By Jake — the guy who’s replaced more burnt ECM motors than he’s eaten breakfasts.

📌 Introduction: Why the Filter Rack Is the Most Underrated Part of Your Furnace

Ask most homeowners what matters in an HVAC system and they’ll say:

-

BTU capacity

-

SEER2 rating

-

Furnace stage (single vs. two-stage)

-

Thermostat features

But Jake knows the truth:

“Forget all that — your entire system depends on the filter rack.”

A filter rack is a tiny piece of sheet metal that determines:

-

how hard the blower works

-

whether the coil stays clean

-

if static pressure stays below 0.5" WC

-

if filters actually seal (or leak dust around them)

-

whether the furnace overheats

-

whether rooms get enough airflow

-

how long the equipment lasts

And yet most racks are:

❌ too small

❌ not square

❌ not sealed

❌ jammed in the wrong place

❌ creating bypass

❌ restricting airflow

❌ impossible to remove the filter from

Jake says:

“A bad filter rack turns a $6,000 furnace into a $600 space heater.”

Today, you get Jake’s Filter Rack Formula — the same one he uses on every job.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

📏 1. Jake’s Rule #1 — The Filter Must Match the System’s CFM (Not the Other Way Around)

Every HVAC system has a required CFM based on:

-

tonnage (AC)

-

BTUs (heat)

-

blower motor tables

-

duct design

Jake starts with the airflow requirement:

| System | Target CFM |

|---|---|

| 2-ton | ~800 CFM |

| 2.5-ton | ~1,000 CFM |

| 3-ton | ~1,200 CFM |

| 4-ton | ~1,600 CFM |

| 5-ton | ~2,000 CFM |

Then he sizes the filter so the filter face velocity stays between 250–350 FPM.

✔ Ideal Filter Face Velocity

250–300 FPM = quiet, efficient, low static pressure.

❌ Bad Face Velocity

> 400 FPM = whistling, high static, dust blow-by.

Filter Sizing Example (Jake’s Method)

A 3-ton system needs 1,200 CFM.

Filter area required:

1,200 ÷ 300 FPM = 4 square feet of filter area

A common 20"×25" filter = 3.47 sq ft → too small.

Jake upgrades to:

-

20×30 = 4.16 sq ft, or

-

a 4" media filter with higher free area

📘 External Reference — EPA Guide to HVAC Filters

📐 2. Jake’s Rule #2 — Bigger Filters = Lower Static Pressure

Static pressure is the #1 enemy of HVAC systems.

A small filter increases static pressure because airflow is forced through a tiny opening.

Jake says:

“The number one cause of high static pressure is a tiny 1-inch filter in a huge return box.”

The Static Pressure Problem:

-

High static → blower works harder

-

Harder work → higher wattage

-

Higher wattage → higher bills

-

Less airflow → hotter heat exchanger

-

Less airflow → colder coil (freezing risk)

-

High heat rise → cracked heat exchanger

-

High motor strain → ECM failure

So Jake sizes the filter like this:

Jake’s Filter Size Chart

| System | Minimum Filter Size (1") | Jake’s Preferred Size (4–5") |

|---|---|---|

| 2-ton | 20×20 | 16×25×4 or 20×25×4 |

| 3-ton | 20×25 | 20×25×4 or 20×30×4 |

| 4-ton | 24×30 | 20×30×4 |

| 5-ton | 30×30 | Dual filters or 20×30×5 |

Jake rarely uses 1" filters for systems above 2 tons.

