By Jake — the guy who says airflow should flow like a lazy river, not a pinball machine.

📌 Introduction: The #1 Reason Most HVAC Systems Are Noisy, Weak, and Uneven

Most airflow problems don’t come from:

-

the furnace

-

the AC coil

-

the blower speed

-

the filter

-

the equipment size

Jake will tell you:

“Your airflow isn’t bad because of the equipment — it’s bad because the air keeps getting punched in the face by bad duct fittings.”

The worst airflow killers are:

-

hard 90° elbows

-

tee fittings

-

cheap takeoffs

-

crushed flex

-

short trunks

-

dead-end ducts

-

sudden size transitions

These create:

-

turbulence

-

pressure spikes

-

noise

-

reduced CFM

-

hot/cold rooms

-

increased blower wattage

Jake’s solution is simple:

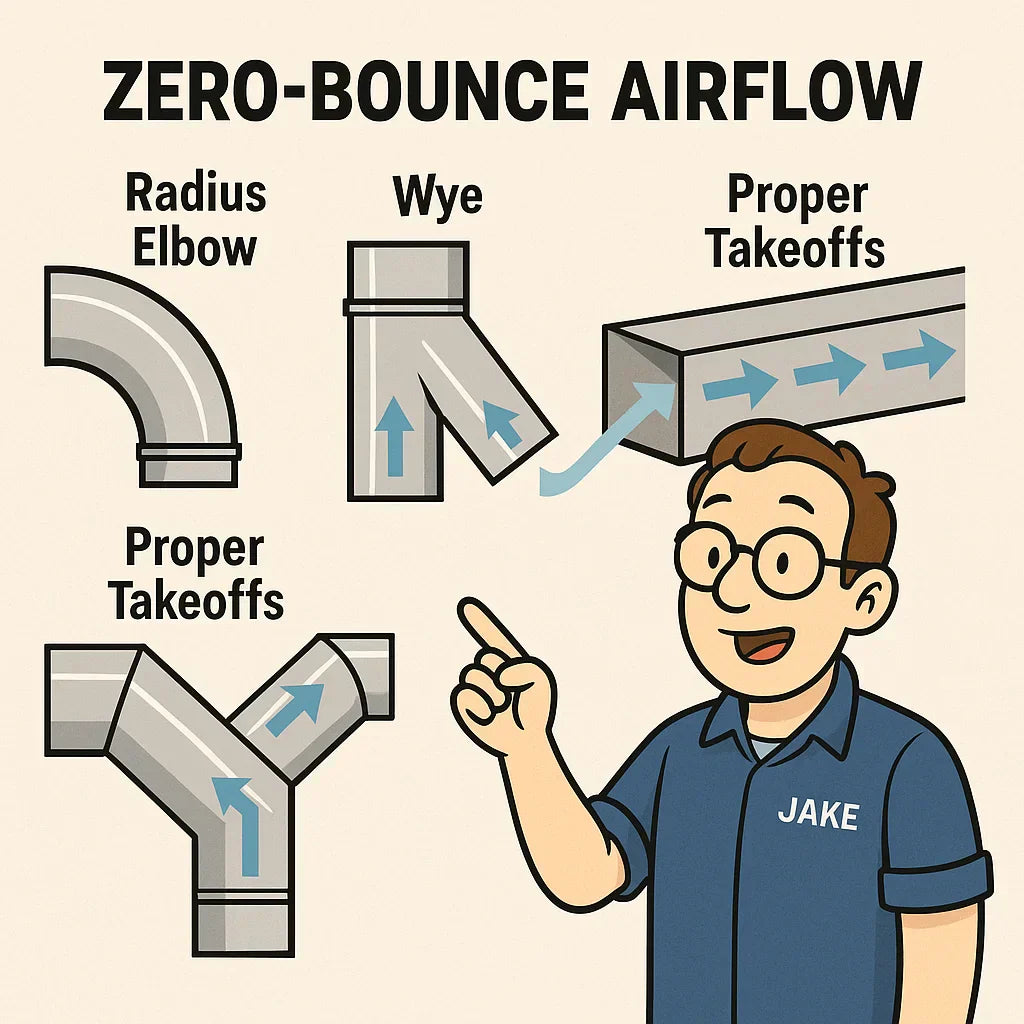

**Zero-Bounce Airflow.

Air moves in smooth curves, not sharp corners.**

This article teaches the exact techniques Jake uses to eliminate turbulence and build duct systems that run silent, smooth, and efficient.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

🏎️ 1. What Is Zero-Bounce Airflow? (Jake’s Definition)

Jake calls it:

“Airflow that never has to stop, turn, bounce, or slam into a wall.”

