Most homeowners believe HVAC efficiency comes from equipment SEER ratings. Mike Sanders knows better.

He’s seen brand-new 16–20 SEER2 systems run like 12 SEER units simply because the static pressure in the home is too high.

And he’s seen older 13 SEER systems perform shockingly well when static pressure is fixed.

That’s why Mike teaches this principle in every training class:

“Efficiency isn’t in the box. It’s in the airflow.”

Static pressure determines:

-

how hard the blower must work

-

how much air actually reaches the coil

-

whether the system hits SEER2 lab conditions

-

how long the equipment lasts

-

how evenly the home cools or heats

-

whether humidity is controlled properly

If static pressure is too high, the system simply cannot perform the way the manufacturer rated it.

This is Mike’s complete, field-tested method for Static Pressure Recovery — a series of home and duct modifications that transform bad systems into true SEER2 performers.

🌬️ 1. Why Static Pressure Is the Silent Killer of HVAC Efficiency

Most homeowners (and many installers) overlook static pressure entirely.

But SEER2 equipment is extremely sensitive to airflow.

A blower that can’t move the correct CFM cannot produce rated performance, regardless of SEER label.

Mike puts it this way:

“Your system can’t reach SEER2 efficiency if it’s choking on the air.”

Why? Because SEER2 testing requires very specific airflow conditions — conditions most homes don’t meet.

📊 2. What Static Pressure Actually Measures

Static pressure (ESP or TESP) measures air resistance in the duct system.

Think of it like the blood pressure of the HVAC system:

-

High static = high resistance

-

Low static = easy airflow

A blower works harder and draws more electricity when static is high.

Typical Equipment Limits:

-

Ideal: 0.40–0.50 inWC

-

Acceptable: 0.60 inWC

-

Failure range: 0.70–1.20 inWC (very common in older homes)

High static leads to:

-

loud airflow

-

poor humidity control

-

coil freezing

-

furnace overheating

-

reduced compressor life

-

shortened blower life

-

duct noise and popping

External Link: ENERGY STAR on airflow and static pressure

🚫 3. The Six Causes of High Static Pressure in Homes

Before Mike fixes anything, he identifies the cause.

Static pressure usually spikes due to one or more of these issues:

1️⃣ Undersized Return Ducts

This is the #1 cause.

80% of homes have inadequate return paths for modern high-static blowers.

2️⃣ One-Inch Filter Racks

A 1" pleated filter alone can add 0.20–0.30 inWC of pressure.

This eats half the entire static pressure budget.

3️⃣ Restricted Coils

Dirty or badly designed evaporator coils can add:

-

0.15–0.40 inWC

-

even more if misaligned

4️⃣ Long Fex Duct Runs

Sagging and kinked flex duct massively increases resistance.

5️⃣ Poor Plenum Geometry

Sharp angles cause turbulence → turbulence increases static.

6️⃣ Undersized Supply Branches

6" runs everywhere can’t feed a 4-ton system.

🧭 4. Mike’s Static Pressure Recovery Blueprint (Overview)

Mike uses the same process for every home:

**STATIC PRESSURE RECOVERY =

Increase Air Capacity

-

Reduce Air Restrictions

-

Improve Air Path Geometry

-

Balance Supply & Return**

This transforms a system from “struggling” to “performing like SEER2 intended.”

