By Jake — the guy who says 90% of airflow problems begin within 18 inches of the furnace.

📌 Introduction: Why the Plenum Is the Most Important 2 Feet of Your HVAC System

Most homeowners think comfort comes from:

-

Bigger ducts

-

Bigger blowers

-

Higher efficiency ratings

-

More supply vents

But Jake knows the truth:

“Your entire airflow future is decided by the first two feet above the furnace — the plenum and the supply trunk.”

The plenum is the air highway on-ramp.

If it’s sized wrong, shaped wrong, sealed wrong, or supported wrong, you’ll get:

-

loud airflow

-

uneven rooms

-

hot/cold spots

-

high static pressure

-

furnace overheating

-

coil freezing

-

duct leaks

-

wasted energy

-

short furnace lifespan

This article is Jake’s complete, real-world blueprint for building the perfect plenum — one that maximizes airflow, stabilizes static pressure, reduces turbulence, and keeps your supply trunk running like a straight, quiet highway.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

📐 1. What the Plenum Actually Does (Most People Get This Wrong)

A lot of people think the plenum is just:

-

a metal box

-

where the ducts attach

-

a place for the coil

But in airflow physics, the plenum does something much more important:

It slows, expands, and stabilizes the air coming out of the blower.

Think of the blower as a fire hose.

The plenum turns that pressure blast into even airflow before it splits into the trunk and branches.

A perfect plenum will:

-

reduce turbulence

-

prevent whistling

-

stabilize air velocity

-

lower blower wattage

-

protect the coil

-

improve system balance

Jake calls it:

“The lungs of the duct system.”

📏 2. Jake’s Ideal Plenum Dimensions (The Real-World Version)

A plenum that is too short, too narrow, or too shallow creates turbulence, pressure spikes, and uneven trunk distribution.

Jake designs plenums using three rules:

📏 Rule 1 — Plenum Height: At Least 12–18 Inches Above the Furnace

Under 12 inches?

Expect:

-

static spikes

-

uneven supply airflow

-

noisy ducts

Ideal height:

-

12" minimum

-

18" preferred

-

24" if space allows

Jake says:

“Tall plenum = smooth air.”

📏 Rule 2 — Plenum Width: Must Match or Exceed Furnace Width

Never choke the airflow by using a plenum narrower than the furnace.

Example:

-

Furnace width: 21"

-

Plenum width must be 21–24"

Jake loves adding an extra 2–3 inches because it reduces velocity.

📏 Rule 3 — Plenum Depth: 18–24 Inches

Deeper plenums reduce turbulence.

Jake keeps it:

| System Size | Ideal Plenum Depth |

|---|---|

| 2–3 ton | 16–20 inches |

| 3.5–4 ton | 18–22 inches |

| 5 ton | 20–26 inches |

📘 External Reference: ACCA Manual D – Plenum Sizing Standards

https://www.acca.org/standards/technical-manuals

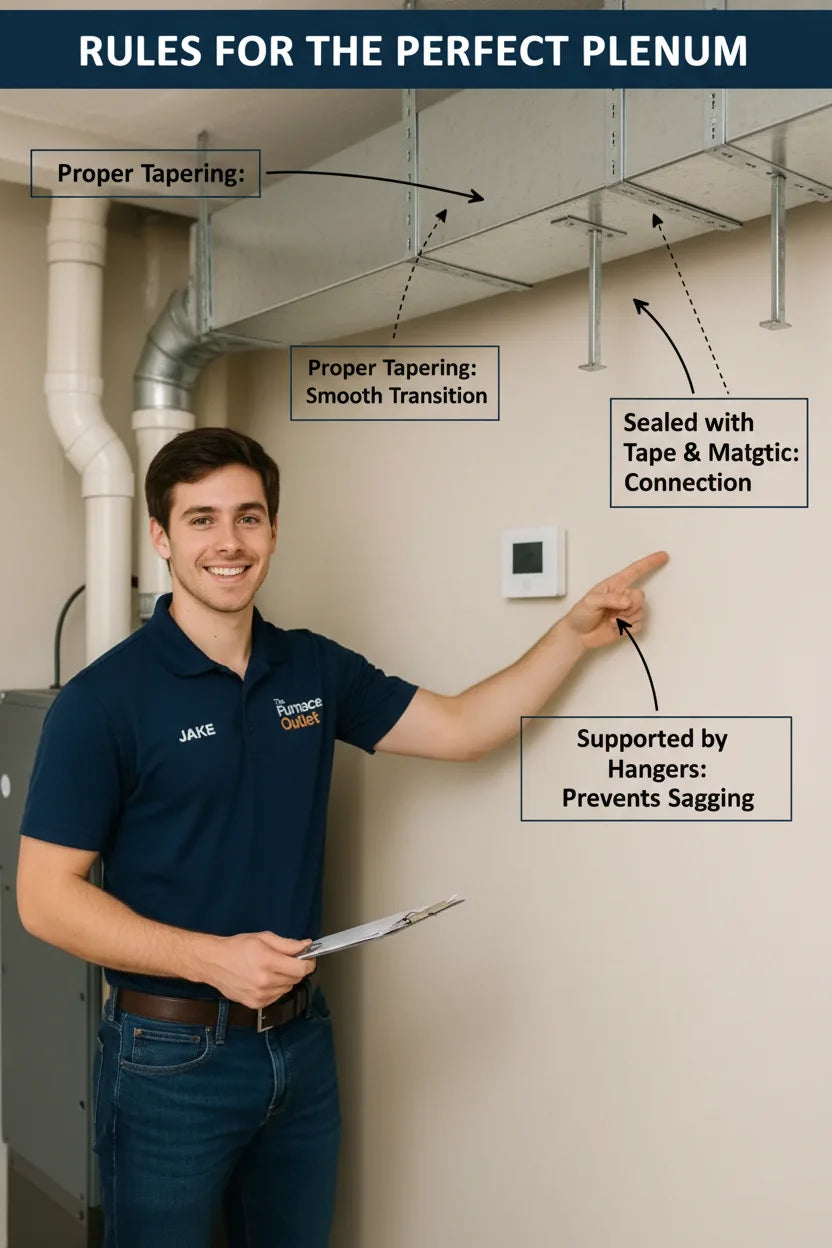

📉 3. Why Tapering Matters (Straight Boxes = Bad Airflow)

Many installers build straight-wall plenums, but Jake never does.

Straight plenums cause:

-

air loading at top

-

uneven branch flow

-

excessive turbulence

-

higher static pressure

-

noise

Jake always uses a tapered plenum.

What is a tapered plenum?

A plenum that gradually narrows as it rises, which keeps:

-

air velocity steady

-

pressure consistent

-

branches equally fed

📐 Jake’s Tapering Formula

For every 12 inches of height:

-

reduce width by 1–1.5 inches

-

reduce depth by 1–1.5 inches

This creates a soft “pyramid” or “frustum” shape.

Perfect taper example:

-

Furnace width: 21"

-

Plenum bottom: 21"

-

Plenum top: 18–19"

Jake calls this:

“The hourglass of airflow balance.”

📘 External Reference: ASHRAE Fundamentals — Airflow Transitions

https://www.ashrae.org/technical-resources/ashrae-handbook

🪚 4. Coil Boxes: Where Plenum Mistakes Start

When installing an evaporator coil, most techs:

-

slap a coil box on

-

attach the plenum

-

move on

Jake does the opposite.

He checks five things:

1️⃣ Coil box width must match plenum width

If coil is 17.5" and plenum is 21", airflow is restricted.

Jake uses transition adapters for perfect alignment.

2️⃣ Coil must sit perfectly level

If not:

-

water leaks

-

mold forms

-

coil overheats

3️⃣ Coil must have at least 6 inches of vertical air space above it

This reduces pressure drop.

4️⃣ Coil must be sealed airtight (no bypass)

Even small leaks cause:

-

bypassed air

-

reduced cooling

-

coil freezing

5️⃣ Coil must not sit too close to the blower

Minimum distance: 4 inches

🔧 5. Sealing the Plenum: Jake’s Leak-Proof Method

A plenum leak is the worst type of duct leak because it happens before the branches.

