Hey folks, Tony here. Let me tell you something I’ve learned from years of working with PTAC units: installing a drain kit is only half the battle. The real secret to keeping your PTAC running leak-free and efficient is maintenance.

My first PTAC drain kit worked perfectly—for about six months. Then, one day, water started pooling on the floor. Turned out the line was clogged with algae and dust. Lesson learned: these kits need a little love.

GE Zoneline PTAC Condensate Internal/External Drain Kit RAD10

The good news? Keeping your PTAC drain kit in top shape doesn’t take much time. A few minutes each month and a seasonal deep clean can save you from water damage, mold, and costly service calls.

This guide will cover:

-

How often to maintain your drain kit

-

My monthly, seasonal, and yearly routines

-

Tools and supplies you’ll need

-

Common problems and DIY fixes

-

Pro tips to keep things running smooth

🗓️ Section 1: How Often Should You Maintain a PTAC Drain Kit?

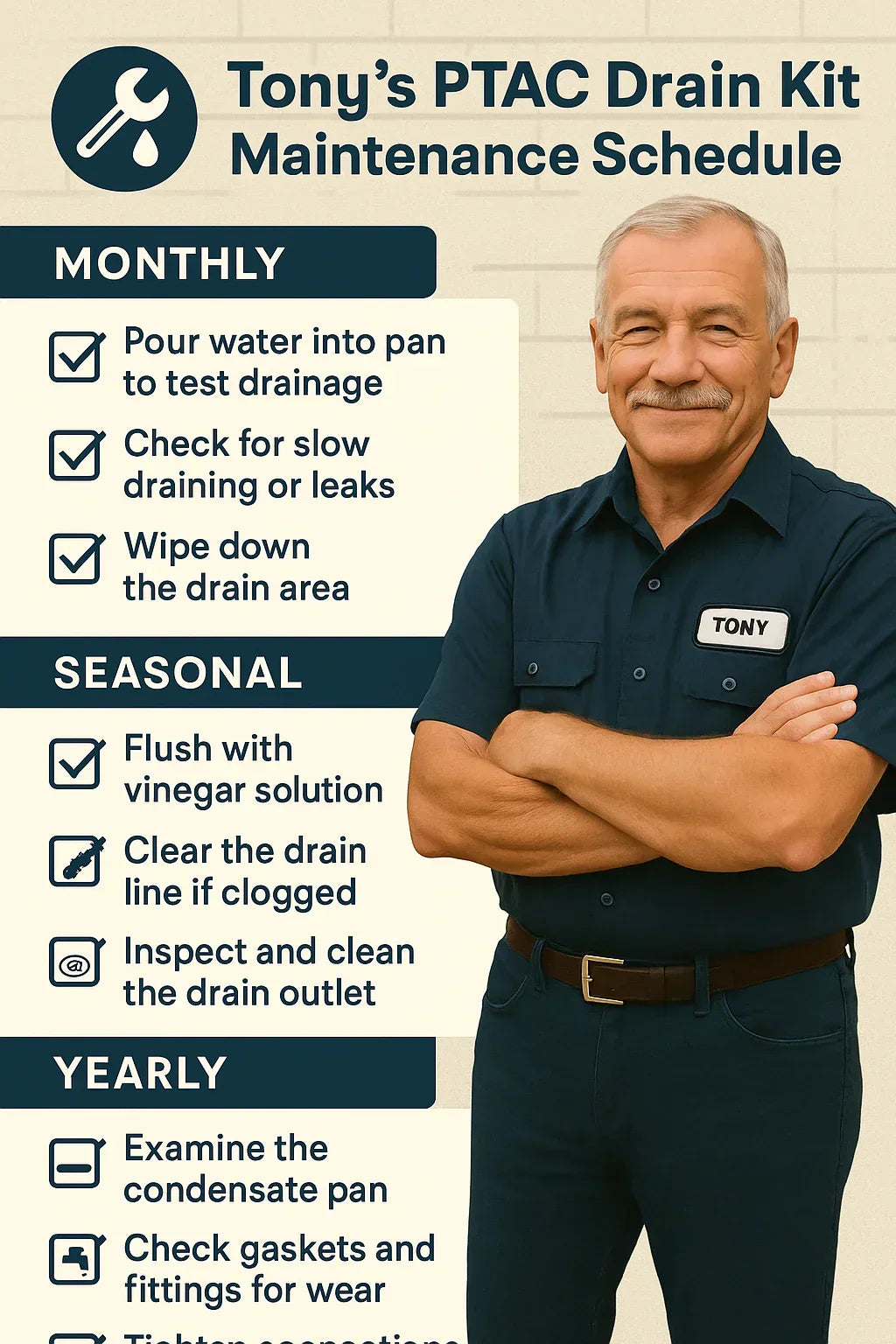

Drain kits don’t require daily attention, but they do need regular checks. Here’s the schedule I use:

-

Monthly: Quick visual check and water test

-

Every 3–6 months: Flush the line with vinegar + water solution

-

Yearly: Full inspection of gaskets, seals, and fittings

👉 According to Beckett, neglecting condensate drains is one of the biggest reasons HVAC systems fail early. Keeping up with this routine avoids costly damage.

