Most homeowners think bigger HVAC equipment means better cooling. Mike Sanders knows the opposite is often true.

A 4-ton system is a serious airflow machine. It moves 1,600–2,000+ CFM, generates higher blower RPM, and pushes air with a force that smaller duct systems simply weren’t designed to handle.

When the equipment is big but the layout is small, tight, or undersized, Mike sees the same problems again and again:

-

loud vents

-

uneven temperatures

-

short-cycling

-

coil freeze-ups

-

furnace overheating

-

ducts “popping” or “pulsing”

-

cold blasts instead of comfort

-

humidity that never drops

-

home feeling clammy even when cold

Mike calls these High-Velocity Pressure Symptoms, and they mean one thing:

“The 4-ton system is overpowering the duct layout instead of serving it.”

This article covers Mike’s complete, field-tested blueprint for diagnosing and correcting high-velocity problems so a 4-ton system can run quietly, evenly, and efficiently — even in a home that originally wasn’t built for it.

📉 1. What Causes a 4-Ton System to Overpower a Home?

Mike starts with a simple truth:

“High velocity doesn’t come from big tonnage. It comes from small ducts.”

When ducts are undersized for a 4-ton system, velocity and static pressure skyrocket.

The root causes are almost always one of these five issues:

1️⃣ Undersized Supply Branches

Most older homes use:

-

6" supply runs

-

5" boot connections

-

narrow trunk lines

But a 4-ton system needs:

-

large branches

-

low pressure

-

smooth, high-volume airflow

If supply ducts can’t move 400+ CFM per ton, velocity spikes and airflow becomes loud and forceful.

2️⃣ Oversized Equipment in a Low-Load Home

Many homes only need:

-

2.5 tons

-

maybe 3 tons

But due to old-school sizing practices (“a ton per 500 sq ft” or “bigger is better”), they end up with 4-ton or even 5-ton systems.

Oversized equipment:

-

cools too fast

-

never dehumidifies

-

creates cold blasts

-

cycles constantly

External Link: DOE on proper sizing

https://www.energy.gov/energysaver/central-air-conditioning

3️⃣ High-Static / Low-CFM Air Handlers

Modern SEER2 units often use restrictive coils and dense filter racks.

Combine that with undersized ductwork, and static pressure skyrockets.

High static → High velocity at registers.

4️⃣ Supply-Return Imbalance

If supply air is high but return air is limited, pressure increases and air speeds up.

Rooms become:

-

pressurized

-

drafty

-

uncomfortable

-

unevenly cooled

5️⃣ Flex Duct Problems

Flex duct is the #1 cause of velocity issues because:

-

it sags

-

compresses

-

raises static pressure

-

causes turbulence

Mike replaces or rehanges flex in half the homes he works on.

🧭 2. The Symptoms of a High-Velocity System (How Mike Diagnoses Them)

Mike doesn’t guess.

He looks and listens for specific velocity indicators.

🔊 2.1 Loud Air Noise From Vents

If you can “hear the air,” velocity is too high.

Normal velocity at registers: 600–900 FPM

High velocity (problematic): 1,100–1,800+ FPM

🥶 2.2 Cold Blasts Instead of Even Cooling

Air moves too fast to mix with room air, creating:

-

cold spots

-

drafts

-

“wind chill effect”

The room may hit the thermostat setting but still feel uncomfortable.

🔥 2.3 Furnace Overheating in Winter

Airflow is too restricted, causing:

-

high temp rise

-

limit switch trips

-

short cycling

External Link: Furnace temperature rise basics

https://www.energy.gov/energysaver/furnaces-and-boilers

❄️ 2.4 AC Coil Freeze-Ups in Summer

When airflow is insufficient, the coil gets too cold.

Blower may be moving fast, but static pressure is starving the coil.

💧 2.5 Humidity Never Drops

Short cycles and high velocity reduce:

-

coil contact time

-

moisture removal

-

latent cooling

Rooms feel clammy even at 71°F.

🔁 2.6 Rooms With Uneven Temperatures

High velocity pushes air toward the “path of least resistance,” not where it’s needed.

Some rooms get blasted; others get nothing.

🏚️ 2.7 Ducts “Boom,” “Pop,” or Pulse

Pressure surges cause metal ducts to flex.

This is a symptom of structural stress in the duct system.