This causes:

-

static pressure drop

-

wasted energy

-

hot/cold spots

-

poor airflow distribution

Jake seals plenums with:

-

mastic (not tape)

-

mastic mesh tape

-

metal-backed UL-181 tape

-

corner caulking

-

internal seam buttering

He never uses:

-

generic silver tape

-

duct tape (illegal in most states)

-

thin foil tape

Because:

“A plenum leak steals more BTUs than a bad filter.”

📘 External Source: DOE Guide to Air Sealing HVAC Ducts

🛠️ 6. Supporting the Supply Trunk: Load, Weight & Vibration Rules

A poorly supported trunk will droop, twist, vibrate, or pull against the plenum — all airflow killers.

Jake uses structural math to prevent this.

📏 Jake’s Support Requirements

✔ Every 4 feet, place a rigid support

Wood, steel hanger, or strut.

✔ For long trunks:

Support at both ends AND midpoint.

✔ Avoid flex straps

Metal strapping only.

✔ No sagging allowed

Sag creates turbulence → turbulence increases static pressure.

✔ Maintain level pitch

Horizontal trunks must be perfectly level, not pitched.

📘 External Source: SMACNA Duct Construction Standards

🌀 7. Airflow Physics: How a Perfect Plenum Lowers Static Pressure

Jake explains it like this:

“A narrow plenum shoots air like a cannon.

A wide plenum lets air relax and spread.”

Here’s what a well-designed plenum does:

📉 Reduces Blower Wattage

A smoother plenum = blower doesn’t fight turbulence.

⚖️ Balances Airflow Across All Branches

Branches closer to the furnace don’t steal all the CFM.

🎧 Reduces Noise

Less turbulence = lower decibels.

🔧 Protects Furnace & Coil

Lower static = lower heat rise = longer life.

❄️ Improves Cooling Performance

Even airflow = even coil temperature.

🛑 8. Common Plenum Mistakes Jake Fixes Every Week

Jake sees these disasters all the time:

🚫 Plenum too short

Less than 10 inches? Airflow is chaotic.

🚫 Plenum narrower than furnace

Airflow bottleneck.

🚫 No taper

Branches get uneven airflow.

🚫 Hard 90° turn into trunk

Creates a pressure spike.

🚫 Coil box mismatch

Bad transitions = heat rise issues.

🚫 Poor sealing

Air leaks = lost BTUs.

🚫 Branch takeoffs too close to furnace

Need 6–12 inches of straight run first.

🚫 Trunk offset too tight

Needs gradual transition.

🔩 9. Jake’s Field Case Studies

Real homes, real fixes:

📂 Case A — No Taper, Overheating Furnace

TESP: 0.82" WC

Fix: Added 18" tapered plenum.

Result: Static pressure dropped to 0.48" WC.

📂 Case B — Short Plenum, Loud Supply Trunk

Sound level: 83 dB

Fix: Extended plenum from 6" to 18".

Result: Sound dropped to 61 dB.

📂 Case C — Leaky Plenum, Weak Cooling

Rooms far end: 20–30% airflow loss

Fix: Resealed plenum, corrected taper.

Result: 23% more CFM at branches.

📋 10. Jake’s Complete Plenum Design Checklist

Jake checks all 15 items before installing a plenum:

✔ Plenum matches furnace width

✔ Height: 12–24 inches

✔ Depth: 18–24 inches

✔ Tapered walls

✔ Straight run before first branch

✔ Coil aligned with plenum

✔ Airtight sealing

✔ No crushed flex

✔ No hard 90° trunk takeoff

✔ Trunk supported every 4 ft

✔ Branches equally spaced

✔ Return and supply pressures balanced

✔ Blower table matched to plenum airflow

✔ System tested with manometer

✔ Static pressure ≤ 0.5" WC

If three or more fail → Jake rebuilds the plenum.

🏁 Conclusion: A Perfect Plenum Makes the Whole System Perfect

Jake’s final word:

“The plenum decides whether the system breathes easy or gasps for air.”

A well-designed plenum results in:

-

quiet airflow

-

balanced temperatures

-

lower energy bills

-

longer furnace life

-

coil efficiency

-

safer operation

-

stronger airflow at registers

-

lower static pressure

The plenum is the hidden heart of the duct system — and when built right, it transforms everything.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Zero-Bounce Airflow: How Jake Eliminates Turbulence with Radius Elbows, Wyes & Proper Takeoffs