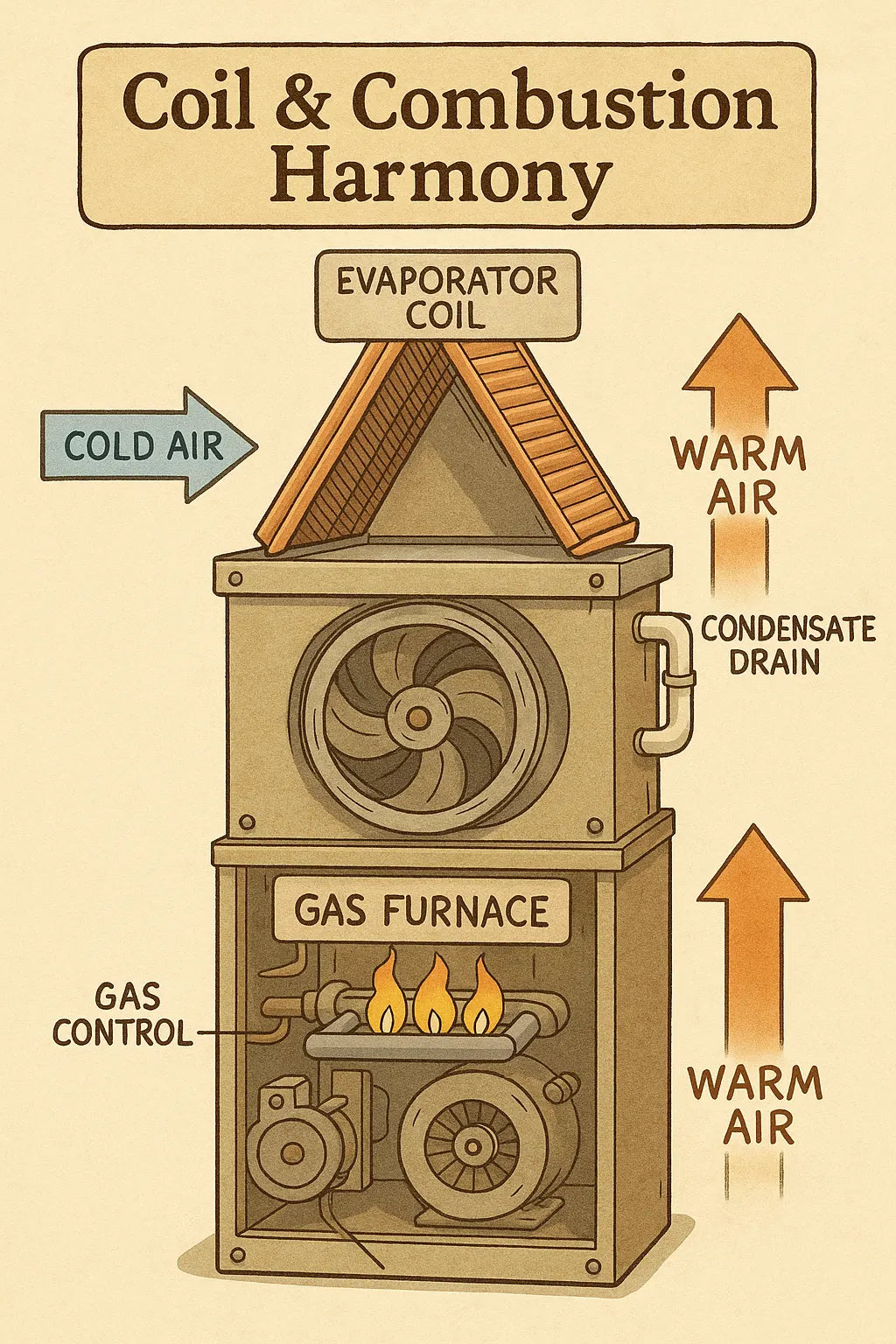

In most homes, the furnace and evaporator coil sit right on top of each other, stacked like pancakes. Simple, right?

Not if you want the system to run safely, efficiently, and without noise, short-cycling, coil sweat, or heat-induced airflow restrictions.

Mike Sanders has a rule he teaches in every training session:

“If your coil and furnace aren’t tuned to each other, the whole system fights itself.”

This is especially true when pairing a vertical evaporator coil with a high-output 80% AFUE gas furnace, like the 100k–120k BTU models commonly installed in large homes.

The coil affects the furnace. The furnace affects the coil.

And if they aren’t synchronized, you end up with:

-

overheating

-

cold-blow complaints

-

furnace limit trips

-

loud airflow

-

long AC recovery times

-

poor humidity removal

-

coil freeze-ups in summer

-

cracked heat exchangers over time

This guide gives you Mike’s full blueprint for achieving coil & combustion harmony — a perfect synchronization of airflow, heat rise, coil load, and blower tuning that results in a quiet, efficient, stable system.

🧠 1. Why Coil-Furnace Synchronization Matters So Much

At first glance, the furnace and coil look like two separate pieces of equipment.

