How Mike prevents structural damage, sleeve wobble, and wall failures before the first cut is ever made.

Every homeowner fears the same thing when cutting a hole for a through-the-wall AC like the Amana PBE123J35AA:

-

Hitting a stud

-

Damaging wiring

-

Nicking plumbing

-

Weakening the wall

-

Creating a crooked or oversized opening

-

Cutting too high, too low, or too off-center

Mike has seen every version of the “wall cut nightmare” — from bowed drywall to entire siding panels having to be replaced because a cut was misaligned by even half an inch.

That’s why he came up with a foolproof method:

The Stud-Safe Cutout Blueprint

A measurement-driven, diagram-based method that ensures every cutout is structurally safe, perfectly level, centered, code-compliant, and sized to the millimeter.

This blueprint is the same process Mike uses on professional installs so the sleeve slides in exactly the way it should — without forcing, wedging, trimming, or later patching.

This long-form guide walks you through the full process step by step.

📐 SECTION 1 — Why Wall Cuts Go Wrong (and How Mike Prevents All of It)

Icon: ⚠️

Mistakes happen because people rush to cutting before they understand the internal geometry of the wall.

Common failures include:

❌ Cutting into load-bearing studs

Weakens the structure, requires major repair.

❌ Cutting through wiring or plumbing

Extremely dangerous, expensive to fix.

❌ Making the opening too big

Sleeve floats, leaks air, warps under pressure.

❌ Making the opening too small

Sleeve binds, compresses, or twists.

❌ Crooked cuts

Cause sleeve misalignment and water leaks.

❌ Off-center placement

Ruins airflow and creates structural asymmetry.

Mike prevents all of these using the Stud-Safe Blueprint.

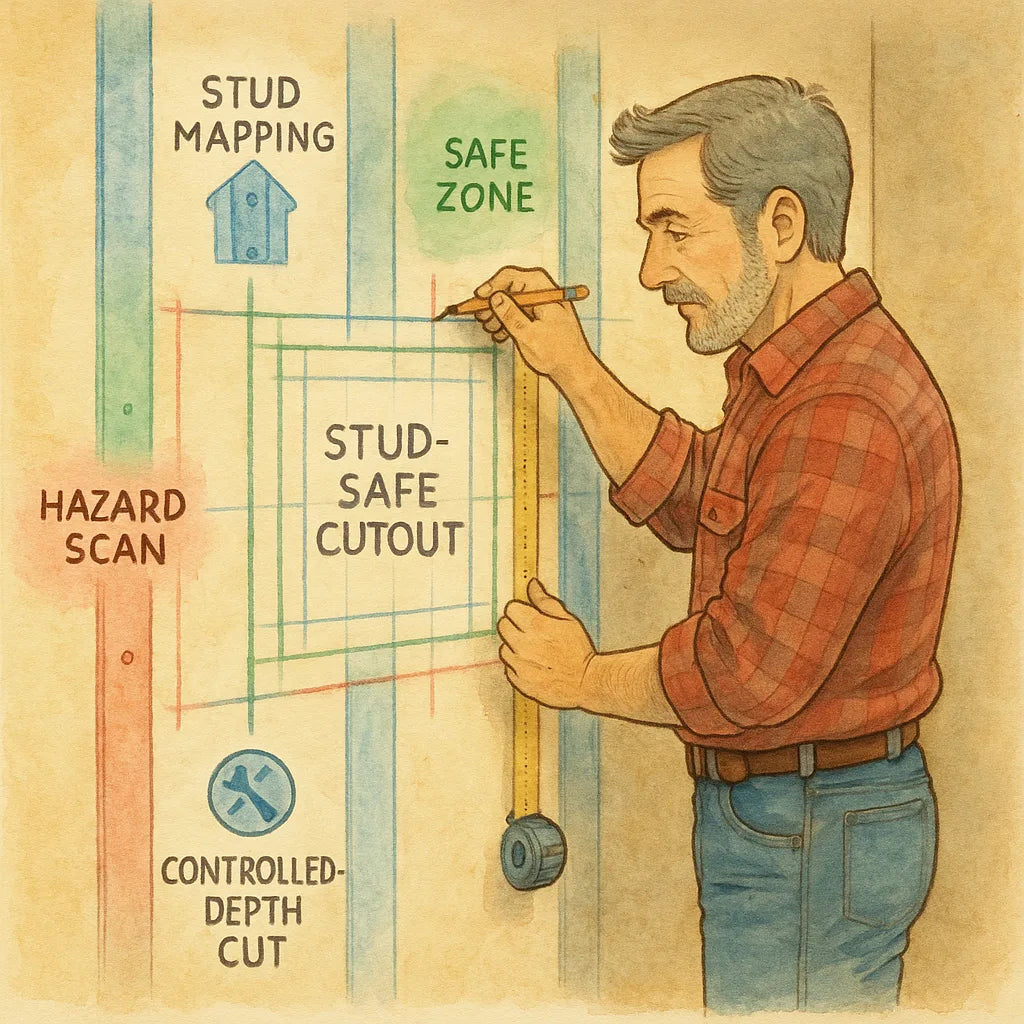

📏 SECTION 2 — The Stud-Safe Blueprint Overview (Mike’s 6-Stage Process)

