Why sleeve slope is the difference between a dry home and a rotted wall.

Most homeowners—and even many installers—believe that as long as the AC sleeve looks “kind of tilted outward,” that’s good enough for drainage.

Mike disagrees.

He has repaired too many failed installs where:

-

Water dripped into the wall cavity

-

The sill plate rotted

-

Mold spread behind the drywall

-

Insulation became soaked

-

The Amana PBE123J35AA froze or short-cycled

-

Exterior siding buckled from moisture

-

Backdrafts pulled humid air inside

-

The interior drywall bubbled or stained

Every one of these failures shared a root cause:

❌ The sleeve slope was wrong.

A drain path that is too flat → pooling & rot

A slope that is too steep → vibration, noise, and airflow distortion

So Mike developed the 3-Point Drainage Slope Formula, a precise, engineered method that ensures perfect condensation evacuation, zero leaks, and long-term structural protection.

This guide teaches you how he calculates, measures, and verifies drainage slope for units like the Amana 11,900 BTU PBE123J35AA—and why getting the slope right is just as important as airflow, sleeve alignment, or Weather Lock sealing.

📚 SECTION 1 — Why Proper Sleeve Drainage Matters

Icon: 🪣

Through-the-wall ACs produce a surprising amount of condensate:

-

0.4 to 1.5 gallons per hour in humid climates

-

More during heat pump operation in shoulder seasons

If this water is not directed outward, it will:

💧 Run backward into insulation

💧 Pool on the interior sill

💧 Wick up drywall

💧 Create mold and mildew

💧 Attract pests

💧 Cause structural wood rot

💧 Shorten the lifespan of the AC

💧 Freeze during winter, creating ice dams

This is why manufacturers—including Amana—require a slight but consistent outward pitch.

But “slight” is vague.

And “eyeballing it” is how problems begin.

Mike’s method eliminates all guesswork.

📏 SECTION 2 — The Core Principle: Slope Does NOT Equal “Tilt”

Icon: 📐

Most people tilt the sleeve downward without understanding the math behind water movement.

Mike explains it this way:

“Water doesn’t care about your eyes. It cares about gravity, surface tension, and resistance.”

The sleeve must have:

