When most people think of “home comfort,” they picture the thermostat: the sleek little puck that tells the HVAC system what to do. But thermostats don’t decide comfort—the building does.

And that’s why Mike Sanders never begins a system design by asking, “What size unit do you need?” Instead, he asks:

-

Where does your home leak heat?

-

How hard does your system have to work to overcome those leaks?

-

And how do the materials, sunlight, airflow pathways, and geometry of your home shape the “thermal behavior” of each room?

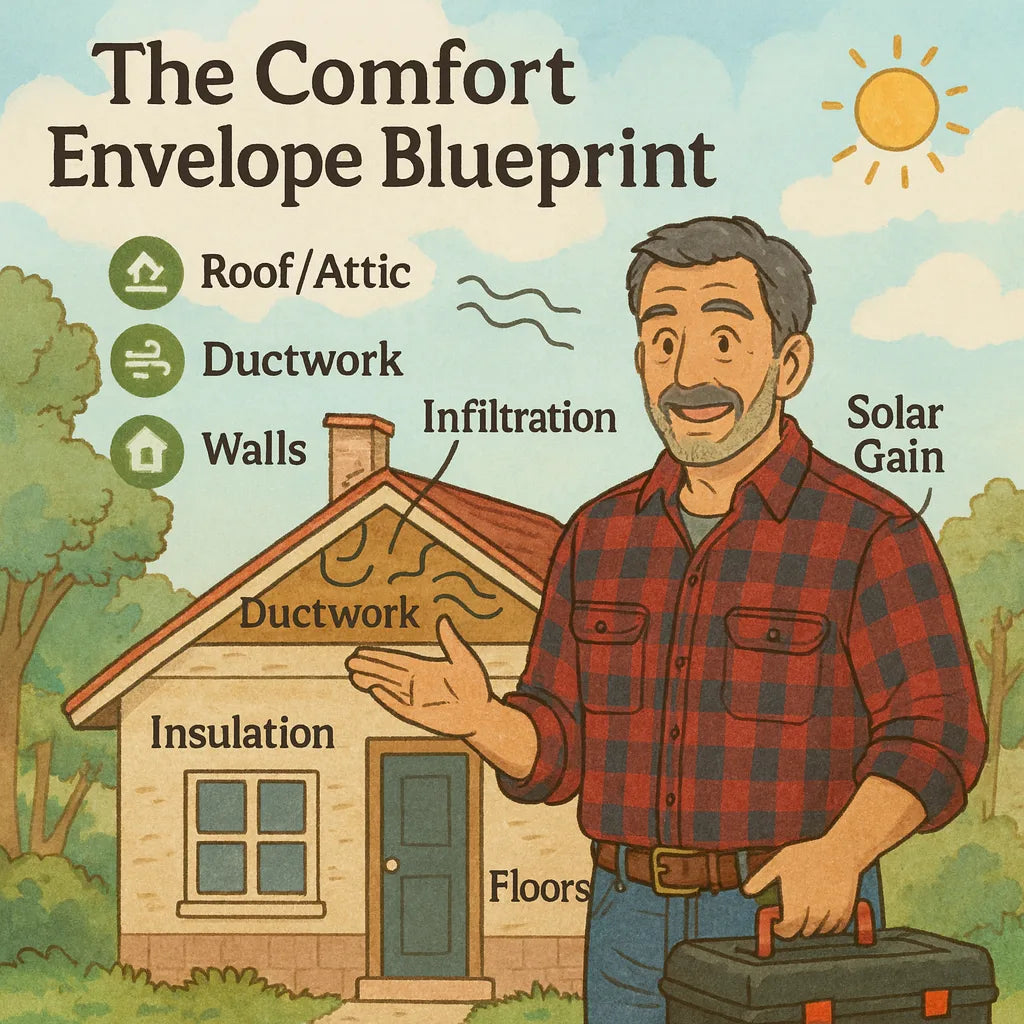

This is the foundation of Mike’s Comfort Envelope Blueprint, a method of mapping heat loads before he even considers tonnage, BTUs, zoning, ducting, or thermostat placement.

