Tony here.

Let me tell you something you won’t find in any install manual:

Every good installer has at least one first-heat story they’ll never forget.

The kind that keeps you humble. The kind that makes you double-check things years later. The kind you only earn by standing in front of a furnace that should work… but doesn’t.

This isn’t about blaming equipment or laughing at mistakes. It’s about lessons learned the hard way—from real installers, on real jobs, during real first-heat startups.

If you’re new to installs, these stories might save you.

If you’re experienced, you’ll recognize yourself in more than one.

100,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T961004CN

🧠 Why First-Heat Stories Matter More Than Training Videos

Training teaches you how things should go.

First heat teaches you how things actually go.

Startup is where:

-

Assumptions get exposed

-

Shortcuts get punished

-

Small oversights become big lessons

Tony rule:

You don’t really know an install until you’ve watched it run.

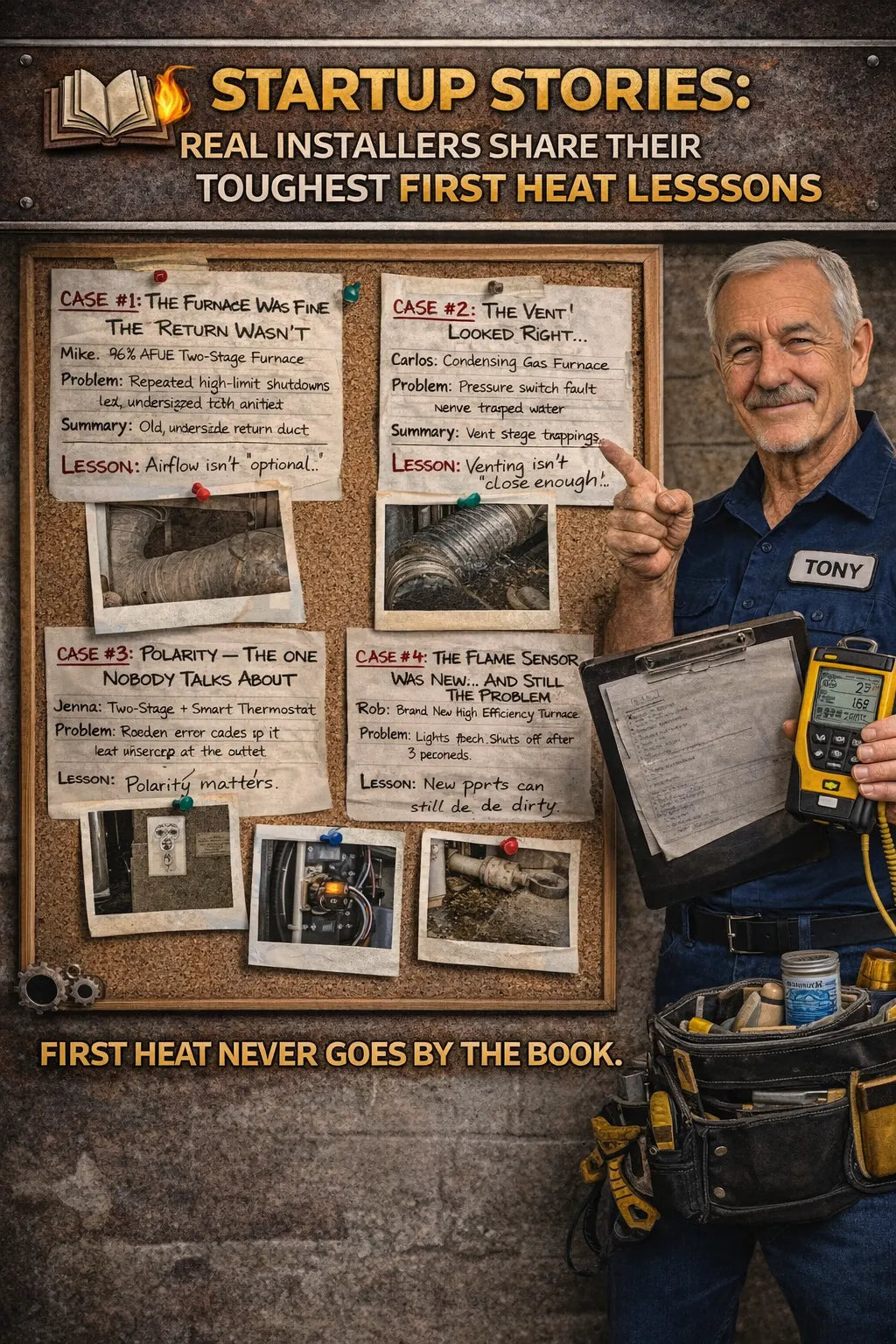

🔥 Story #1: “The Furnace Was Fine — The Return Wasn’t”

Installer: Mike, 12 years in the field

System: 96% AFUE two-stage furnace

Problem: Repeated high-limit shutdowns on first heat

Mike did everything “right.”

