Most PTAC problems don’t start with comfort complaints.

They start with someone saying, “It’s probably fine.”

Startup is where safety, legality, and liability all meet. If something goes wrong after startup, the first questions aren’t:

-

“Did it cool well?”

They’re: -

“Was it wired correctly?”

-

“Was it permitted?”

-

“Did it meet code?”

I’ve seen perfectly good PTACs blamed for issues that were really startup safety failures. This guide lays out the non-negotiable safety protocols every homeowner, installer, or property manager needs to understand before first power-up.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

🧠 The Truth About Startup Safety

Startup safety isn’t about being overly cautious.

It’s about understanding this reality:

If it isn’t safe, it isn’t legal. And if it isn’t legal, you’re on your own.

Manufacturers, inspectors, insurers, and fire marshals all look at startup the same way:

Was this system energized correctly, legally, and safely?

⚡ Electrical Safety: Where Startup Risk Is Highest

Electricity is the single biggest startup hazard for PTAC systems.

Modern PTACs—especially those with 3.5 kW electric heat—draw significant current. Startup mistakes here don’t just damage equipment; they create fire and shock risks.

🔌 Dedicated Circuits Are Not Optional

Every PTAC must be on a dedicated circuit.

That means:

-

No shared outlets

-

No extension cords

-

No tapping into existing loads

Why this matters at startup:

-

Heat mode creates peak amperage

-

Shared circuits overheat quietly

-

Breakers may not trip until damage is done

Code doesn’t care if “it worked before.”

It cares what happens under full load.

Verified reference:

National Electrical Code (NEC) Overview

🧯 Correct Voltage & Breaker Sizing

Startup safety requires matching three things exactly:

-

PTAC voltage rating (often 208/230V)

-

Correct receptacle type

-

Proper breaker size for maximum load

Undersized breakers don’t protect equipment—they stress wiring.

At startup, verify:

-

Voltage with a meter

-

Breaker amperage matches data plate

-

Breaker type is approved for HVAC loads

If voltage is wrong, do not power the unit. Even brief mis-voltage events can permanently damage control boards.

🔥 Grounding & Bonding: The Invisible Protection

Grounding isn’t something you “notice” until it’s missing.

A properly grounded PTAC:

-

Protects users from shock

-

Provides fault paths for breakers

-

Reduces fire risk

-

Satisfies inspection requirements

At startup:

-

Confirm grounding conductor is present

-

Inspect receptacle grounding

-

Never defeat ground pins

Missing ground = failed inspection + denied warranty + real danger.

🧱 Wall Sleeve, Clearance, and Fire Safety

Startup safety isn’t just electrical.

PTACs require:

-

Proper wall sleeve installation

-

Clearance from combustibles

-

Correct exterior grille placement

Why it matters:

-

Electric heat creates localized high temperatures

-

Poor clearance traps heat

-

Improper sleeves allow moisture and pests

If the sleeve isn’t installed to spec, startup should not proceed.

📜 Permits: When They’re Required (And Why You Want Them)

A lot of homeowners skip permits because they think:

“It’s just a wall unit.”

That assumption gets expensive.

Permits may be required when:

-

New electrical circuits are added

-

Breakers are changed

-

Receptacles are upgraded

-

Commercial or rental properties are involved

Permits protect you, not the city.

They:

-

Create a paper trail

-

Validate code compliance

-

Protect resale value

-

Support insurance claims

Verified reference:

International Residential Code (IRC) Overview

https://codes.iccsafe.org/content/IRC2021P2

🧾 What Inspectors Look For at Startup

If an inspector shows up, they’re checking:

-

Proper voltage and breaker sizing

-

Dedicated circuit

-

Correct receptacle

-

Secure wall sleeve

-

Clearances met

-

Grounding verified

They are not checking:

-

Whether it cools fast

-

Whether the app connects

-

Whether it’s quiet

Startup inspections are about safety and compliance, not comfort.

🚨 Insurance & Liability Reality Check

Here’s the part nobody likes to talk about.

If a PTAC causes:

-

A fire

-

Electrical damage

-

Personal injury

Insurance companies will ask:

-

Was it permitted?

-

Was it code-compliant?

-

Was it installed correctly?

If the answer is no, coverage can be reduced or denied—even if the equipment itself didn’t fail.

Startup safety is financial protection, not just technical correctness.

🧯 R32 Refrigerant Safety Considerations

Modern PTACs often use R32 refrigerant, classified as A2L (mildly flammable).

At startup, safety protocols include:

-

No cabinet damage

-

No refrigerant odor

-

No hissing sounds

-

No modification of refrigerant components

R32 systems are safe when installed correctly. Safety problems arise when damaged units are powered anyway.

