When a furnace is installed correctly, you barely hear it. The airflow is smooth, the cabinet is quiet, and the home feels comfortable without calling attention to the equipment.

But when a furnace is installed incorrectly, you hear everything:

-

cabinet hum

-

wall resonance

-

floor vibration

-

blower buzz

-

duct “boom”

-

heat strip rattle

-

the infamous “morning roar” when the unit first fires up

And here’s the thing:

90% of HVAC noise problems have nothing to do with the blower or the duct — they come from vibration transfer.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow - MBVK20DP1X00, HKTAD201

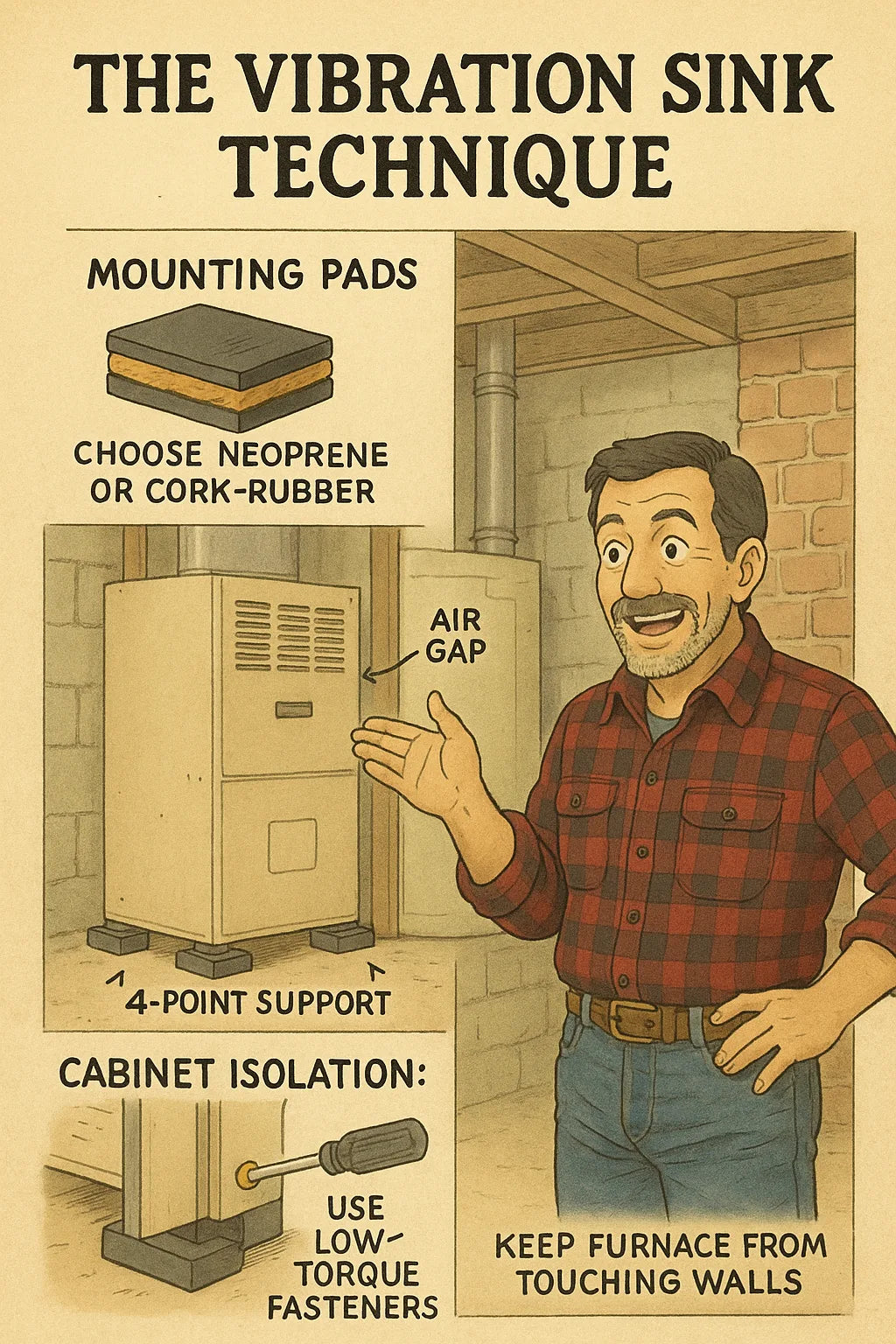

This article introduces The Vibration Sink Technique, Mike’s three-part strategy for eliminating furnace vibration at the source by controlling:

-

Mounting Pads

-

Wall-Break Structures

-

Cabinet Isolation Geometry

If you want a whisper-quiet furnace, this is the system that gets you there.

