Why Mike’s bolt pattern turns loud, rattling wall units into whisper-quiet performers.

Most homeowners believe vibration and noise from a through-the-wall AC—like the Amana PBE123J35AA—come from the unit itself.

Mike knows the truth:

“Ninety percent of AC vibration problems aren’t from the machine.

They’re from the sleeve being fastened wrong.”

When a sleeve is screwed into the wall incorrectly—

with the wrong pattern, spacing, angle, or torque—

the wall amplifies every little hum, compressor thump, and airflow pulse.

In a bad install, the sleeve becomes:

-

A drum

-

A resonance chamber

-

A soundboard

-

A vibration amplifier

-

A mechanical echo chamber

Mike’s Quiet-Home Bolt Pattern eliminates all that by distributing forces correctly along the sleeve and wall.

This guide explains, in detail, the exact fastener locations, spacing, torque rules, and geometry Mike uses to guarantee the sleeve stays rock-solid and noise-free for decades.

🧊 SECTION 1 — Why Sleeves Vibrate: The Real Cause Nobody Teaches

Icon: 🎵

When the AC runs, it produces:

-

Compressor pulses

-

Fan induction vibrations

-

Airflow turbulence

-

Housing resonance

If the sleeve is fastened improperly, these vibrations don’t dissipate—they transfer into the wall structure, bounce around studs, and come back into the room as noise.

The 4 causes of sleeve vibration amplification:

1️⃣ Fasteners placed only on the corners

Corners act as tension points that magnify vibration.

2️⃣ Fasteners over-tightened

This pulls the sleeve into the uneven wall surface → warping → harmonic resonance.

3️⃣ Too few screws

The sleeve flexes and “chatter vibrates.”

4️⃣ Uneven spacing

Creates micro-tension zones that amplify compressor cycles.

Mike designed a bolt pattern that eliminates these issues entirely.

