When someone installs a high-power electric furnace — especially a 15–20 kW model like the Goodman MBVK20DP1X00 with HKTAD201 heat kit — the part that gets messed up the most isn’t the blower, the ductwork, or even the breaker sizing.

It’s the heat strip integration.

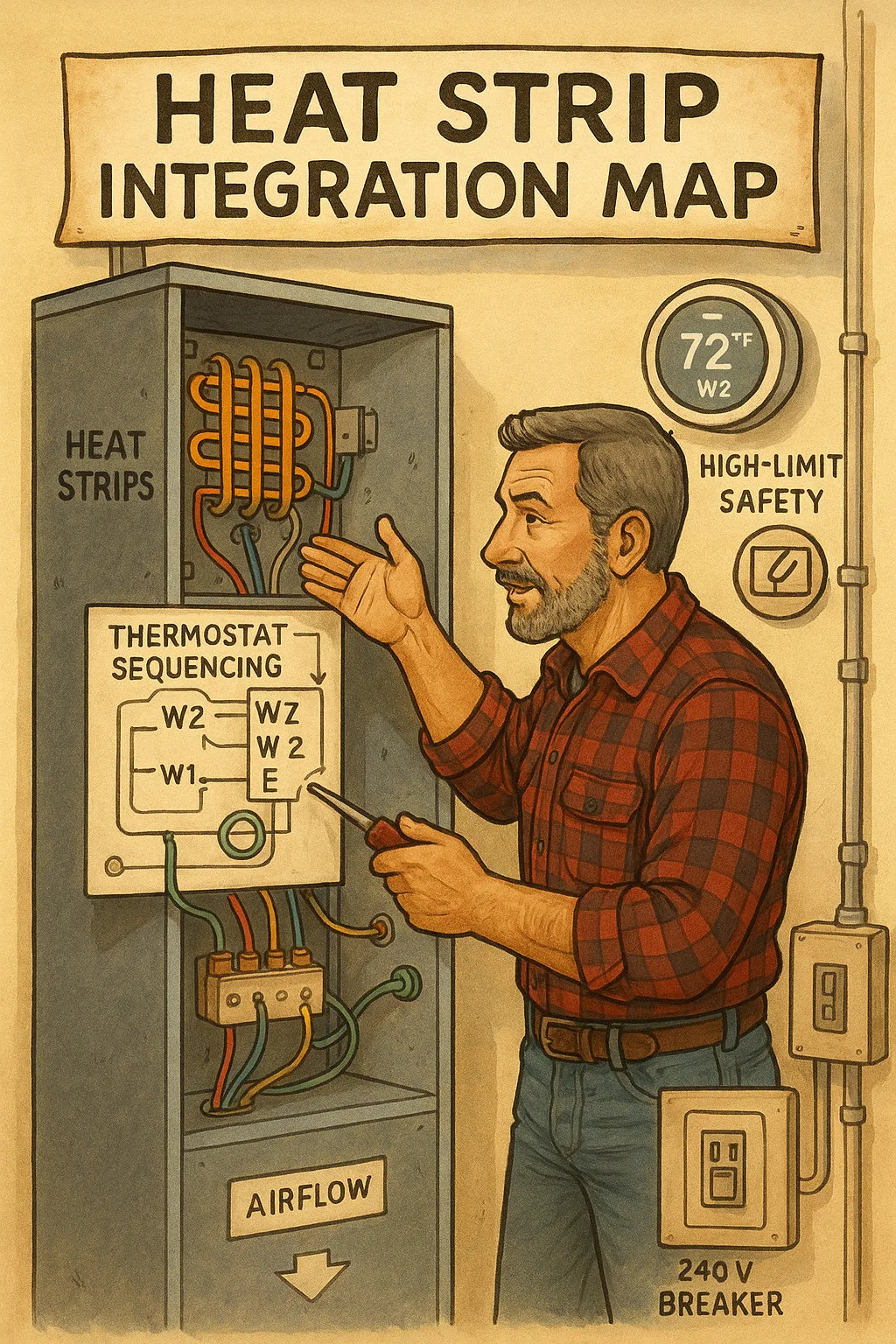

Heat strips look simple: a few electrical elements, a sequencer, and some high-gauge wiring. But behind that simplicity is a carefully choreographed system of timed staging, airflow coordination, electrical protection, high-limit safety, and thermostat logic that determines whether the furnace runs smoothly… or becomes a breaker-tripping, element-burning, airflow-starved headache.

