Most HVAC installs fail before the furnace or air handler is even unboxed.

The equipment arrives perfectly engineered. The blower is balanced. The elements or coils are ready. The controls are flawless.

Yet once installed, the system:

-

overheats

-

short-cycles

-

starves for air

-

pressurizes rooms incorrectly

-

can’t hit setpoint

-

feels drafty

-

drives up utility bills

-

sounds like a wind tunnel

Why?

Because someone guessed the airflow path instead of engineering it.

After fixing thousands of airflow disasters in homes, here’s the truth:

Your system will only run as well as the airflow path you give it.

The blower does not “make airflow.”

The duct system permits or prevents airflow.

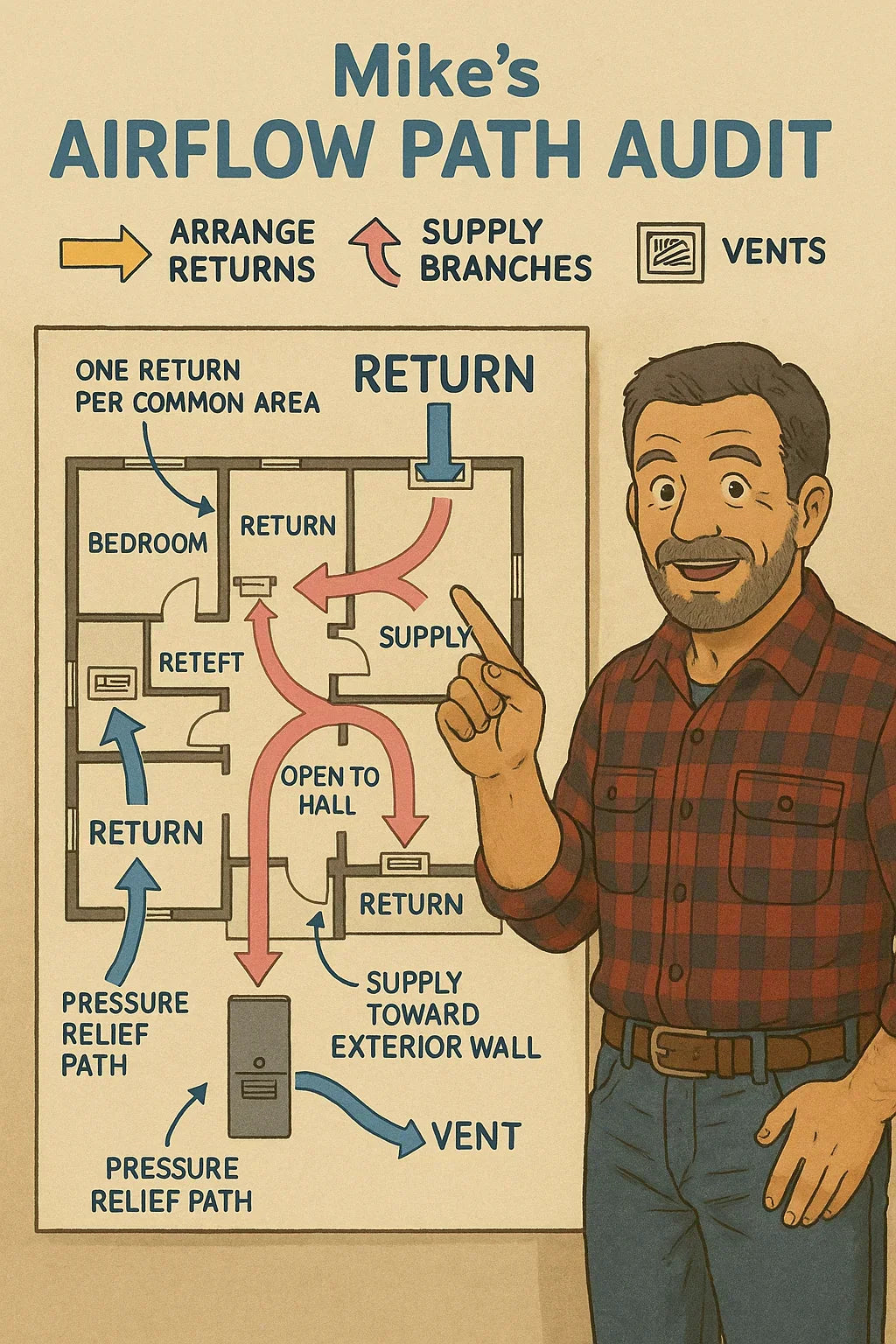

This guide walks you through Mike’s Airflow Path Audit, the method I use to pre-design return placement, supply branch strategy, vent layout, room-by-room throw patterns, and pressure balance — before installing anything.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow - MBVK20DP1X00, HKTAD201

