A 4-ton AC condenser is a workhorse. It can cool large homes, open layouts, and energy-hungry spaces. But without smart system design, it can also be a noise machine—vibrating through walls, humming through ductwork, and thumping during startup.

Mike Sanders has designed thousands of systems, and he’ll tell you the same thing he tells every homeowner:

“Quiet isn’t about brand. Quiet comes from layout. You can’t buy your way into silence—you design your way there.”

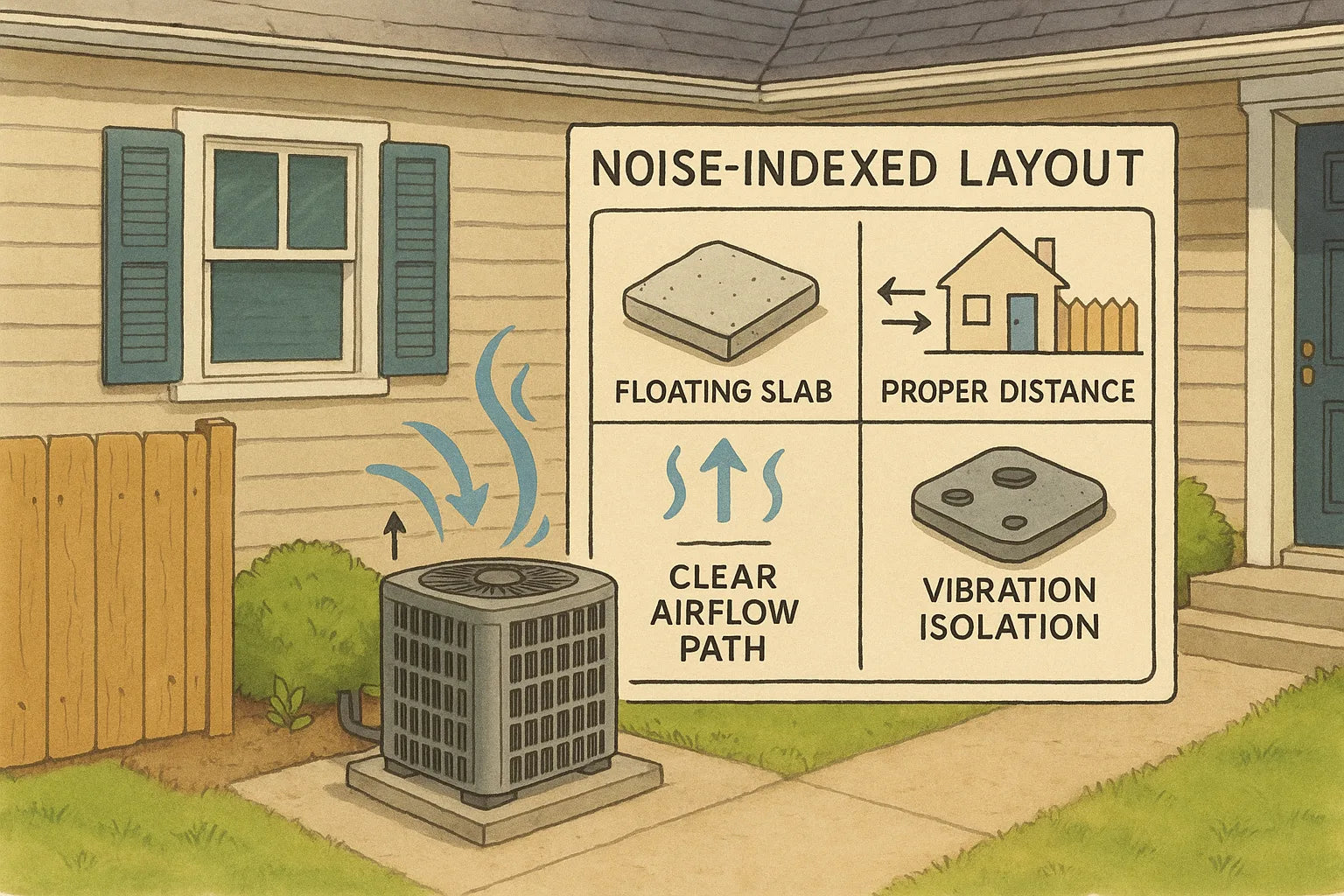

That’s the foundation of Mike’s Noise-Indexed System Layout, a method that analyzes the mechanical, structural, and airflow elements of an HVAC design to make a powerful 4-ton condenser operate whisper-quiet—indoors and out.

This is the complete guide to how Mike does it.

🔍 1. Why 4-Ton Condensers Are the Noisiest Units in Residential HVAC

Noise is physics.