Zero-bounce airflow means:

-

every directional change is curved

-

every transition is gradual

-

every takeoff is angled

-

every trunk distributes evenly

-

every branch sees predictable airflow

Why it matters:

Turbulence = Lost BTUs, Lost CFM, Lost Comfort

When air slams into a sharp corner:

-

static pressure spikes

-

velocity drops

-

noise increases

-

airflow becomes uneven

-

blower works harder

-

system efficiency falls

Jake’s goal is to help the blower — not fight it.

📚 External Reference: ACCA Manual D – Airflow Fundamentals

🌀 2. Why Hard 90° Elbows Ruin Airflow (Jake’s Physics Version)

Hard elbows are installed every day because:

-

they’re cheap

-

they’re easy

-

they look neat

-

they fit tight spaces

But airflow sees them differently.

Here’s what happens inside:

1. Air slams into the elbow wall

Velocity collapses.

2. Pressure spikes

Static pressure goes up.

3. Turbulence forms behind the elbow

Air separates and spins.

4. Branch takeoffs get uneven airflow

More air on one side, less on the other.

5. Noise increases

Whistle / rumble / “air hammering.”

Jake can measure these mistakes instantly using a manometer.

🟢 3. Radius Elbows: Jake’s Secret Weapon

Jake always replaces hard 90s with radius elbows — also called “long-sweep elbows.”

✔ A radius elbow has a gentle curve

✔ Allows airflow to turn without slamming

✔ Reduces turbulence dramatically

Jake’s rule:

Use radius elbows everywhere except where code or framing makes them impossible.

For supply trunks:

-

ideal radius = 1–1.5 × duct diameter

-

minimum radius = equal to duct diameter

For rectangular ducts:

-

use long-radius elbows or segmented elbows

📘 External Reference: SMACNA Duct Construction Standards

🔀 4. Why Wyes Beat Tees Every Time

Most installers use tee fittings for branch takeoffs.

Jake hates tees.

Why?

Tees split air using a violent 90° collision.

This causes:

-

high turbulence

-

low branch CFM

-

uneven airflow

-

noise

-

pressure loss

Jake replaces tees with wye fittings, which split airflow at a 30°–45° angle.

Benefits of Wye Fittings:

✔ smoother airflow

✔ even branch distribution

✔ less pressure drop

✔ quieter system

✔ up to 40–60% more usable CFM in branches

Jake says:

“A tee is a fight. A wye is a partnership.”

📏 5. The Takeoff Rules: How Jake Ensures Every Branch Gets Proper CFM

A takeoff is where a small branch line connects to the main supply trunk.

Bad takeoff placement = bad room airflow.

Jake's rules:

Rule 1 — Start with 8–12 Inches of Straight Trunk

Never attach takeoffs immediately after an elbow.

Why?

Because right after a turn, air is unstable and uneven.

Jake’s rule:

Leave 8–12 inches of straight duct before the first takeoff.

If space doesn't allow → use a radius elbow with a smoother curve.

Rule 2 — Never Put Takeoffs on the Inside of a Bend

Inside bend airflow is weak because of centrifugal force.

Jake always installs takeoffs on:

-

the top

-

the side

-

the outside of a curve

Never the inside.

Rule 3 — Use Spin-In or Saddle Takeoffs with Dampers

Jake prefers:

-

spin-in takeoffs

-

saddle takeoffs

-

wyes for high-performance systems

And always with manual balancing dampers.

Rule 4 — Space Takeoffs 12 Inches Apart

Too many takeoffs in one section:

-

rob air from each other

-

cause noise

-

create turbulence

Rule 5 — Angle Branches at 30°–45°, Never 90°

90° branches cause:

-

low airflow

-

high velocity noise

-

turbulence

A gentle angle gives smoother airflow.

🚫 6. Flex Duct Mistakes That Create Turbulence

Jake loves flex duct for convenience — when installed correctly.

He hates it when:

-

it’s sagging

-

it’s crushed

-

it’s pinched

-

it’s too long

-

it’s twisted

-

it turns 90° immediately

-

it has no support

-

it's stretched tight like a guitar string

Jake’s rule:

Flex must be pulled tight, supported every 4 feet, and never used for sharp turns.

Flex duct should:

-

have < 5% sag

-

be sized correctly

-

be insulated

-

be secured with two zip ties and tape

🧪 External Reference: DOE Duct Installation Guide

🧭 7. Jake’s Branch Balancing Method for Zero-Bounce Airflow

To get even airflow, Jake balances branches using:

1. Proper sizing

Never undersize — 6" minimum for most rooms.

