If your Amana J-Series PTAC isn’t heating or cooling the way it used to, chances are the problem isn’t the compressor, the heater, or some expensive internal part. Nine times out of ten, it’s airflow.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

Airflow is the lifeblood of a PTAC system. When air moves freely, everything works easier. When it doesn’t, the unit strains, efficiency drops, and parts wear out faster than they should.

This guide breaks down how to optimize airflow the right way, what restricts it, how to fix it, and how to keep your Amana J-Series breathing easy year-round.

🧠 Why Airflow Matters More Than Almost Anything Else

PTAC units are designed around specific airflow volumes. When airflow drops:

-

Cooling capacity decreases

-

Heating elements overheat

-

Energy consumption rises

-

Moisture control suffers

-

Error codes become more likely

-

Component life shortens

The U.S. Department of Energy lists restricted airflow as one of the top causes of HVAC inefficiency and premature failure.

https://www.energy.gov/energysaver/air-conditioner-maintenance

Good airflow doesn’t just improve comfort—it protects your investment.

🔄 How Air Moves Through the Amana J-Series PTAC

Understanding the airflow path helps you fix problems faster.

Normal Airflow Path

-

Room air enters through the front intake grille

-

Air passes through the filter

-

Air moves across the evaporator coil or heating element

-

Conditioned air exits through the discharge vents

-

Heat is rejected outside via the condenser side

Any restriction along this path hurts performance.

🚫 The Most Common Airflow Killers (That I See Constantly)

Let’s call these out clearly.

❌ Dirty or Misinstalled Filters

The #1 airflow problem—by far.

❌ Blocked Intake or Discharge Vents

Furniture, curtains, luggage racks, or beds too close to the unit.

❌ Dust-Clogged Coils

Even with a clean filter, coils still collect debris.

❌ Poor Wall Sleeve Fit

Gaps or misalignment disrupt air movement.

❌ Improper Unit Tilt

Affects drainage and internal airflow patterns.

Fix these, and most PTAC “problems” disappear.

🧼 Step 1: Filter Maintenance (The Foundation of Airflow)

If you skip everything else, don’t skip this.

Best Practices

✔ Clean or wash filters every 30 days

✔ Clean more often with pets, smoke, or high traffic

✔ Ensure the filter sits flat and fully seated

✔ Replace damaged or warped filters

Never run the Amana J-Series without a filter installed—even briefly.

ENERGY STAR confirms that clean filters are one of the simplest ways to maintain HVAC airflow and efficiency.

https://www.energystar.gov/newhomes/features-benefits/heating-cooling

🪑 Step 2: Clear the Air Path (Inside the Room)

PTACs need open breathing space.

Minimum Clearance Guidelines

-

12–18 inches in front of the unit (recommended)

-

No furniture blocking the intake

-

Curtains should never drape over vents

Even partial blockage can:

-

Cause short cycling

-

Create uneven room temperatures

-

Increase noise

-

Trigger safety shutdowns

If airflow can’t enter freely, nothing downstream matters.

❄️ Step 3: Keep the Coils Clean (Airflow’s Silent Partner)

Airflow and coil condition go hand in hand.

Dirty coils:

-

Restrict air passage

-

Trap moisture

-

Reduce heat transfer

-

Increase fan workload

Inspect coils at least once per year, and more often in dusty environments.

The Department of Energy emphasizes that clean coils are essential to maintaining proper airflow and efficiency.

https://www.energy.gov/energysaver/air-conditioner-maintenance

💧 Step 4: Drainage & Airflow Are Connected

This one surprises people.

When condensate can’t drain properly:

-

Water pools near airflow paths

-

Humidity increases inside the unit

-

Mold and bio-growth restrict airflow

-

Odors develop

A clear condensate drain supports clean airflow.

The EPA highlights moisture control as critical for HVAC airflow and indoor air quality.

https://www.epa.gov/indoor-air-quality-iaq

🧱 Step 5: Wall Sleeve & Installation Check

Airflow problems aren’t always inside the unit.

Inspect the Wall Sleeve For:

✔ Proper alignment

✔ No crushed insulation

✔ No gaps allowing air bypass

✔ Clear outdoor vent openings

Poor sleeve fit allows air to short-circuit instead of flowing correctly through the coils.

📐 Step 6: Confirm Proper Unit Level

PTACs are designed with a slight outward tilt.

If the unit is level or tilted inward:

-

Drainage slows

-

Moisture builds up

-

Internal airflow patterns suffer

This doesn’t just cause leaks—it disrupts airflow balance inside the cabinet.

🔊 Step 7: Listen—Your Ears Catch Airflow Issues Early

Healthy airflow sounds steady and smooth.

Warning Sounds

⚠ Whistling → restriction

⚠ Rattling → loose panels disrupting airflow

⚠ Loud fan noise → working too hard

⚠ Pulsing air → short cycling

New sounds after maintenance almost always mean airflow alignment issues.

🔄 Step 8: Seasonal Airflow Adjustments

Cooling Season

-

Filters clog faster

-

Coils collect pollen and dust

-

Drain lines work harder

Heating Season

-

Airflow keeps heating elements safe

-

Dust burns off initially

-

Blocked airflow increases electrical load

Test airflow at the start of each season, not after problems show up.