More tonnage means more:

-

refrigerant mass flow

-

fan RPM

-

compressor load

-

vibration energy

-

airflow turbulence

-

thermal expansion

A 4-ton unit generates nearly 2× the airflow noise of a 2-ton unit because its fan blade diameter and motor torque scale disproportionately.

But most noise complaints don’t come from the condenser itself—they come from the environment around it.

Here’s why.

🔊 2. The Three Sources of HVAC Noise (Most Homeowners Blame Only One)

Noise in a 4-ton condenser comes from three very different sources.

🎛️ 2.1 Mechanical Noise (Compressor + Fan)

This includes:

-

compressor hum

-

fan blade chopping air

-

contactor “click”

-

refrigerant pulsations

Modern units are quieter than ever, but a 4-ton still produces notable mechanical energy.

🧱 2.2 Structural Noise (Vibration to House Framing)

This is the one homeowners don’t expect.

If the condenser transmits vibration through:

-

a patio slab

-

a wooden deck

-

siding

-

foundation block

…it can turn your bedroom wall into a speaker.

🌬️ 2.3 Aerodynamic Noise (Air Movement + Turbulence)

A 4-ton unit moves a lot of air.

Poorly designed airflow paths cause:

-

whistling

-

loud whooshing

-

back-pressure roaring

-

pulsation noise during defrost (in heat pumps)

This is where Mike’s Noise-Indexed System Layout begins.

📊 3. Mike’s Noise Index Score (NIS) — The Formula for Predicting Loudness

Noise is predictable when you break it into variables.

Mike uses his own field-tested Noise Index Score (NIS):

NIS = Mechanical Output + Structural Transmission + Aerodynamic Turbulence – (Environmental Dampening + Layout Correction)

In simple terms:

-

Bad slab + bad airflow + bad placement = loud

-

Good slab + good airflow + smart placement = quiet

Every design choice shifts the Noise Index up or down.

🏡 4. The Big Rule: “Noise Starts Outside, But It’s Heard Inside.”

When homeowners say:

-

“My bedroom wall hums.”

-

“The AC is so loud at night.”

-

“My office vibrates when it runs.”

…Mike explains the truth:

“The condenser isn’t in your bedroom. The noise travels there.”

That means the key to quiet operation is controlling:

-

vibration transmission

-

airflow trajectory

-

acoustic reflections

Everything else is secondary.

🛠️ 5. Mike’s Noise-Indexed System Layout – The Full Blueprint

Here’s the complete method he uses for 4-ton units.

🧱 5.1 STEP ONE — Slab Engineering (The Most Overlooked Noise Factor)

The slab determines structural transmission, which determines indoor noise.

🪨 Mike’s Slab Rules:

-

Never mount a condenser on a wooden deck (instant drum).

-

Use rubber isolation feet at all four corners.

-

Use a floating slab or pad that does not touch the house foundation.

-

Ensure the slab is level to prevent fan imbalance.

-

Use a polymer composite pad when possible—they absorb vibration better.

External Link: EPA outdoor HVAC noise considerations

🏙️ 5.2 STEP TWO — Placement Distance (The Silent Zone Concept)

Mike identifies a “Silent Zone,” where sound disperses instead of reflecting.

✔️ Ideal distance from walls: 30–60 inches

Less than 24" causes:

-

fan turbulence buildup

-

reflected noise amplifying back toward the home

-

condenser overexertion

NEVER place the condenser:

-

under a window

-

against a corner

-

in a side yard echo chamber

-

in a rigid alcove

A 4-ton unit needs breathing room.

🌬️ 5.3 STEP THREE — Airflow Trajectory Mapping

Every condenser pushes air up (top discharge) or out (side discharge).

Mike studies:

-

roofline geometry

-

nearby fences

-

bushes

-

soffits

-

wall angles

-

neighbor layout

🌀 Mike’s Airflow Rules:

-

Top-discharge units: require open sky, not under decks or soffits.

-

Side-discharge units: require 3–5 ft clearance.

-

Never direct airflow toward:

-

windows

-

patios

-

kids’ play areas

-

metal sheds (they reflect sound)

-

Airflow = soundflow. They follow the same paths.

🛑 5.4 STEP FOUR — Back-Pressure Noise Elimination

A 4-ton’s fan creates powerful suction and exhaust forces.

Obstructions cause:

-

pitch changes

-

loud whooshing

-

buffeting noises

Key offenders:

-

fences

-

shrubbery

-

house corners

-

low deck beams

-

retaining walls

Mike maintains:

“A condenser should never feel boxed in. Give it an open lane.”

🔧 5.5 STEP FIVE — Line Set & Vibration Isolation

Copper tubing can transmit vibration like a tuning fork.

Mike installs:

-

line-set isolation pads

-

insulated wall penetrations

-

suction line mufflers (only if needed)

-

gentle bends → NOT tight 90° turns

-

wall brackets with rubber dampers

This eliminates structural hum.

