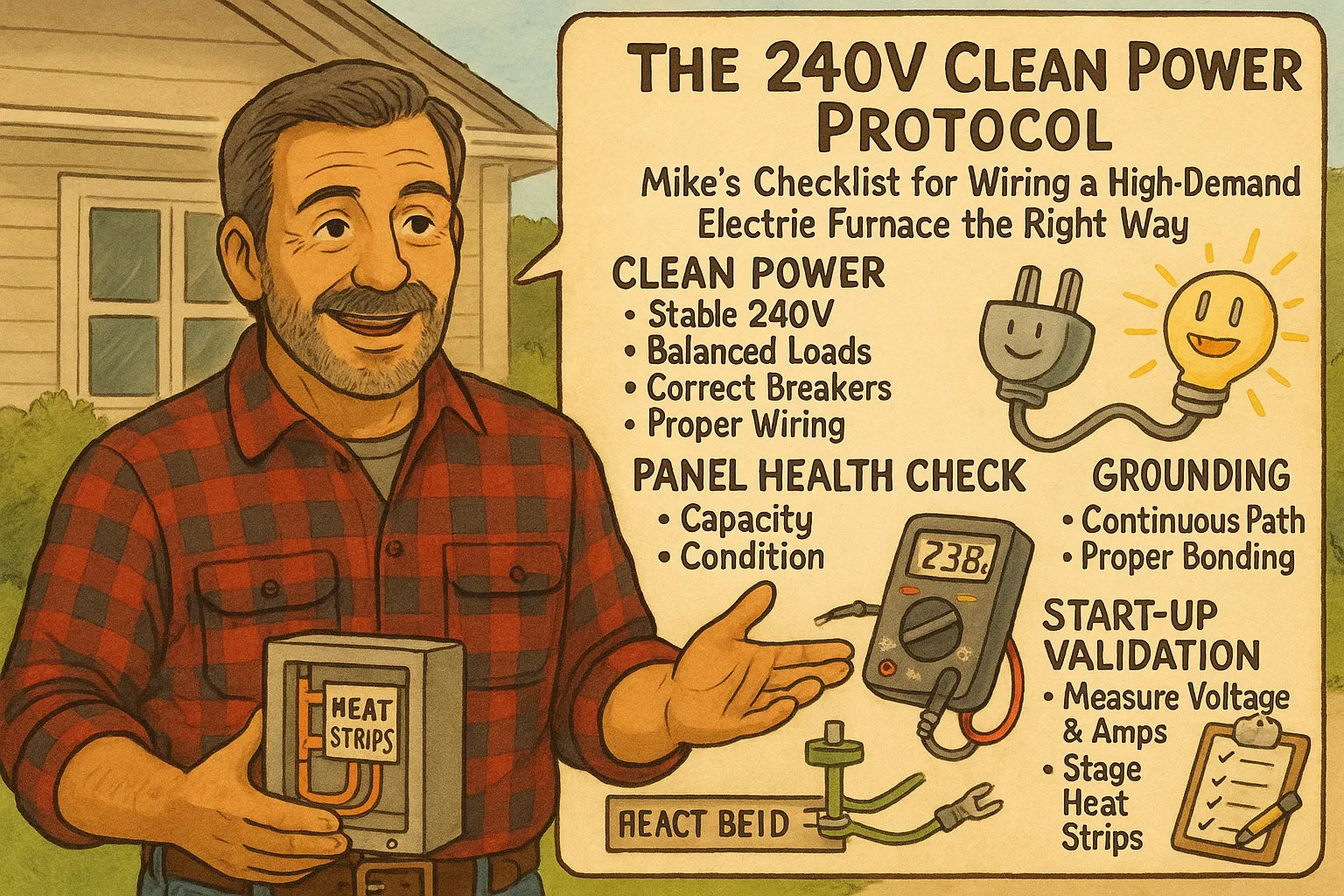

The biggest difference between a quiet, efficient, reliable high-wattage electric furnace and one that trips breakers, overheats, vibrates, or burns up heat strips comes down to one thing:

Clean 240V power.

When you install a high-demand electric furnace like the Goodman MBVK20DP1X00 with HKTAD201 heat kit, you’re dealing with an appliance that can draw 60–120 amps, depending on staging and configuration. That’s more than most water heaters, more than most ranges, and far more than any central AC blower.

