When someone installs a high-airflow electric furnace — like the 2,000+ CFM Goodman 20 kW electric furnace — the biggest performance killer isn’t the heat strips, the blower, or the electrical feed.

It’s the duct transition.

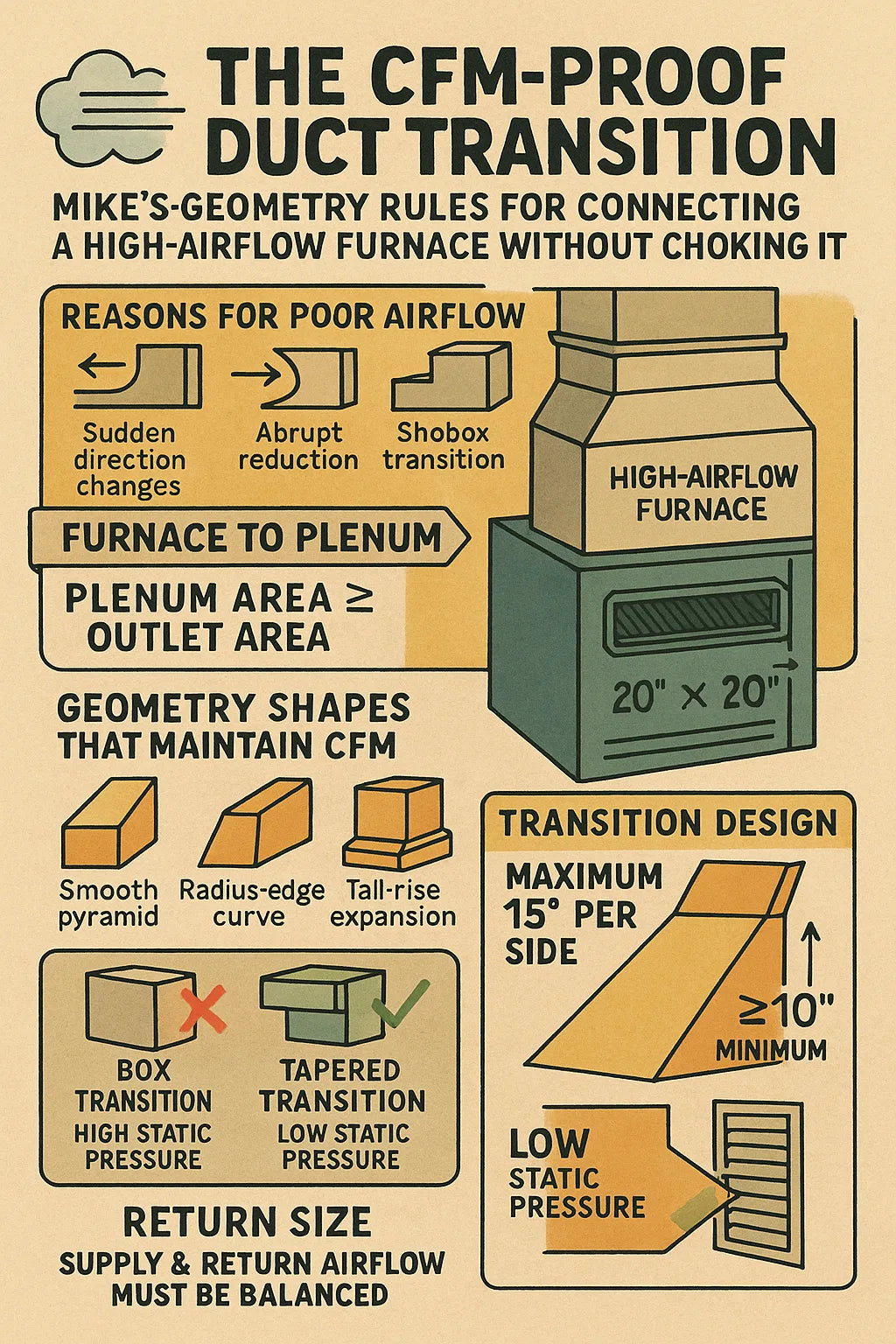

A furnace pushing 1,600–2,000+ CFM cannot perform correctly if the transition between the furnace outlet and the supply plenum is shaped wrong, sized wrong, angled wrong, or attached wrong. A bad transition strangles airflow, creates noise, increases static pressure, overheats heat strips, and destroys efficiency.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow - MBVK20DP1X00, HKTAD201

Most installers still slap on a square-to-rectangle adapter or a sloppy sheet-metal box and call it a day. But in my world — Mike’s world — the geometry of that transition is engineered, not improvised.

