What you actually need on Day One—and what can wait

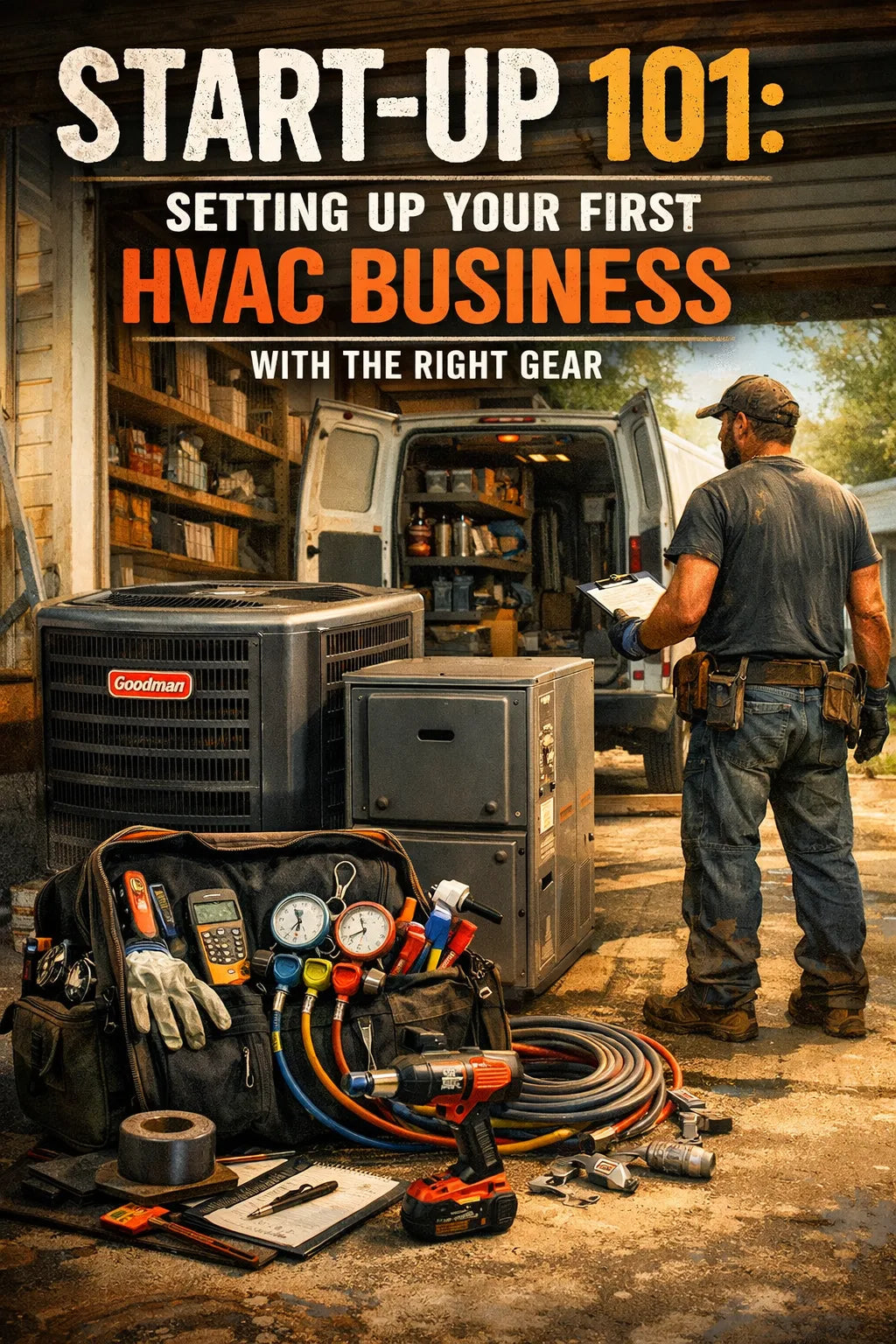

Starting an HVAC business isn’t about having the fanciest logo or the newest truck. It’s about showing up prepared, doing clean installs, and not bleeding cash in your first six months.

I’ve seen guys fail with great skills and others succeed with average skills—but the difference was always the same: they bought the right gear first.

This guide walks you through what matters, what doesn’t, and how to set up your HVAC startup so your first installs don’t turn into expensive lessons.

🏁 Step One: Understand What “Right Gear” Actually Means

Before we talk tools or equipment, let’s clear something up.

Right gear does NOT mean:

-

Buying everything you see on YouTube

-

Maxing out a credit card on day one

-

Carrying inventory you don’t know how to move

Right gear DOES mean:

-

Tools that prevent callbacks

-

Equipment you can confidently install and service

-

Systems your customers trust

-

Gear that pays for itself quickly

Your goal is simple: finish jobs clean, fast, and safely—every time.