🔍 1. Why Furnaces Vibrate — And Why Homeowners Hear It

Electric furnaces — especially high-CFM models like the Goodman MBVK20DP1X00 — move a tremendous amount of air. Even a perfectly balanced blower creates small vibrations. The danger isn’t the vibration itself.

The real problem is structural transfer.

When vibration travels into:

-

wall studs

-

floor joists

-

drywall

-

subfloor decking

-

metal duct supports

…it amplifies like sound waves in a guitar body.

A tiny internal vibration becomes a loud external noise.

Mike’s Rule:

Vibration doesn’t need to be eliminated — it needs to be redirected into a sink where it dies quietly.

That’s what this technique is all about.

🧱 2. Mike’s Three-Stage Vibration Sink System

Every furnace installation needs all three:

1. Mounting Pads – absorb and diffuse point-source vibration

2. Wall-Breaks – block vibration from entering structural members

3. Cabinet Isolation – prevent resonance inside the metal housing

When these three are paired correctly, the furnace becomes nearly silent.

🧰 3. The Mounting Pad Formula: Material, Density & Compression

Mounting pads are the first line of defense.

But store-bought rubber squares aren’t enough.

You must use pads engineered to match the weight and vibration profile of the furnace.

🟧 Step 1: Choose the Right Material

Here are the only materials I recommend:

Neoprene (40–60 durometer)

Best for general furnace vibration.

Cork-Neoprene Laminates

Best for mixed-frequency vibration (blower + heat strip hum).

Sorbothane

Premium option — unmatched damping, rarely needed but incredible.

Verified Reference for Vibration-Isolating Materials:

ASHRAE HVAC Applications Handbook

https://www.ashrae.org

🟫 Step 2: Determine Pad Density

Pads compress over time. Too soft → bottoms out. Too firm → transmits vibration.

Rule of thumb:

Pad should compress 10–15% under furnace weight.

Example: A 140-lb electric furnace should sit on pads designed for ~15 lbs/sq in.

🟦 Step 3: Pad Layout (Mike’s 4-Point Distribution)

Never place pads in a straight line.

Instead use:

-

Four corner pads

-

Optional: center pad for long furnaces

This prevents cabinet torque that amplifies noise.

🧱 4. The Wall-Break Strategy: How to Block Structure-Borne Vibration

A wall-break is any method that prevents vibration from entering studs, drywall, or joists.

Most noisy furnace rooms have one of these sins:

❌ furnace mounted directly to a wall

❌ metal plenum touching the studs

❌ return box screwed to shared walls

❌ platform bolted into joist cavities

A wall-break stops all that.

🧱 Wall-Break Technique #1: The Floating Platform

Instead of anchoring the furnace directly to framing:

-

Build a platform on rubber isolation feet

-

Use double-layer ¾” plywood with Green Glue

-

Never tie platform to wall studs

This creates a dead zone where vibration cannot transfer.

🧱 Wall-Break Technique #2: The 1" Air Gap Rule

Furnace cabinets and plenums must maintain a 1-inch minimum gap from:

-

studs

-

walls

-

drywall

-

water lines

Air is the best vibration insulator.

🧱 Wall-Break Technique #3: Flexible Connection to Ductwork

Rigid duct transitions cause vibration transfer.

Use:

-

insulated flex collars

-

vibration-isolation connectors

-

double-shear hanger supports

Valid duct isolation guidance appears in SMACNA manuals:

https://www.smacna.org

📦 5. Cabinet Isolation Tricks: Controlling Resonance Inside the Furnace

Even a perfectly mounted furnace can resonate internally.

The cabinet acts like a drum unless you tune it.

Here’s how I do that.

🎛️ Isolation Trick #1: Panel Decoupling

This technique quiets 70% of hums.

Use:

-

neoprene washer

-

oversized screw holes

-

low-torque fasteners

This allows panels to vibrate independently instead of transferring noise across the housing.

