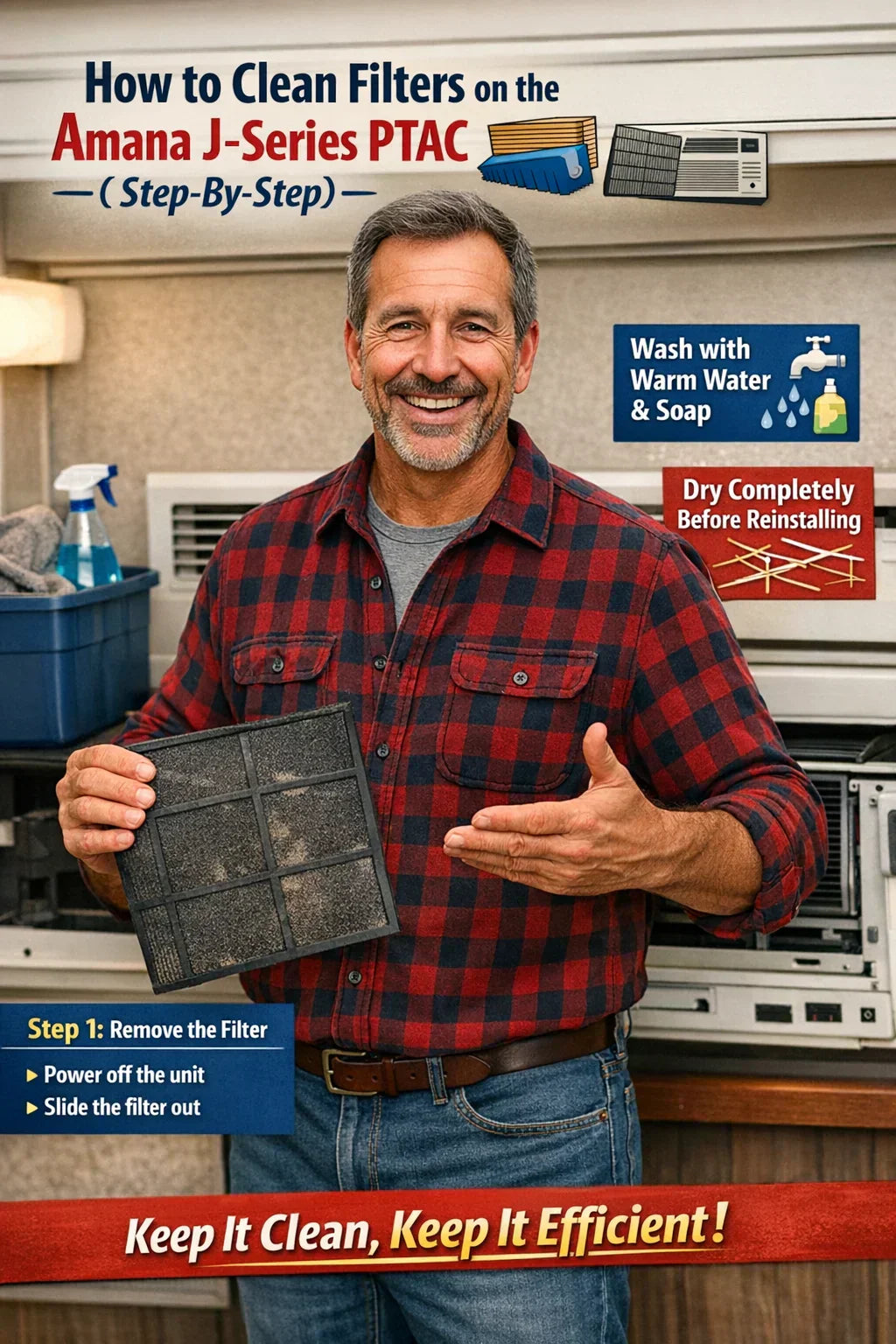

How to Clean Filters on the Amana J-Series PTAC (Step-by-Step)

If there’s one maintenance task that keeps your Amana J-Series PTAC running efficiently, quietly, and reliably, it’s cleaning the air filter. Skip ...