Amana recommends seasonal operational checks for PTAC performance.

https://www.amana-hac.com/resources/hvac-learning-center

🧰 DIY vs Professional Airflow Optimization

Safe DIY Tasks

✔ Filter maintenance

✔ Vent clearance

✔ Visual coil inspection

✔ Drain flushing

✔ Panel reseating

Call a Pro If You See

⚠ Weak airflow with clean filters

⚠ Repeated error codes

⚠ Ice buildup

⚠ Persistent overheating

⚠ Fan motor noise or failure

Amana provides owner support and service guidance for PTAC airflow-related issues.

https://www.amana-hac.com/support

❌ Airflow Myths That Cause Problems

Let’s clear these up:

❌ “If air comes out, airflow is fine”

❌ “More fan speed fixes everything”

❌ “Filters only affect air quality, not performance”

❌ “Heating mode doesn’t need airflow”

All false—and all expensive over time.

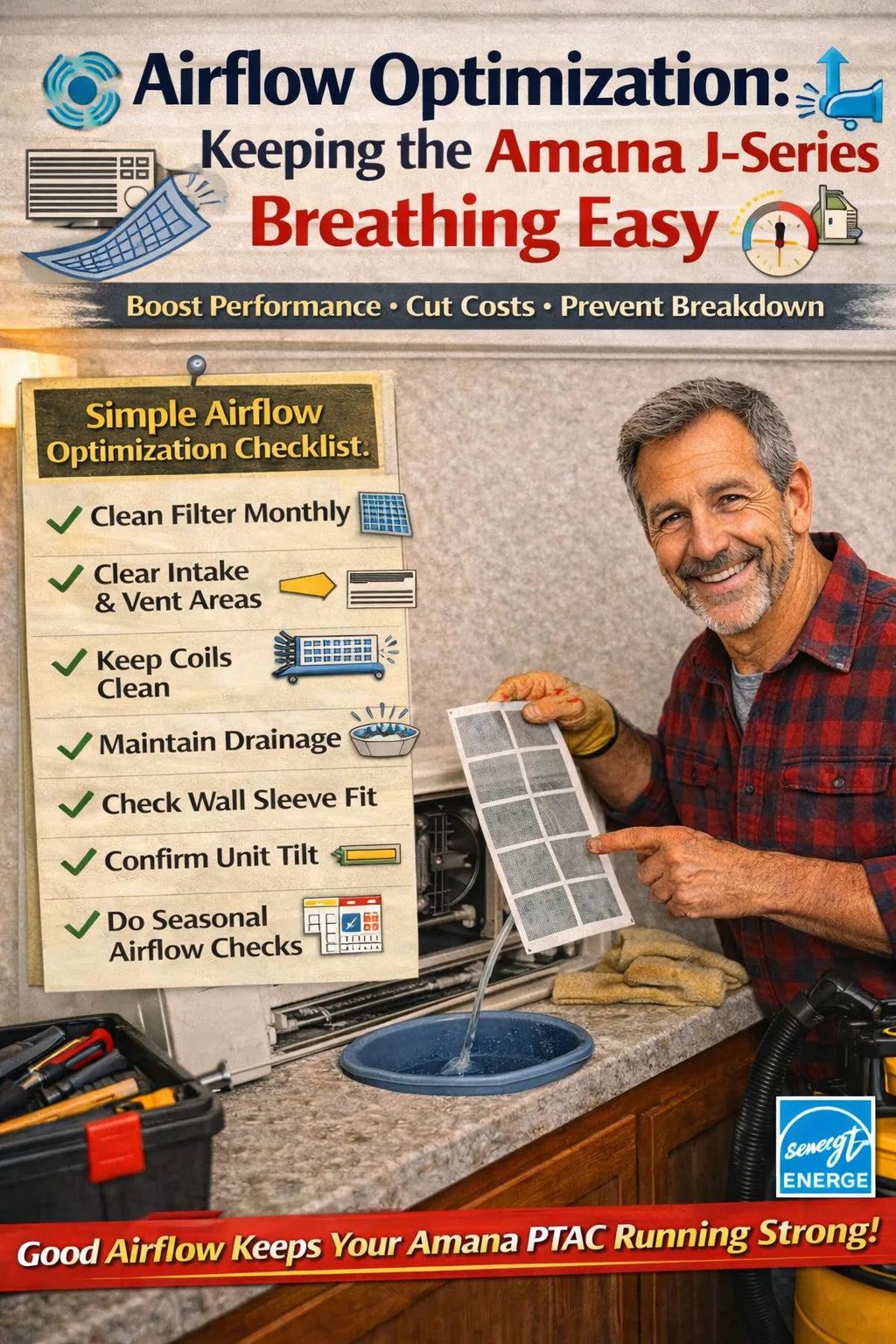

📅 Simple Airflow Maintenance Schedule

Monthly

-

Clean filter

-

Check vent clearance

-

Listen for airflow changes

Seasonally

-

Inspect coils

-

Test airflow strength

-

Check drainage

Annually

-

Deep coil cleaning

-

Sleeve and tilt inspection

Consistency beats emergency repairs every time.

🧠 Final Advice from Mike

If the Amana J-Series PTAC could talk, it would say one thing:

“Just let me breathe.”

Clean air in, clean air out—that’s the formula. When airflow is right, everything else works better, lasts longer, and costs less to operate.

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know more about: Electrical System Check: Safely Inspecting Wiring & Connections