This article lays out my complete CFM-Proof Geometry Method, the build rules I use to make sure a furnace’s airflow is never choked, restricted, or turbulent.

📐 1. The Real Reason Transitions Fail: Geometry, Not Gaps

People think transitions fail because of:

-

leaks

-

poor sealing

-

sloppy metal work

But the real reason is geometry.

Air hates:

-

sudden direction changes

-

sudden velocity changes

-

sudden compression

Yet most transitions do exactly those three things.

Mike’s Core Rule:

Airflow behaves like water — give it a smooth river, not a concrete corner.

This means:

-

No 90° shifts

-

No abrupt reductions

-

No “shoebox” transitions

-

No throat pinch points

-

No supply plenums narrower than the furnace

If the duct transition violates smooth geometry, the CFM will drop — no exceptions.

🔳 2. Furnace to Plenum Sizing: Mike’s Golden Area Ratio

The #1 rule in duct geometry:

The supply plenum must have equal or greater cross-sectional area than the furnace outlet.

Otherwise, you’re compressing moving air — and compression causes static pressure spikes.

Example

If a furnace has a 20" × 20" discharge opening:

Your plenum must be 400 sq in or larger.

If it’s smaller:

-

CFM drops

-

Blower uses more watts

-

Heat strips overheat

-

Noise increases

-

Motor lifespan shortens

Verified Reference

ACCA Manual D (Duct System Design)

https://www.acca.org

This manual backs up the area-matching principle.

🧩 3. Mike’s Four Geometry Shapes That NEVER Choke CFM

After hundreds of installs and field fixes, these are the only transition geometries I trust.

Shape 1 — The Smooth Pyramid Transition

A four-sided tapered transition where each wall changes angle at ≤15°.

Shape 2 — The Radius-Edge Curve Transition

Sheet metal bent into a gentle curve for ultra-low static pressure.

Shape 3 — The Offset Pyramid

Used when the furnace and plenum aren’t perfectly aligned.

Shape 4 — The Tall-Rise Expansion Box

Not preferred, but useful when height constraints exist.

The 15° Rule

Never exceed 15° of directional change per side.

More than 15° and airflow separates from the walls → turbulence → pressure loss.

(This is physics — not opinion.)

🧱 4. Transition Height: The “Rise-to-Run Ratio” That Makes or Breaks Performance

A transition must be tall enough to expand airflow smoothly.

Mike’s Rule:

Minimum transition rise = 10 inches

Ideal = 12–18 inches

Short transitions cause:

-

Back-pressure against the blower

-

Uneven airflow into branches

-

Loud whooshing sound

-

Higher watt draw

I fix more choking problems by increasing plenum height than anything else.

🔧 5. Static Pressure Reality Check: Why Most Systems Are Already Too Tight

Even without a transition, many homes have duct systems that are already borderline restrictive.

Most systems run at:

0.6–0.8 in.wc static pressure → Too high

A properly designed system runs at:

0.3–0.5 in.wc

Every 90° turn, every small grille, every dirty filter adds resistance. A bad transition is simply the final straw.

Testing Tools

You can verify static with a manometer.

ASHRAE duct recommendations support it:

https://www.ashrae.org

Mike’s Operating Rule:

If static is above 0.5 in.wc, the transition must be a long taper — no exceptions.

🧲 6. Why “Shoebox Transitions” Kill Airflow

A shoebox transition is:

-

A rectangular box

-

Same height as the furnace

-

With no taper or curve

These are static pressure bombs.

They create:

-

Instant velocity drop

-

Turbulence pockets

-

Uneven distribution

-

Extremely loud operation

Even if sheet metal looks neat, airflow inside looks like a hurricane.

