Most homeowners think ductwork is sized for the air conditioner. Most contractors still design around the cooling tonnage. But Mike Sanders — who has installed more systems than most people will ever see — teaches something very different:

“Air conditioning is easy. Heating is unforgiving. So I size ducts for the furnace — every time.”

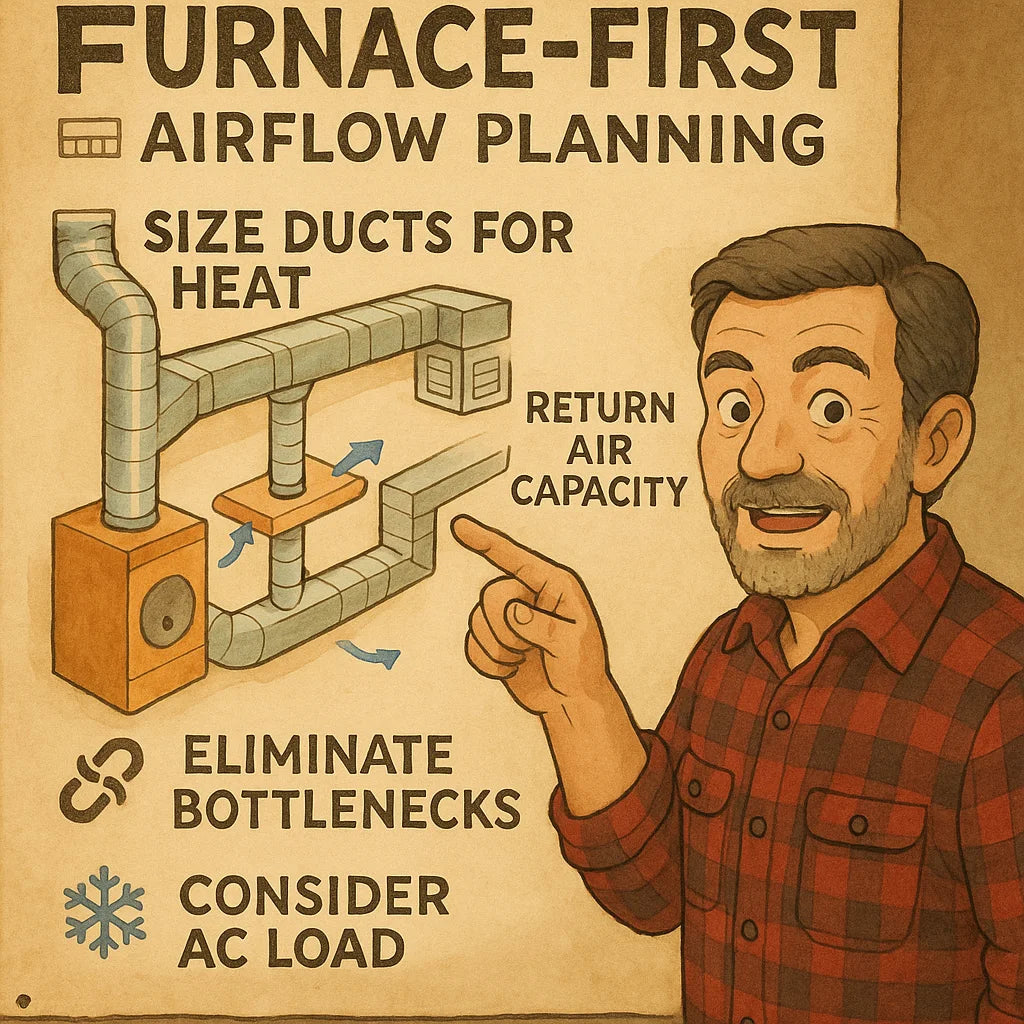

This is the foundation of Mike’s Furnace-First Airflow Planning philosophy. And it’s the reason his systems run quieter, cycle smoother, heat evenly, and avoid the airflow bottlenecks that destroy the efficiency of modern high-static SEER2 equipment.

In this article, you’ll learn why 120,000 BTU furnaces demand a different duct sizing strategy, why AC-based designs fail, and how Mike maps out airflow pathways to handle the demands of high-output heating.

Let’s dive in.

🧠 1. Why Furnace-First Airflow Planning Matters

Mike starts every design with a simple truth:

Heat requires more airflow than cooling — and way more stability.

Here’s what that means.

🔥 1.1 Heating Needs Higher CFM Per BTU Than Cooling Does

Cooling airflow is typically:

❄️ AC Airflow Rule of Thumb

350–450 CFM per ton

= 1400–1800 CFM for a 4-ton system

But heating is harder on airflow.