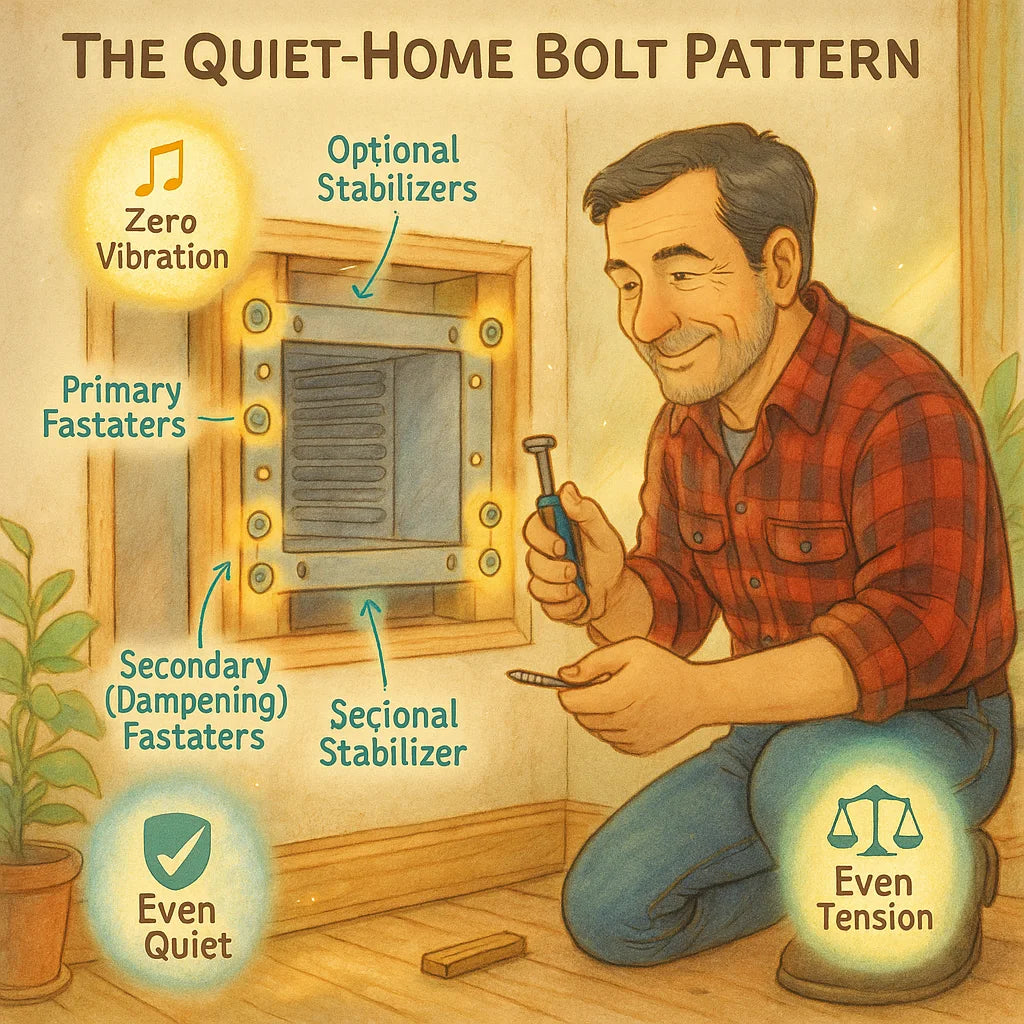

🧭 SECTION 2 — What Is the Quiet-Home Bolt Pattern?

Icon: 📏

This is Mike’s signature fastener layout designed specifically for through-the-wall AC sleeves.

It uses:

-

8 primary fasteners (structural points)

-

4 secondary fasteners (dampening points)

-

2 optional stabilizers (for older homes or uneven framing)

Fasteners are placed strategically to:

✔ Stop harmonic resonance

✔ Stop sleeve rattle

✔ Isolate compressor vibration

✔ Prevent sleeve warp over time

✔ Reduce sound transmission into framing

✔ Keep airflow paths consistent

It is NOT symmetrical—because walls are not symmetrical.

Mike’s layout creates a pressure-balanced “quiet frame” around the sleeve.

🧱 SECTION 3 — The 4 Sound Zones of a Sleeve

Icon: 🎛️

Mike divides the sleeve into four zones:

Zone A — Upper Lateral Frame

Carries most vibration from the fan motor.

Zone B — Lower Lateral Frame

Carries compressor vibration.

Zone C — Left Vertical Frame

Carries resonance from the exterior grille turbulence.

Zone D — Right Vertical Frame

Carries resonance from interior return airflow.

Each zone has different vibration profiles, so each requires unique fastener placement.

📌 SECTION 4 — The Quiet-Home Bolt Pattern (Exact Layout)

Icon: 🧩

Below is the full layout used by Mike.

🔧 Primary Fasteners (8 total)

Icon: 🔨

These create the structural backbone.

Placement:

Top Left — 2 fasteners

-

One 2" from the top corner

-

One 6" from the top corner

Top Right — 2 fasteners

-

Mirrored from the left

Why:

Controls lateral flex + fan vibration.

Bottom Left — 2 fasteners

-

One 3" from bottom corner

-

One 7" from bottom corner

Bottom Right — 2 fasteners

-

Mirrored from the left

Why:

Controls compressor-induced vibration + sleeve settling.

🧰 Secondary Fasteners (4 total)

Icon: 🧯

These fasteners dampen structural resonance.

Placed at:

-

Center of left vertical frame

-

Center of right vertical frame

-

Center of top horizontal frame

-

Center of bottom horizontal frame

Why:

These points stop sleeve “drumming,” a major cause of noise.

🪵 Optional Stabilizers (2 total — for older homes)

Icon: 🛠️

Placed:

-

One on each side, mid-depth into the wall cavity

-

Installed with rubber isolation washers

Why:

Old walls with inconsistent framing benefit from stabilizers that reduce mid-frame flex.

🔩 SECTION 5 — Mike’s Fastener Rules (Critical for Zero Noise)

Icon: 📐

These rules are just as important as the bolt pattern.

Rule 1 — Use Fine-Thread Structural Screws

Coarse threads bite aggressively → create vibration points.

Fine-thread screws compress consistently and resist loosening.

Rule 2 — Pre-drill holes 1/16" smaller than fastener diameter

Prevents sleeve distortion when screws tighten.

Rule 3 — Torque to “snug,” NOT tight

Mike describes perfect torque as:

“One-quarter turn past contact.”

Over-tightening:

-

Warps the sleeve

-

Creates tension points

-

Amplifies vibration by 300–700%

Rule 4 — Rubber washers on all top screws

These absorb fan vibration better than metal-to-metal contact.

