R-32 is shaking up the HVAC world. It’s more efficient, lower-GWP, easier to charge accurately, and gives homeowners cooler air using less energy. But Mike Sanders will tell you the real truth:

“You don’t get R-32 performance unless your ductwork is ready for it.”

The refrigerant, the coil, the blower, and the duct system operate as one machine. And when you drop next-gen refrigerant technology into old ducts built for R-22 or R-410A systems, you’re mixing modern efficiency with 20-year-old airflow math.

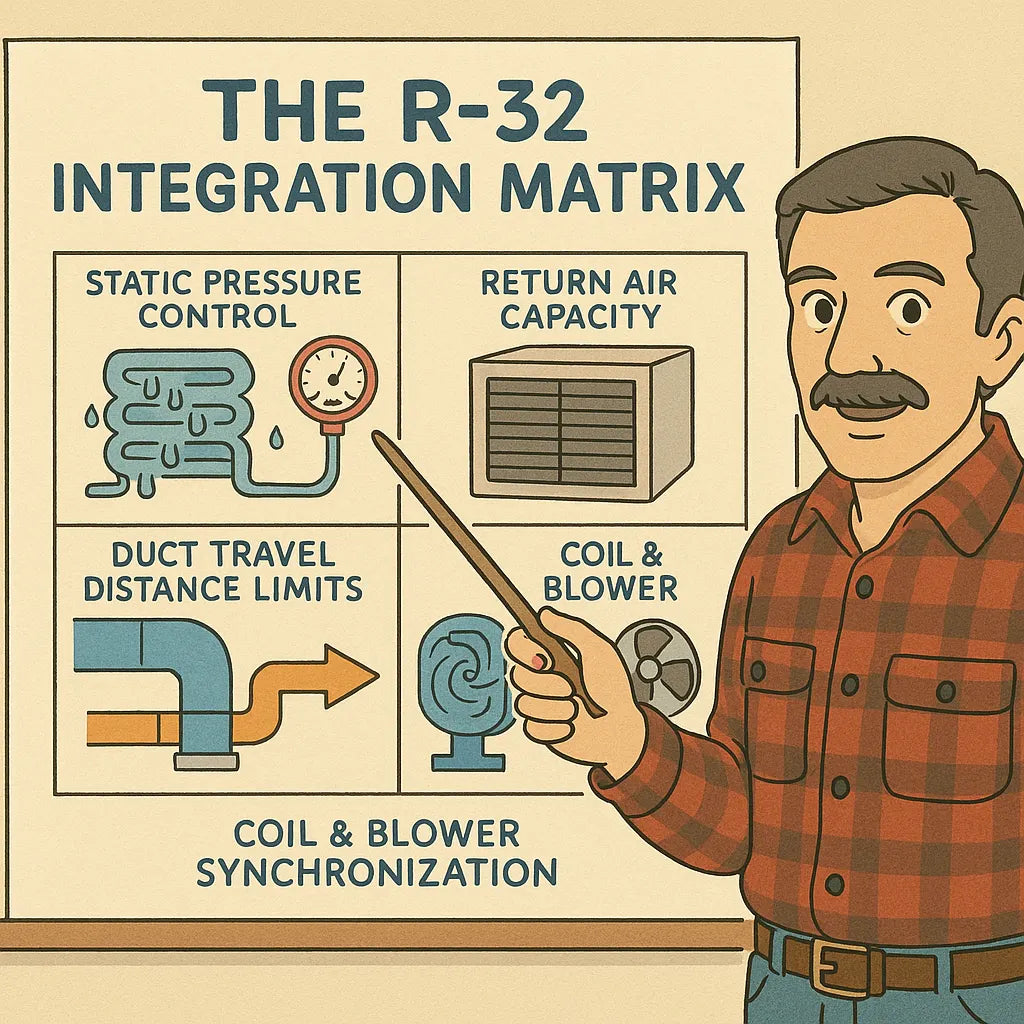

That’s where Mike’s R-32 Integration Matrix comes in — a ruleset he uses to adapt legacy duct systems to modern refrigerant performance requirements, ensuring the home actually sees the efficiency R-32 is capable of delivering.

This article gives you the full blueprint.

📘 1. Why R-32 Systems Behave Differently Than R-410A

Before you match any next-gen equipment to old ducts, you need to understand why R-32 behaves differently.

🧊 1.1 Higher Volumetric Efficiency

R-32 carries more heat per pound than R-410A — roughly 10%–12% more thermal capacity.