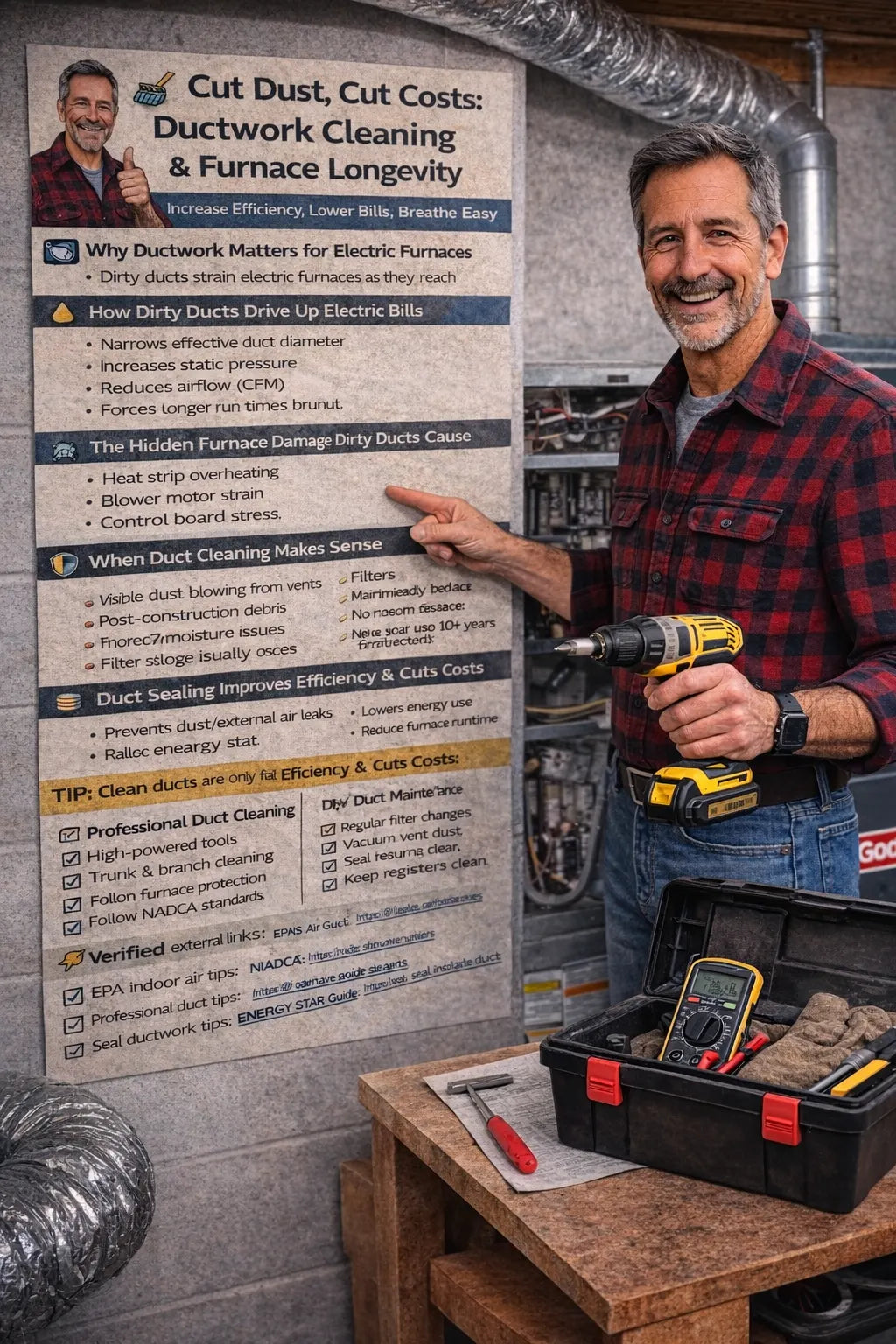

Cut Dust, Cut Costs: Ductwork Cleaning & Furnace Longevity

When homeowners ask me how to make their furnace last longer, they’re usually surprised by my answer.

It’s not just the furnace.

👉 It’s the ductwor...

How Power Surges Hurt Your Furnace — And Surge Protection That Pays Back

Most homeowners think power surges are dramatic events.

Lightning strikes.Big storms.Neighborhood-wide outages.

But the surges that quietly kill el...