I’ve said it for years: “Your system is only as good as the tools you build it with.”

Most homeowners think tool selection is for the installation step — the drilling, cutting, wiring, sealing. But in real system design, tools shape decisions long before construction starts.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

A stud finder tells you where your sleeve can’t go.

A thermal camera tells you how hard your PTAC or mini split will have to work.

A clamp meter tells you whether your panel agrees with your heat kit dreams.

Tools aren’t an afterthought — they’re the blueprint.

This guide lays out every tool I use to design a space before installing a PTAC, mini split, heat pump, or any HVAC equipment. If you follow this process and use the right gear, you won’t be surprised later by a wall full of pipes, a tripping breaker, or an airflow pattern that makes half your room feel like a meat locker.

Let’s build your toolkit — the same one I use on every jobsite.

🧰 1. Why Tools Matter Before You Build Anything

Most system design mistakes happen early — during planning, measuring, visualizing, and calculating. The right tools help you:

-

Avoid hidden studs and wiring

-

Map airflow geometry

-

Verify electrical capacity

-

Measure heat gain and cold spots

-

Choose the right BTU rating

-

Place sleeves, line sets, and power safely

-

Prevent rework and unnecessary wall cuts

In short: tools eliminate surprises — the expensive kind.

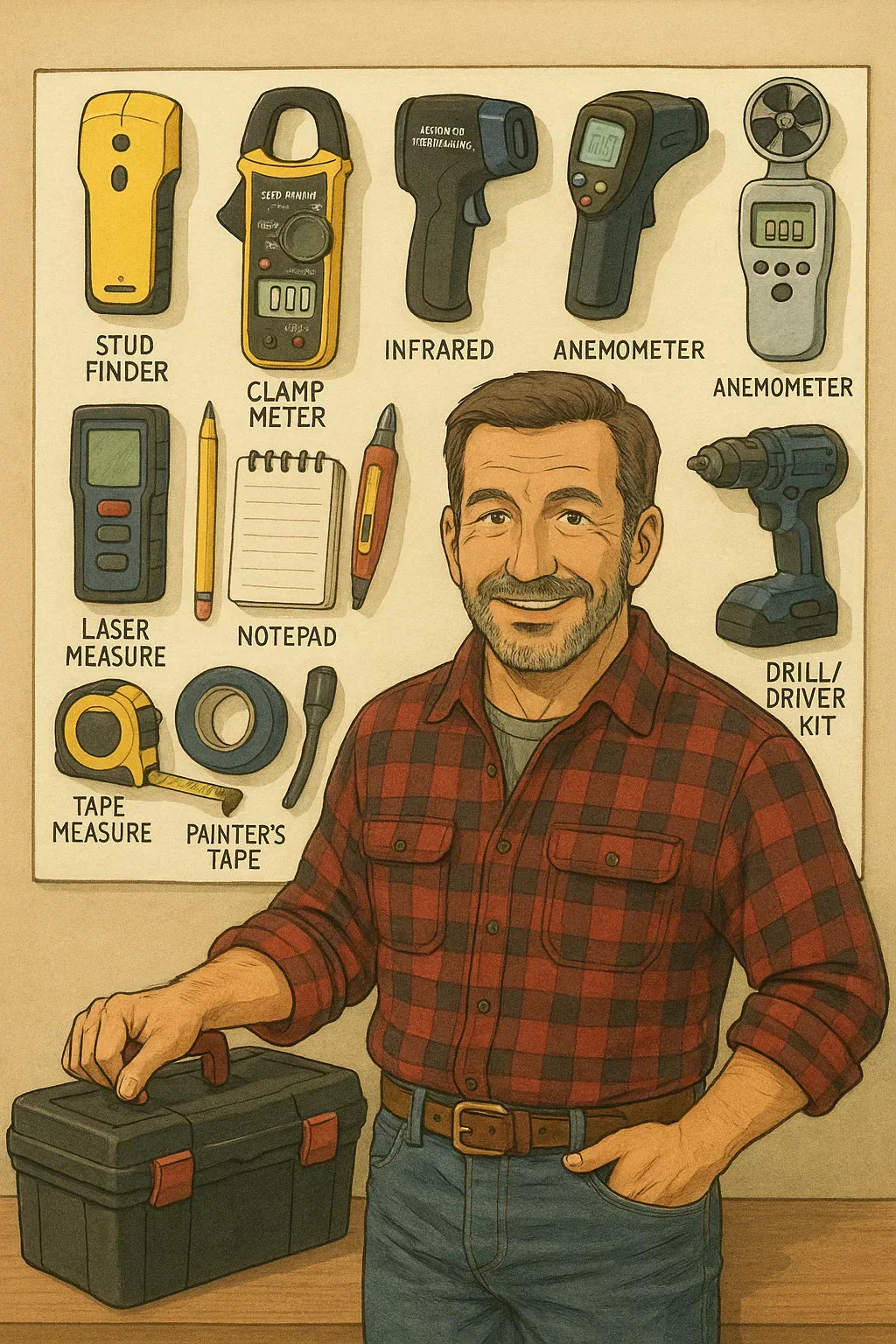

📐 2. The Foundational Tools Mike Never Starts Without

These are your must-haves for any system design project.