🔥 120k BTU Heating Airflow Requirement

1200–2000+ CFM, depending on furnace stage and temperature rise.

A 120,000 BTU furnace uses:

-

higher blower RPM

-

higher static pressure

-

faster air expansion across the heat exchanger

-

tighter limits on duct restriction

A duct system built for AC airflow alone often:

-

overheats during furnace operation

-

triggers limit switches

-

short cycles

-

creates hot/cold room imbalance

-

increases utility bills

-

reduces furnace lifespan

This is why Mike says:

“If it can handle the furnace, it can handle anything.”

🎚️ 1.2 The Furnace Has Stricter Safety and Performance Limits

High-output furnaces have:

-

ignition temperature thresholds

-

maximum temperature rise

-

blower RPM limits

-

limit switch triggers

If ducts are undersized, the furnace overheats before the home heats up.

That means:

-

frequent shutdowns

-

uneven room temperatures

-

cracked heat exchangers

-

warranty-voiding operating conditions

External Link: Understanding furnace temperature rise

https://www.energy.gov/energysaver/furnaces-and-boilers

💨 1.3 Heating Air Is More Sensitive to Restriction Than Cooling Air

Cold air is dense. Warm air expands.

Warm expanded air requires:

-

more duct volume

-

larger trunk transitions

-

smoother airflow paths

If ducts are too small:

-

friction increases

-

blower RPM spikes

-

heat exchanger overheats

-

supply air velocity becomes loud

-

return air becomes starved

This is why AC-only duct designs fail the moment winter arrives.

🧱 2. Why Legacy Homes Struggle With 120k BTU Furnaces

Older duct systems were often built for:

-

60k–80k BTU furnaces

-

R-22 air conditioners

-

PSC blower motors

-

1970–2005 airflow rules

This means:

-

6” supply branches everywhere

-

small return plenums

-

tiny filter racks

-

low R-value duct insulation

-

lightweight, low-pressure trunks

A modern 120k BTU furnace with a high-static ECM blower will overpower this duct system instantly.

Symptoms include:

-

Whooshing vents

-

Hot upstairs, cold downstairs

-

Furnace shutting off after a few minutes

-

AC coil icing in summer

-

High energy bills year-round

-

Loud blower operation

Mike’s solution is simple:

“Design around heating airflow. Cooling will fall perfectly into place.”

📐 3. Mike’s Furnace-First Airflow Formula

Mike uses a highly structured formula to ensure the duct system is ready for the 120k BTU furnace at full fire.

📏 3.1 Step 1: Calculate Required CFM for the Furnace

Every furnace has a rated temperature rise, usually:

35°F – 65°F

Using furnace engineering data, Mike determines airflow:

CFM = BTU Output ÷ (1.08 × Temperature Rise)

Example for 120k BTU:

-

At 40°F rise: 2778 CFM

-

At 55°F rise: 2043 CFM

-

At 65°F rise: 1703 CFM

Most 120k units operate best around 1,800–2,200 CFM.

This is MUCH higher than the airflow for a 3.5–4-ton AC system.

🌀 3.2 Step 2: Map Supply Duct Capacities

Mike sizes trunks using:

Minimum Trunk Diameter (120k furnace)

-

18" round

or -

20"x8" rectangular (minimum)

-

24"x8" or larger (preferred for quiet airflow)

Then he sizes branches based on room loads:

-

6" → ~75 CFM

-

7" → ~125 CFM

-

8" → ~200 CFM

Mike’s Rules:

-

No more than 10–12 supply runs of 6"

-

Any run >25 feet must be upsized

-

Second floor MUST get larger ducts than first floor

-

No 90° elbows on the plenum

🫁 3.3 Step 3: Return Air Is Doubled

Mike sizes returns to exceed supply airflow.

Return Rules:

-

At least two returns per 120k furnace

-

No return smaller than 14" round

-

Return filter area of 3–4 sq ft minimum

-

Prefer 2" or 4" pleated filters

-

One return centrally located

-

One return for the second floor

🌬️ 3.4 Step 4: Eliminate Pressure Bottlenecks

Mike checks for:

-

crushed flex duct

-

kinks

-

sagging runs

-

unreinforced elbows

-

undersized boots

-

closed-off rooms

-

restrictive grilles

Most “furnace issues” come from airflow bottlenecks, not the furnace itself.

🧊 3.5 Step 5: Consider Cooling as a Secondary Load

Once the furnace airflow is correct:

-

The AC air volume is automatically sufficient

-

Static pressure matches SEER2 specs

-

Coil heat transfer improves

-

Cooling becomes quieter

This is why Mike uses furnace-first math for duct planning.

📊 4. Furnace vs. AC Load: Two Completely Different Airflow Profiles

Understanding the physics is key.

