🏠 Introduction: Why Leaks Happen

Hey folks, Tony here. If you’ve installed a PTAC drain kit like the GE RAD10, you’ve already done one of the smartest things to protect your walls and flooring from condensate water damage. But here’s the reality: even with a kit, leaks can still happen.

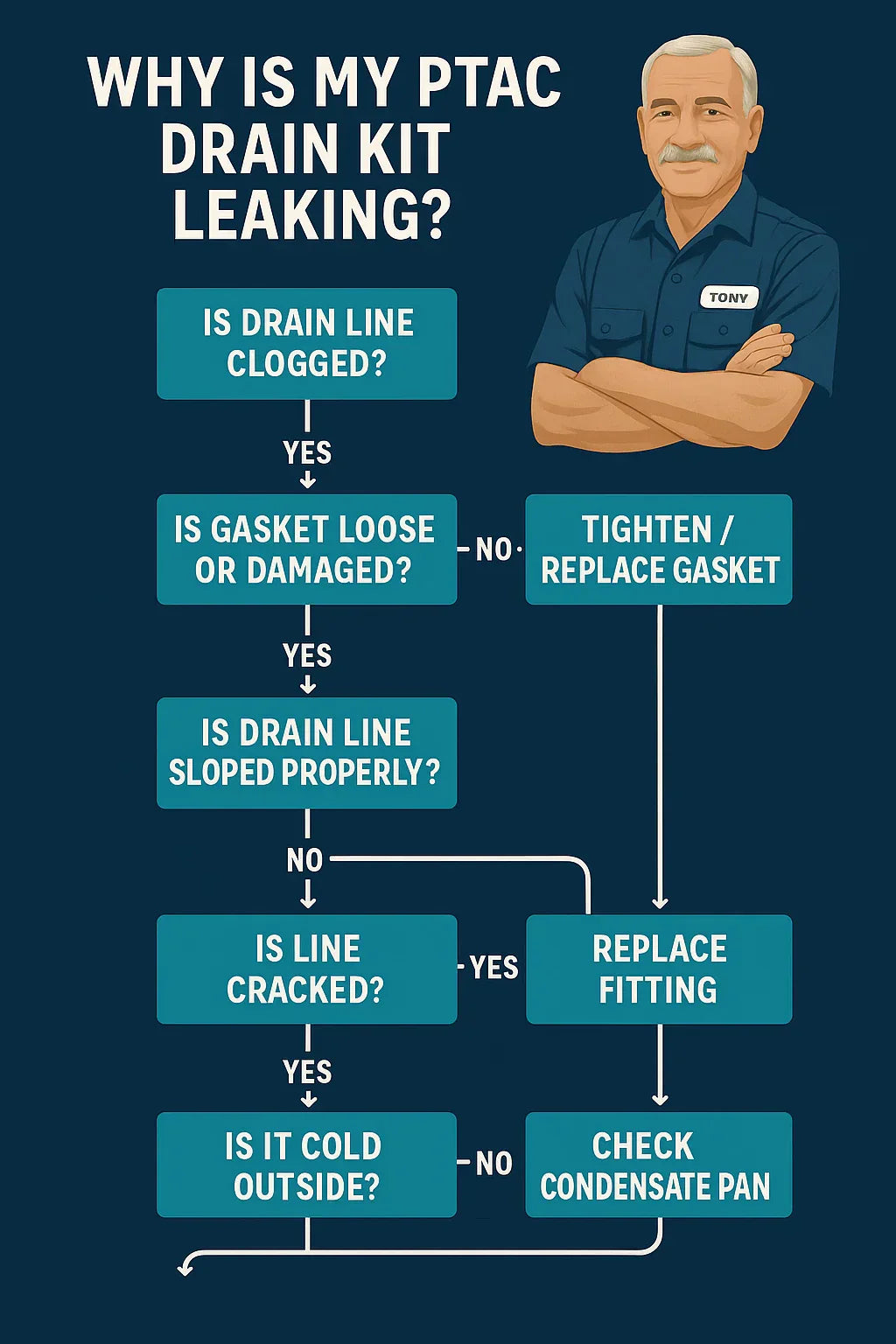

I’ve seen it plenty of times: a customer calls me, panicked about water dripping from their PTAC. Nine times out of ten, it’s not a catastrophic failure—it’s a clogged line, a loose gasket, or a slope issue. The good news? Most of these problems are easy to troubleshoot and fix yourself.

In this guide, I’ll show you:

-

The most common causes of drain kit leaks

-

Quick DIY fixes you can do with basic tools

-

A step-by-step troubleshooting checklist

-

When to call in a pro

-

Preventive measures so it doesn’t happen again

⚠️ Section 1: Common Causes of PTAC Drain Kit Leaks

Leaks are frustrating, but usually they boil down to a handful of culprits.

🔹 1. Clogged Drain Line

Dust, dirt, algae, and even insects can block the tubing. Water backs up and finds another path—often into your room.

👉 Beckett confirms that clogged lines are the #1 cause of condensate overflows in HVAC systems.