Rule 5 — Sound-damping strips on vertical frames

Closed-cell foam between sleeve and framing eliminates resonance paths.

Rule 6 — Never fasten all four corners first

This creates an “X-tension” warp.

Mike fastens in this order:

-

Top left

-

Top right

-

Bottom left

-

Bottom right

-

Center verticals

-

Center horizontals

This ensures a perfectly even load across the sleeve.

🎧 SECTION 6 — Why This Bolt Pattern Makes Homes Quiet

Icon: 🔇

Mike’s layout solves every noise path:

✔ Solves Problem 1 — Harmonic Resonance

The four mid-frame screws absorb energy waves.

✔ Solves Problem 2 — Sleeve Flex

The bottom fasteners prevent the sleeve from bouncing during compressor cycles.

✔ Solves Problem 3 — Fan Pulse Amplification

Rubber-isolated upper screws stop the frame from becoming a tuning fork.

✔ Solves Problem 4 — Wall Structure Echoing

Vertical frame fasteners break resonance transfer to studs.

✔ Solves Problem 5 — High-frequency grille rattle

Center vertical screws reduce turbulence vibration by absorbing micro-shocks.

✔ Solves Problem 6 — Long-term Screw Loosening

Fine threads + pre-drill + proper torque ensures no mechanical loosening.

🧊 SECTION 7 — Common Fastener Mistakes (Mike Fixes These Constantly)

Icon: ⚠️

Here are the problems Mike sees on almost every DIY install:

❌ 1. Screws driven into drywall only

Drywall is NOT a structural anchor → sleeve moves, rattles, vibrates.

❌ 2. Too few screws

Sleeve flexes under compressor cycles.

❌ 3. Screws placed only at the corners

Creates tension-box dynamics → amplifies vibration.

❌ 4. Using decking screws

Too aggressive, distort sleeve metal.

❌ 5. Using drywall screws

Weak, brittle, prone to snapping.

❌ 6. Uneven screw spacing

Creates asymmetric tension, pulling sleeve off alignment.

❌ 7. Over-torquing

Sleeve bows inward → warps AC chassis.

❌ 8. Fastening the exterior and interior differently

Creates torsion.

🧬 SECTION 8 — How the Quiet-Home Bolt Pattern Integrates With Mike’s Other Methods

Icon: 🔗

This layout works best when combined with:

✔ Two-Plane Sleeve Alignment Method

Ensures no twist before fastening.

✔ Compression Zones Mapping

Prevents uneven sleeve pressure.

✔ Weather Lock Strategy

Stops exterior vibrations from reaching frame.

✔ Centerline Thermal Pathing

Ensures airflow doesn’t cause turbulence noise.

✔ Stud-Safe Cutout Blueprint

Guarantees structurally sound fastening surfaces.

Each method enhances the others.

🧪 SECTION 9 — Verified External References

These links support best practices Mike uses:

-

Building Science Corporation – Wall Moisture & Cavity Pressure

https://www.buildingscience.com/ -

U.S. Department of Energy – Moisture Management & Wall Integrity

https://www.energy.gov/ -

NFPA – Electrical Requirements for Room Air Conditioners

https://www.nfpa.org/ -

Family Handyman – Understanding Stud Walls & Hidden Utilities

https://www.familyhandyman.com/ -

HUD Residential Construction Guide – Structural Load Path Basics

https://www.huduser.gov/ -

EPA Indoor Moisture & Ventilation Guide

https://www.epa.gov/

🏁 Conclusion — Quiet Is Engineered, Not Accidental

Noise-free performance doesn’t come from:

-

Luck

-

A quiet brand

-

A heavy sleeve

-

Foam padding

-

“Tightening until snug”

It comes from fasteners.

Mike’s Quiet-Home Bolt Pattern:

✔ Distributes energy

✔ Neutralizes resonance

✔ Straightens sleeve geometry

✔ Prevents vibration transfer

✔ Extends equipment life

✔ Creates whisper-quiet operation

This is why Mike can take a loud, rattling unit and make it nearly silent in under 30 minutes—

because the noise was never the AC’s fault.

It was the fasteners.

Buy this on Amazon at: https://amzn.to/47M5ozS

In the next topic we will know more about: The Return-Air Guardrail: Mike’s Guide to Keeping Furniture, Curtains & Corners from Killing Performance