This means:

-

Faster heat transfer

-

Higher coil performance

-

Lower refrigerant mass flow

-

More efficient compressor operation

But also:

-

Coil saturation happens faster

-

Blower speed becomes more sensitive

-

Poor ducts choke performance faster than before

External Link: Basic R-32 vs R-410A comparisons

🔥 1.2 Higher Discharge Temperatures

R-32 compressors run at higher discharge temps, which impacts:

-

TXV behavior

-

Coil temperature splits

-

Sensible cooling ratios

In a restrictive duct system, higher discharge temps can force the compressor into shorter cycles, tanking efficiency.

🌡️ 1.3 Faster Coil Response = Less Room for Airflow Mistakes

R-32 systems have faster evaporator coil reactions — meaning:

-

Undersized ducts → coil freezes sooner

-

Oversized ducts → lower coil temperature split

-

Bad return paths → pressure imbalance faster

This makes R-32 far less tolerant of old ductwork problems.

🗂️ 2. Mike’s Integration Matrix: The Four Pillars of R-32 Compatibility

Mike’s entire approach comes down to four pillars:

🌀 Pillar 1: Static Pressure Control

R-32 systems need lower total external static pressure than older systems.

Ideal: 0.4–0.5 inWC total ESP for most 3–5 ton systems.

Legacy duct systems often hit 0.7–0.9 inWC—or worse.

🔍 Mike’s Rules:

-

If ESP exceeds 0.6, R-32 performance drops by 15–30%.

-

If ESP exceeds 0.8, the system loses SEER2 efficiency entirely.

-

Tight ducts must be enlarged, not “balanced.”

🚫 What Mike Never Does:

“I never install a variable-speed R-32 system on legacy 6-inch supplies alone.”

Most older homes have:

-

6" supply runs

-

Undersized returns

-

Flex duct with sag

-

Sharp-elbow takeoffs

All of which kill airflow.

🔄 Pillar 2: Return Air Capacity

R-32 systems REQUIRE high return air volume because the coil works harder.

🧮 Mike’s Return Air Rule:

Every ton of cooling requires 350–425 CFM — and that airflow must actually reach the coil.

Mike’s Return Rules:

-

Minimum 1 sq in per 1 CFM for filter area

-

No single return may serve more than 900 CFM

-

Homes with closed-door bedrooms must have jumper ducts or transfer grilles

-

Return air must be within 25 ft of the air handler for 4+ ton systems

Why this matters:

R-32 evaporator coils produce stronger negative pressure on the return side.

Weak returns = starved coil = short cycling + poor humidity control.

External Link: EPA guidelines on airflow & return sizing

🚚 Pillar 3: Duct Travel Distance Limits

R-32 systems hate long duct runs.

Mike’s Rule:

No individual branch should exceed 25–30 linear feet for a 4–5 ton system.

Anything longer must be:

-

upsized

-

re-routed

-

or split into two branches

Why?

Long runs = friction loss

Friction loss = reduced CFM

Reduced CFM = coil freezes faster

Legacy systems commonly have:

-

40–50 ft attic runs

-

Compressed flex duct

-

90° hard elbows

These choke R-32 coils immediately.

❄️ Pillar 4: Coil & Blower Synchronization

R-32 systems often use:

-

optimized evaporator coils

-

larger fin density

-

higher SUCTION pressure requirements

-

more aggressive TXVs

The blower must be tuned exactly right to match coil behavior.

Mike’s Coil-Blower Rules:

-

If coil is oversized, blower must ramp slower

-

If coil is undersized, blower must ramp faster

-

Always use TXV or EEV on R-32 systems

-

Never rely on piston metering devices in retrofits

External Link: ASHRAE refrigerant design standards

🧱 3. What Legacy Ductwork Does Wrong With R-32

Mike has seen this hundreds of times:

“The homeowner buys a fancy new system, but the old ducts force it to run like a 15-year-old unit.”

Here’s where old duct systems fail the most.

🟥 3.1 Undersized Supply Trunks

A 4-ton system should have:

-

18–20" main trunk

-

14–16" secondary trunks

Legacy systems often have:

-

14" trunks for 4–5 ton units

-

Bottlenecked wyes

-

Mismatched trunk insulation

This can cut system CFM by 40%.

🟥 3.2 Undersized Returns

A 4-ton unit requires 1600 CFM minimum.

Legacy returns often supply only 900–1200 CFM.

R-32 coils starve instantly.

🟥 3.3 Flex Duct That Is Sagging or Crushed

Mike calls this “the silent killer.”

A flex run sagging only ½ inch per foot reduces airflow by:

-

8–12% over 20–25 ft

-

20–30% with two bends

-

30–50% with attic heat

🟥 3.4 Leaky Ducts in Attics

Attic duct leakage causes:

-

20–30% loss in delivered BTUs

-

Higher heat gain

-

Return air pulling in 140°F attic air

External Link: Duct leakage & energy losses

🟥 3.5 Wrong Filter Rack Geometry

Older systems often used:

-

1" filters

-

Undersized filter grilles

-

Poor sealing

R-32 systems need MERV 8–11 at low pressure drop.