🔹 2. Loose or Misaligned Gasket

The gasket that seals the drain fitting to the sleeve can shift, crack, or compress over time, allowing water to drip.

🔹 3. Cracked or Brittle Fittings

Plastic fittings wear out, especially in older units or those exposed to temperature swings. A hairline crack can lead to steady leaks.

🔹 4. Improper Slope

Gravity does the heavy lifting in drainage. If your line runs flat or uphill, water won’t flow. Instead, it sits in the line until it seeps out somewhere it shouldn’t.

👉 Quality Home Air Care emphasizes that improper slope is a major cause of poor drainage.

🔹 5. Frozen External Line

In colder climates, water in an external drain line can freeze, blocking the flow and causing backups.

🔹 6. Overfilled Condensate Pan

If the pan is cracked, rusted, or simply overwhelmed by humidity, it can overflow before the drain kit even has a chance to work.

🧰 Section 2: Quick DIY Fixes

Most leaks are DIY-friendly. Here’s how I tackle each cause.

✅ For a Clogged Drain Line

-

Mix vinegar + warm water (50/50).

-

Pour through the line to dissolve algae.

-

Use a wet/dry vacuum to pull out blockages.

-

For stubborn clogs, insert a flexible drain brush.

✅ For a Loose Gasket

-

Power down the PTAC.

-

Remove the fitting and inspect the gasket.

-

Clean any debris, reseat the gasket, and tighten screws.

-

If cracked, replace with an OEM gasket (never skip replacements).

✅ For Cracked Fittings

-

Order a replacement fitting (stick with GE or Amana OEM parts).

-

Remove the old fitting and gasket.

-

Install the new one with fresh hardware.

👉 PTAC Central stresses the importance of using manufacturer-approved parts for long-term reliability.

✅ For Improper Slope

-

Check that the line drops ¼ inch per foot toward the discharge point.

-

Reposition tubing or add clips to hold slope.

✅ For Frozen Lines

-

Reroute to an internal drain if possible.

-

Add insulation around the tubing.

-

Never use heat tape unless manufacturer-approved.

✅ For Overfilled Pans

-

Inspect pan for cracks or rust.

-

Replace if damaged.

-

Make sure the drain port is fully clear.

👉 Manualslib’s Amana DK9001D manual includes instructions on properly seating pans and drain kits to avoid leaks.

📋 Section 3: Step-by-Step Troubleshooting Checklist

When I walk into a job, here’s my systematic process:

1️⃣ Power Down the Unit

Safety first. Unplug or switch off the PTAC.

2️⃣ Inspect the Condensate Pan

-

Look for cracks, rust, or overflowing water.

-

If cracked, it needs replacing.

3️⃣ Check the Gasket & Fitting

-

Feel around the connection point for drips.

-

Tighten screws or reseat gasket as needed.

4️⃣ Flush the Drain Line

-

Use vinegar + water solution.

-

If water doesn’t exit smoothly, it’s clogged.

5️⃣ Verify the Slope

-

Use a level or eyeball the line.

-

Adjust clips, straps, or tubing placement.

6️⃣ Test with Water

-

Pour a cup of water into the pan.

-

Watch to confirm smooth flow out of the drain.

👉 The Furnace Outlet recommends always testing with water after adjustments.

7️⃣ Reassemble & Restore Power

-

Once everything checks out, put the cover back on.

-

Turn the unit on and monitor for leaks.

📞 Section 4: When to Call a Pro

Not every leak is DIY-safe. Call a licensed HVAC pro if:

-

The leak persists after flushing and reseating gaskets.

-

The condensate pan is cracked and needs replacement.

-

You notice mold damage in walls or flooring.

-

You’re tying into internal plumbing and don’t feel confident.

👉 Amana PTAC notes that proper installation and service are critical for warranty coverage—so don’t hesitate to call a pro when needed.

🔄 Section 5: Preventing Future Leaks

The best troubleshooting is prevention.

🔹 Monthly

-

Pour water into the pan to test drainage.

-

Check for leaks around fittings.

🔹 Every 3–6 Months

-

Flush line with vinegar solution.

-

Vacuum or brush out stubborn debris.

🔹 Yearly

-

Inspect gaskets, fittings, and condensate pan.

-

Replace worn parts before they fail.

💬 Section 6: Tony’s Bottom Line

Here’s the truth: most PTAC drain kit leaks aren’t serious. They’re usually caused by a clogged line or loose gasket—things you can fix with vinegar, a screwdriver, and a little patience.

But don’t ignore them. A drip today can be mold, drywall damage, and costly repairs tomorrow.

My advice:

-

Troubleshoot step by step.

-

Fix what you can.

-

Call a pro when needed.

-

And most importantly, maintain your drain kit regularly so leaks don’t sneak up on you.

Tony’s Take: Five minutes of maintenance beats five hundred bucks in repairs—every single time.

In the next topic we will know more about: GE Zoneline Accessories Compared Why Tony Picked the RAD10 Drain Kit