By Jake — the guy who refuses to leave a furnace until the heat rise is perfect.

📌 Introduction: Why Heat Rise Is the #1 Metric Homeowners Never Hear About

When most people talk about furnace performance, they focus on:

-

BTU output

-

AFUE efficiency

-

Furnace stage

-

Blower type (PSC, X13, ECM)

-

Thermostat features

But Jake knows something most homeowners (and far too many installers) don’t:

“If your heat rise is wrong, nothing else about the furnace will ever be right.”

Heat rise determines:

-

whether the furnace overheats

-

whether the blower works too hard

-

how long the heat exchanger lasts

-

how evenly the home warms

-

how efficiently the burner combusts

-

whether ducts deliver correct CFM

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

The furnace’s heat rise rating is printed on the nameplate — often something like:

35°F–65°F

or

40°F–70°F

Your actual heat rise must fall within this range.

If it’s too low → coil freezing, condensation, poor heating.

If it’s too high → furnace overheating, short cycling, cracked heat exchanger.

Jake’s goal?

Dial in the airflow (CFM) to match the furnace’s BTUs perfectly.

Every installation. Every home. Every time.

This is his exact, field-tested, step-by-step method.

🔥 1. Understanding Heat Rise (Jake’s No-Math Explanation)

Heat rise is simply the temperature difference between:

-

air going into the furnace (return air), and

-

air coming out of the furnace (supply air).

Jake explains it like this:

“Heat rise tells you how hard the furnace is working — and whether the blower is helping or choking it.”

✔ Ideal Heat Rise

Right in the middle of the furnace’s rated range.

Example:

If the range is 35–65°F, Jake aims for 45–55°F.

✔ High Heat Rise (Bad)

Too little airflow → furnace cooks itself.

✔ Low Heat Rise (Also Bad)

Too much airflow → furnace runs cold and inefficient.

📘 Lennox Furnace Heat Rise Guide

📐 2. The BTU–CFM Formula (The Science Behind Jake’s Method)

Jake sizes airflow using the real HVAC formula:

CFM = BTUs ÷ (1.08 × Heat Rise)

Where 1.08 is a constant based on air properties.

Example:

80,000 BTU furnace

Target heat rise: 50°F

80,000 ÷ (1.08 × 50)

= 80,000 ÷ 54

≈ 1,480 CFM

So an 80k furnace needs ~1,450–1,500 CFM of airflow to operate correctly.

Jake says:

“You can’t set your blower speed without doing this math — unless you like callbacks.”

📘 Carrier Gas Furnace Engineering Data

🌬️ 3. Jake’s Rule: BTUs Mean Nothing Without Airflow

A furnace is a machine that transfers heat into moving air.

Not enough moving air?

-

heat exchanger overheats

-

blower ramps harder

-

furnace cycles too fast

-

flame rolls out

-

limit switch trips

-

heat exchanger cracks prematurely

Too much moving air?

-

rooms feel lukewarm

-

furnace runs constantly

-

you lose efficiency

-

noise at registers increases

Jake’s law:

“The blower is the engine. The ducts are the exhaust. The filter is the intake. If one is wrong, the whole system is wrong.”

🔧 4. Jake’s Step-by-Step Heat Rise Dial-In Method

This is the exact process Jake uses during every installation and tune-up.