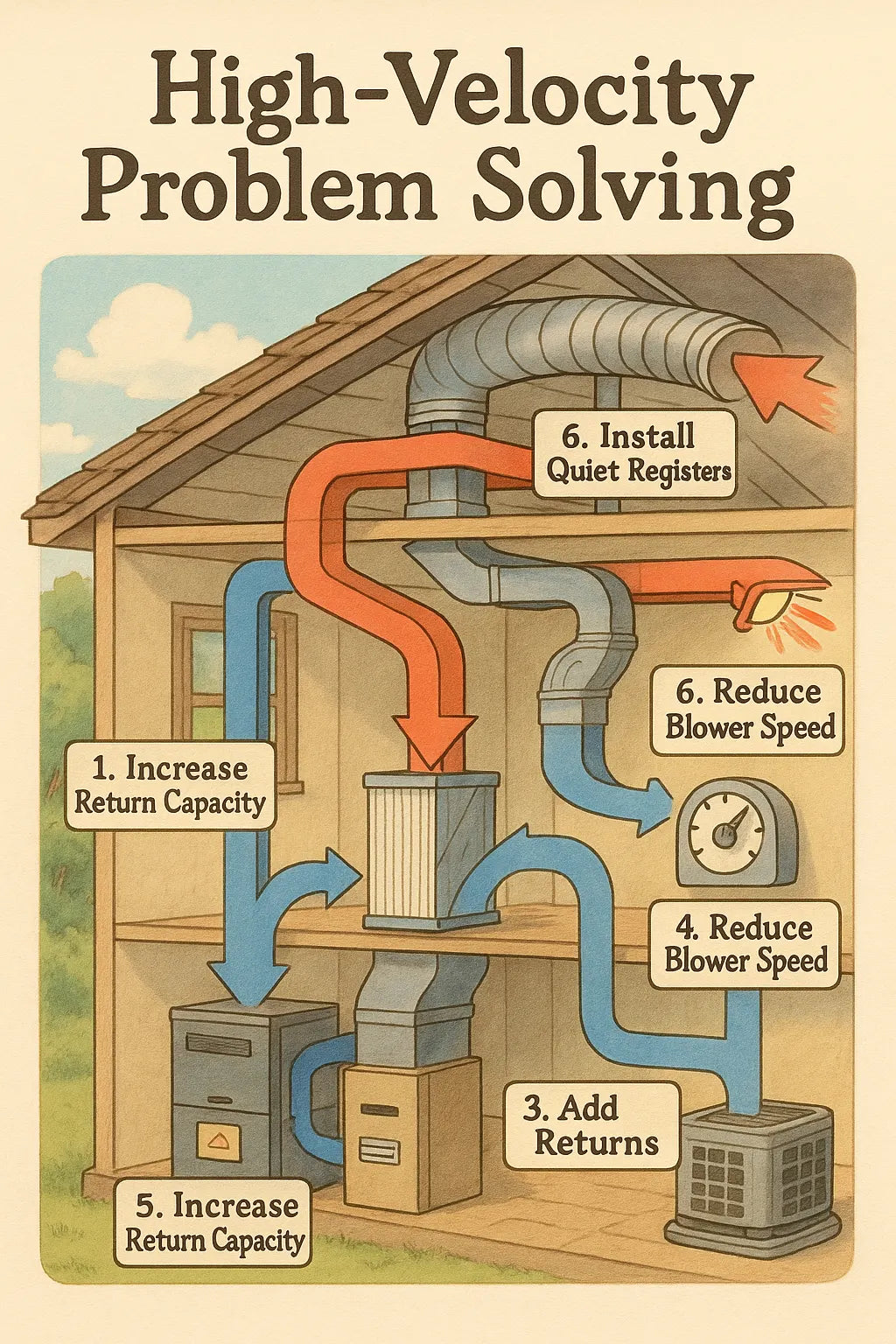

🔧 3. Mike’s High-Velocity Problem Solving Blueprint

Now we get into the corrections — the real fixes Mike applies to tame an overpowered 4-ton system.

There are eight major fixes, and Mike chooses them based on the home’s pressure map.

1️⃣ 🛠️ Increase Return Air Capacity (First Priority)

Mike’s rule:

“If the supply is loud, the return is wrong.”

4-ton systems need at least 1,600 CFM of return air — preferably 1,800–2,000.

Mike’s return fixes include:

-

adding additional return ducts

-

enlarging the main return trunk

-

installing multiple return grilles

-

switching from 1" filters to 4" media racks

-

adding jumper ducts in bedrooms

-

sealing all return leaks

Return-side corrections alone often reduce airflow noise by 25–40%.

External Link: EPA on return air systems

2️⃣ 🌪️ Upsize Critical Supply Branches

This is the #1 fix for loud vents and uneven cooling.

Mike’s standard upgrades:

-

6" → 7" or 8"

-

7" → 8" or 9"

-

8" → 10"

He especially enlarges:

-

long attic flex runs

-

2nd-floor branches

-

rooms with high solar load

-

rooms with two exterior walls

Upsizing lowers both velocity and static pressure.