✔️ Stud Finder

Before planning placement for a PTAC, heat pump, or through-the-wall AC, you need to know what’s inside the wall.

You should be able to map:

-

Stud spacing

-

Crossbeams

-

Fire blocks

-

Electrical lines

A reliable stud finder prevents bad sleeve placement and costly mistakes.

✔️ Laser Measure

Forget the tape measure for big projects — laser measures give you perfect, instant room dimensions.

Critical for:

-

Airflow path mapping

-

Ceiling height verification

-

Determining clearance and throw distance

(Example of a reliable option: Bosch GLM Series – available through verified sellers.)

✔️ Infrared Thermometer / Thermal Scanner

This tool alone can change your entire system design.

With it, you can see:

-

Heat leaks around windows

-

Hot zones from sun exposure

-

Cold spots from bad insulation

-

Airflow drop-off patterns

-

Surface temperatures near vents

Your Amazon toolkit link includes a solid IR thermometer

This tool determines where your unit should go — not just where it fits.

✔️ Tape Measure & Straight Edge

Even with lasers, nothing beats tape for:

-

Marking cutouts

-

Checking sleeve height

-

Confirming depth clearances

No build starts without basic measuring fundamentals.

✔️ Notepad or Digital Sketch Tool

System design isn’t just numbers — it’s visual mapping.

Mike’s rule: “If you don’t draw it, you don’t know it.”

Sketch:

-

Wall cavities

-

Airflow paths

-

Electrical routes

-

Stud locations

-

Line set channels

-

Sleeve placement height

The entire build becomes smoother when you have a map.

🔌 3. Electrical Tools That Make or Break a Design

Electrical planning is the #1 reason PTAC and mini split installs fail.

Use these tools before choosing equipment:

✔️ Clamp Meter (Amp Meter)

Lets you measure:

-

Real-time amperage draw

-

Circuit loading

-

Breaker performance

-

Startup surge behavior

A must-have before selecting:

-

Heat kits

-

230V vs. 115V models

-

Circuit size (20A vs. 30A)

-

Hardwired vs. plug-in options

A clamp meter prevents the dreaded breaker trip.

✔️ Voltage Tester

Before routing wires or cutting a wall, confirm:

-

Which lines are live

-

Circuit paths

-

Outlet condition

Safety first. Always.

✔️ Circuit Load Calculator

Use an online tool to confirm your panel can support your selected PTAC/heat kit:

These two links alone can prevent thousands in electrical upgrades.

🌬️ 4. Tools for Mapping Airflow, Pressure & Circulation

System design lives or dies based on airflow geometry.

For that, Mike uses:

✔️ Anemometer (Airflow Meter)

Measures airspeed from existing vents and helps you identify:

-

Dead corners

-

Stagnant air pockets

-

High-flow pathways

-

Obstructions

-

Cross-draft locations

This tool helps determine the perfect:

-

PTAC louver angle

-

Air handler placement

-

Wall cutout location

✔️ Smoke Pencil / Airflow Tracer

Used by pros to see airflow patterns in real time.

You can detect:

-

Drafts

-

Leaks

-

Return path behavior

-

Airflow turbulence

Great for older homes and tricky room shapes.

✔️ Painter’s Tape for Air Path Mapping

I use tape to mark:

-

Airflow direction

-

Louver aim points

-

Return paths

-

Obstruction zones

The room becomes a living blueprint.

🧱 5. Wall, Structure & Sleeve-Mapping Tools

Before you cut, drill, or commit, use these tools to prevent problems.

✔️ Inspection Scope / Borescope Camera

A small camera that goes inside the wall to identify:

-

Pipes

-

Electrical lines

-

Insulation

-

Fire stops

-

Mold or moisture

This determines whether your desired PTAC or sleeve position is safe.

✔️ Mini Level & Torpedo Level

Ensures:

-

Straight sleeves

-

Proper condensate drainage angle

-

Level PTAC installation

A PTAC that is even 1/8” off level can leak or vibrate.

✔️ Drywall & Masonry Test Bits

Before cutting into brick or drywall, test the material.

This tells you:

-

What blade you need

-

Whether you need a sleeve support frame

-

Whether the wall cavity is viable

🔥 6. Tools That Help Choose the Right PTAC or Mini Split

These tools help you avoid overpricing, oversizing, or picking the wrong heat kit.