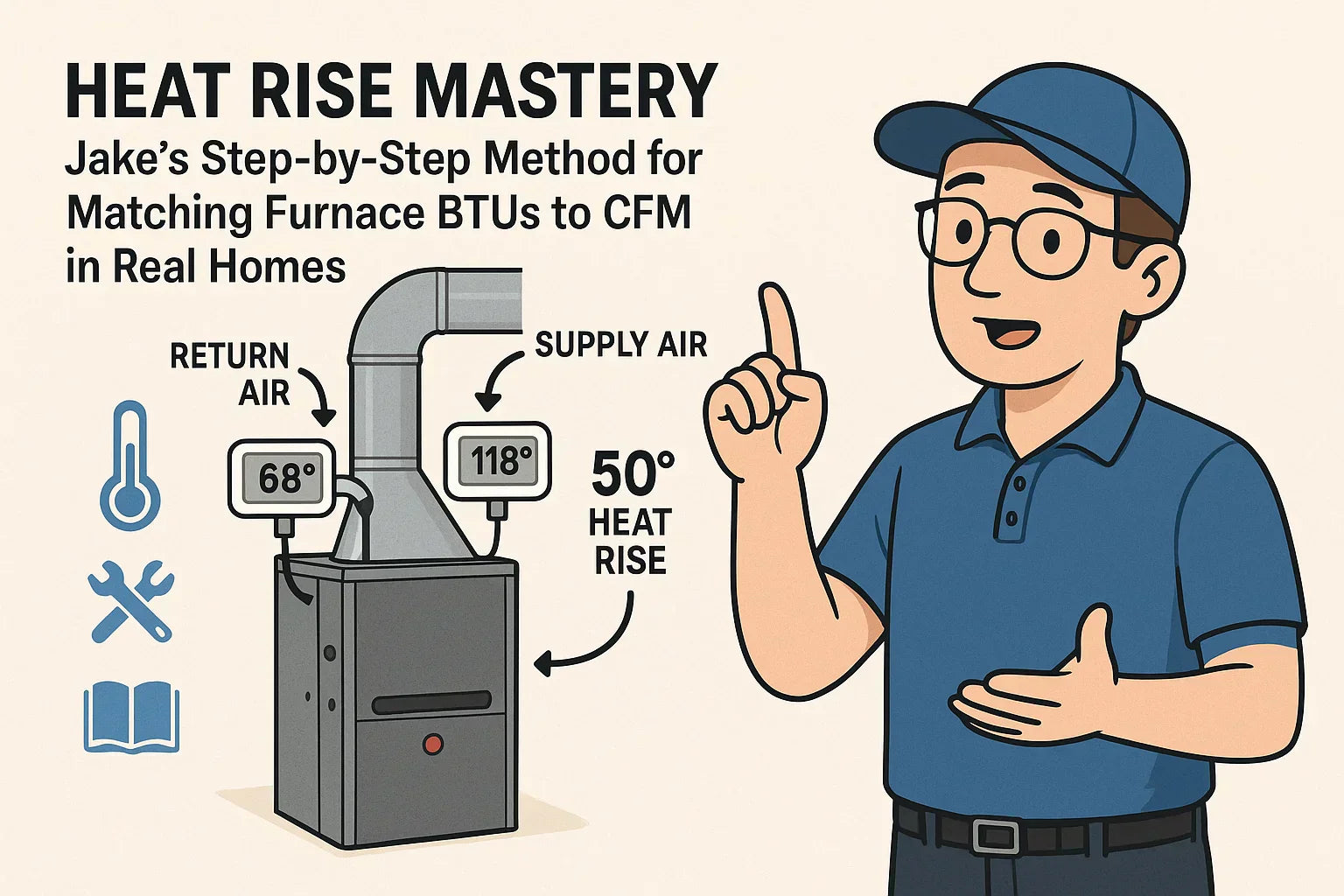

STEP 1 — Measure Return Air Temperature

Jake inserts a probe thermometer in the return drop before the blower.

Record:

-

temperature after system stabilizes (3–5 minutes)

Let’s say it’s 68°F.

STEP 2 — Measure Supply Air Temperature

Probe goes into supply plenum after the heat exchanger.

Let’s say supply air = 118°F.

STEP 3 — Calculate Heat Rise

Supply 118°F – Return 68°F = 50°F heat rise

If the furnace chart says range is 35–65°F, then 50°F is perfect.

Jake wants the system to hit:

Mid-range heat rise = maximum furnace lifespan.

📘 Goodman Furnace Heat Rise Specifications

STEP 4 — Compare Heat Rise to BTU–CFM Formula

Jake runs the numbers:

-

If heat rise is too high → furnace is starved → increase CFM

-

If heat rise is too low → furnace is overfed → decrease CFM

STEP 5 — Adjust Blower Speed on Furnace Board

ECM & X13 blowers have:

-

Heat speed

-

Cool speed

-

Circulate speed

Jake adjusts heat speed first, then cooling.

He matches blower tap to the calculated CFM using the blower table in the manual.

📘 ECM Motor Behavior Explained

STEP 6 — Evaluate Return & Supply Restrictions

Heat rise too high even after max blower speed?