BONUS:

Running line sets through conditioned space walls makes noise far worse.

🧊 5.6 STEP SIX — Compressor Technology Tuning

Modern 4-ton units may use:

-

single-stage

-

two-stage

-

variable-speed inverter compressors

Mike adjusts expectations and layout accordingly.

📦 Single-stage

Loudest startup → requires strongest slab isolation.

🌀 Two-stage

Much quieter, but can “drone” against walls.

⚡ Inverter-type

Quietest—but only with excellent airflow clearance.

External Link: DOE guide on high-efficiency compressor technology

🎛️ 5.7 STEP SEVEN — Duct Noise Reduction for 4-Ton Systems

A powerful condenser often pairs with a high-static blower.

Mike checks:

-

return duct sizing

-

filter restriction

-

supply branch velocity

-

plenum geometry

-

flex duct sag

-

boot noise

Mike’s Rule:

“If the ductwork is noisy, the AC condenser gets blamed.”

A 4-ton system needs 2,000+ CFM.

Poor ducts turn that into a wind tunnel.

🌡️ 6. Why Layout Affects Noise More Than Equipment Brand

Mike often says:

“A well-placed cheap condenser is quieter than a badly placed premium one.”

That’s because layout controls:

-

vibration paths

-

airflow pressure

-

acoustic reflections

-

ground resonance

-

mechanical “coupling” with the house

Brands can’t fix physics.

But smart layout can.

🌲 7. Mike’s Outdoor Sound-Dampening Enhancements

After layout optimization, Mike sometimes adds:

✔️ Dense landscaping barriers

(Placed 3 ft away—NOT touching the unit)

✔️ Acoustic fence panels

(Only effective when used for reflection control, not blocking airflow)

✔️ Sound blankets for compressor

(Used sparingly—must not trap heat)

✔️ Rubber isolation blocks

(High-mass pads to minimize slab resonance)

External Link: Outdoor HVAC noise mitigation overview

https://www.energy.gov/energysaver/heating-and-cooling

📉 8. Indoor Noise Reduction: Mike’s 3-Part Strategy

Homeowners often think the condenser is too loud—when the real noise comes from the air handler.

Mike solves this in three steps.

🪵 8.1 Step 1 — Furnace/air handler vibration isolation

-

rubber feet

-

anti-vibration pads

-

cabinet anchoring

-

plenum realignment

🌬️ 8.2 Step 2 — Return air silencing

He adds:

-

lined return boxes

-

acoustic ductboard

-

larger filter racks

-

proper turning vanes in returns

🔇 8.3 Step 3 — Static pressure reduction

If static pressure drops:

-

blower noise decreases

-

duct roar decreases

-

coil turbulence decreases

4-ton systems are extremely sensitive to static pressure.

🧰 9. Real-World Example: Mike Silences a 4-Ton “Noise Monster”

Home: 2800 sq ft

Equipment: 4-ton R-410A single-stage

Complaint: “The AC sounds like a helicopter landing.”

Mike’s Findings:

-

condenser 14" from exterior wall

-

slab touching foundation

-

line set strapped to wall studs

-

return static pressure at 0.42 inWC

-

clogged 1" filter

-

airflow blocked by shrubs

Mike’s Fixes:

-

moved condenser 40" away

-

floated slab on isolation pads

-

re-routed line set with insulation

-

installed 4" media filter

-

trimmed vegetation

-

lowered blower RPM

-

sealed return leaks

Results:

-

noise dropped by ~60%

-

indoor hum eliminated

-

airflow stabilized

-

outdoor turbulence gone

-

homeowner ecstatic

🎯 10. Mike’s Quick-Reference Quiet-Home Rules

Here’s the checklist Mike gives technicians:

✔️ Rule #1: Pad must float, never anchor

✔️ Rule #2: Minimum 30–60" from walls or corners

✔️ Rule #3: Top discharge = open sky

✔️ Rule #4: Line set must NOT contact framing

✔️ Rule #5: Allow 5 ft of “sound release space”

✔️ Rule #6: Increase return air size for quieter airflow

✔️ Rule #7: Remove obstructions causing back-pressure

✔️ Rule #8: Use rubber isolation for every mounting point

✔️ Rule #9: Avoid alcoves; noise multiplies in corners

✔️ Rule #10: Quiet is created in layout—not by equipment alone

🏁 Final Takeaway

Mike says it best:

“Think like sound. If you can picture how it moves, you can control it.”

A noise-indexed system layout transforms a powerful 4-ton condenser into a whisper-quiet cooling machine.

It’s not complicated — it’s intentional.

Every inch of spacing, airflow direction, slab contact point, and duct transition matters.

Design it right, and the whole home becomes quieter, cooler, and more comfortable.