Gas pressure checked. Venting perfect. Clean ignition.

But ten minutes into first heat, the furnace shut down. Restarted. Shut down again.

The issue?

-

Old return duct reused

-

Undersized for ECM airflow

-

Static pressure through the roof

Once the return was rebuilt, the furnace ran quietly for hours.

Lesson learned:

A furnace can’t fix bad airflow — it can only complain about it.

👉 Furnace airflow basics (DOE):

https://www.energy.gov/energysaver/furnaces-and-boilers

🌬️ Story #2: “The Vent Looked Right… Until It Wasn’t”

Installer: Carlos, new business owner

System: Condensing gas furnace

Problem: Pressure switch fault on startup

Carlos reused the existing PVC vent.

Slope looked fine. Joints were glued. Termination was clear.

Except one section dipped just enough to trap condensate.

The furnace would start… then shut down once water built up.

Lesson learned:

Venting doesn’t fail loudly. It fails slowly and repeatedly.

👉 Manufacturer venting guidance:

https://www.goodmanmfg.com/products/gas-furnaces

🔌 Story #3: “Polarity — The One Nobody Talks About”

Installer: Jenna, residential tech

System: Two-stage furnace with smart thermostat

Problem: Random error codes and weird staging

Everything fired. Everything ran.

But staging was erratic. Error codes didn’t make sense.

The fix?

-

Hot and neutral reversed at the outlet

Once corrected, the furnace behaved perfectly.

Lesson learned:

Electrical mistakes don’t always stop a furnace — they confuse it.

🔥 Story #4: “The Flame Sensor Was New… And Still the Problem”

Installer: Rob, 20+ years experience

System: Brand-new high-efficiency furnace

Problem: Lights, then shuts off after 3 seconds

Rob assumed the new flame sensor couldn’t be the issue.

It was.

Manufacturing residue coated the sensor. A light polish fixed it.

Lesson learned:

New parts can still be dirty. Trust behavior, not assumptions.

👉 Combustion safety basics (EPA):

https://www.epa.gov/indoor-air-quality-iaq/carbon-monoxides-impact-indoor-air-quality

🌡️ Story #5: “The Thermostat Was Smarter Than the Installer”

Installer: Alex, helper turned lead tech

System: Two-stage furnace + smart thermostat

Problem: Furnace always ran in high stage

Alex wired W1 and W2 correctly — or so he thought.

The thermostat was configured for single-stage heat.

Once staged properly, low stage handled most calls.

Lesson learned:

Smart controls only work if you tell them the truth.

💧 Story #6: “The Drain That Waited a Week”

Installer: Sam, service tech

System: Condensing furnace

Problem: Random lockouts after several days

Startup went perfectly.

First heat was smooth.

Then — lockouts days later.

The condensate trap was installed… but never tested.

Debris blocked it after a few cycles.

Lesson learned:

If you don’t test the drain, the drain will test you later.

🔥 Story #7: “The House Was the Problem”

Installer: Dana, comfort specialist

System: Properly sized high-efficiency furnace

Problem: Homeowner complaints of cold rooms

Dana checked everything. Furnace was perfect.

The real issue?

-

Poor insulation

-

Leaky attic

-

Old windows

Once expectations were reset, complaints stopped.

Lesson learned:

The furnace heats the house you give it — not the house you wish you had.

🚫 The Common Thread in Every Story

Different techs.

Different systems.

Same lesson:

First heat doesn’t lie.

Every startup problem traced back to:

-

Airflow

-

Venting

-

Controls

-

Drainage

-

Expectations

Rarely the furnace itself.

🧰 What These Stories Teach New Installers

If you’re early in your career, take this to heart:

✔ Measure everything

✔ Watch a full cycle

✔ Test drains and safeties

✔ Verify staging

✔ Don’t rush startup

✔ Trust behavior, not assumptions

Tony rule:

The furnace always tells you what it needs — if you stay long enough to listen.

🧠 What These Stories Teach Homeowners

If you’re a homeowner, here’s the takeaway:

-

First heat is a test phase

-

Some adjustments are normal

-

Quiet operation is good

-

Long run times are normal

-

Communication beats panic

Ask questions — don’t assume failure.

📋 Tony’s “First Heat Story Prevention” Checklist

Before leaving any install:

✔ Full heat cycle observed

✔ Low and high stage verified

✔ Drain flowing

✔ No error codes

✔ Thermostat confirmed

✔ Homeowner educated

If you skip these, you’re writing your own story.

🔚 Final Tony Takeaway

Every installer earns their stripes at first heat.

The good ones:

-

Learn from mistakes

-

Share the lessons

-

Never stop checking basics

The best installs don’t create stories — they create silence.

And in HVAC, silence is success.