Verified reference:

ASHRAE A2L Refrigerant Safety Overview

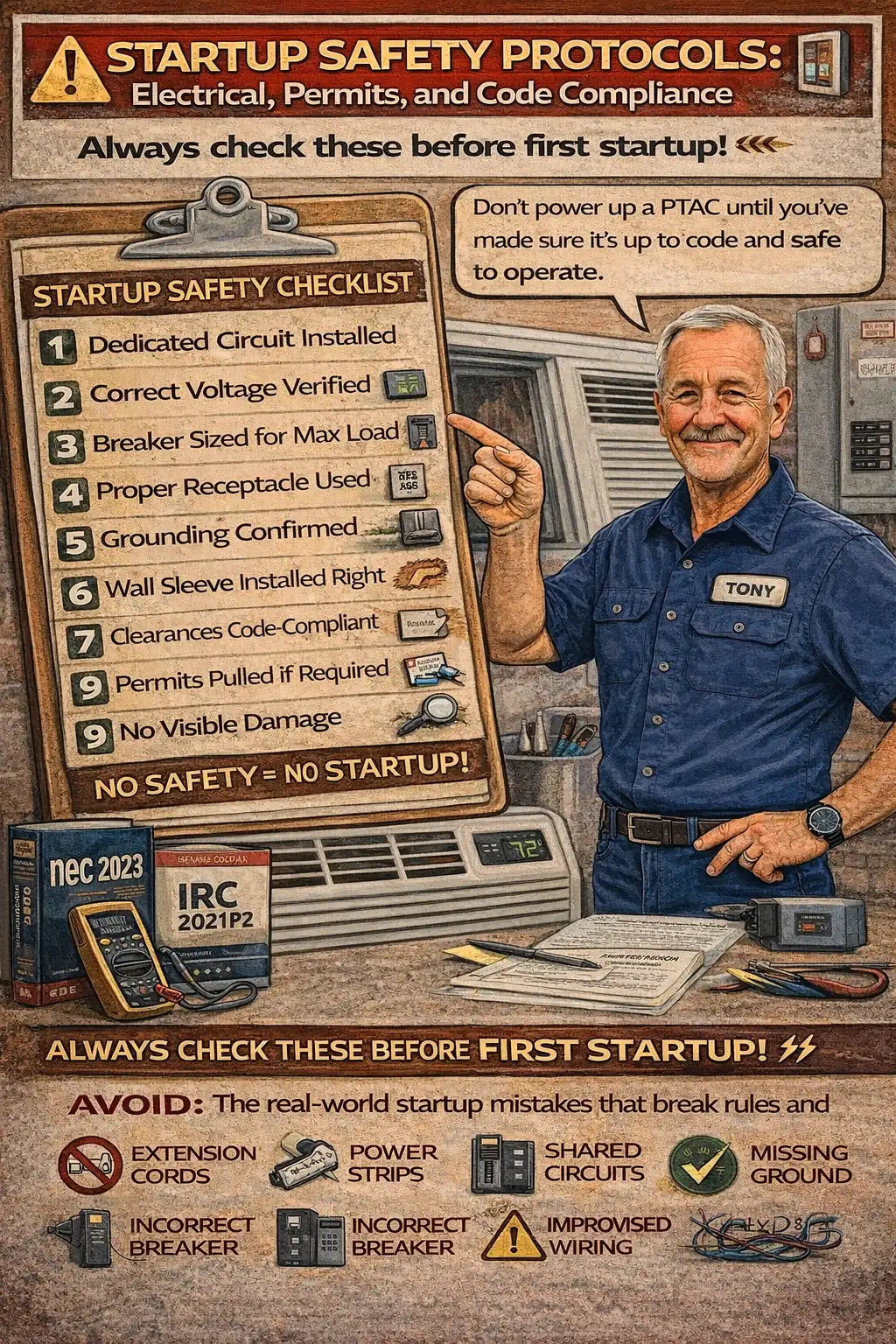

🚫 Startup Actions That Violate Code Instantly

These are automatic red flags:

-

Extension cords

-

Power strips

-

Shared circuits

-

Missing ground

-

Incorrect breaker

-

Improvised wiring

If any of these exist, startup should stop immediately.

📋 Startup Safety Protocol Checklist

Before powering on, confirm:

✅ Dedicated circuit installed

✅ Correct voltage verified

✅ Breaker sized for max load

✅ Proper receptacle used

✅ Grounding confirmed

✅ Wall sleeve installed correctly

✅ Clearances met

✅ Permits pulled if required

✅ No visible damage

✅ No code violations present

If even one box is unchecked, fix it first.

🧠 Tony’s Final Word

Startup safety isn’t about fear.

It’s about respecting electricity, respecting code, and respecting the fact that once power flows, responsibility starts.

Do startup safely, legally, and by the book—and your PTAC will quietly do its job for years.

Skip steps, ignore permits, or guess at wiring, and the machine won’t be the problem—you will.