This kind of load demands something more than “just run some wires and land them on a breaker.”

It requires The 240V Clean Power Protocol — the exact checklist I’ve developed over hundreds of field installations to ensure your furnace receives stable voltage, balanced loads, safe wiring paths, and rock-solid grounding.

If you want a furnace that runs smoothly for decades, this is where you start.

🔌 1. Understanding What ‘Clean Power’ Really Means

Most DIYers think “clean power” means simply:

-

No brownouts

-

No flickering lights

-

No tripped breakers

But electrically, clean power means something much more precise:

✔️ Stable incoming voltage (228–240V)

✔️ Each leg of the 240V line carries the correct share of load

✔️ Breakers sized to protect the wiring — NOT oversized

✔️ Proper copper wire gauge with temperature rating

✔️ Neutral and ground paths isolated and low-resistance

✔️ No voltage drop beyond 3% under load

If any of these aren’t true, your furnace may still “work,”

but it won’t work right.

Supporting Reference:

National Electric Code (NEC) safety standards

https://www.nfpa.org

🧭 2. Mike’s Rule #1: Start With a Panel Health Check

Before you even think about wiring the furnace, you need to understand the condition of the electrical panel feeding it.

✔️ Verify the panel has enough amperage capacity

Most electric furnaces require two or three 2-pole breakers, depending on heat strip kit size.

Your main service must have enough headroom.

✔️ Inspect for defects

Look for:

-

Double-lugged neutrals

-

Burn marks

-

Corrosion

-

Loose lugs

-

Under-torqued breakers

✔️ Identify which side of the panel is least loaded

You want the furnace breakers distributed across both legs of the service.

✔️ Confirm panel labeling and organization

If the panel is chaos, future servicing becomes dangerous.

NEC Guidelines for Safe Panel Installation

🪫 3. The Voltage Drop Test — The Step Most DIYers Don’t Even Know Exists

Before installing a furnace, run a voltage drop test from the panel to the proposed furnace location.

How to Test Voltage Drop

-

Measure unloaded voltage (L1–L2).

-

Plug in a resistive load like a heater or load bank.

-

Re-measure voltage under load.

If voltage drops more than 3%, you need:

-

Larger wire gauge

-

Shorter run

-

Better connection at panel

High-watt furnaces hate voltage drop.

DOE Energy Delivery Guidelines

https://www.energy.gov/energysaver/energy-saver

🔥 4. Breaker Sizing: Protect the Wires, Not the Furnace

Here’s where most installations go wrong.

Installers match breaker size to the furnace instead of the wiring.

This is backwards.

⚠️ Mike’s Law:

The breaker’s job is to protect the wire — not the furnace.

Never oversize “just to prevent nuisance trips.”

Breakers don’t trip without a reason.

Typical Heat Kit Requirements

-

10 kW → ~60A

-

15 kW → ~80A

-

20 kW → ~100A

But furnace blowers often require their own 15–20A breaker as well.

NEC Ampacity Tables (Verified Reference)

Use these tables to confirm breaker size for copper wire at 60°C or 75°C ratings.

🧵 5. Choosing the Right Wire Gauge: The Most Critical Step of All

Electric furnaces use continuous loads, meaning the NEC 125% rule applies:

Continuous Load Rule:

Furnace amp draw × 1.25 = Minimum circuit ampacity

Then use the NEC wire gauge table to select proper wire size.

Typical Wire Requirements

-

6 AWG copper for 60–70A

-

4 AWG copper for 90–100A

-

2 AWG copper for 110–125A

Copper only unless the manufacturer explicitly allows aluminum with antioxidant paste.

Aluminum’s resistance increases with heat — not good for high-watt strip heat.

🧱 6. Conduit, Routing & Protection — Keeping Wires Safe

Where and how you route furnace wiring drastically affects safety.

Mike’s Routing Rules:

-

No sharp bends stressing conductors

-

No resting wires on sheet metal edges

-

Conduit required for exposed runs

-

Flexible whip allowed only for final connection

-

No junction boxes buried behind the furnace

-

Secure every 3–4 feet

ASHRAE & SMACNA Routing Safety Recommendations

https://www.ashrae.org

https://www.smacna.org

🧲 7. Grounding: The Hidden Stability System

Most people treat grounding as an afterthought.

