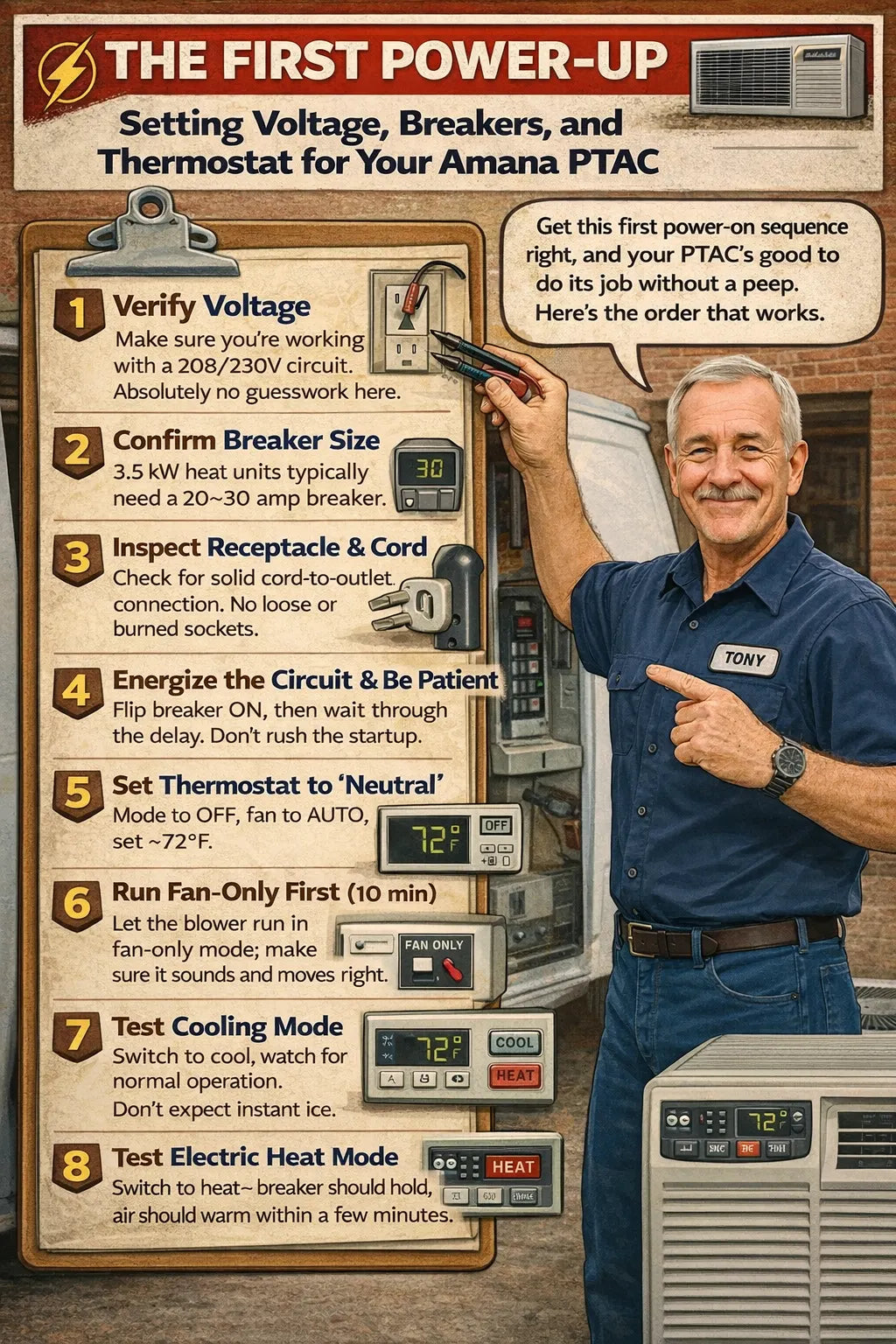

The first time you power up a PTAC is not a test.

It’s a commissioning moment.

Get the voltage wrong, rush the breaker setup, or let the thermostat start barking orders too early, and you’ll spend the next week wondering why a “brand-new unit” doesn’t feel right.

I’ve powered up hundreds of PTACs. The quiet, reliable ones all have one thing in common:

they were started correctly — in the right order.

This guide walks you through exactly how to do that with an Amana PTAC, step by step.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

🔌 Step 1: Confirm You’re Supplying the Correct Voltage (No Guessing)

Before you even look at a breaker, read the unit’s data plate.

Most Amana 12,000 BTU PTACs with electric heat are designed for 208/230V. That’s not “either/or.” It means the unit can tolerate both — but your building supplies one specific voltage, and the unit must be set up accordingly.

What to verify:

-

Dedicated 208V or 230V circuit (not shared)

-

Correct receptacle type for the PTAC plug

-

No adapters, extension cords, or “temporary” power

If you’re not 100% sure what voltage you have, check it with a meter. Assumptions ruin compressors.