🌪️ 1. Airflow Path 101: What Air Wants to Do (Not What You Want It to Do)

Before designing ducts or vents, you need to understand the physics of airflow.

Air naturally moves:

-

from high pressure → low pressure

-

by the path of least resistance

-

in smooth arcs rather than sharp turns

-

toward temperature differences

-

based on surface friction and duct geometry

So HVAC design isn’t about forcing air — it’s about guiding it.

Airflow Only Works When:

✔ returns are placed strategically

✔ supplies point toward load-bearing surfaces

✔ pressure inside rooms remains near neutral

✔ duct resistance stays low

Verified source on airflow fundamentals

ASHRAE Fundamentals Handbook

https://www.ashrae.org

🏠 2. Step One: Map the Home’s Airflow Geometry (Before Choosing ANY Duct Placement)

Most installers start by placing the furnace.

Wrong.

You start by analyzing how air moves through the home when the blower is running.

This mapping requires four layers.

📐 Layer 1: Identify the Thermal Boundaries

These include:

-

exterior walls

-

areas with high solar load

-

basements

-

attic-facing walls

Hottest surfaces dictate where supplies go.

Coldest surfaces dictate return strategy.

🪟 Layer 2: Identify Airflow Obstructions

Airflow hates:

-

hallways with 90° turns

-

closed bedrooms

-

stairwells

-

long narrow corridors

-

dropped ceilings

-

bulkheads

Mark these on the audit map.

⚡ Layer 3: Identify Mechanical Anchors

These are places where ducts must pass or avoid:

-

beams

-

plumbing stacks

-

chimneys

-

electrical panels

-

load-bearing framing

-

fire blocking

These don’t dictate airflow — but they dictate realism.

🧭 Layer 4: Identify Room Pressure Zones

Every room should be close to 0 Pascals relative to the central zone.

Rooms with only a supply and no return path often go:

-

positive pressure (air trapped inside)

or -

negative pressure (air stolen through cracks)

Which leads us to the next stage.

🔁 3. Step Two: The Return Air Strategy — The Heart of the Airflow Path Audit

Supplies get all the attention.

But returns determine whether a system breathes.

Mike’s Rule:

A system with perfect returns will almost always perform well.

A system with bad returns will never perform well.

Here’s how to design perfect returns.

🔵 Rule 1: One Return Per Common Area — NOT Per Floor

Open areas share pressure.

Floors do not.

Ideal return placements:

-

living room

-

hallway junction

-

open loft

-

large basement room

🟣 Rule 2: Never Put the Main Return in a Room with a Door

If the door closes, you starve the system.

🟡 Rule 3: Bedrooms Must Have a Pressure Relief Path

Options:

-

undercut door (¾ inch max)

-

transfer grille

-

jump duct

-

dedicated small return

DOE ventilation guidelines support pressure balancing:

https://www.energy.gov/energysaver/energy-saver

🟢 Rule 4: Return Must Be 15–20% Larger Than Total Supply Area

This prevents:

-

heat strip over-temperature

-

blower strain

-

duct boom

Reference: ACCA Manual D (return sizing tables)

https://www.acca.org

🌬️ 4. Step Three: Supply Branch Strategy — How to Feed Rooms Evenly

This is where most installers get lazy and use a “spider duct” layout.

But real airflow design uses branch logic.

🧩 Supply Branch Rule 1: Supplies Follow the Load

Place supplies:

-

under windows

-

near glass sliders

-

on exterior walls

-

facing solar load surfaces

This “cuts off” heat gain before it enters the room.

