Turning on a PTAC for the first time isn’t a “flip the switch and hope” moment.

It’s a checkpoint.

I’ve seen brand-new PTACs fail on day one — not because the unit was bad, but because something small was skipped before power-up. Crooked sleeves. Wrong breaker. Pinched cords. Units blamed for problems they didn’t cause.

This checklist exists so that doesn’t happen to you.

Whether you installed the unit yourself or had a contractor do the work, this is the moment to verify everything before electricity meets equipment.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

🔌 Step 1: Confirm the Power Supply Matches the PTAC — Exactly

Before anything else, stop and read the data plate on the unit.

A 12,000 BTU PTAC with 3.5 kW electric heat, like the Amana Distinctions model, is designed to run on 208/230V power — not 115V, not “close enough.”

👉 What to verify:

-

Dedicated 208/230V circuit

-

Correct breaker size (usually 20–30 amps depending on configuration)

-

No extension cords or shared outlets

-

Receptacle matches the PTAC plug type

If the voltage is wrong, don’t power it. You won’t “test it quickly.” You’ll damage it.

🧯 Step 2: Inspect the Wall Sleeve — Level, Sealed, and Solid

Most PTAC problems start before the unit even slides in.

The wall sleeve must be:

-

Level left-to-right

-

Slightly pitched outward (¼” max) for drainage

-

Fully supported on the bottom rail

-

Square in the opening (no twist)

If the sleeve is off:

-

The condensate won’t drain correctly

-

The fan will vibrate

-

The compressor will sound louder than it should

Put a level on it. If it’s wrong, fix it now — not after startup.

Verified reference:

PTAC Installation & Startup Best Practices

🧱 Step 3: Seal the Sleeve — Air Leaks Kill Performance

Before the unit goes in, inspect all four sides of the sleeve.

You’re looking for:

-

Gaps between sleeve and wall

-

Daylight visible from inside

-

Missing foam or insulation

Unsealed sleeves cause:

-

Hot or cold air infiltration

-

Moisture problems

-

Higher energy bills

-

Short cycling

Use non-expanding foam or approved PTAC sleeve insulation — not spray foam that bows metal.

This isn’t optional. Air leaks undo everything the unit is designed to do.

🌬️ Step 4: Verify the Filter Is Installed and Clean

Never power a PTAC without a filter installed.

Ever.

Before startup:

-

Remove the front cover

-

Confirm the filter is seated correctly

-

Make sure no packaging plastic is left behind

-

Clean factory dust if needed

Running without a filter allows debris straight into the coil. That’s how brand-new units end up icing or overheating.

Verified reference:

Amana PTAC Owner & Installation Manual

https://www.manualslib.com/manual/531523/Amana-Ptac.html

🌀 Step 5: Check Fan & Blower Clearance

Reach inside (with power off) and visually inspect:

-

Fan wheel spins freely

-

No shipping brackets remain

-

No wires rubbing the blower housing

-

Nothing loose in the cabinet

A ticking, scraping, or rattling noise on startup usually means this step was skipped.

It takes 30 seconds. It saves hours of troubleshooting later.

🌡️ Step 6: Thermostat & Control Settings — Start Neutral

Before first power-up:

-

Set mode to OFF

-

Set fan to AUTO

-

Set temperature to a neutral point (around 72°F)

-

Disable timers or schedules

You want the unit to boot cleanly before commanding heating or cooling.

Smart controls and occupancy sensors can come later. First startup should be simple.

💧 Step 7: Confirm Condensate Drain Path Is Clear

PTACs manage condensate internally, but that doesn’t mean water can’t get trapped if something’s wrong.

Check:

-

Sleeve pitch outward

-

No packing material blocking drain ports

-

Exterior grille unobstructed

Standing water inside a PTAC leads to corrosion, odors, and freeze-ups — none of which are warranty issues.

🔥 Step 8: Electric Heat Verification (Critical for Cold Startups)

For units with 3.5 kW electric heat, confirm:

-

Breaker can handle heating load

-

No GFCI interference

-

Heat mode isn’t locked out in controls

-

Room air intake isn’t blocked

Electric heat draws serious amperage. If power isn’t right, the unit may trip breakers or refuse to engage heat.

Verified reference:

Electric Heat Operation Explained (Amana PTAC)

https://www.amana-ptac.com/resources

🧪 Step 9: First Power-Up Procedure (Do This in Order)

Once everything checks out:

-

Turn on breaker

-

Wait 2–3 minutes (internal delay)

-

Power unit ON

-

Run FAN ONLY for 10 minutes

-

Switch to COOL — verify airflow & temperature drop

-

Switch to HEAT — verify warm air output

If anything sounds wrong, smells wrong, or trips power — stop. Don’t push through it.