Never use them.

🪚 7. Mike’s Step-by-Step Process for a Perfect Transition

Here’s the exact workflow I use in the field.

🔹 Step 1 — Measure the Furnace Outlet

Record:

-

width

-

height

-

collar depth

-

screw flange width

Example:

Goodman MBVK20DP1X00 = 20 × 20 = 400 sq in

🔹 Step 2 — Measure the Plenum Area

If the plenum is smaller than the furnace → rebuild it.

If it’s larger, ensure the transition expands evenly.

🔹 Step 3 — Determine the Transition Angle

Use this formula:

If rise is too small → angle too steep → choking guaranteed.

🔹 Step 4 — Build the Transition with Smooth Edges

I prefer:

-

26-gauge metal minimum

-

1" reinforcement ribs

-

No internal corners sharper than 90°

-

No inward bends

🔹 Step 5 — Install Turning Vanes (When Needed)

Only install vanes when:

-

The plenum immediately turns 90°

-

Or airflow has to be redirected sharply

Never install vanes inside the transition itself.

🔹 Step 6 — Seal and Torque

Use:

-

Mastic (not tape) for seams

-

Minimal screw penetration

-

Even torque to avoid flexing

💨 8. Return Air Balance — The Often Ignored Part of the Transition

People forget that supply and return airflow must match.

A perfect supply transition is useless if the return is undersized.

DOE guidelines on HVAC airflow balance validate this:

https://www.energy.gov/energysaver/energy-saver

Mike’s Return Ratio:

Return must be 10–20% larger than supply for electric furnaces.

This prevents:

-

cabinet vibration

-

heat strip overheating

-

blower overamp

-

noise amplification

If returns are too small, even the most perfect transition chokes.

🔍 9. Six Common DIY Transition Mistakes (and Mike’s Fixes)

Mistake 1: Transition is too short

Fix: Minimum 10" rise, ideally 12–18".

Mistake 2: Plenum smaller than furnace outlet

Fix: Rebuild plenum to meet or exceed area.

Mistake 3: Angles too steep

Fix: Keep each wall under 15°.

Mistake 4: Box transitions used

Fix: Replace with tapered transition.

Mistake 5: No allowance for duct branch turbulence

Fix: Install smooth-taper plenum extensions.

Mistake 6: High static pressure ignored

Fix: Measure ESP before and after transition.

🧰 10. Mike’s Field Verification Test for CFM-Proofing

This is the practical performance test I trust the most.

✔️ Step 1: Run Blower on Heat Speed

Expect full CFM output.

✔️ Step 2: Measure External Static

Target: 0.3–0.5 in.wc

✔️ Step 3: Listen

Noise reveals turbulence:

-

whooshing = narrowing

-

booming = restriction

-

whistling = sharp edges

✔️ Step 4: Feel Supply Temperature

If heat strips are staged correctly but the temp is low → airflow imbalance.

✔️ Step 5: Check Throw Patterns at Vents

Uneven throw = turbulence in transition or plenum.

🏁 11. Why Good Transitions Outperform Bigger Blowers

Most people try to fix airflow problems by:

-

increasing blower speed

-

upgrading motors

-

adding branch dampers

But none of this works if the transition is wrong.

A perfect transition:

-

increases actual CFM

-

lowers blower watt draw

-

increases heat strip lifespan

-

drops noise dramatically

-

improves comfort at every register

Good geometry beats brute force every single time.

🎉 Conclusion: Airflow Never Lies — Geometry Makes or Breaks the Furnace

If the transition is wrong, nothing else in the HVAC system can compensate.

If the transition is right, the furnace runs:

-

quiet

-

smooth

-

efficient

-

safe

-

long-lasting

Remember Mike’s three golden rules:

1. Match or exceed outlet area

2. Limit wall angles to 15°

3. Build with at least 10–18" of rise

Follow these geometry rules and your furnace will move air like a champ — without choking, booming, or burning extra watts.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know more about: The 240V Clean Power Protocol: Mike’s Checklist for Wiring a High-Demand Electric Furnace the Right Way