Icon: 🧩

Mike completes this sequence in roughly 15–20 minutes:

-

Locate all studs and map their widths

-

Find safe zones between studs

-

Identify hazard lines (wiring, plumbing, HVAC)

-

Mark reference lines using the 4-Point Grid

-

Draw the cutout with the 2-Layer Centerline Diagram

-

Score, drill, and cut using the controlled-depth method

Each stage ensures the cut is accurate, safe, and mathematically square.

🪵 SECTION 3 — Stage 1: Locating and Mapping Studs

Icon: 🔍

Before lifting a saw, Mike identifies:

-

Every stud

-

Every void

-

Every potential obstruction

He uses three-tool confirmation, never relying on just one method.

🧲 Tool 1 — Rare-Earth Magnet

Finds drywall screws → identifies stud edges.

📡 Tool 2 — Multi-sensor stud finder

Gives approximate stud centerlines.

🔦 Tool 3 — Flashlight + raking light

Reveals subtle drywall screw dimples.

📌 Mike’s Rule:

“Confirm studs in three different ways before marking.”

He then labels each stud zone with painter’s tape:

-

Blue tape = confirmed stud

-

Green tape = void

-

Red tape = uncertain / needs verification

This gives Mike a full stud map for the wall segment.

🏛️ SECTION 4 — Stage 2: Calculating the Safe Zone Between Studs

Icon: 📏

A through-the-wall sleeve typically needs:

-

~14⅛" width (varies by manufacturer)

-

~8⅝" height

-

~24"+ interior-to-exterior depth

Studs are normally spaced 16" on center, but older houses may be 18", 20", or 24".

Mike identifies the largest uninterrupted void between studs.

He needs:

-

Enough width

-

Enough clearance

-

Enough margin for insulation and shimming

If the sleeve cannot fit between studs, he moves to another section of wall.

He never cuts into studs unless the project includes header framing.

❗ Mike’s Warning:

“If you cut a load-bearing stud without reframing, you didn’t install an AC — you damaged the house.”

⚡ SECTION 5 — Stage 3: Identifying Hazard Lines (Wiring, Plumbing, HVAC)

Icon: ⚡

Even if studs are clear, the cavity may contain:

-

Electrical runs

-

Junction boxes

-

Plumbing stacks

-

Gas lines

-

Old vent chases

-

HVAC returns

Mike checks via:

📍 1. Outlet & switch alignment

If there’s an outlet above/below the cut, wiring may cross the area.

📍 2. Thermal camera

Hidden pipes or wires show temperature signatures.

📍 3. Knock test

Hollow vs. stiff sound changes with behind-wall materials.

📍 4. Tiny inspection hole

Mike drills a ⅛" pilot hole and inserts a borescope camera.

📌 Safety Rule:

“Never cut blind. Every cavity must be inspected.”

🧭 SECTION 6 — Stage 4: Drawing the 4-Point Reference Grid

Icon: 🗺️

Once the safe zone is identified, Mike builds his reference grid.

This grid ensures:

-

Square cuts

-

Correct height

-

Perfect centerline placement

-

Exterior alignment

-

Backdraft-safe positioning

The 4 Points Are:

1️⃣ Vertical Centerline

This aligns airflow with the room’s thermal path.

2️⃣ Horizontal Centerline

Placed 10–14 inches above furniture level.

3️⃣ Sleeve Width Lines

Measured outward from centerline to each side.

4️⃣ Sleeve Height Lines

Measured upward/downward from centerline.

Mike marks all of this with high-visibility chalk or painter’s tape.

This creates a cutout box that is:

-

Perfectly level

-

Perfectly centered

-

Mathematically square

✏️ SECTION 7 — Stage 5: The 2-Layer Cutout Diagram

Icon: 🔲

Most installers draw one cutout rectangle.

Mike draws two:

Outer Diagram (Drywall Cut Line)

Oversized by 1/8" to allow for sleeve shimming.

Inner Diagram (Sheathing Cut Line)

Matches manufacturer sleeve specs exactly.

Why two diagrams?

Because interior drywall thickness varies:

-

½"

-

⅝"

-

Double-layered

And exterior materials vary:

-

Vinyl siding

-

Wood

-

Fiber cement

-

Stucco

-

Brick

The inner diagram ensures a perfect sleeve fit.