This guide walks you through Mike’s full Heat Strip Integration Map, the method I’ve developed to keep homeowners safe and ensure electric furnaces deliver stable heat without overheating the cabinet, choking the blower, or driving up utility bills.

Let’s get to work.

🧩 1. Understanding What Heat Strips Actually Do — and Why Integration Matters

Before touching wires, screws, or sequencers, you have to know what a heat strip system is.

A heat strip assembly includes:

-

Heating elements (usually nichrome coil)

-

Sequencer(s) or relay banks

-

Terminal block

-

High-limit safety switch

-

Fusible links

-

Blower interlock logic

-

Optional: staging relays

-

Optional: field-installed breakers

Most problems come from installers treating heat strips like “plug-and-play heaters.” They aren't.

Heat strips are designed to:

-

Add supplemental heat during low outdoor temps

-

Provide emergency heat if the heat pump fails

-

Maintain comfortable discharge temps above 90°F

-

Ramp in stages, not all at once

-

Never energize without the blower running

Without proper sequencing and wiring validation, you risk:

❌ Melted connectors

❌ Heat rise beyond listed limits

❌ Tripped main breakers

❌ Burned sequencers

❌ Blower motor overstrain

❌ Hot spots inside the cabinet

❌ Scorched duct insulation

This is why integration — not just installation — matters.

⚡ 2. Mike’s Wiring Overview: The Safe, Correct Electrical Path

Heat strip wiring is all about matching load to protection and protection to panel capacity.

Here’s the simple version of my professional rule:

The breaker protects the wires,

the wires protect the heat kit,

and the heat kit protects the homeowner.

Typical Wiring Flow for a 10–20 kW Heat Kit

National Electrical Code (NEC) Requirements

-

Electric heat must be on dedicated circuits

-

Breakers must match the ampacity of the heat kit

-

Wiring must be sized for continuous load (125% rule)

You can reference the NEC here:

https://www.nfpa.org

Most DIYers make three wiring mistakes:

-

Incorrect breaker size (overfusing or underfusing)

-

Using aluminum wire where copper is required

-

Failing to separate heat strip and blower circuits

Always follow manufacturer wiring diagrams and NEC guidelines.

🧠 3. The Sequencing Logic Map — How Heat Strips Turn On Without Killing Your Breaker

This is one of the biggest misunderstood parts of electric furnace operation.

When heat strips energize, they do NOT turn on all at once.

If they did, you’d see instant lights dimming or full breaker trips.

Instead, sequencers or relays activate gradually.

Standard Sequencing Timeline Example

-

Stage 1: Blower starts (0 seconds)

-

Stage 2: First element energizes (10–30 seconds)

-

Stage 3: Second element energizes (30–90 seconds)

-

Stage 4: Third element energizes (if applicable) (60–120 seconds)

The delay reduces:

-

Inrush current

-

Voltage drop

-

Thermal shock to elements

-

Breaker overload

Mike’s Rule: Sequencing must always be verified manually

Too many installers assume factory settings are correct.

They aren’t always.

How to verify:

-

Start system in Emergency Heat mode

-

Use a clamp meter

-

Watch amp draw increase in stages

-

Verify blower starts before any strip energizes

-

Confirm final amp draw matches nameplate

If everything energizes immediately?

Your sequencer has failed — replace it.

🌡️ 4. Airflow Requirements: The Most Ignored Safety Rule of All

If heat strips come on before the blower hits full speed, the cabinet can overheat in under 30 seconds.

Minimum Airflow Rules

Manufacturers list airflow requirements in CFM per kW.

Typical rule-of-thumb:

350–400 CFM per 5 kW of heat

So a 15 kW heat kit requires at least:

The Goodman 20 kW furnace with 2,000 CFM capability easily meets this — but only if:

-

Filters are clean

-

Duct static pressure is under 0.5 in.wc

-

Return air isn’t choked (a very common mistake)

For proper airflow and duct sizing recommendations, refer to ACCA Manuals here:

https://www.acca.org

If airflow is too low, you get:

❌ High-limit trips

❌ Premature element burnout

❌ Overheating smell in ducts

❌ Short-cycling

❌ Excessive watt draw

Heat strip integration fails without airflow verification — period.