The result?

Systems that are quieter, longer-lasting, balanced, and more efficient—because they’re designed around reality, not guesses.

🏠 1. Understanding the Comfort Envelope

Before we go into diagnostics, you need the basic concept:

Your comfort envelope is the boundary that separates conditioned indoor air from the outside environment.

Inside is your controlled temperature, humidity, and airflow.

Outside is heat, cold, moisture, wind, radiation, and pressure differences.

Your comfort envelope includes:

-

Walls

-

Ceilings & attics

-

Floors (especially over crawlspaces or garages)

-

Windows & doors

-

Insulation layers

-

Ventilation openings

-

Ductwork running through unconditioned space

-

Attic hatches, recessed lights, and other infiltration points

To Mike, this envelope is the starting point and the biggest variable in how much HVAC muscle a building actually needs.

🧭 2. Mike’s Rule #1: Square Footage Is Not a Load Calculation

The HVAC industry loves shortcuts:

“400–600 square feet per ton” or “20 BTUs per square foot.”

Mike hates shortcuts.

Because they fail in every real-world scenario:

-

Homes with cathedral ceilings

-

Rooms with south-facing window walls

-

Open-concept first floors

-

Bonus rooms above garages

-

Split-level homes

-

Houses with poor insulation or major air leakage

-

Sunrooms, dens, lofts, basements

A simple example:

A 300 sq ft south-facing sunroom with bad insulation may need more BTUs than a 600 sq ft shaded, insulated bedroom zone.

The envelope dictates the load—not the footprint.

🔎 3. The Diagnostic Walkthrough: Mike’s Comfort Envelope Inspection

This is where Mike’s blueprint process begins.

He walks a home with a notepad, a laser thermometer, a smoke pen, and a pressure meter.

Here’s what he looks for:

🪟 3.1 Windows: The Biggest Thieves of Comfort

Mike checks:

-

Orientation (north, south, east, west)

-

Size of glass surfaces

-

Shading (trees, awnings, roof overhangs)

-

U-factor and SHGC rating

-

Air leakage around frames

-

Thermal imaging for hot/cold spots

Windows are usually the #1 source of heat gain in summer and heat loss in winter.

External Link:

Energy-efficient window ratings:

https://www.energy.gov/energysaver/design/windows-doors-and-skylights

🧱 3.2 Exterior Walls & Insulation Grade

Mike uses thermal cameras to detect:

-

Missing insulation bays

-

Settled insulation in older walls

-

Thermal bridging from studs, beams, and posts

-

Heat gain through west-facing walls

He notes the wall type:

-

Brick veneer

-

Vinyl siding

-

Fiber cement

-

Stucco

-

Log or timber

Different materials store and release heat differently—affecting how long a room stays hot or cold.

🌤️ 3.3 Solar Gain Mapping: The Sun’s Daily Path

Mike prints a simple compass and marks:

-

Where sunlight enters in morning

-

Where it hits at noon

-

Where it strikes in late afternoon

-

How it interacts with window angles

A west-facing wall at 5 PM can produce more BTUs than an entire room’s interior load.

This is one of the biggest reasons homeowners complain about:

-

“That room is always hot.”

-

“My upstairs is unbearable in the summer.”

-

“The back bedrooms never cool.”

99% of the time, the sun is the culprit.

🧊 3.4 Attic Heat Behavior: The Hidden Load Multiplier

Attics are the major wild card.

Mike checks:

-

R-value of insulation

-

Whether it’s loose-fill or batts

-

If there are air gaps around pipes, wires, and lights

-

Ventilation quality (ridge vents, soffits, gables)

-

Attic temperature differences across the day

Attic temperatures can hit:

-

120°F on mild days

-

140°F on summer days

-

160°F in closed-roof assemblies

Every degree over indoor temperature adds additional BTU load.