They are not.

They share:

-

the same blower

-

the same return duct

-

the same supply plenum

-

the same static pressure environment

-

the same airflow limitations

Most homeowners — and even many installers — don’t realize how tightly integrated these components are.

To Mike, they’re part of the same machine.

🔥 1.1 The Furnace Generates Heat — But the Coil Controls Back-Pressure

A vertical evaporator coil sits directly in the furnace’s path of heated air.

That means the coil:

-

resists airflow

-

adds static pressure

-

affects temperature rise

-

impacts combustion stability

The hotter the furnace output, the more resistance the coil creates.

High BTU furnaces and restrictive coils do not mix unless tuned properly.

❄️ 1.2 The Coil Controls AC Efficiency — But Relies on Furnace Airflow

In cooling season, the furnace’s blower becomes the AC blower.

Its ability to:

-

hit target CFM

-

maintain static pressure

-

stay below low-temperature limits

determines whether the coil stays cold without freezing.

A coil starved of airflow becomes:

-

too cold

-

too moist

-

prone to icing

-

unable to dehumidify the home

So heating airflow and cooling airflow are tightly bound.

⚙️ 1.3 High-Output 80% Furnaces Demand More Airflow Than AC Loads

A 120k BTU furnace may need 1800–2200 CFM, while the AC coil may only need 1400–1600 CFM.

If the ductwork or blower tuning favors cooling airflow, the furnace overheats.

If it favors heating airflow, the coil can flood or freeze.

Thus, synchronization is mandatory.

External Link: Furnace temperature rise fundamentals

https://www.energy.gov/energysaver/furnaces-and-boilers

🧩 2. The Four Interactions Between a Vertical Coil & 80% Furnace

Mike teaches four behavior patterns that determine system harmony.

🔥📈 2.1 Interaction #1: Temperature Rise vs. Coil Restriction

Every furnace has a rated temperature rise, usually:

-

35–65°F (typical for 80% furnaces)

If airflow is too low because the coil is restrictive, temperature rise skyrockets.

This causes:

-

limit switch trips

-

short cycling

-

overheated exchangers

-

reduced blower life

Target:

✔️ Keep rise inside manufacturer spec

✔️ Target the middle of the rise range for long furnace lifespan

🌬️💨 2.2 Interaction #2: Static Pressure vs. Coil Surface Area

Vertical coils can be:

-

A-coil

-

N-coil

-

Slab coil (rare)

The larger the coil surface area, the lower the resistance — usually.

But some high-efficiency coils are dense with fins and tubing, increasing restriction.

Static pressure directly affects:

-

blower speed

-

airflow volume

-

heat exchanger temperature

Target:

✔️ Total external static pressure ≤ 0.5 inWC

✔️ Never exceed 0.8 inWC or equipment life drops dramatically

❄️🧊 2.3 Interaction #3: Coil Flooding vs. Furnace Blower Speed

If blower speed is too high:

-

coil moisture removal drops

-

coil temperature split shrinks

-

home feels humid

If blower speed is too low:

-

coil gets too cold

-

refrigerant floods

-

coil freezes

This requires seasonal blower tuning, something Mike does automatically.

External Link: AC coil performance basics

https://www.energy.gov/energysaver/central-air-conditioning

🔥🌀 2.4 Interaction #4: Furnace Combustion vs. Airflow Path Turbulence

Combustion stability depends on consistent heat removal from the heat exchanger.

Bad coil alignment creates turbulence, which causes:

-

inconsistent rising air patterns

-

hot pockets

-

unstable flame patterns (rare but real)

-

nuisance limit trips

Thus, coil alignment is not cosmetic — it’s thermal engineering.

🛠️ 3. Mike’s Coil & Combustion Harmony Checklist

This is Mike’s full synchronization framework.

📏 3.1 Step 1: Verify Coil Type, Tonnage & Orientation

Mike checks:

-

coil tonnage

-

coil static rating

-

coil cabinet width to match furnace

-

coil offset and alignment

-

A-coil vs N-coil pressure profile

📘 Coil selection rules:

-

A-coil = lower pressure drop, better harmonization with 80% furnaces

-

N-coil = high efficiency but higher restriction; must correct static pressure

-

Coil tonnage must be equal to or greater than system tonnage

External Link: AHRI matched system guidelines

https://www.ahridirectory.org

🔄 3.2 Step 2: Match Furnace Blower to Coil Requirements

Mike checks blower CFM tables, then sets:

✔️ High heat stage CFM

✔️ Low heat stage CFM

✔️ Cooling CFM

✔️ Dehumidification mode (if ECM blower)

He tunes blower speed based on:

-

coil wet performance

-

temperature rise targets

-

static pressure

-

duct capacity

This step alone eliminates 50% of furnace/coil conflicts.

🧱 3.3 Step 3: Ensure Proper Coil Positioning (Vertical Coil Best Practices)

Mike checks:

🟦 3.3.1 The Coil Sits Fully Centered Over the Furnace

Misaligned coils cause:

-

turbulence

-

heat pockets

-

coil sweat

-

premature rust

🟦 3.3.2 The Coil Pan Must Be Below Load-Bearing Rails

A sagging coil pan floods the furnace vestibule.