✔️ BTU Calculator Tools

Use DOE guidelines:

https://www.energy.gov/energysaver/room-air-conditioners

But adjust with:

-

Ceiling height

-

Window load

-

Sun exposure

-

Insulation

-

Room purpose

The right BTU rating saves thousands in energy.

✔️ Heat Load Calculator

Heat load is MUCH more important than cooling load when choosing heat kits.

✔️ Outlet Tester

Checks:

-

Outlet quality

-

Grounding

-

Polarity

Critical for plug-in PTACs and line-voltage thermostats.

🧱 7. Tools for Pre-Routing Power & Line Sets

Before buying the PTAC or mini split, you must know how you’ll route:

-

Power

-

Condensation

-

Refrigerant (if applicable)

-

Airflow

-

Drain lines

Tools include:

✔️ Drill/Driver Kit (from your Amazon link)

Perfect for:

-

Testing pilot holes

-

Mounting templates

-

Routing conduit

-

Installing sleeve anchors

✔️ Conduit Bender (for pros)

Only needed if:

-

You’re running hardwired power

-

You’re installing a disconnect

-

You’re using EMT or armored cable

✔️ Hole Saw Kit

Used for:

-

Drain exits

-

Wiring holes

-

Line set pass-throughs

Measure twice, drill once.

🛑 8. Tools That Prevent System Failure Before It Happens

These tools catch mistakes before they become expensive repairs.

✔️ Moisture Meter

Detects:

-

Damp studs

-

Failing insulation

-

Leaky window frames

Installing a PTAC in a moist wall = disaster.

✔️ Sound Meter

Identifies:

-

High-noise zones

-

Echo chambers

-

Vibration-prone areas

Don’t put a PTAC behind the headboard of a bedroom unless you’ve tested sound behavior first.

✔️ Electrical Infrared Scanner

Shows:

-

Overheated outlets

-

High-resistance wiring

-

Overloaded circuits

This is how Mike confirms a home is safe before installing a heat kit.

🧭 9. Mike’s Workflow: The Step-by-Step Tool-Driven System Design Process

Here’s how Mike uses tools in order — before buying any equipment.

STEP 1 — Measure the Room

Tools: Laser measure, tape measure

Goal: Exact square footage + ceiling height

STEP 2 — Map the Walls

Tools: Stud finder, borescope

Goal: Identify viable cutout space

STEP 3 — Check Electrical Capacity

Tools: Clamp meter, voltage tester, panel map, load calculator

Goal: Confirm breaker size and panel availability

STEP 4 — Analyze Heat & Sun Exposure

Tools: IR thermometer, thermal camera

Goal: Decide which wall the PTAC should face

STEP 5 — Predict Airflow Behavior

Tools: Anemometer, smoke pencil, painter’s tape

Goal: Choose the best airflow path

STEP 6 — Confirm Wall Structure

Tools: Level, inspection scope, test bits

Goal: Safe cutting and mounting

STEP 7 — Map Power & Line Placement

Tools: Drill kit, hole saw, conduit bender

Goal: A clean, conflict-free routing plan

STEP 8 — Match Tools to Equipment Selection

Tools: BTU calculators, heat load calculators

Goal: Choose the right PTAC/heat kit model

📋 10. Mike’s Ultimate Pre-Build Checklist

Before you buy anything, ask:

Room & Walls

-

☐ Do you know exact room dimensions?

-

☐ Do you know where studs, pipes, and wiring are located?

-

☐ Did you scan for heat gain and cold spots?

Electrical

-

☐ Does the panel support the heat kit you want?

-

☐ Do you have a dedicated circuit?

-

☐ Did you verify voltage and amperage with a clamp meter?

Airflow

-

☐ Did you test airflow paths with tape or a smoke pencil?

-

☐ Is the PTAC pointing toward the longest room dimension?

-

☐ Is there a return pathway?

Structure

-

☐ Is the sleeve location level, safe, and accessible?

-

☐ Did you inspect inside the wall cavity?

Safety

-

☐ Did you test outlets?

-

☐ Did you check moisture levels?

-

☐ Did you check for sound issues?

If all the boxes are checked — you’re ready to design and build.

🎯 Conclusion: Tools Aren’t Optional — They’re the Blueprint

Every great installation starts with the right tools.

Not for drilling.

Not for mounting.

But for designing.

Tools answer the questions your walls won’t.

They reveal:

✔️ What your electrical system allows

✔️ Where your airflow will flow

✔️ How your room behaves

✔️ Which PTAC or heat kit to choose

✔️ Where problems hide

Mike’s rule:

“Use your tools first — choose your equipment second.”

Buy this on Amazon at: https://amzn.to/3WuhnM7

In the next topic we will know more about: The Comfort Flow Diagram: Mike’s Way of Drawing Air Paths Before Installing a PTAC or Any HVAC Gear