🧯 Step 2: Set the Correct Breaker Size (Cooling + Heat Matters)

This is where a lot of installs quietly go wrong.

A PTAC with 3.5 kW electric heat pulls significantly more current in heating mode than cooling mode. That means the breaker must be sized for maximum load, not average use.

General rules (always confirm with the data plate):

-

Cooling only: typically 15–20 amps

-

Cooling + 3.5 kW heat: often 20–30 amps

-

Circuit must be dedicated

An undersized breaker won’t always trip immediately. It’ll trip on cold nights — the worst time to learn this lesson.

If your breaker size doesn’t match the unit requirements, stop here and fix it.

🧰 Step 3: Inspect the Power Connection Before Energizing

Before flipping the breaker:

-

Inspect the receptacle for burn marks or looseness

-

Ensure the plug seats fully

-

Confirm the cord isn’t pinched by the sleeve or chassis

-

Verify strain relief is intact

Loose connections create heat. Heat kills electronics slowly — and invisibly.

This is five minutes of work that can add years to a unit’s life.

⏳ Step 4: Understand the Built-In Time Delays (Don’t Fight Them)

Amana PTACs include compressor time delays for a reason.

When power is first applied:

-

The unit may appear “dead” for 2–5 minutes

-

The compressor will not start immediately

-

This is normal and intentional

Do not:

-

Cycle power repeatedly

-

Toggle modes impatiently

-

Assume something is wrong

Time delays protect the compressor from starting under pressure. Bypassing that protection is how compressors die young.

Verified reference:

Amana PTAC Installation & Operation Manual

https://www.manualslib.com/manual/531523/Amana-Ptac.html

🌡️ Step 5: Set the Thermostat to Neutral Before First Run

Before commanding heating or cooling, the thermostat needs to stay out of the way.

Initial thermostat setup:

-

Mode: OFF

-

Fan: AUTO

-

Temperature: neutral (around 72°F)

-

Schedules, timers, occupancy sensors: disabled

This allows the unit to:

-

Power up cleanly

-

Initialize controls

-

Run self-checks without load

The thermostat works for you — but only after the unit is awake and stable.

🌀 Step 6: First Mode to Run — Fan Only (Always)

The very first operational mode should be FAN ONLY.

Why?

-

Confirms blower operation

-

Confirms airflow path is clear

-

Confirms no shipping brackets remain

-

Confirms no abnormal vibration or noise

Run fan-only for 10 minutes.

If it’s quiet, smooth, and steady, you’re cleared to move on.

If it rattles, scrapes, or pulses — stop and investigate.

❄️ Step 7: Cooling Mode — What “Normal” Looks Like

After fan verification:

-

Switch to COOL

-

Set temperature at least 5°F below room temp

-

Wait through the compressor delay

Normal cooling signs:

-

Steady airflow

-

Gradual temperature drop

-

Low, consistent compressor hum

-

No sharp clicks, grinding, or electrical smells

Don’t expect instant ice-cold air. PTACs are designed for controlled comfort, not shock cooling.

🔥 Step 8: Electric Heat Startup (Where Power Issues Show Up)

Now comes the real test.

Switch to HEAT and set temperature above room temp.

What to watch for:

-

Breaker holds (no trip)

-

Fan engages smoothly

-

Air warms within a few minutes

-

No burning smell beyond brief “new element” odor

Electric heat exposes weak wiring, undersized breakers, and poor connections fast.

If something trips here, the issue is upstream — not the PTAC.

Verified reference:

Amana PTAC Electric Heat Overview

https://www.amana-ptac.com/resources

🧠 Step 9: Control Board Indicators & Error Codes

If your Amana PTAC uses LED indicators or digital diagnostics:

-

Observe lights during startup

-

Note any blinking patterns

-

Consult the manual if codes appear

Error codes during first power-up usually point to:

-

Voltage mismatch

-

Control lockout

-

Sensor connection issues

Don’t ignore them. The unit is telling you something — politely.

🚫 Step 10: First Power-Up Mistakes I See Too Often

Here’s what causes callbacks:

-

Turning on heat before verifying fan

-

Cycling power repeatedly during delay

-

Assuming breaker size is “probably fine”

-

Letting smart controls override startup

-

Blaming the unit instead of the setup

PTACs are simple machines. Problems almost always come from sequence errors, not defects.

📋 Tony’s First Power-Up Order (Bookmark This)

-

Verify voltage

-

Confirm breaker size

-

Inspect receptacle & cord

-

Energize circuit

-

Wait through delay

-

Fan-only (10 min)

-

Cooling test

-

Heating test

That order matters.

🧱 Final Word from Tony

A PTAC doesn’t need babysitting — it needs respect at startup.

Give it the right power, the right protection, and a calm first run, and it’ll settle in like it belongs there.

Rush it, and you’ll spend years blaming the machine for mistakes made in the first 30 minutes.