The outer diagram ensures a perfect interior finish.

🪚 SECTION 8 — Stage 6: Scoring, Drilling & Cutting (Mike’s Controlled-Depth Method)

Icon: 🪓

Mike uses a three-step cutting method that prevents:

-

Over-cutting

-

Broken studs

-

Frayed drywall

-

Torn insulation

-

Ragged holes

-

Unsafe plunge cuts

Step 1 — Score the drywall perimeter

Using a sharp utility knife:

-

Score along all four drawn sides

-

Repeat 3–4 passes for clean edges

This prevents tearing.

Step 2 — Drill relief holes in all corners

Relief holes:

-

Stop cracks

-

Prevent overcuts

-

Give the saw room to pivot

Mike uses a ⅜" drill bit for precision.

Step 3 — Use a drywall saw with depth control

He sets the saw’s blade depth to just barely exceed drywall thickness so he doesn’t hit:

-

Wiring

-

Pipes

-

Insulation

-

Sheathing

Once drywall is removed, he repeats a similar process for the sheathing—

but uses a different tool depending on material:

-

Oscillating saw (wood sheathing)

-

Diamond wheel (stucco)

-

Carbide blade (cement board)

-

Masonry blade (brick veneer)

❗ Mike’s Rule:

“Never cut the siding from inside; always cut siding from outside only.”

🌬️ SECTION 9 — Ensuring Exterior Alignment

Icon: 🔧

A perfect interior cut doesn’t mean a perfect exterior cut.

Mike transitions the opening outward by:

-

Drilling pilot holes through all four corners

-

Going outside

-

Using those holes as reference points

-

Drawing the exterior cut box

-

Cutting siding to meet exterior flange depth

This ensures:

-

Weather Lock integration

-

Sleeve sits square

-

Exterior trim aligns

-

Drainage pitch is correct

🔨 SECTION 10 — Inspecting & Reinforcing the Opening

Icon: 🧱

Once the rough opening is complete, Mike checks:

✔ Stud condition

If studs flex, he reinforces the sides.

✔ Header strength

Not needed unless a stud was removed.

✔ Sill plate angle

Should match required sleeve pitch.

✔ Cavity cleanliness

Debris removed to prevent sleeve warping.

✔ Insulation

Compressed insulation is fluffed back into place.

🧊 SECTION 11 — Preparing for Sleeve Insertion

Icon: 📦

Mike performs several pre-insert tasks:

-

Adds side shims

-

Checks interior level

-

Confirms exterior pitch

-

Tests airflow direction

-

Ensures centerline thermal pathing has not changed

-

Pre-measures Weather Lock materials

Then—and only then—he slides the sleeve in halfway to test compression zones.

📚 SECTION 12 — Why Mike’s Stud-Safe Blueprint Works

Icon: 💡

Because the blueprint solves all structural challenges before they happen.

✔ No surprise wires

✔ No damaged studs

✔ No crooked openings

✔ No oversized cuts

✔ Perfect sleeve alignment

✔ Perfect weather sealing

✔ Perfect airflow placement

✔ Minimal repair risk

This blueprint eliminates the guesswork and turns a dangerous step into a repeatable, engineered process.

🔗 SECTION 13 — Verified External References

These links support best practices Mike uses:

-

Building Science Corporation – Wall Moisture & Cavity Pressure

https://www.buildingscience.com/ -

U.S. Department of Energy – Moisture Management & Wall Integrity

https://www.energy.gov/ -

NFPA – Electrical Requirements for Room Air Conditioners

https://www.nfpa.org/ -

Family Handyman – Understanding Stud Walls & Hidden Utilities

https://www.familyhandyman.com/ -

HUD Residential Construction Guide – Structural Load Path Basics

https://www.huduser.gov/ -

EPA Indoor Moisture & Ventilation Guide

https://www.epa.gov/

🏁 Conclusion — A Perfect Cutout Isn’t an Accident. It’s a Blueprint.

Most installers cut first and discover problems later.

Mike discovers everything first, then cuts.

The Stud-Safe Cutout Blueprint ensures:

-

The wall stays strong

-

The sleeve fits perfectly

-

No hidden surprises

-

No callbacks

-

The Amana PBE123J35AA performs exactly as intended

When the cutout follows the blueprint, everything downstream becomes easier:

-

Weather Lock

-

Two-Plane Sleeve Alignment

-

Centerline Thermal Pathing

-

Compression Zone Mapping

A perfect cutout isn’t the start of the installation—

it’s the foundation of the entire system.

Buy this on Amazon at: https://amzn.to/47M5ozS

In the next topic we will know more about: The 3-Point Drainage Slope Formula: Mike’s Rule for Zero Drips, Zero Rot & Perfect Condensation Management