🚫 Step 10: Common Pre-Start Mistakes That Cost Money

I see these constantly:

-

Powering on with packaging still inside

-

Running heat before fan verification

-

Ignoring sleeve pitch

-

Assuming outlet voltage is correct

-

Blaming the unit instead of the install

Most PTAC “failures” aren’t failures. They’re missed steps.

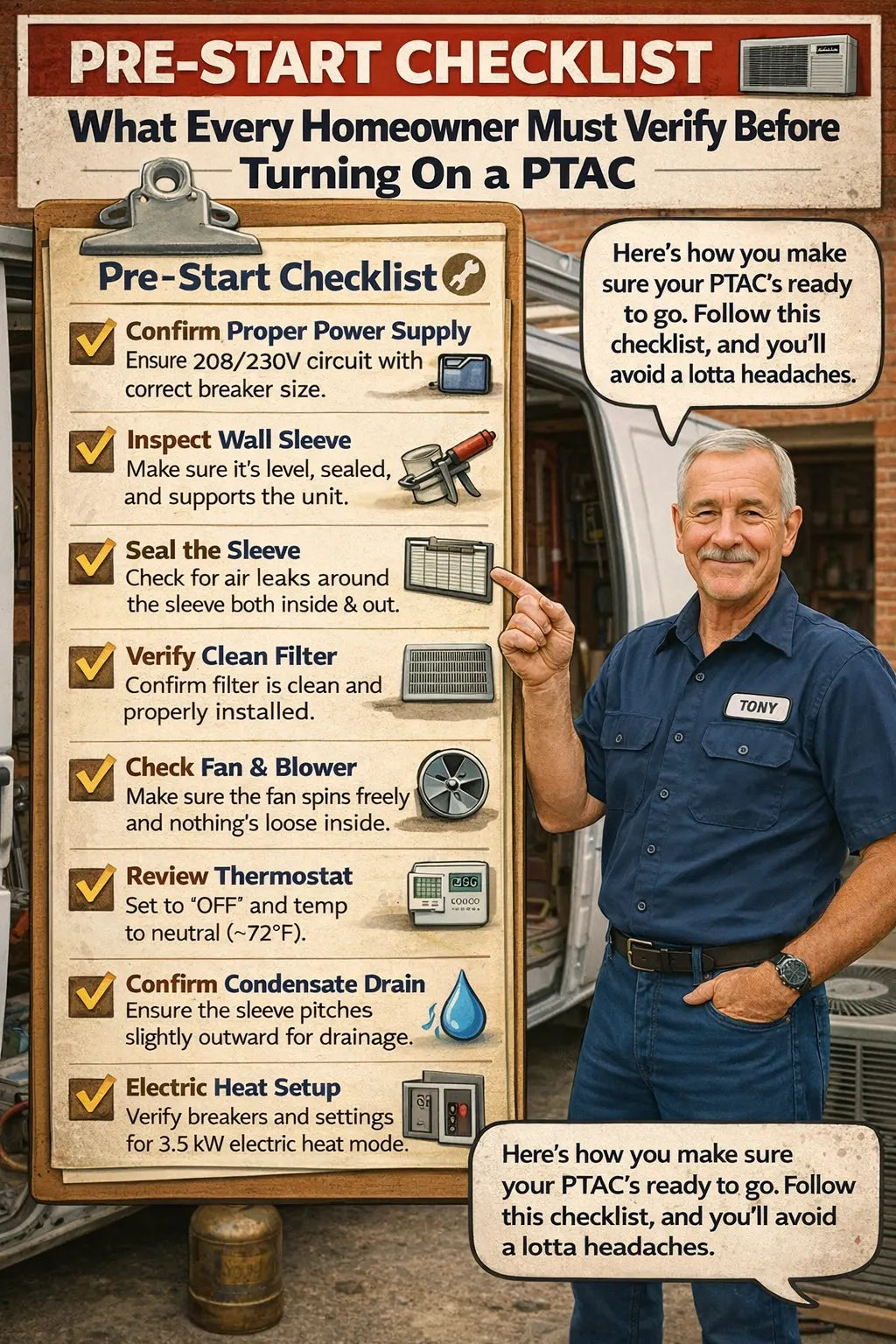

📋 Final Pre-Start Checklist (Print This)

Before turning on your PTAC, confirm:

✅ Correct voltage & breaker

✅ Sleeve level, sealed, supported

✅ Filter installed

✅ Fan spins freely

✅ Thermostat neutral

✅ Drain path clear

✅ Heat circuit verified

✅ No packaging remains

If all boxes are checked, then you power it.

🧠 Tony’s Final Word

A PTAC doesn’t get a second first impression.

Start it wrong, and you’ll chase problems that never needed to exist. Start it right, and it’ll quietly do its job for years.

This checklist isn’t about being careful.

It’s about being professional — even in your own home.