🧩 Supply Branch Rule 2: Branches Must Reduce Static, Not Add to It

Use:

-

long-radius elbows

-

smooth metal, not flex

-

wide-radius boots

-

minimal 90° angles

SMACNA duct construction standards verify this:

https://www.smacna.org

🧩 Supply Branch Rule 3: Keep Velocity Under 900 FPM in Branch Runs

Fast-moving air is noisy and turbulent.

Below 900 FPM = comfort.

🧩 Supply Branch Rule 4: Trunk-and-Branch Outperforms Spider Layout

A trunk keeps pressure stable.

A spider layout makes every run a bottleneck.

🎯 5. Step Four: Vent Placement — The Part Homeowners Always Feel

Vent placement determines:

-

airflow throw

-

mixing of room air

-

elimination of hot/cold spots

-

comfort in seating areas

Vent placement is the difference between comfort and complaints.

🪟 Vent Rule 1: Throw Toward the Load

Point vents at:

-

windows

-

exterior walls

-

sunlit walls

Air mixes more efficiently.

🪑 Vent Rule 2: Never Blow Air at Furniture or Curtains

Obstructions kill throw patterns.

🌬️ Vent Rule 3: Use Opposing Vents in Large Rooms

Two smaller vents beat one big one every time.

🧊 Vent Rule 4: Ceiling Vents Should Not Blow Straight Down

Angle them across the room to prevent drafts.

🧲 6. Step Five: Pressure Balance — The Most Overlooked Part of the Audit

Even if returns and supplies are perfect, you can still ruin airflow with pressure imbalance.

Pressure imbalance causes:

-

cold bedrooms

-

whistling doors

-

poor filtration

-

infiltration of outdoor air

-

blower strain

Mike’s Target:

Every room = ±1 Pascal relative to hallway.

How to achieve this:

-

add transfer grilles

-

widen return pathways

-

increase supply duct size

-

reduce branch friction

🧪 7. Step Six: The Walkthrough Audit — Before Any Equipment Is Installed

This is the on-site process I use to finalize duct and vent layout.

🚪 Audit Step 1: Open & Close Every Door

If a room should receive airflow but seals tight when closed → add relief path.

🧱 Audit Step 2: Stand in Each Room & Identify the Load Wall

This tells you where the vent must blow.

🪟 Audit Step 3: Identify Where People Sit, Sleep, Work

Never blast air at:

-

couches

-

pillows

-

desks

-

dining tables

Comfort > BTU math.

🛠️ Audit Step 4: Use a Laser to Mark Return Centerlines

Return placement is geometry — not guesswork.

📏 Audit Step 5: Calculate Required CFM per Room

Use ACCA Manual J or load software.

Goal = distribute air proportionally.

🌀 Audit Step 6: Confirm Return Air Path Back to Furnace

Must be:

-

unobstructed

-

short as possible

-

not competing with exhaust appliances

EPA indoor airflow recommendations support maintaining neutral pressure in living spaces:

https://www.epa.gov/mold

🔧 8. Mike’s Pre-Install Airflow Layout Template

I create a one-page diagram showing:

✔ Main Trunk

✔ Supply Branches

✔ Return Locations

✔ Vent Directions

✔ Pressure Relief Paths

✔ CFM per Room

✔ Branch Diameters

✔ Duct Lengths

This becomes the installation blueprint.

If the duct team doesn’t have this, the system is a gamble.

🏁 9. Real-World Results: What Happens When You Use This Audit

Homes with proper airflow path auditing experience:

-

Even temperatures across the home

-

No “cold bedroom problem”

-

Quieter airflow

-

Lower static pressure

-

Higher system efficiency

-

Longer blower life

-

Better filtration

-

Better humidity management

-

Happier homeowners

It’s not an upgrade — it’s the foundation of HVAC performance.

🎉 Conclusion: Never Install Before You Audit

Your equipment is only as good as the airflow you prepare for it.

Mike’s Airflow Path Audit ensures:

✔ returns breathe freely

✔ supplies deliver proper throw

✔ vents eliminate hot/cold spots

✔ pressure stays balanced

✔ ducts follow physics, not convenience

If you audit first, everything else becomes easier — installation, commissioning, performance, comfort.

If you install without auditing…

You’re fixing problems for the next 10 years.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know more about: The Breaker-to-Blower Coordination Plan: Mike’s Rules for Matching Electrical Protection to Actual Airflow Demand