External Link: DOE guidelines for attic insulation:

https://www.energy.gov/energysaver/weatherize/insulation

🪜 3.5 Floors, Crawlspaces & Basements

People forget floors—Mike doesn’t.

He checks:

-

Floor insulation above garages

-

Crawlspace vapor barriers

-

Air movement under the home

-

Basement humidity

-

Duct runs through unconditioned areas

A bonus room over a garage may require double the cooling capacity per square foot of the main level.

➿ 3.6 Air Leakage: The Silent Destroyer

Air leakage creates unplanned air exchanges that destroy comfort and efficiency.

Using smoke pencils and pressure meters, Mike identifies leakage in:

-

Attic access panels

-

Recessed lights

-

Fireplace surrounds

-

Plumbing penetrations

-

Electrical boxes

-

Window frames

-

Door sweeps

External Link: Blower door testing standards:

https://www.energy.gov/energysaver/home-energy-audits/professional-home-energy-audits

When Mike finds more than 0.35 air changes per hour, he adjusts the load upward—sometimes significantly.

🌬️ 3.7 Duct Losses: When Your Cold Air Never Reaches the Room

Mike inspects:

-

Leaks in supply/return trunks

-

Uninsulated attic ductwork

-

Collapsed or kinked flex runs

-

Undersized return air pathways

Leaky ductwork can reduce a system’s delivered cooling by 20–30%.

External Link: EPA: Duct sealing and energy savings

He adjusts load calculations upward whenever ducts run in:

-

attics

-

crawlspaces

-

garages

📐 4. Mike’s Heat Load Calculation Framework (Simplified)

After mapping the envelope, Mike uses a refined Manual J–style approach (but with extra real-world corrections).

His formula includes:

✔️ 1. Envelope Heat Gains

-

Walls

-

Windows

-

Roof/attic

-

Floors

-

Infiltration

✔️ 2. Internal Gains

-

People

-

Appliances

-

Electronics

-

Lighting

✔️ 3. Duct Losses and Pressure Penalties

-

Based on layout and insulation

✔️ 4. Solar Gains

-

Orientation

-

Window SHGC

-

Shading

✔️ 5. Thermal Storage

-

Brick, stone, and concrete hold heat (thermal lag)

-

Wood and drywall release heat faster

✔️ 6. Micro-Zone Adjusters

Mike applies “penalties” or “boosts” depending on:

-

Room on 2nd floor (+10–20%)

-

Over-garage rooms (+20–40%)

-

Corner rooms (+10%)

-

Rooms with two or more exterior walls (+15–30%)

-

Sunrooms (+50–200%)

✔️ 7. Design Temperature Delta

This is key:

BTU load = How hot your area gets compared to your desired indoor temperature.

External Link: ASHRAE climate design data

🔥 5. Real-World Example: Why Mike Rejects “Rule of Thumb” Sizing

Let’s compare two 300 sq ft rooms:

Room A: Bonus Room Over Garage

-

R-13 walls

-

R-19 floor

-

Two exterior walls

-

South-facing windows

-

Infiltration around knee walls

-

No shading

-

Attic ducts

Calculated load: ~10,000–12,000 BTU

This room may need its own system zone or a 9k–12k mini-split.

Room B: Interior Bedroom

-

R-21 walls

-

North-facing

-

Small window

-

On 1st floor

-

No duct exposure

-

Shaded by trees

Calculated load: ~3,000–4,000 BTU

If you used square footage alone, you’d size them equally—and Room A would always overheat.

This example is why Mike insists:

“You size the system to the envelope—not the floor plan.”

🧩 6. Mike’s Envelope-Based System Design Rules

Once the envelope is mapped, Mike applies these design principles:

🌀 6.1 Rule: Don’t Oversize for Bad Envelope Conditions

Example:

Homeowner: “My upstairs is hot. I want a 5-ton unit.”