🛠️ Core Tools Every HVAC Startup Needs (No Exceptions)

If you skip these, you’re gambling with your reputation.

🔧 Hand Tools That Earn Their Keep

You don’t need 5 versions of the same wrench. You need durable, job-tested tools you can rely on.

Must-haves:

-

Nut drivers (¼”, 5/16”, ⅜”)

-

Torque wrench (for gas + refrigerant connections)

-

Tube cutters and deburring tools

-

Adjustable wrenches (quality matters here)

-

Drill/impact combo

This is where a starter HVAC tool kit makes sense—especially when you’re watching cash flow.

(You’re buying time, not just tools.)

⚡ Electrical & Diagnostic Tools (Don’t Cheap Out Here)

Bad readings lead to bad installs.

You need:

-

True RMS multimeter

-

Clamp meter

-

Non-contact voltage tester

-

Manometer (gas pressure checks aren’t optional)

If you can’t verify voltage, pressure, and airflow, you’re guessing—and guessing costs money.

❄️ Refrigeration Tools (The Line Between Pro and Amateur)

If you’re installing ACs or heat pumps, this is non-negotiable.

Required:

-

Vacuum pump (rated for real evacuation, not “good enough”)

-

Micron gauge

-

Manifold gauge set

-

Recovery machine (know your local rules)

Skipping proper evacuation is the fastest way to destroy a compressor—and your reputation.

🏗️ Choosing the Right Equipment to Sell & Install

This is where startups either stabilize—or sink.

🔥 Why Reliable Systems Matter More Than Brand Hype

When you’re new, you don’t need exotic equipment. You need:

-

Proven reliability

-

Easy parts availability

-

Straightforward installs

-

Manufacturer support

That’s why systems like Goodman’s 14.5 SEER2 R32 setups are popular with startups—they’re predictable.

This isn’t about brand loyalty—it’s about repeatable installs.

🧊 Why R-32 Matters for Startups

R-32 isn’t just a refrigerant change—it’s a business decision.

Benefits:

-

Lower GWP (future-proofing)

-

Better heat transfer

-

Smaller charge sizes

-

Growing code acceptance

Starting with modern refrigerant systems keeps you ahead instead of scrambling later.

🚚 Vehicles, Storage & Jobsite Readiness

You don’t need a wrapped Sprinter on Day One—but you do need organization.

🚐 Startup Vehicle Reality Check

Your vehicle must:

-

Secure tools

-

Protect equipment

-

Carry ladders safely

-

Stay organized

A messy truck = longer jobs = fewer installs = less money.

Start simple. Upgrade later.

📦 Inventory: Carry Less Than You Think

New startups lose money by overstocking.

Carry:

-

Common fittings

-

PVC + venting essentials

-

Filters

-

Electrical connectors

-

Condensate parts

Order big equipment per job until cash flow stabilizes.

📋 Licenses, Permits & Compliance (The Stuff You Can’t Ignore)

This isn’t optional—even if others cut corners.

🧾 Business & Tax Basics

Before your first install:

-

Register your business

-

Get an EIN

-

Open a separate business bank account

👉 IRS small business basics:

🔗 https://www.irs.gov/businesses/small-businesses-self-employed

Mixing personal and business money ends startups fast.

🦺 Safety & OSHA Awareness

You don’t need to memorize the codebook—but you must understand safety expectations.

👉 OSHA small business safety overview:

🔗 https://www.osha.gov/smallbusiness

One injury can end a new business before it starts.

📞 Software & Systems That Make You Look Legit

You don’t need enterprise software—but you do need structure.

Minimum requirements:

-

Scheduling & dispatch

-

Invoicing

-

Estimates

-

Customer records

If customers can’t pay easily, they won’t call you again.

💵 Startup Budget: What You Actually Need to Spend

Here’s a realistic breakdown for many one-truck startups:

-

Tools & equipment: $5,000–$10,000

-

Licensing & insurance: $1,500–$3,000

-

Vehicle setup: $2,000–$5,000

-

Initial marketing & software: $500–$1,500

You don’t need perfection—you need operational readiness.

🚨 Common Startup Mistakes I See Every Year

Let me save you some pain.

❌ Buying equipment you can’t install confidently

❌ Skipping proper evacuation to “save time”

❌ Overloading inventory

❌ Underpricing jobs

❌ Ignoring documentation

Every shortcut comes back as a callback—or worse.

🧠 Tony’s Final Advice: Build Slow, Build Right

Your first year isn’t about growth—it’s about survival and reputation.

If you:

-

Buy reliable gear

-

Use the right tools

-

Follow proper procedures

-

Keep installs clean

You’ll still be standing when others disappear.

The right gear doesn’t make you successful—but the wrong gear will absolutely make you fail.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: The First 30 Days: A Start-Up Checklist From Empty Garage to First Install