📘 External Reference — ACHR News on High Static Pressure

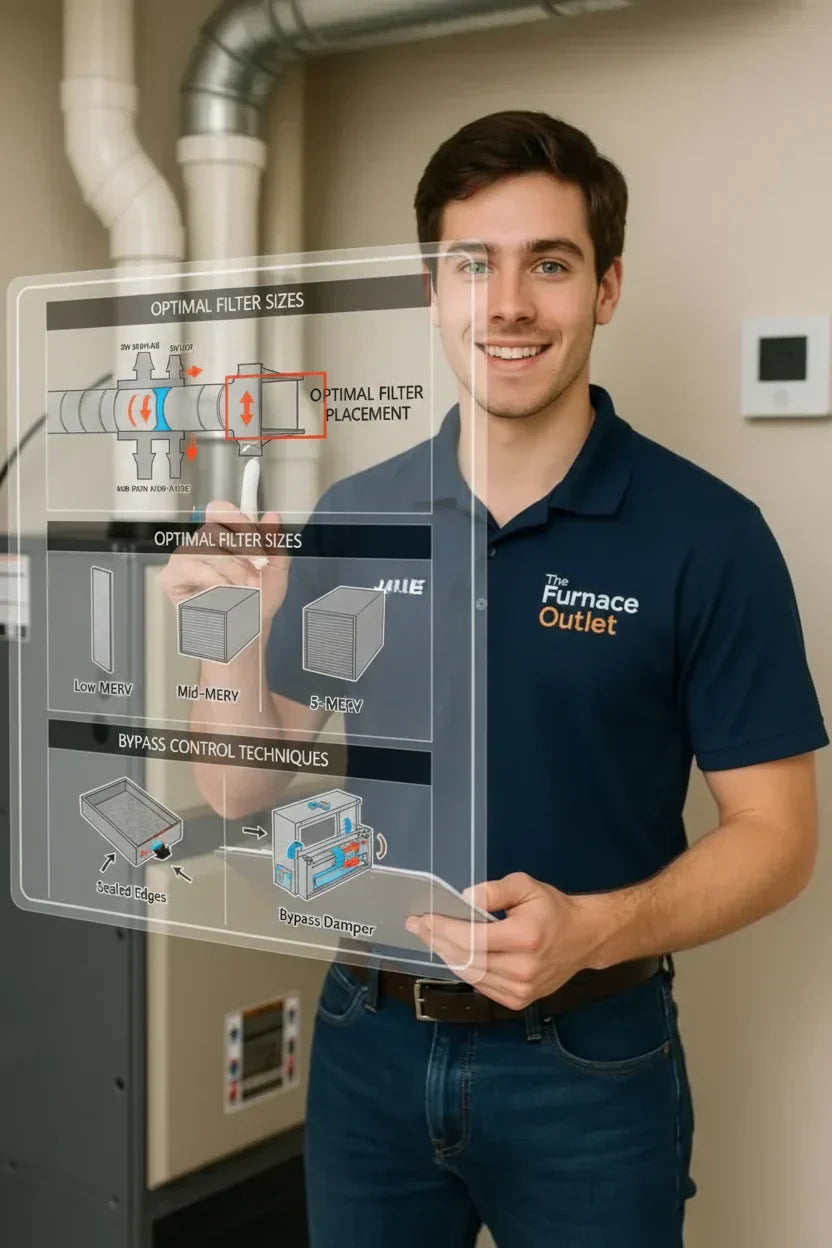

📍 3. Jake’s Rule #3 — Filter Placement Must Be on the Return Side Only

You’d be shocked how many systems Jake sees with filters:

❌ in the supply

❌ in the coil box

❌ behind the furnace

❌ in weird horizontal trays

❌ stuck in the blower door

❌ inside flex duct

Jake insists on:

✔ Proper Filter Location Options

-

At the return grille

-

At the return drop

-

At the furnace filter rack

-

In a media cabinet between return and furnace

That’s it. No exceptions.

Why return side only?

-

protects the blower

-

protects the coil

-

protects the furnace cabinet

-

filters dust before entering the system

Supply side = illegal in many states + dangerous.

Jake’s Placement Priorities

-

Media filter cabinet at the furnace

-

If space is tight → filter rack on return drop

-

If airflow is high → two return grilles with filters

-

Never → filter on supply

📘 External Reference — DOE Duct Placement Guide

🚫 4. Jake’s Rule #4 — NO Filter Bypass Allowed

Filter bypass is when air leaks around the filter instead of through it.

Jake sees it constantly:

-

filter too small for rack

-

rack too big for filter

-

filter crooked

-

warped frame

-

gaps on corners

-

missing door gasket

-

filter door bent

Bypass = dust in coil

Dust in coil =

❌ higher static

❌ less airflow

❌ freezing AC

❌ overheating furnace

❌ blower strain

Jake treats filter bypass like a catastrophic leak.

How Jake Eliminates Filter Bypass

✔ Step 1 — Upgrade the rack

He installs a sealed filter rack or 5" media cabinet.

✔ Step 2 — Use closed-cell foam gasket

Jake seals:

-

top

-

bottom

-

sides

-

door edges

✔ Step 3 — Correct filter sizing

Filter must slide in snug — not loose.

✔ Step 4 — Check for rack alignment

If crooked → rebuild.

✔ Step 5 — Seal unused holes

Gaps = bypass.

Jake says:

“One nickel-sized gap can bypass $40 worth of filter.”

🔧 5. Jake’s Rule #5 — Always Use a Sealed Filter Rack (Not a Slot)

Most installers cut a slot into the return drop and slide a filter in.

Jake hates filter slots with a passion.

Why?

-

unsealed slots leak

-

dust gets sucked in

-

blower strains harder

-

filter door rattles

-

filters warp

-

bypass skyrockets

Jake replaces slots with sealed filter cabinets.