🧴 Section 2: Tony’s Monthly Routine

Every month, I do a quick check—takes less than 5 minutes.

✅ Steps

-

Pour a cup of water into the pan

-

This confirms water flows freely through the kit.

-

-

Look for leaks

-

Check around the gasket and fittings for drips.

-

-

Wipe the sleeve area

-

A damp cloth keeps dust from collecting near the drain.

-

-

Check for stains

-

Look for new wall discoloration that could signal a hidden leak.

-

Tony’s Tip: If water pools instead of draining, fix it right away—don’t wait until next month.

🌦️ Section 3: Seasonal Cleaning Steps (Every 3–6 Months)

Condensate lines love to grow algae. That’s why seasonal cleaning is essential.

✅ Steps

-

Mix a solution of vinegar + warm water (50/50 mix).

-

Vinegar breaks down algae and slime without harming components.

-

-

Flush the line

-

Pour solution through the drain fitting slowly.

-

If available, use a small pump or funnel.

-

-

Vacuum or brush if clogged

-

A wet/dry shop vacuum can suck out stubborn clogs.

-

A flexible drain brush works for smaller lines.

-

-

Inspect the discharge point

-

For external drains, clear leaves, dirt, or ice.

-

For internal drains, ensure tubing is secure and sloped.

-

👉 Quality Home Air Care recommends vinegar flushes every 3–6 months to prevent clogs and odor issues.

🔍 Section 4: Yearly Deep Check

Once a year, I do a thorough inspection. Think of it as a tune-up for the drain kit.

✅ Steps

-

Remove the PTAC front cover

-

Access the condensate pan.

-

-

Check pan for cracks or rust

-

Replace if damaged.

-

-

Inspect gaskets and seals

-

Rubber parts wear out; replace brittle or cracked gaskets.

-

-

Tighten fittings and screws

-

Vibration can loosen connections over time.

-

-

Re-seal if needed

-

Apply HVAC-safe sealant around joints for extra protection.

-

👉 Manualslib’s Amana DK9001D instructions recommend checking and reseating gaskets annually to avoid leaks.

⚠️ Section 5: Common Issues & How Tony Fixes Them

Even with maintenance, issues can pop up. Here are the big ones I see:

1. Clogged Drain Line

-

Cause: Algae, dust, or insects blocking the line.

-

Fix: Flush with vinegar solution or vacuum out blockage.

2. Leaky Gasket

-

Cause: Worn or misaligned seal.

-

Fix: Replace gasket or reseat fitting.

3. Frozen External Line

-

Cause: Cold climate + poor routing.

-

Fix: Reroute internally or insulate external tubing.

4. Musty Odors

-

Cause: Standing water or mold growth.

-

Fix: Disinfect pan with mild cleaner, flush drain line.

🛠️ Section 6: Tools & Supplies Tony Keeps on Hand

Here’s my go-to kit for drain maintenance:

-

White vinegar (1 gallon jug)

-

Warm water + small funnel

-

Wet/dry shop vacuum

-

Flexible drain brush (3–6 feet)

-

Replacement gaskets (OEM recommended)

-

Towels and small bucket

-

Screwdriver and adjustable wrench

👉 PTAC Central notes that OEM kits like the GE RAD10 or Amana DK900 include gaskets and fittings designed for long-term reliability—always keep spares handy.

💬 Section 7: Tony’s Pro Tips

Here’s what I tell customers (and follow myself):

-

❌ Never use harsh chemicals like bleach—it corrodes pans and fittings.

-

✅ Always slope external drain lines away from the building foundation.

-

✅ Label maintenance dates on a tag near your PTAC.

-

❄️ In freezing climates, prefer internal drains with the RAD10 to avoid ice.

-

🛡️ Don’t wait for signs of trouble—prevent them with routine care.

👉 The Furnace Outlet stresses that drainage-related callbacks are preventable with proactive checks and seasonal cleaning.

✅ Section 8: Wrap-Up – The Payoff of Regular Care

Here’s my bottom line:

-

Five minutes a month → confirm your PTAC is draining.

-

One flush per season → prevent clogs and odors.

-

One yearly checkup → replace worn parts before they leak.

Do that, and your GE RAD10 drain kit (or any PTAC kit) will run smoothly for years. You’ll avoid:

-

Water damage

-

Mold and mildew

-

Costly repairs or early replacement

Tony’s Bottom Line: Maintenance is cheaper than drywall repair. Don’t skip it.

In the next topic we will know more about: Troubleshooting Guide: What to Do If Your PTAC Drain Kit Is Leaking