1" filters often add 0.20–0.25 inWC to static pressure — which is unacceptable.

🏗️ 4. Mike’s Retrofit Framework: Upgrading Old Ducts for R-32

This is Mike’s actual checklist when retrofitting next-gen refrigerant systems into legacy homes.

🔧 Step 1: Measure Total Static Pressure

Mike uses a manometer to measure:

-

Return static

-

Supply static

-

TESP (total external static pressure)

Good: 0.30–0.50

Acceptable: 0.50–0.60

Bad: 0.60–0.80

Fail: 0.80+

If ESP > 0.6, he starts correcting immediately.

🔧 Step 2: Fix the Returns First

For 4–5 ton units:

-

Add dedicated return to master bedroom

-

Add 2nd story return

-

Add jumper ducts for closed-door rooms

-

Switch to 2" or 4" media filter cabinets

-

Replace closets with air-tight return enclosures

Return centric design is the MOST important part of R-32 retrofits.

🔧 Step 3: Resize Critical Supply Branches

Mike upsizes:

-

6" → 7"

-

7" → 8"

-

8" → 10"

Especially for:

-

long runs

-

rooms with high solar load

-

2nd-floor zones

He also removes:

-

sharp elbows

-

unnecessary wyes

-

kinked flex

🔧 Step 4: Correct Duct Leakage

He seals ducts with:

-

mastic

-

foil tape

-

aerosol duct sealing if extreme

Goal: <10% leakage

Old ducts often leak 20–40%.

🔧 Step 5: Clamp Down on Attic Heat Transfer

Mike reinsulates:

-

supply trunks

-

return trunks

-

branch ducts

Target: R-8 insulation minimum for attics.

🔧 Step 6: Tune the Blower to the Coil

Variables include:

-

coil tonnage

-

blower motor (ECM vs PSC)

-

duct size

-

return capacity

Mike uses static pressure targets and temperature splits to dial blower speed to match the coil’s optimal evaporating temperature.

External Link: Goodman / Daikin R-32 engineering specs

https://www.goodmanmfg.com

📊 5. Real-World Case Study: Mike’s R-32 Duct Retrofit Formula

Home: 2,800 sq ft two-story

Original Ducts: 1998 R-22 system

New System: 4-ton Goodman R-32 14.5 SEER2

Problems:

-

high static pressure (0.82)

-

hot 2nd floor

-

low humidity removal

-

noisy airflow

-

compressor short cycling

Mike’s Fixes:

-

Added 2nd return upstairs

-

Upgraded 1" filter to 4" media cabinet

-

Upsized three 6" ducts to 8"

-

Removed two 90° elbows

-

Reinsulated attic duct trunks to R-8

-

Added jumper ducts to bedrooms

-

Balanced blower speed from 75% to 65%

Result:

-

Static pressure dropped to 0.47

-

Upstairs temps evened out

-

Compressor cycles stabilized

-

18–22% lower energy consumption

-

35% better humidity control

THIS is what proper R-32 pairing looks like.

🧠 6. Mike’s R-32 Retrofit Rules (Quick List)

✔️ Rule 1: Fix returns before supplies

✔️ Rule 2: 4-ton = minimum 1600 CFM delivered

✔️ Rule 3: No branch run >30 ft

✔️ Rule 4: Always upgrade filter racks

✔️ Rule 5: Aim for ≤0.5 inWC total static pressure

✔️ Rule 6: Seal all ducts in unconditioned spaces

✔️ Rule 7: Match blower speed to coil tonnage

✔️ Rule 8: Use TXV/EEV — no piston metering

✔️ Rule 9: Add jumper ducts for closed-door rooms

✔️ Rule 10: Replace sagging flex duct immediately

Follow these rules and R-32 will perform at the efficiency levels promised on paper.

Ignore them, and your “efficient system” will run like a 2006 R-410A unit.

🎯 Final Takeaway: R-32 Performance Lives or Dies by Ductwork

Mike Sanders says it best:

“R-32 isn’t magic. It’s a high-output refrigerant that needs high-capacity airflow. Give it good ducts, and it’ll outperform anything you’ve ever installed.”

The R-32 Integration Matrix is all about respecting how advanced these systems are — and how outdated most duct systems in American homes have become.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: Furnace-First Airflow Planning: Why Mike Sizes Ducts Around the 120k BTU Heat Cycle, Not the AC Load