Startup is when your PTAC uses the most electricity in the shortest amount of time.

Not because something’s wrong — but because physics doesn’t care about your utility bill.

Compressors overcome pressure. Electric heat ramps up. Fans spin from zero to full speed. If startup is sloppy, power draw spikes higher, lasts longer, and sometimes repeats itself over and over.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

I’ve seen PTACs that were “efficient on paper” become energy hogs simply because startup was rushed, mistimed, or poorly configured.

This guide shows you:

-

Where PTACs draw the most power during startup

-

How to measure that draw accurately

-

What changes actually reduce startup energy — and which ones don’t

🧠 The Reality of Startup Power Draw

Here’s the truth most people don’t hear:

You don’t pay for how efficient a PTAC is — you pay for how often it ramps up inefficiently.

Startup is inherently inefficient. The goal isn’t to eliminate startup draw — it’s to:

-

Make it shorter

-

Make it smoother

-

Make it less frequent

That’s where real savings happen.

⚙️ What Happens Electrically During PTAC Startup

At startup, three major components demand power almost at once:

🌀 Fan motor

-

Low-to-moderate draw

-

Ramps quickly

-

Usually stabilizes fast

❄️ Compressor (cooling)

-

High inrush current

-

Short but intense draw

-

Protected by time delays

🔥 Electric heat (if engaged)

-

Continuous high amperage

-

Longest sustained load

-

Biggest energy impact

Startup energy problems come from stacking these loads incorrectly.

🔌 Measuring Startup Power the Right Way

If you want to reduce energy use, you have to measure reality — not estimates.

Tools that work

-

Plug-in energy monitors (where compatible)

-

Clamp meters (most accurate)

-

Smart breakers or panel monitors

-

Utility smart meter real-time data

What you want to capture:

-

Peak amperage at startup

-

Duration of peak draw

-

Time to stabilize

-

Frequency of startups per hour

One bad startup costs little. Hundreds of bad startups cost real money.

Verified reference:

U.S. Department of Energy – Measuring Home Energy Use

https://www.energy.gov/energysaver/home-energy-assessments

⏱️ The Most Expensive Startup Pattern (And Why It Happens)

The worst-case energy scenario looks like this:

-

PTAC starts

-

Compressor engages

-

Thermostat overshoots

-

Unit shuts down quickly

-

Restarts minutes later

-

Repeats all day

This is called short cycling, and it’s brutal on both:

-

Energy consumption

-

Equipment lifespan

Startup energy use isn’t high because the unit runs — it’s high because it keeps restarting.

🌀 Why Fan-Only Startup Saves Energy (Indirectly)

Running fan-only first doesn’t save power immediately — it saves power later.

Here’s how:

-

Establishes airflow

-

Prevents compressor strain

-

Reduces pressure imbalance

-

Shortens cooling runtime

A compressor that starts with proper airflow:

-

Draws less peak current

-

Stabilizes faster

-

Cycles less often

Fan-only startup is an energy stabilizer, not an energy hog.

❄️ Cooling Startup: How to Reduce Inrush Impact

You can’t eliminate compressor inrush — but you can minimize its impact.

Energy-saving startup habits

-

Let compressor delays complete

-

Avoid rapid mode switching

-

Don’t power-cycle to “force cooling”

-

Start cooling after fan-only run

Every interrupted startup forces the compressor to fight pressure again — and that costs energy.

Verified reference:

EPA – Energy Use in Room Air Conditioners

🔥 Electric Heat: The Biggest Startup Energy Risk

Electric heat doesn’t spike — it stays high.

A 3.5 kW electric heater draws:

-

~15 amps at 230V

-

Continuously while heating

At startup, energy waste happens when:

-

Heat engages before airflow is established

-

Thermostats overshoot

-

Heat cycles repeatedly in short bursts

How to reduce heat startup energy

-

Always run fan-only first

-

Avoid large temperature jumps

-

Use smaller setpoint changes

-

Confirm breaker stability (no nuisance trips)

Heat should be deliberate, not reactive.

📱 Smart Controls: When They Help — And When They Hurt

Smart controls can reduce startup energy if configured correctly.

They increase startup energy when:

-

Schedules are too aggressive

-

Recovery mode runs at full power

-

Multiple mode changes occur close together

Smart control best practices

-

Delay schedules after startup

-

Use gradual temperature ramps

-

Avoid frequent on/off schedules

-

Let PTAC logic manage compressor timing

Smart controls don’t save energy automatically. Good programming does.

Verified reference:

ENERGY STAR – Smart Thermostat Energy Use

https://www.energystar.gov/products/smart_thermostats

🌡️ Temperature Setpoints: Small Changes, Big Savings

The biggest startup energy mistake I see:

Setting the thermostat too far from room temperature.

Large jumps cause:

-

Longer runtime

-

Higher sustained amperage

-

More frequent cycling

Better strategy:

-

Adjust in 2–3°F increments

-

Let the PTAC stabilize

-

Avoid chasing comfort instantly

PTACs reward patience with lower power draw.

🧪 R32 Refrigerant & Startup Efficiency

Modern PTACs using R32 refrigerant respond faster and stabilize quicker.