🧱 5. The High-Limit Safety Chain — The Last Line of Defense Most DIYers Miswire

Heat kits include:

-

Automatic high-limit switch

-

Manual reset limit switch

-

Thermal fuse or fusible link

These protect the furnace from unsafe temperatures.

Where DIYers Fail

-

Bypassing limit switches “just to test the system”

-

Accidentally wiring around the limit

-

Reinstalling limits incorrectly after replacing elements

-

Not checking continuity after mounting

Limits must be wired exactly as shown in the furnace diagram.

If a limit is bypassed, miswired, or failed closed, the furnace becomes genuinely dangerous.

For safety standards review, see U.S. DOE guidelines:

https://www.energy.gov/energysaver/energy-saver

🛠️ 6. Thermostat Sequencing — The Hidden Part That Determines If Your Heat Strips Behave

Your thermostat decides when heat strips come on — but only if it’s correctly configured.

Correct Thermostat Wiring for Heat Strip Use

-

W2 = Second heat stage (heat strips)

-

W1 = Primary heat stage (blower/heat pump)

-

E = Emergency heat

If W2 isn’t connected or configured correctly, your heat strips may:

-

Never turn on

-

Turn on too early

-

Turn on with the heat pump even when not needed

A thermostat with heat strip support is essential.

Honeywell, Ecobee, and Emerson provide wiring documentation:

https://www.honeywellhome.com

https://www.ecobee.com

🔍 7. Mike’s Heat Strip Integration Checklist

This is the exact field checklist I use on every installation.

✔️ Pre-Wiring

-

Confirm breaker size matches heat kit

-

Confirm wire gauge meets NEC 125% rule

-

Ensure furnace is on dedicated circuits

-

Verify torque on all terminal screws

✔️ Mechanical Assembly

-

Mount heat kit securely

-

Check element spacing and no coil touching

-

Inspect limit switches for intact wiring

✔️ Sequencing Verification

-

Blower starts before heat strip staging

-

Stage 1 amps match nameplate

-

Stage 2 amps match incremental rise

-

Delay timing is smooth and progressive

✔️ Airflow Validation

-

Confirm CFM meets manufacturer table

-

Run blower at max heat speed

-

Check external static pressure

-

Confirm filter door seal isn’t whistling

✔️ Safety

-

High-limit switches tested

-

Fusible link visually inspected

-

Wiring strain relief installed

-

No aluminum wire unless rated

🚨 8. Six Integration Mistakes That Cause 90% of All Heat Strip Failures

Here’s what I see the most on bad installs:

1. Heat strips wired without staged sequencing

Everything energizing at once is catastrophic.

2. Blower not tied into heating call

Elements energize with no airflow → instant overheating.

3. Mis-sized breakers

Either nuisance trips or unsafe overfusing.

4. Undersized ductwork choking the system

Static pressure is the silent killer of electric heat.

5. Thermostat not configured for W2/E

Heat strips never energize — or energize all the time.

6. High-limit bypassing

Never bypass a safety switch.

Not even for 10 seconds.

Not even “just to test.”

🏁 9. Final Integration Test — Mike’s Commissioning Sequence

This is the final 5-minute test I perform before signing off:

Step 1: Call for Heat

System should delay element activation.

Step 2: Measure Amps

Stage 1 → Stage 2 → Stage 3, slowly and predictably.

Step 3: Verify Heat Rise

Supply + Return temp difference must match manufacturer spec.

Step 4: Watch for Limit Trips

If any limit opens → airflow problem, not a wiring issue.

Step 5: Run Emergency Heat

Confirms thermostat and sequencer logic.

This is how you know your integration is bulletproof.

🎉 Conclusion: Heat Strip Integration Isn’t Complicated — But It Must Be Precise

When installed correctly, a heat strip kit makes an electric furnace:

-

Reliable

-

Efficient

-

Safe

-

Smooth-running

-

Low-maintenance

When installed incorrectly, it becomes:

-

Loud

-

Overheating

-

Breaker-tripping

-

Short-lived

-

A safety hazard

The difference is integration — wiring, sequencing, airflow, and safety logic working together in harmony.

Follow the steps in Mike’s Heat Strip Integration Map and you’ll never cook a set of elements or smoke a sequencer again.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know more about: The CFM-Proof Duct Transition: Mike’s Geometry Rules for Connecting a High-Airflow Furnace Without Choking It