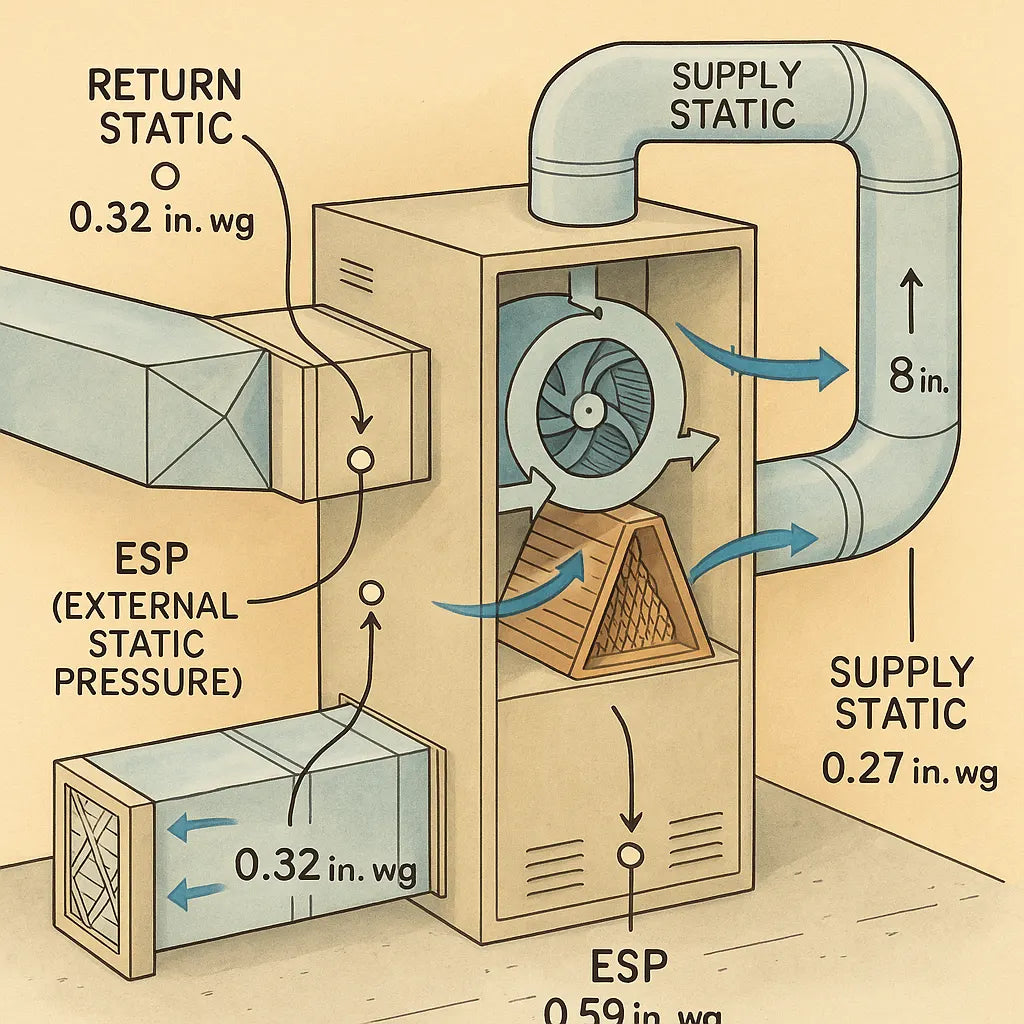

🧰 5. Step 1: Measure Static Pressure at Four Points

Mike doesn’t guess — he measures:

📍 Return static

📍 Supply static

📍 Total external static pressure

📍 Coil/static drop across key components

He uses pressure taps on:

-

the return plenum

-

the supply plenum

-

just before and after the coil

-

before and after the filter

This creates a complete static pressure map.

🧱 6. Step 2: Recover Return-Side Airflow

(Return side contributes 50–70% of static pressure problems.)

Mike’s Rule:

“Fix the return, fix the system.”

🟦 6.1 Add or Enlarge Return Ducts

4-ton systems usually need:

-

(2) 14–16" returns

or -

(1) 18–20" return

Mike often adds a second return on the opposite end of the house.

🟦 6.2 Replace 1" Filter Racks

A 1" filter rack can add 0.25 inWC.

Mike installs:

-

4" media cabinets

-

2" commercial filter racks

External Link: EPA on air filter resistance

https://www.epa.gov/indoor-air-quality-iaq/air-cleaners-and-air-filters-home

🟦 6.3 Seal Return Leaks

Leaky returns suck in:

-

attic air

-

dust

-

insulation

-

hot/cold outdoor air

…which dramatically increases static and decreases system performance.

🟦 6.4 Widen Return Grilles

Grilles must have:

-

2× the free area of the filter

-

angled louvers

-

tall/wide openings

🌬️ 7. Step 3: Improve Supply-Side Airflow Capacity

Once the return side is fixed, Mike corrects the supply ducts.

🟥 7.1 Enlarge Main Supply Trunks

Most 4-ton homes need:

-

18" round trunk

-

or 20"x8" rectangular minimum

-

ideally 24"x8" for quiet operation

🟥 7.2 Upsize Long Supply Branches

Long branches create enormous friction loss.

Typical upgrades:

-

6" → 7" or 8"

-

7" → 8" or 9"

🟥 7.3 Remove Kinks and Sags in Flex Duct

Flex duct increases static by:

-

10% (perfect install)

-

30% (average install)

-

60% (bad install)

Mike rehanges and straightens flex to factory spec:

-

no more than ½" sag per foot

-

smooth sweeping bends

🟥 7.4 Add Additional Supply Runs

Under-supplied rooms create pressure traps.

Mike adds new supply runs to:

-

large living rooms

-

upstairs bedrooms

-

bonus rooms

-

sunrooms

📐 8. Step 4: Correct Plenum & Coil Geometry

Plenums are airflow bottlenecks when badly built.

🟧 8.1 Lengthen Transitions (Laminar Flow Creation)

Short transitions create turbulence.