Mike: “You need a better attic, not a bigger system.”

Oversizing causes:

-

Short cycling

-

High humidity

-

Noise

-

Premature compressor wear

-

Inefficient operation

❄️ 6.2 Rule: Prioritize Envelope Fixes Over Equipment Upgrades

Mike always recommends improving:

-

attic insulation

-

window shading

-

duct sealing

-

air sealing

-

attic ventilation

Because these reduce the load—allowing a properly sized system to work beautifully.

🌬️ 6.3 Rule: Size Ducts to the True Load

If Room A needs 12k BTUs, Mike gives it the airflow for 12k BTUs.

If Room B only needs 4k BTUs, he restricts or trims airflow there to keep temperatures even.

Duct design is a direct extension of envelope analysis.

💨 6.4 Rule: Use Return Air Strategically

Returns remove heat.

Rooms with high loads need more return air pathways.

Mike often adds:

-

Jumper ducts

-

Transfer grilles

-

Undercut doors

-

Dedicated returns

Returns are not optional—they’re load-balancing tools.

☀️ 6.5 Rule: Always Correct for Solar Orientation

North-facing rooms get reduced BTU estimates.

West-facing rooms get the “Mike multiplier.”

This alone solves most hot-room complaints.

🔧 7. Tools Mike Uses to Map the Comfort Envelope

-

FLIR thermal camera

-

Laser infrared thermometer

-

Manometer / pressure meter

-

Smoke pen or incense

-

Attic ruler for insulation depth

-

Compass or sun-path mobile app

-

Duct CFM flow hood

These tools reveal the real thermal behavior of each zone.

🧱 8. Improving the Comfort Envelope: Mike’s Fix List

To reduce heat load (and maximize system life), Mike often recommends:

🔨 Envelope Upgrades

-

Add R-38 to R-60 attic insulation

-

Seal top plates, recessed lights, and attic bypasses

-

Install insulated attic hatches with weatherstripping

-

Replace failing windows or add low-E films

-

Add shade screens on west-facing glass

🌬️ Airflow and Duct Improvements

-

Seal ducts with mastic

-

Replace crushed flex duct

-

Add return air pathways

-

Insulate attic ductwork

-

Re-size supply branches based on room loads

🌞 Solar Heat Control

-

Add window awnings

-

Install interior cellular shades

-

Plant shade trees

-

Use exterior solar screens

-

Add reflective roof coatings

🚪 Room-by-Room Solutions

-

Boost airflow to hot rooms

-

Reduce airflow to cold rooms

-

Add zoned dampers

-

Install mini-splits for extreme rooms

-

Use load-based damper logic

📊 9. Final Output: Mike’s Comfort Envelope Blueprint Report

When Mike designs a system, he delivers a full map:

-

Room-by-room heat load sheet

-

Insulation and infiltration diagnosis

-

Solar gain mapping

-

Duct airflow plan

-

Return air strategy

-

Equipment capacity range

-

Recommendations to reduce load before installation

Only after all of this is done does he choose the:

-

tonnage

-

furnace BTUs

-

SEER2 rating

-

blower configuration

-

coil pairing

-

refrigerant charge adjustments

-

ventilation plan

The thermostat is almost an afterthought.

🎯 10. The Result: Systems That Actually Work in the Real World

By following the Comfort Envelope Blueprint, Mike consistently designs systems that:

-

Feel more comfortable at higher thermostat settings

-

Run quieter

-

Last longer

-

Cycle properly

-

Maintain stable humidity

-

Deliver even temperatures throughout the home

-

Cost less to operate

He doesn’t size systems to houses— the sizes systems to physics.

And that’s the difference between HVAC that “sort of works” and HVAC that feels incredible.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: The R-32 Integration Matrix: Mike’s Rules for Pairing Next-Gen Refrigerant Systems With Legacy Ductwork