3️⃣ 📏 Resize or Rebuild the Main Supply Trunk

A 4-ton system needs a large trunk, usually:

-

18" round

or -

20"x8" (minimum), 24"x8" (ideal)

Many homes use 14"–16" trunks that are completely inadequate for 4-ton airflow.

Mike reworks the trunk to:

-

increase volume

-

reduce friction

-

quiet the system

-

stabilize pressure

This is often a “night and day” improvement.

4️⃣ 🌬️ Reduce Blower Speed (The Quieting Trick)

Mike uses performance tables to find the correct CFM for:

-

cooling

-

heating

-

dehumidification

Typical adjustments:

-

reduce cooling CFM from 1600 → 1400–1500

-

reduce heating CFM slightly (if temp rise is stable)

-

enable dehumidify-on-demand mode

This has immediate effects:

-

quieter supply vents

-

better humidity removal

-

longer cooling cycles

-

less cycling stress on the compressor

But blower changes must be paired with duct corrections — otherwise static pressure increases.

5️⃣ 🧵 Correct Flex Duct Installation (Huge Static Pressure Drop)

Flex duct problems magnify high velocity.

Mike repairs by:

-

straightening sagging flex

-

eliminating excess length

-

replacing kinked sections

-

supporting flex every 4 feet

-

shifting long runs to metal duct

-

replacing flex elbows with metal elbows

Flex is the silent killer of airflow performance.

6️⃣ 🔇 Install Low-Velocity Supply Registers

The register (vent cover) can add surprising noise.

Mike installs:

-

curved-blade registers

-

high-capacity diffusers

-

wider neck diffusers

-

“quiet-flow” low-velocity grilles

This reduces vent noise by 5–10 dB instantly.

7️⃣ 📉 Static Pressure Budgeting (Mike’s Precision Method)

Mike measures:

-

return static

-

supply static

-

total external static

A good 4-ton system must stay at:

-

0.5 inWC or lower (ideal)

-

0.8 max (manufacturer redline)

If static is high:

-

blower fights itself

-

velocity skyrockets

-

noise increases

Mike lowers static pressure until system enters the “quiet zone.”

8️⃣ 🧱 Lengthen Duct Transitions (Laminar Flow Creation)

Short transitions cause turbulence → turbulence creates noise.

Mike lengthens transitions to:

-

reduce air churn

-

lower velocity

-

smooth airflow into the coil or plenum

He builds transitions at:

-

30° angles (ideal)

-

45° angles (acceptable)

-

90° angles (never)

This has a huge impact on both volume and sound.

🧰 4. Real-World Case Study: Mike Fixes a Loud 4-Ton System

Home: 2,600 sq ft

Equipment: 4-ton R-410A

Symptoms:

-

loud airflow at every vent

-

cold blasts

-

high humidity

-

coil froze twice

-

upstairs too hot

-

downstairs too cold

Mike’s Findings:

-

14" trunk (too small)

-

6" branches everywhere

-

return duct leak in attic

-

1" filter rack

-

blower at max CFM

-

2nd-floor return missing

Mike’s Fixes:

-

added upstairs return

-

replaced 1" filter with 4" media rack

-

upsized three main supply runs

-

installed curved-blade registers

-

reduced blower speed 12%

-

sealed return leaks

-

added proper flex supports

Results:

-

static pressure: 0.81 → 0.48

-

humidity dropped 12%

-

airflow noise cut in half

-

coil freeze-ups eliminated

-

system finally cooled evenly

📘 5. Mike’s Rules for Taming a High-Velocity 4-Ton System

Here are his guiding principles.

✔️ Rule 1: High velocity = high static

✔️ Rule 2: Noise is a symptom of pressure, not airflow volume

✔️ Rule 3: Returns must exceed supply airflow

✔️ Rule 4: Blower tuning only works if static is corrected

✔️ Rule 5: Flex duct must be treated like metal duct

✔️ Rule 6: Registers are part of the airflow system

✔️ Rule 7: Trunk sizing is non-negotiable

✔️ Rule 8: Every ton needs 350–450 CFM of actual airflow

✔️ Rule 9: High velocity always hides at the most restrictive point

✔️ Rule 10: The quieter the system runs, the longer it lasts

🏁 Final Takeaway

Mike puts it simply:

“A 4-ton system isn’t the problem. The layout is.”

When a 4-ton HVAC system feels overpowering, the real issue is airflow engineering.

With the right duct corrections, static pressure budgeting, blower tuning, and return air expansion, even the highest-output systems can run whisper-quiet, evenly, and efficiently.

A properly corrected system won’t just feel quieter — it will:

-

dehumidify better

-

cool more evenly

-

reduce energy bills

-

dramatically extend equipment life

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: Static Pressure Recovery: Mike’s Building Mods That Transform Bad Systems Into SEER2-Performing Ones