-

Enough pitch for water to flow

-

Not so much pitch that the AC vibrates

-

A measured, repeatable angle consistent across all three reference points

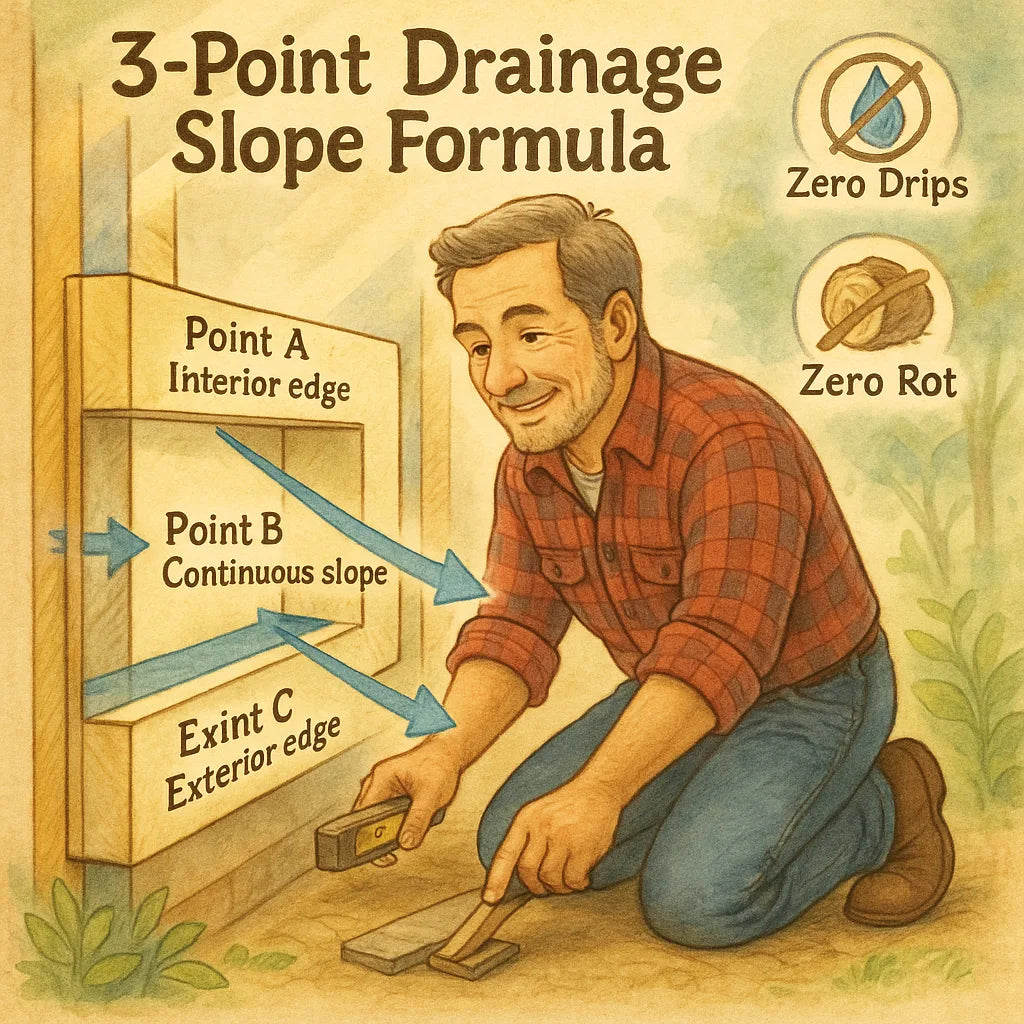

Thus the 3-Point Formula.

🧮 SECTION 3 — The 3-Point Drainage Slope Formula (Overview)

Icon: 🔢

Mike measures slope at:

1️⃣ Point A — Interior Sleeve Edge

Where the sleeve meets the interior wall.

2️⃣ Point B — Sleeve Midline

The center of the sleeve depth—critical for airflow + water path.

3️⃣ Point C — Exterior Sleeve Edge

Where the sleeve exits the siding and drains outside.

Water must flow:

A → B → C

with no dips, voids, or counter-slopes.

Mike targets:

📌 ¼ inch drop per 14–16 inches of sleeve depth

(Industry best practice for wall units)

For a typical 24" sleeve, this means:

📌 ~⅜ to ½ inch total pitch downward toward the outside

This creates a drainage path long enough to overcome surface tension and prevent backflow.

🧰 SECTION 4 — Tools Mike Uses to Measure the Slope

Icon: 🧲

Mike doesn’t trust eyeballing, because:

-

Walls aren’t level

-

Floors aren’t level

-

Interior trim isn’t square

-

Siding slopes vary

So he uses:

✔ Torpedo level (magnetic)

✔ 24" bubble level

✔ Digital angle gauge

✔ Laser level with tripod

✔ ⅛" and ¼" plastic shims

✔ Straightedge

✔ Carpenter’s pencil

With these tools, slope becomes measurable—not a guess.

🔍 SECTION 5 — Step-by-Step: How Mike Sets Each of the 3 Points

Icon: 🧭

Now the blueprint of how the slope is created.

1️⃣ Point A — Interior Sleeve Edge

Icon: 🏠

The interior must sit slightly higher than the exterior, but it must also sit perfectly level left-to-right.

Mike checks:

✔ Zero lateral tilt

Left side and right side must be perfectly level.

Why?

-

Lateral tilt causes corner pooling

-

Corner pooling becomes mold

-

Corner pooling shifts during heating cycles

-

It causes sensor misreads

Mike places a level across the interior flange to confirm no sideways slope.

Only the front-to-back slope is allowed.

2️⃣ Point B — Sleeve Midline

Icon: ➖

This is the most overlooked part.

Even if the interior and exterior edges are correct, the middle can dip or bow due to:

-

Wall compression zones

-

Poor shimming

-

Warped framing

-

Misaligned studs

-

Twisted sheathing

Mike runs a 24" straightedge or a laser level through the sleeve.

If the midpoint sits lower than intended:

→ Water pools

→ Ice can form in winter

→ Algae or mold can grow

→ Odors develop

→ Water backflows during heavy condensate periods

If the midpoint sits too high:

→ Water tries to flow backward

→ Sleeves whistle during high wind

→ Interior moisture wicks into drywall

Mike adjusts with thin shims (⅛" or less) to ensure a single consistent downward grade.

3️⃣ Point C — Exterior Sleeve Edge

Icon: 🌦️

This is where drainage physically exits the home.

Mistakes at Point C cause:

-

Siding rot

-

Drips against foundation

-

Water entering weep holes

-

Winter ice sheets

-

Insect attraction

-

Paint failure

Mike verifies:

✔ The exterior flange sits lower than both A and B

✔ The exterior siding does not block the drip path

✔ There is a clear ¼" to ½" downward offset

✔ No sealant or foam obstructs drainage channels

He also ensures:

✔ There is a drip edge or Weather Lock flashing

so water doesn’t migrate backward along the siding.

🧪 SECTION 6 — The Water Test (Mike’s Final Verification)

Icon: 💦

Mike pours 4–6 ounces of water into the sleeve at the interior edge.

He watches:

✔ Does water move smoothly past Point B?

