Every HVAC installer learns early that water and electricity don’t mix. But in the furnace world, too many people think only air conditioners leak, only heat pumps sweat, and only drain pans matter.

Wrong.

When you install a high-wattage electric furnace, especially one with 10–20 kW heat strips, the real enemy isn’t runoff water — it’s airborne moisture.

Humidity, condensation, vapor migration, and wet building materials are silent killers. They corrode terminals, pit sequencers, rust the cabinet, deteriorate wiring, and even trigger nuisance high-limit lockouts. I’ve replaced more burned elements from moisture exposure than almost any other failure mode — and almost always in furnace rooms with no moisture-control prep.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow - MBVK20DP1X00, HKTAD201

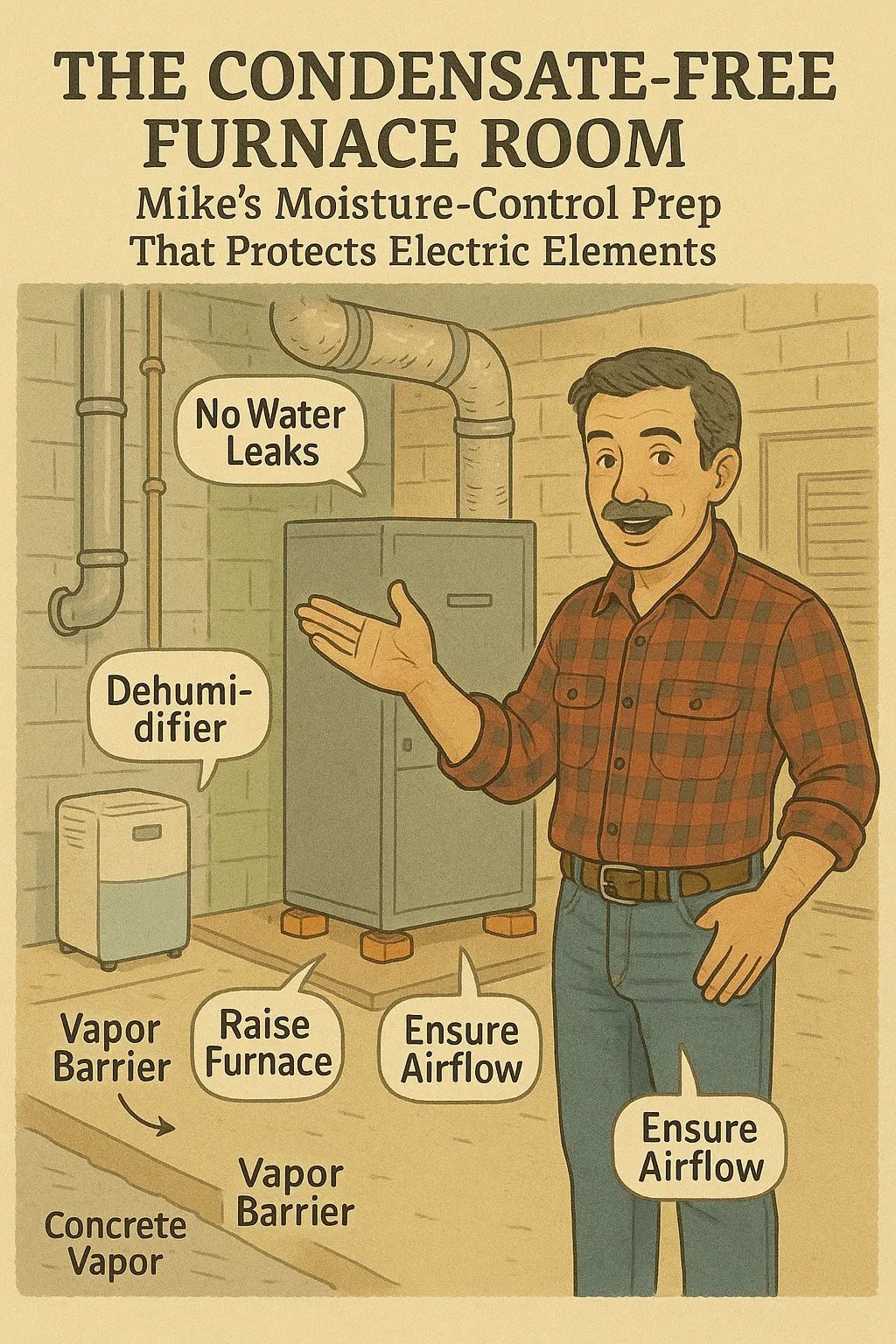

This guide lays out my complete “Condensate-Free Furnace Room” prep process — a moisture-defense system that keeps electric elements safe, wiring dry, and cabinets corrosion-free for decades.