That means:

-

Shorter startup windows

-

Faster temperature correction

-

Less wasted runtime — if airflow is correct

But R32 is less forgiving:

-

Poor airflow = faster cycling

-

Electrical instability = quicker shutdowns

Startup efficiency with R32 depends heavily on clean filters and steady airflow.

Verified reference:

EPA – Transition to Lower-GWP Refrigerants

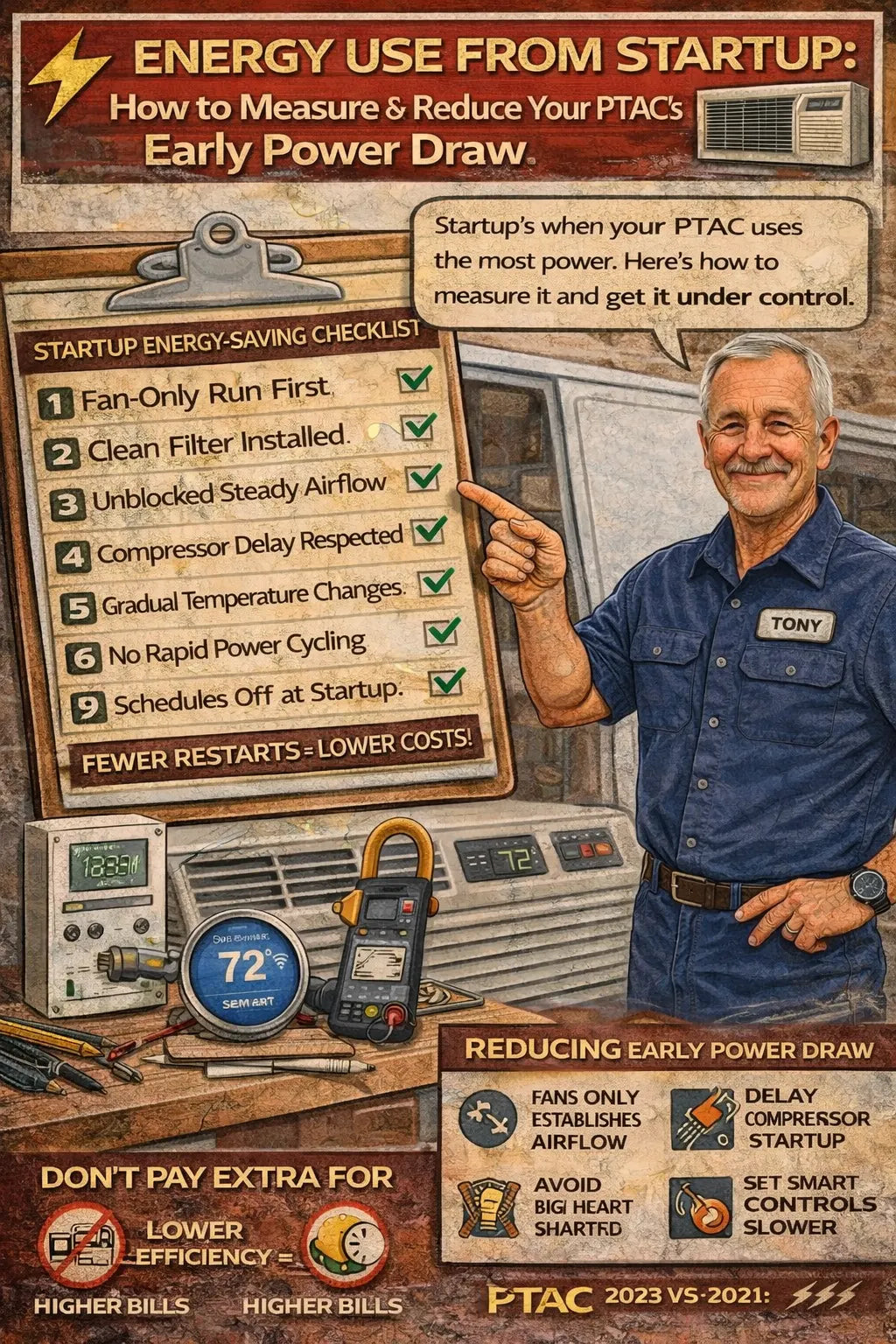

📋 Startup Energy Reduction Checklist

Before and during startup, confirm:

✅ Fan-only run completed

✅ Clean filter installed

✅ Airflow unobstructed

✅ Compressor delay respected

✅ No rapid power cycling

✅ Gradual temperature changes

✅ Smart schedules disabled initially

If you do nothing else, do these.

🧱 Tony’s Final Word

Startup energy isn’t about how powerful your PTAC is.

It’s about how often you force it to work harder than it needs to.

Smooth startups cost less. Stable operation costs less. Fewer restarts cost a lot less.

If you want lower energy bills, don’t chase comfort — let the machine settle into it.

Buy this on Amazon at: https://amzn.to/3WuhnM7

In the next topic we will know more about: Pre-Start Checklist: What Every Homeowner Must Verify Before Turning On a PTAC