Jake checks:

-

filter size

-

return drop diameter

-

return grille free area

-

coil cleanliness

-

plenum height

-

duct restrictions

-

undersized trunk

-

closed dampers

-

flex duct kinks

If static pressure > 0.5" WC, heat rise will never stabilize.

Most often, Jake finds:

-

1" filters choking 3–5 ton systems

-

undersized return

-

crushed flex duct

-

short plenums

-

coil completely matted with dust

📘 DOE Coil & Filter Maintenance

STEP 7 — Retest Heat Rise After Adjustments

Jake repeats the measurement until:

-

heat rise is stable

-

fan speed matches BTU output

-

static pressure is within limits

-

supply temperature delta is correct

-

blower wattage is reasonable

-

no limit switch trips

He doesn’t leave a job until it’s perfect.

🔥 5. How Bad Heat Rise Damages Real Homes (Jake’s Field Notes)

Jake has seen the same failures hundreds of times.

CASE A — Heat Rise Too High (Common in Undersized Return Systems)

Symptoms:

-

furnace shuts off too fast

-

room temperatures uneven

-

blower loud

-

coil freezing in AC mode

What Jake found:

-

80k furnace receiving only 900 CFM

-

filter slot bypass

-

return drop too small

After fixing return air:

-

heat rise dropped from 75°F → 48°F

-

static pressure dropped from 0.82 → 0.47" WC

CASE B — Heat Rise Too Low (Common in Oversized Blower Speeds)

Symptoms:

-

lukewarm supply air

-

long run times

-

high gas bills

-

rooms take forever to heat

Jake’s diagnosis:

-

blower on high speed

-

1,900 CFM blowing across 80k furnace

-

heat rise only 28°F, below rating

After adjusting blower:

-

heat rise increased to 52°F

-

gas consumption dropped 15%

CASE C — Cracked Heat Exchanger From Chronic Overheat

Cause:

-

clogged 1" filter

-

coil leak dripped onto furnace

-

high static → high heat rise → metal fatigue

Jake says:

“I’ve replaced more heat exchangers from high heat rise than anything else.”

🧠 6. Jake’s Heat Rise Optimization Principles

💡 Jake follows six core principles when tuning a furnace.

1. Furnaces need airflow, not wishes.

CFM must match BTU output.

2. Mid-range heat rise is always the goal.

Even if the rating is broad.

3. High heat rise = choked return side.

Almost always.

4. Low heat rise = blower too fast or duct too big.

5. Static pressure must stay below 0.50” WC.

Or heat rise will become unstable.

6. Blower tables are the holy scripture.

Never guess.

📝 7. Jake’s Full Heat Rise Mastery Checklist

Jake signs off only when the system meets ALL 20 conditions:

✔ Furnace heat rise within rated range

✔ Heat rise in middle of range (ideal)

✔ CFM matches BTU output

✔ Coil clean

✔ Filter rack sealed, correctly sized

✔ Filter ΔP below 0.20" WC

✔ Static pressure < 0.5" WC

✔ Return grille free-area correct

✔ All supply dampers fully open

✔ No crushed or kinked flex

✔ Plenum tall enough (12–18"+)

✔ Takeoffs correctly placed

✔ Wyes instead of tees

✔ Radius elbows instead of hard 90s

✔ Blower speed set using furnace table

✔ Supply temp probe confirmed

✔ Return temp probe confirmed

✔ Furnace runs without hitting limit

✔ Blower watt draw reasonable

✔ System heats smoothly & evenly

If 3+ items fail → Jake rebuilds the airflow path.

🏁 Conclusion: Matching BTUs to CFM Is the Secret to a Healthy Furnace

Jake sums it up:

“Every furnace is a heat machine — but without the right amount of airflow, it becomes a heat grenade.”

Master the heat rise, and you master:

-

comfort

-

efficiency

-

system longevity

-

blower health

-

coil performance

-

safety

-

energy bills

A furnace tuned using Jake’s Heat Rise Method will:

-

heat faster

-

heat safer

-

heat quieter

-

heat longer

-

heat more evenly

Heat rise is the heart of furnace performance — and airflow is the lifeblood that keeps everything running right.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: The Basement-to-Bedroom Pathway: Jake’s Method for Balancing Two-Story Homes with One Furnace