🟦 3.3.3 The Coil Must Have Correct Pitch

Forward pitch of ¼" ensures drainage.

🔥 3.4 Step 4: Temperature Rise Testing (The Make-or-Break Step)

Mike tests:

-

supply air temp

-

return air temp

-

mid-plenum temp

Then calculates temperature rise:

Rise = Supply Temp – Return Temp

Target range:

✔️ Middle of furnace spec

✔️ Usually 45–55°F

Too high = coil too restrictive

Too low = blower too fast or bypassing coil

This ensures combustion heat is properly absorbed.

🌀 3.5 Step 5: Static Pressure Testing

Mike tests:

-

return static

-

supply static

-

total external static pressure

Targets:

✔️ ≤ 0.50 inWC total

✔️ Return side ≤ 0.20

✔️ Supply side ≤ 0.30

If static is high:

-

enlarge return duct

-

increase filter size

-

fix sagging flex

-

add additional returns

-

enlarge critical supply branches

External Link: Duct performance basics

💧 3.6 Step 6: Condensate & Coil Drainage Optimization

Mike ensures:

-

proper trap height

-

anti-float checks for coil pan

-

correct slope for drain lines

-

secondary drain protection

Improper drainage leads to:

-

coil freeze

-

musty odors

-

overflow safety shutoff trips

🔧 3.7 Step 7: Seasonal Mode Synchronization

Mike sets two blower profiles:

Summer Mode:

-

lower CFM for better dehumidification

-

tighter temperature split

-

reduced coil flood risk

Winter Mode:

-

higher CFM for heat rise control

-

faster warm-up

-

furnace protection

This dual-profile approach is the secret to perfect harmony.

📐 4. Furnace-to-Coil Airflow Sizing: Mike’s Golden Ratios

These ratios eliminate 90% of system conflicts.

🟦 4.1 80% Furnace Output vs. Coil Tonnage

For a 120k BTU furnace:

-

3.5–4 ton coil = ideal pairing

-

2–3 ton coils = overly restrictive

-

5 ton coil = low velocity, poor dehumidification

🟥 4.2 Furnace Output vs. Blower CFM

Mike targets:

-

400 CFM/ton for cooling

-

20–30% more for heating

-

Add 10% extra if ducts include long flex runs

🟩 4.3 Filter Sizing Rules

Mike’s minimum rules for a 120k furnace:

-

2" filter = 2000 CFM max

-

4" filter = 2200+ CFM max

-

Filter grille area = 2–4 sq ft minimum

1" filters are almost always too restrictive.

🟧 4.4 Coil Pressure Drop Compensation

If coil has high fin density:

-

open additional returns

-

increase trunk size

-

change blower tap

-

upsize key duct runs

🛠️ 5. What Happens When Coil & Furnace Are NOT in Harmony?

Mike sees certain failures repeatedly.

❌ 5.1 Furnace Trips High-Limit Switch

Most common failure.

Caused by:

-

coil too restrictive

-

blower too slow

-

duct system undersized

❌ 5.2 Coil Sweating or “Raining” on Furnace

Warm furnace air meets cold coil pan.

Caused by:

-

rapid cycling

-

short blower off-delay

-

coil misalignment

❌ 5.3 Loud Airflow or Whistling

Static pressure too high.

❌ 5.4 AC Freeze-Ups

Blower tuned too low for the coil.

❌ 5.5 Furnace Heat Exchanger Overstress

This shortens furnace lifespan dramatically.

🧱 6. Real-World Example: Mike Fixes a Bad Furnace-Coil Match

Home: 2,400 sq ft

Equipment: 4-ton coil + 120k 80% furnace

Symptoms:

-

AC freeze-ups

-

furnace overheating

-

loud airflow

-

high humidity

-

short cycling

What Mike Found:

-

coil offset ¾" off center

-

static pressure 0.82 inWC

-

return undersized

-

1" filter rack

-

blower set too high for cooling

Mike’s Fixes:

-

centered coil

-

installed 4" media filter

-

added 2nd return

-

reduced blower speed in cooling

-

increased heat-stage CFM

-

upsized two flex runs

Final Results:

-

static pressure: 0.82 → 0.47

-

furnace stabilized

-

AC stopped freezing

-

humidity decreased

-

airflow noise cut in half

-

comfort dramatically improved

This is coil & combustion harmony in action.

🎯 7. Final Takeaway

Mike sums it up perfectly:

“Your furnace and coil don’t work in isolation — they speak the same airflow language. My job is to make sure they’re speaking it clearly.”

Synchronizing a vertical evaporator coil with a high-output 80% furnace is the difference between:

-

a loud, inefficient system

-

and a quiet, high-performance home comfort machine

When coil, combustion, airflow, and static pressure are all in harmony, the system becomes stable, efficient, and long-lasting — exactly as it should be.