🔩 Isolation Trick #2: The Mass-Loading Patch

Add a 1–3 lb mass to the inside of a resonating panel.

Options:

-

roofing membrane squares

-

automotive sound deadener

-

mass-loaded vinyl

Heavier panels vibrate less.

🪛 Isolation Trick #3: Cross-Bracing the Weak Wall

If the blower side panel drums:

-

Add L-bracket support

-

Use short self-tapping screws

-

Pair with neoprene backing washers

This strengthens the panel without increasing vibration transmission.

🧊 Isolation Trick #4: Return Box Stabilization

Return plenums often “oil can” (pop inward) due to negative pressure.

Fix it by:

-

adding perimeter reinforcement

-

installing a return wall stiffener

-

reducing static pressure

See ACCA Manual D for static pressure guidelines:

https://www.acca.org

🎚️ 6. Frequency Matching: The Key to Stopping Blower Hum

Blower motors operate across multiple RPM bands.

Each RPM band has a “natural frequency.”

If this matches the cabinet’s frequency, the furnace hums.

Mike’s Frequency Matching Process:

-

Run blower at each speed tap

-

Listen for resonance peaks

-

Apply targeted damping to those panels

-

Verify with vibration meter (optional)

This is how you tune a furnace like a musical instrument.

🎤 7. The Return-Air Trap: Why Return Geometry Creates Noise

Most noise complaints come from the return air side.

Common mistakes:

-

undersized return

-

return box touching framing

-

filter door sucking shut

-

plenum rotation creating turbulence

The cure is simple:

✔️ Isolate the return box from structural members

✔️ Add mass to the return wall

✔️ Use long-radius turns instead of sharp elbows

✔️ Seal filter doors and add padding to latches

DOE’s airflow management guidelines support these design principles:

https://www.energy.gov/energysaver/energy-saver

📐 8. Mike’s 7-Point Vibration Sink Checklist

Before I leave any installation, I run through this checklist:

1. Furnace sits on four or five isolation pads

Pads matched to weight and durometer.

2. Furnace platform is floating — not anchored to framing

Platform must break vibration paths.

3. No cabinet surface touches a wall or stud

Maintain 1" clearance.

4. Plenum and return transitions use flex connectors

Rigid-to-rigid equals noise transfer.

5. Resonant cabinet panels mass-loaded or braced

Silence the drum effect.

6. Return-air geometry tuned for smooth flow

No sharp elbows, no undersized grilles.

7. System tested across all blower speeds

High, medium, low — no speed should resonate.

🎧 9. The Vibration Sink Technique in the Real World: What Homeowners Report

After applying this method, homeowners consistently tell me:

-

“The furnace sounds expensive now.”

-

“The low-speed hum disappeared.”

-

“I don’t hear the blower anymore.”

-

“My walls don’t shake when emergency heat kicks in.”

-

“It’s quieter than my old gas furnace.”

Quiet is comfort.

Comfort is quality.

Quality is what keeps systems efficient and homeowners happy.

🧩 10. Troubleshooting Noise: Mike’s Diagnostic Table

If a homeowner calls about noise, here’s where I start.

| Symptom | Likely Cause | Fix |

|---|---|---|

| Low-frequency hum | cabinet resonance | mass-load + decouple |

| “Boom” when turning on | platform touching framing | wall-break correction |

| Rattle near blower | unbalanced torque on panel screws | torque isolation |

| Vibration in vents | rigid duct transition | flex connector |

| High-pitch whistle | return door gap | seal and pad filter door |

| Drumming sound | thin sidewall | L-bracket brace + neoprene backing |

If the noise persists, you haven’t broken the vibration path completely.

🎉 Conclusion: Silence Isn’t Accidental — It’s Engineered

Electric furnaces don’t have burners, combustion, or flue noise — so they should be the quietest systems in the home.

When you apply the Vibration Sink Technique:

✔️ vibration stays in the furnace

✔️ nothing transfers into walls

✔️ no resonance rings through the duct system

✔️ blower sounds disappear

✔️ installation looks and feels premium

Noise isn’t an unavoidable side effect.

It’s a design flaw — one you can eliminate with the right tools, spacing, and geometry.

Follow these rules and you’ll deliver whisper-quiet comfort, every time.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know more about: The Condensate-Free Furnace Room: Mike’s Moisture-Control Prep That Protects Electric Elements