2. Angled takeoffs

Improves airflow direction.

3. Branch dampers

Fine-tuning per room.

4. Consistent trunk pressure

Achieved with radius elbows + wyes.

5. No dead-end trunks

All trunks must terminate in a diffuser or endcap.

Jake says:

“You don’t balance airflow at the registers — you balance it at the trunk.”

📏 8. The Five Duct Geometry Mistakes That Cause Most Turbulence

Jake sees these every week:

❌ Mistake 1: Hard 90° Elbows Near the Plenum

Creates a pressure spike and uneven distribution.

❌ Mistake 2: Tee Fittings for Branches

90° splits cause violent air collisions.

❌ Mistake 3: Takeoffs Within 4 Inches of a Turn

Air is unstable immediately after a turn.

❌ Mistake 4: Crushed Flex Turning at 90°

This alone can drop airflow by 40–60%.

❌ Mistake 5: Sudden Size Transitions

Going from a 20" trunk to a 12" trunk instantly?

Airflow disaster.

Transitions must be gradual — 1–2" per foot.

🔧 9. How Jake Designs Perfect Airflow Paths

Jake uses a simple formula:

**Curves > Angles

Wyes > Tees

Radius > Hard Bends

Gradual > Instant

Straight > Turbulent**

Let’s walk through the ideal airflow path:

1️⃣ From the plenum: Use a tall, smooth transition

Reduces turbulence.

2️⃣ Into the trunk: Use a long-radius 90° elbow

Prevents pressure spikes.

3️⃣ First 12 inches: Keep it straight

Allows airflow to stabilize.

4️⃣ Add takeoffs on top or side

Never bottom or inside of curve.

5️⃣ Space takeoffs 10–12" apart

Reduces interference.

6️⃣ Use wye fittings wherever a branch splits

Smoother airflow.

7️⃣ Use angled branches (30°–45°)

Prevents velocity loss.

8️⃣ Keep flex tight, short, and supported

Ensures strong register airflow.

9️⃣ Balance with dampers

Final CFM tuning.

📊 10. Real-World Results: Jake’s Zero-Bounce Airflow Case Studies

📂 Case Study A — Loud, Weak Branches

Before:

-

tee fittings

-

hard 90s

-

takeoffs too close to elbows

-

sagging flex

After Jake:

-

wyes installed

-

radius elbows added

-

flex straightened

-

takeoffs re-angled

Result:

Noise dropped 30–40%.

CFM increased 25–50%.

📂 Case Study B — Second Floor Too Hot

Before:

-

inside-bend takeoffs

-

long flex

-

tee splitting airflow

After Jake:

-

moved takeoffs

-

shortened flex

-

added wye

-

installed radius elbow

Result:

Even cooling throughout the home.

📂 Case Study C — High Static Pressure 0.82" WC

After:

-

replacing hard elbow with radius

-

replacing tees with wyes

-

correcting transitions

Static dropped to 0.46" WC.

📋 11. Jake’s Zero-Bounce Airflow Checklist

Jake signs off only when all 20 boxes are checked:

✔ Long-radius elbows installed

✔ No hard 90s near plenum

✔ First 12" of trunk straight

✔ Wyes used instead of tees

✔ Angled takeoffs (30°–45°)

✔ No takeoffs on inside of bends

✔ Takeoffs spaced 10–12" apart

✔ Flex duct tight and supported

✔ Dampers on key branches

✔ Gradual trunk transitions

✔ No sagging flex

✔ No sudden size reductions

✔ Main trunk sized correctly

✔ Return path unrestricted

✔ No airflow collisions

✔ Low static pressure (< 0.5" WC)

✔ Even CFM across all branches

✔ No turbulence noise

✔ Coil and plenum aligned

✔ Verified with manometer readings

If three or more fail → Jake rebuilds the airflow path.

🏁 Conclusion: Smooth Curves = Smooth Comfort

Jake says it best:

“Air wants to flow. Your job is not to fight it.”

Zero-bounce airflow gives you:

-

quiet operation

-

stronger rooms

-

balanced upstairs/downstairs

-

lower energy usage

-

colder AC

-

hotter heat

-

safer furnace operation

-

lower static pressure

-

longer blower life

Jake’s three rules cover it all:

1. Always use curves.

2. Never force air into a wall.

3. Don’t let fittings fight the airflow.

With radius elbows, wyes, and proper takeoffs, any HVAC system can move air like a perfectly smooth river.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: The Filter Rack Formula: How Jake Optimizes Filter Size, Placement & Bypass Control