☀️ 4.1 AC Load Profile

-

Lower airflow

-

Lower discharge temperature

-

Lower safety risk

-

Lower static pressure sensitivity

-

Optimized for moisture removal

A duct system can be slightly undersized and still cool well.

🔥 4.2 Furnace Load Profile

-

High airflow

-

High discharge temperature

-

High safety risk

-

Extremely sensitive to static pressure

-

Zero tolerance for restriction

A duct system that is too small will immediately fail during heating.

🔧 4.3 Why Mike Ignores AC During Duct Design

Because:

-

AC can adapt to low airflow

-

Furnaces cannot

-

High heat output needs large physical volume

-

Heat exchanger stress increases exponentially under restriction

If you size ducts only for AC, you guarantee heating failure.

🏚️ 5. The Most Common Duct Mistakes in 120k BTU Homes

Mike sees these on every job.

❌ 5.1 The 6-Inch Supply Problem

6" supplies are too small for:

-

large rooms

-

long runs

-

second-floor branches

-

high-output furnaces

He upsizes many 6” to 7” or 8”.

❌ 5.2 Undersized Return Trunks

A single 14" return cannot handle a 120k furnace.

Minimum: 18" or dual 14" returns

❌ 5.3 Restrictive 1" Filter Racks

Mike replaces almost every 1" filter rack with a 4" media cabinet.

Small filters add 0.25 in static pressure — unacceptable for heating.

❌ 5.4 Overreliance on Flex Duct

Flex duct reduces airflow by:

-

10% if installed correctly

-

20–30% with mild sag

-

40–60% with bad installation

Mike replaces critical flex with metal.

❌ 5.5 No Second-Floor Return Air Path

Second floors overheat unless they have an additional return.

🧩 6. Mike’s Furnace-First Duct Redesign Blueprint

This is the step-by-step method Mike uses on furnace-driven airflow upgrades.

🟦 Step 1: Identify Room Heating Loads

He calculates:

-

room size

-

insulation grade

-

number of exterior walls

-

window direction

Then he assigns branch CFM accordingly.

🟧 Step 2: Redesign the Supply Trunk

Mike always:

-

upsizes the trunk

-

adds smooth-radius elbows

-

adds branch takeoffs spaced to reduce turbulence

-

prevents “high-pressure zones” near the plenum

🟥 Step 3: Add Return Capacity

Mike typically installs:

-

one 16–18" return near the furnace

-

one upstairs return

-

one central main-level return

-

jumper ducts for bedrooms

🟩 Step 4: Set Blower RPM for the Furnace First

He uses:

-

manometer readings

-

temperature rise testing

-

commissioning specs

-

duct friction loss calculations

External Link: Furnace blower commissioning procedures

https://www.ahridirectory.org

🟨 Step 5: Balance & Noise Control

Once heating airflow is stable, Mike adjusts:

-

register direction

-

damper positions

-

boot sizes

-

diffuser styles

This is where noise is eliminated.

🟪 Step 6: Validate AC Operation

After the furnace airflow is perfect, he checks:

-

coil temperature split

-

suction pressure

-

liquid line temperature

-

blower efficiency

-

duct heat gain

When furnace airflow is correct, AC almost always performs flawlessly.

🧱 7. Real-World Example: Mike Fixes a Bad 120k BTU Install

Original Configuration:

-

120k furnace

-

4-ton AC

-

14" return

-

6" supply runs

-

sagging flex duct

-

small filter grille

-

furnace short cycling on heat

Symptoms:

-

Furnace overheated every 10–12 minutes

-

Upstairs scorching hot

-

Main floor cold

-

Loud airflow

Mike’s Fixes:

-

Added 18" return plenum

-

Installed second-floor return

-

Upgraded filter rack to 4" media cabinet

-

Upsized three 6" ducts to 8"

-

Rehung flex duct with proper supports

-

Balanced airflow using temperature rise targets

Final Results:

-

Furnace stabilized

-

Noise reduced by 50%

-

Even temperatures

-

AC efficiency increased

-

Static pressure dropped from 0.82 to 0.45

-

System finally performed like a 120k furnace should

🎯 Final Takeaway: Size Ducts for Heat, Enjoy Perfect Cooling Automatically

Mike’s philosophy solves everything:

“Design around the furnace. Cooling will always benefit.”

Because heating demands:

-

more airflow

-

better duct sizing

-

safer temperature rise

-

lower static pressure

-

stronger return capacity

This is why furnace-first design is the correct modern HVAC design method — especially with high-output 120k BTU units and high-static SEER2 AC systems.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: Attic Thermal Draft Control: Mike’s Strategy for Stopping “Unconditioned Air Cascades