Mike replaces them with:

-

30° transitions

-

45° if space limited

-

never 90°

This dramatically drops static pressure.

🟧 8.2 Replace Old Coils or Clean Them

Coils cause static pressure spikes when:

-

dirty

-

rusted

-

misaligned

-

mismatched to blower

Mike ensures coil static drop stays under:

-

0.15–0.20 inWC for SEER2 M coils

-

0.25–0.30 inWC for denser coil designs

External Link: Coil maintenance & efficiency

https://www.energy.gov/energysaver/central-air-conditioning

🌀 9. Step 5: Balance the System for Pressure-Neutral Operation

Once capacity and geometry are fixed, Mike balances the system.

🟩 9.1 Adjust Blower Speeds

He matches blower profiles to:

-

duct capacity

-

coil load

-

comfort goals

-

humidity control

🟩 9.2 Balance Dampers

Supply dampers are adjusted to:

-

reduce high-flow rooms

-

boost low-flow rooms

-

balance overall airflow

🟩 9.3 Fix Bedroom Pressure Traps

Mike adds:

-

jumper ducts

-

transfer grilles

-

undercut doors

🔧 10. Step 6: Perform Post-Recovery Static Pressure Testing

After modifications, Mike retests:

Return static

Supply static

Total external static

A successful recovery meets:

✔️ 0.45–0.55 inWC (SEER2 performance zone)

✔️ Correct CFM for system size

✔️ Balanced pressure between rooms

If high static remains, Mike revisits:

-

filter size

-

coil mismatch

-

tight duct bends

-

trunk undersizing

-

flex replacements

Static pressure must be inside the “quiet zone” for full SEER2 performance.

🧪 11. Case Study: Static Pressure Recovery on a 4-Ton R-32 System

Home: 2,700 sq ft

Equipment: Goodman 4-Ton SEER2 R-32 System

Original static: 0.84 inWC

Symptoms:

-

loud airflow

-

poor cooling

-

humidity above 63%

-

short cycling

-

high energy bills

Mike’s Modifications:

-

added second return duct

-

replaced 1” filter rack with 4” media filter cabinet

-

upsized trunk from 16" to 20"x8"

-

added new 8" supply run to great room

-

fixed sagging flex duct

-

re-tuned blower for optimal CFM

Results:

-

final static: 0.46 inWC

-

humidity dropped to 51%

-

airflow noise reduced 40%

-

compressor runtime smoothed

-

SEER2 performance restored

-

customer could raise thermostat 3 degrees

This is static pressure recovery at its finest.

🎚️ 12. What Happens When Static Pressure Drops Back Into the SEER2 Zone?

Once static pressure returns to acceptable levels, the system transforms:

🌡️ 12.1 Better Cooling & Heating Performance

Air moves more freely across the coil and heat exchanger.

💧 12.2 Improved Humidity Removal

Lower velocity + proper CFM = ideal dehumidification.

💨 12.3 Quieter Airflow

Lower static = less duct noise and blower ramping.

⚡ 12.4 Lower Energy Use

Blowers use less wattage.

Compressors cycle less often.

🛠️ 12.5 Longer Equipment Life

Blower motors and compressors last much longer when not fighting high static pressure.

🏡 12.6 More Even Room Temperatures

Pressure-neutral homes feel:

-

less drafty

-

more consistent

-

more comfortable

Even at higher thermostat settings.

🎯 13. Mike’s Static Pressure Recovery Rules (Quick Summary)

✔️ Rule 1: Static pressure above 0.60 means the system is underperforming

✔️ Rule 2: 1-inch filters are the #1 airflow choke point

✔️ Rule 3: Return ducts must exceed supply ducts in capacity

✔️ Rule 4: Flex duct must be straight and lifted

✔️ Rule 5: Coil airflow drop must be measured, not guessed

✔️ Rule 6: SEER2 systems demand perfect airflow

✔️ Rule 7: Transitions must be long and smooth

✔️ Rule 8: Never tune blower speed until duct restrictions are fixed

✔️ Rule 9: Seal all return leaks before supply leaks

✔️ Rule 10: You cannot buy SEER2 performance — you must design for it

🏁 Final Takeaway

Mike says it plainly:

“Releasing static pressure is like opening the lungs of the system. Once it breathes, it performs.”

Static Pressure Recovery is not optional — it is the difference between:

-

a loud, short-cycling, energy-hungry system

-

and a quiet, efficient, SEER2-performing comfort machine

When you control airflow, you control comfort.

And when you control static pressure, you unlock the true performance of the HVAC equipment.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: The Comfort Envelope Blueprint: How Mike Maps Heat Loads Before Touching a Thermostat