🧐 1. Why Electric Furnaces Hate Moisture More Than Other HVAC Units

Electric furnaces don’t burn fuel and don’t create combustion vapor. They should be dry environments. But because many are installed in:

-

basements

-

crawlspaces

-

garages

-

utility rooms

-

laundry areas

…they’re constantly exposed to moisture in ways that gas furnaces aren’t.

How moisture destroys electric furnace components:

-

Oxidizes heat strip terminals → leads to high resistance → overheating

-

Rusts sequencer plates → causes stuck relays

-

Corrodes blower wheel and motor shell → unbalances blower

-

Causes dripping onto element coils → flash-off events

-

Increases electrical resistance at lugs → breaker trips

-

Shortens life of transformers and boards

An electric furnace needs a dry atmosphere, or the entire system ages prematurely.

Supporting research

U.S. DOE Moisture Control & Ventilation Guidelines:

https://www.energy.gov/energysaver/energy-saver

🧩 2. Mike’s Furnace-Room Moisture Triangle: Source → Movement → Contact

Before you build a moisture-free environment, you must understand the three-part triangle:

1. Moisture Source

Where is water or humidity coming from?

2. Moisture Movement

How does it travel through air, walls, floors, and equipment zones?

3. Moisture Contact

Where does it finally touch the furnace?

Break any part of the triangle and the system stays dry.

🧱 3. Stage One: Eliminate Moisture Sources in the Room

Start by removing every source of water that can enter the furnace space.

🍃 Source Type A: Airborne Humidity

Common in basements, crawlspaces, laundry rooms, and coastal climates.

Fixes:

-

Seal foundation cracks

-

Install dehumidifier (40–55% RH target)

-

Insulate cold-water lines

-

Wrap refrigerant lines from nearby AC systems

-

Ensure exterior doors seal properly

Humidity control is the #1 factor in furnace longevity.

🏚️ Source Type B: Ground or Foundation Moisture

Concrete is porous — it wicks water upward and evaporates it into the room.

Fixes:

-

Install vapor barriers

-

Apply concrete sealant

-

Raise furnace off the floor (4–6”)

-

Ensure sump pump is functional

-

Extend exterior downspouts

Verified building science reference

EPA Moisture Control Guidelines:

https://www.epa.gov/mold

🚰 Source Type C: Mechanical Water Sources

These include water heaters, laundry machines, water softeners, and broken drainpipes.

Fixes:

-

Maintain 3 ft clearance between any water source and furnace

-

Install drip trays

-

Add shutoff valves on washing machine supply lines

-

Insulate cold water pipes

If it can leak, drip, sweat, or burst — keep it away from the furnace.

🌬️ 4. Stage Two: Control Moisture Movement Through Air & Surfaces

Now that you’ve eliminated sources, you block the pathways moisture uses to reach the furnace.

🪟 Movement Path A: Air Leakage (Infiltration)

Unsealed walls, floors, and ceilings leak humid outdoor air.

Mike’s Air-Sealing Checklist:

-

Seal rim joists with foam

-

Install weatherstripping around utility room door

-

Caulk wall penetrations

-

Seal around refrigerant lines and gas lines (if present)

-

Install insulated access panels

Verified HVAC envelope guidance

ACCA Manual RS — Residential Envelope & Sealing

https://www.acca.org

🧊 Movement Path B: Cold Surfaces Creating Condensation

When warm indoor air hits a cold surface, condensation forms — sometimes directly above the furnace.

Common culprits:

-

uninsulated metal ducts

-

water lines

-

foundation walls

-

steel support beams

-

uninsulated attic hatches

Fix:

Wrap or insulate anything cold.

📦 Movement Path C: Vapor Diffusion Through Walls

Moisture vapor slowly migrates through porous materials.

Fixes:

-

Install vapor retarder paint

-

Add polyethylene barriers (where allowed)

-

Ensure basement walls are insulated correctly

🛡️ 5. Stage Three: Prevent Moisture Contact With Electric Components

This is where most furnace rooms fail.

Even if the room is only slightly humid, the furnace itself becomes a moisture magnet because:

-

electric elements heat up and cool quickly

-

cooling cycles draw moist air into cabinet

-

metal surfaces sweat when cold

Here’s how to stop that.

🔩 6. Mike’s Cabinet Protection System

These internal protections keep electric components safe even when room RH fluctuates.