✔ Does it accelerate slightly as it approaches Point C?

✔ Does any droplet cling to a midpoint?

✔ Does water return toward the inside?

✔ Does water exit the sleeve cleanly and drip into free air?

If anything fails:

-

He re-checks shimming

-

He re-checks compression zones

-

He re-checks siding clearance

-

He confirms sleeve straightness

A unit must pass the water test before installation continues.

🧱 SECTION 7 — The 7 Most Common Slope Mistakes Mike Fixes

Icon: ⚠️

Mike encounters the same errors repeatedly:

❌ Mistake 1: Sleeve sits perfectly level

Water has nowhere to go.

❌ Mistake 2: Sleeve slopes sideways

Water pools in a corner and rots the framing.

❌ Mistake 3: Midpoint dip

The invisible “belly” that causes mold and odor.

❌ Mistake 4: Exterior flange touches siding

Creates backflow and water migration.

❌ Mistake 5: Over-sloping (>1 inch)

Causes:

-

Compressor noise

-

Fan turbulence

-

Internal vibration

-

Refrigerant line stress

❌ Mistake 6: Foam sealing blocks drainage path

DIYers often foam over the drain channel by accident.

❌ Mistake 7: No drip guard or flashing

Water runs down the wall instead of falling away.

📦 SECTION 8 — Why the 3-Point Formula Works for the Amana PBE123J35AA

Icon: 🧊🔥

This unit is designed with a built-in condensate management strategy:

-

Tilt-compatible drain pan

-

Exterior sump edge

-

Noise-minimizing airflow

-

Internal slope detection

But these features rely on proper sleeve angle.

Poor slope → poor performance.

Correct slope →

✔ quieter operation

✔ better dehumidification

✔ predictable heating behavior

✔ no biological growth

✔ longer lifespan

🏡 SECTION 9 — Climate Considerations

Icon: 🌎

Mike adjusts slope slightly depending on climate:

Humid climates:

Increase slope toward ½ inch for more rapid drainage.

Arid climates:

Standard ¼–⅜ inch slope is perfect.

Cold climates:

Avoid steep slopes—steep angles increase ice formation risk.

Wind-exposed walls:

Ensure the sleeve floor is smooth and unobstructed for low-pressure wind-assisted drainage.

🧰 SECTION 10 — Calculating Slope With the Mike’s Ratio Rule

Icon: 📊

Mike uses a simple ratio:

1/4 inch drop per 14–16 inches of sleeve length

= 1.5–2% grade

Or:

Slope (%) = (Drop ÷ Run) × 100

For a 24" sleeve:

Drop = 0.375" → 0.50"

Run = 24"

Slope = 1.5–2%

This is ideal for water movement without acoustic penalties.

🧱 SECTION 11 — How the Slope Integrates With Weather Lock & Sleeve Alignment

Icon: 🧩

Mike reinforces that slope isn’t done in isolation:

The formula integrates with:

-

Weather Lock Strategy (4 layers of sealing)

-

Compression Zone Mapping (avoiding warping)

-

Two-Plane Sleeve Alignment (anti-twist)

-

Centerline Thermal Pathing (optimal airflow)

-

Stud-Safe Cutout Blueprint (structural stability)

Slope is a structural performance variable, not a cosmetic decision.

🔗 SECTION 12 — Verified External References

These links support best practices Mike uses:

-

Building Science Corporation – Wall Moisture & Cavity Pressure

https://www.buildingscience.com/ -

U.S. Department of Energy – Moisture Management & Wall Integrity

https://www.energy.gov/ -

NFPA – Electrical Requirements for Room Air Conditioners

https://www.nfpa.org/ -

Family Handyman – Understanding Stud Walls & Hidden Utilities

https://www.familyhandyman.com/ -

HUD Residential Construction Guide – Structural Load Path Basics

https://www.huduser.gov/ -

EPA Indoor Moisture & Ventilation Guide

https://www.epa.gov/

🏁 Conclusion — The Slope Is Small, the Impact Is Huge

Mike’s 3-Point Drainage Slope Formula ensures:

-

Zero drips

-

Zero rot

-

Zero mold

-

Zero backflow

-

Zero noise penalties

-

Perfect coil and pan performance

-

Long AC lifespan

-

Safe, dry wall cavities

Most failures come from using the eye instead of the formula.

But with:

✔ measured pitch

✔ controlled alignment

✔ verified midline

✔ water testing

✔ proper shimming

…a through-the-wall AC like the Amana PBE123J35AA will drain perfectly for decades.

Buy this on Amazon at: https://amzn.to/47M5ozS

In the next topic we will know more about: The Quiet-Home Bolt Pattern: Mike’s Fastener Layout That Kills Sleeve Vibration at the Source