But with a high-draw electric furnace, grounding is non-negotiable.

Furnace Grounding Checklist:

-

Ground conductor must be continuous

-

Connections must be under torque

-

Bare copper or green insulated only

-

Verify continuity from panel to furnace cabinet

-

Check for correct bonding at panel

If the furnace isn’t grounded properly, heat elements can energize without a safe return path — a major hazard.

🔌 8. Landing the Wires: Stress-Free, Flex-Free, Heat-Proof Terminations

Inside the furnace, wiring mistakes cause more failures than panel errors.

Mike’s Terminal Landing Rules:

-

No loose strands (use ferrules if needed)

-

Torque to manufacturer spec (usually around 35–50 in-lbs)

-

Ensure all lugs are mechanically supported

-

Use high-temperature wire where required

-

Never mix stranded and solid wire under the same screw

Loose terminations cause:

-

Arcing

-

Heat buildup

-

Melted insulation

-

Burned sequencers

-

Flickering elements

This is where a torque screwdriver matters.

🎛️ 9. Heat Strip Sequencer Power Logic — Why Clean Wiring Matters

Heat strips rely on sequencers or relays to bring elements online gradually.

If wiring isn’t perfect, sequencers:

-

Delay incorrectly

-

Fail to open

-

Cause simultaneous inrush

-

Trip breakers unexpectedly

Thermostat Wiring Requirements

From Ecobee and Honeywell documentation:

https://www.ecobee.com

https://www.honeywellhome.com

Clean power ensures sequencers operate at correct timing intervals.

🧯 10. Safety Devices in the Power Circuit — Don’t Disable Them

Electric furnaces include multiple safety layers:

-

High-limit switch

-

Thermal fuse

-

Fusible links

-

Blower interlock

-

Breaker interlocks

-

Overcurrent protection

If any installer bypasses a high-limit switch “just to test,” they’ve invalidated both safety and warranty.

Every safety device exists because someone once got burned — literally.

🧪 11. Mike’s 240V Start-Up Validation Protocol

This is the final commissioning procedure I use to confirm the wiring is perfect.

✔️ Step 1 — Measure incoming voltage (L1–L2)

Should be 228–240V.

✔️ Step 2 — Energize blower only

Voltage should barely drop.

✔️ Step 3 — Stage heat strips one at a time

Verify:

-

Amps match nameplate

-

Voltage drop stays under 3%

-

No flicker in panel lights

-

Breaker temperatures remain normal

✔️ Step 4 — Emergency Heat

Confirms thermostat wiring logic.

✔️ Step 5 — Full Load Test (10 minutes)

Check:

-

Wire temperature

-

Conduit temperature

-

Panel breaker warmth

-

Furnace cabinet heat rise

If anything smells hot or abnormal, stop immediately.

📋 12. Mike’s Complete Clean Power Checklist

Below is the exact checklist I hand to apprentices.

Panel

-

Panel capacity verified

-

Breakers matched to wire ampacity

-

No double taps

-

No corrosion

-

Lugs torqued

Wiring

-

Correct gauge

-

Copper where required

-

Straight routing

-

No pinch points

-

Proper strap spacing

Grounding

-

Furnace bonded

-

Continuous ground path

-

Verified continuity

Sequencers / Heat Strips

-

W2 and E wired correctly

-

Proper delay staging

-

Full amp draw verified

Performance

-

Voltage drop < 3%

-

Stable 240V under load

-

Breakers cool

-

Elements cycle properly

-

Blower responds to heat call

If any box isn’t checked, the furnace isn’t ready.

🎉 Conclusion: Clean Power Is the Foundation of a Healthy Furnace

A high-watt electric furnace is the heart of the home’s heating system — but it’s also one of the largest electrical loads a home will ever carry.

When wired correctly using The 240V Clean Power Protocol, you get:

-

Quiet operation

-

Stable heat

-

Safe element staging

-

Long equipment life

-

Lower electrical costs

-

No nuisance tripping

When wired incorrectly…

you get problems quickly, and often catastrophically.

Following this protocol ensures your furnace receives the clean, stable, balanced power it needs to perform at the top of its game for decades.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know more about: The Vibration Sink Technique: Mike’s Mounting Pads, Wall-Break Strategies & Cabinet Isolation Tricks