🔧 Technique 1: Raise the Furnace on Isolation Pads

Never install an electric furnace directly on concrete.

Use:

-

4–6” risers

-

neoprene isolation pads

-

composite blocks

This prevents moisture wicking from floor to cabinet and reduces corrosion.

🌀 Technique 2: Control Airflow Into the Furnace Room

Most furnace rooms lack ventilation strategy.

Use:

-

louvered doors

-

passive return grilles

-

transfer grilles for balanced pressure

A sealed room traps humidity like a jar.

🛑 Technique 3: Filter Door Isolation

Filter doors often create condensation from temperature differential.

Add:

-

neoprene gasket

-

magnetic latch

-

anti-rattle tape

This keeps warm and cold air separated around the cabinet.

🧱 Technique 4: Install a Moisture Shield Behind the Furnace

A reflective or vinyl moisture barrier stops condensation forming on colder exterior walls and dripping onto furnace.

Options:

-

foil-faced bubble insulation

-

moisture-retarder sheeting

-

rigid foam board

🧼 Technique 5: Anti-Corrosion Terminal Treatment

Heat strip terminals should be treated with an anti-oxidation compound.

This prevents:

-

oxidation

-

high-resistance points

-

terminal overheating

Even a thin layer of corrosion can increase terminal temperature by 20–40°F.

🌡️ 7. Moisture vs. Heat Strips: The Hidden Failure Mode

Electric elements operate at 1,000–1,600°F surface temperatures.

When moisture hits them:

-

water flash-boils

-

element coating fractures

-

coil brittles

-

resistance changes

-

premature burnout occurs

Humidity doesn’t need to be high — even 60–70% RH increases this risk dramatically.

🧰 8. Mike’s Condensate-Free Commissioning Checklist

Before powering an electric furnace for the first time, I check these items.

ROOM CONDITIONS

-

RH under 55%

-

No visible condensation on pipes or ducts

-

Floor dry

-

No musty smell

-

Walls insulated if touching exterior

FURNACE CONDITIONS

-

Cabinet dry inside

-

No rust on blower or housing

-

Heat strips visually clean

-

Sequencers not oxidized

MECHANICAL CONDITIONS

-

No water lines directly above furnace

-

Condensate lines from AC routed safely away

-

No return-air leaks pulling basement air into cabinet

ELECTRICAL CONDITIONS

-

Terminal lugs clean

-

No green oxidation

-

Correct wire gauge

-

Heat strips ohm-tested

If anything is wet, sweating, rusted, or humid — system stays off until fixed.

🧪 9. Diagnosing Moisture Problems After Installation

If a homeowner calls six months later with noise, smell, or operational issues, here’s what moisture damage typically looks like:

| Symptom | Moisture Cause | Fix |

|---|---|---|

| breaker tripping | oxidized terminal | clean + apply antioxidant |

| furnace smell | damp insulation | dry room + replace panel insulation |

| rattling | blower rust throw-off | clean wheel + stop moisture |

| uneven heat | sequencer malfunction | replace sequencer |

| buzzing | terminal corrosion | tighten + treat |

Moisture problems never “go away” — they accelerate.

🛠️ 10. Pro-Level Furnace Room Moisture Upgrades

If you want true long-term protection, I recommend:

1. Dedicated Dehumidifier

Aim for 45–55% RH.

2. Insulated Supply Duct

Prevents sweating above furnace.

3. Sloped Floor or Drain Path

If anything leaks, it drains away — never toward furnace.

4. Wall Insulation (Rigid Foam or Spray Foam)

Keeps surfaces warm → eliminates condensation.

5. Sump Pump with Battery Backup

A flooded basement destroys an electric furnace instantly.

ASHRAE residential moisture control recommendations:

🎉 Conclusion: A Dry Furnace Room Is a Long-Lived Furnace Room

Electric furnaces are simple machines — but extremely sensitive to moisture.

If the room is damp, the furnace will age prematurely.

If the room is dry, the furnace will last decades.

Mike’s Condensate-Free Prep Method delivers:

✔️ Dry cabinet

✔️ Corrosion-free terminals

✔️ Protected heat strips

✔️ Stable sequencer operation

✔️ No flash-off events

✔️ Lower maintenance costs

✔️ Longer equipment lifespan

Moisture is invisible — until it ruins your furnace.

Control it now, and the system will thank you for the next 20 years.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know more about: Mike’s Airflow Path Audit: How to Arrange Returns, Supply Branches & Vents Before Installing Anything