Benefits:

-

airtight

-

holds a 4–5” filter

-

huge free area

-

stable airflow

-

no rattling

-

less static pressure

Result:

-

quieter system

-

predictable airflow

-

massive lifespan benefits

📘 External Reference — Aprilaire Air Cleaner Cabinets

📏 6. Jake’s Rule #6 — Filter Always Goes Before the Blower, Never After

Filters must always be upstream of:

-

blower motor

-

heat exchanger

-

coil

Jake explains:

“A filter after the blower is like putting the airbag behind the driver.”

Placement order:

✔ Return grille

➡️ return duct

➡️ filter rack

➡️ blower

➡️ coil

➡️ supply

If the filter is placed:

-

after blower → coil gets filthy

-

after coil → blower deteriorates

-

in supply → illegal

📦 7. Jake’s Rule #7 — A Filter Rack Must Be Deep Enough to Prevent Whistling

Whistling filters = high face velocity + poor rack design.

Causes:

-

narrow rack

-

sharp edges

-

too-fast airflow

-

loose filter

-

bypass gaps

Jake builds racks:

-

with smooth, rounded edges

-

deep enough for big filters

-

gasketed doors

🌬️ 8. The 1", 2", 4", 5" Filter Debate — Jake’s Take

Jake breaks it down:

1" Filters

Pros:

-

cheap

-

easy

Cons:

-

high static

-

short lifespan

-

low free area

-

noisy

-

clog fast

-

restrict airflow

-

bad for ECM motors

-

bad for large AC systems

Jake uses these ONLY on small single-story homes under 2 tons.

2" Filters

Rarely worth it.

Jake says:

“If you’re going to upgrade, go to 4 inches.”

4" Media Filters

Pros:

-

huge free area

-

low static pressure

-

last 6–12 months

-

quieter

-

safer for motors

-

better filtration

Jake’s preferred option.

5" Filters

Best option for:

-

large homes

-

high-static duct systems

-

ECM blower furnaces

-

homes with allergies

-

long duct runs

Jake loves them because:

-

quieter

-

lower pressure drop

-

cleaner coil

-

less bypass

🔄 9. Jake’s Airflow Math Behind Filter Racks

Jake uses a simple formula:

Filter Area (sq ft) = CFM / 300

And:

Return grille area must exceed filter area by 25–40%.

If airflow is too fast → restricts CFM → coil freezes → furnace overheats.

Jake measures static before and after installing new racks.

He ensures:

✔ ΔP across filter = 0.06–0.20" WC

Above 0.25" WC → bad filter sizing.

📊 10. Real-World Case Studies

📂 Case A — 1" Filter Causing Furnace Overheating

Before:

-

20×25×1

-

static = 0.82"

-

heat rise = 75°F

After Jake:

-

installed 20×25×5 media cabinet

-

static dropped to 0.44"

-

heat rise normalized

📂 Case B — Filter Bypass Clogging Coil

Symptoms:

-

weak airflow

-

warm AC

-

blower loud

Jake found:

-

filter slot had ½" gaps

-

no gasket

-

filter bowed inward

Fix:

-

sealed cabinet

-

coil cleaning

Airflow improved by 32%.

📂 Case C — Return Grille Too Small

Before:

-

grille: 16×20

-

filter: 20×25

-

system starved for air

Jake upsized grille to 24×30.

Static dropped from 0.72 → 0.41.

📝 11. Jake’s Complete Filter Rack Checklist

Jake checks all 18 items before calling a rack “done.”

✔ Filter fits snugly

✔ No bypass gaps

✔ Door gasketed

✔ Rack level and square

✔ Filter area ≥ CFM ÷ 300

✔ Rack supports 4–5" filters

✔ Rack sealed with mastic

✔ No whistling

✔ Filter can be removed easily

✔ No sharp transitions

✔ Correct airflow direction

✔ Return duct unobstructed

✔ No flex kinks

✔ Rack accessible for service

✔ No supply-side filters

✔ ΔP across filter ≤ 0.20" WC

✔ No leaks at seams

✔ No suction around the door

If 3 or more fail → Jake rebuilds the rack.

🏁 Conclusion: The Filter Rack Determines the System’s Health

Jake says it perfectly:

“You can have perfect ductwork and a $5,000 furnace — a bad filter rack will still destroy it.”

A proper filter rack improves:

-

airflow

-

static pressure

-

indoor air quality

-

coil longevity

-

energy efficiency

-

blower safety

-

overall comfort

The Filter Rack Formula is simple:

✔ Size for airflow

✔ Seal for performance

✔ Place for protection

✔ Control bypass

✔ Upgrade to media filtration

Do that, and the entire HVAC system becomes quieter, stronger, and more efficient.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Heat Rise Mastery: Jake’s Step-by-Step Method for Matching Furnace Btus to CFM in Real Homes