When most people think about sizing breakers for an electric furnace, they focus only on heat strips.

When they think about airflow performance, they focus only on blower speed or ductwork.

But the truth — the part nobody teaches homeowners or even many new installers — is this:

Electrical protection and airflow performance are inseparable.

If your breakers don’t match your blower’s real electrical load, the system will never run right.

Oversized breakers create unsafe conditions.

Undersized breakers trip during normal operation.

Incorrect wire gauge starves the motor.

Wrong blower tap increases amp draw beyond breaker limits.

Improper static pressure sends watt draw skyrocketing.

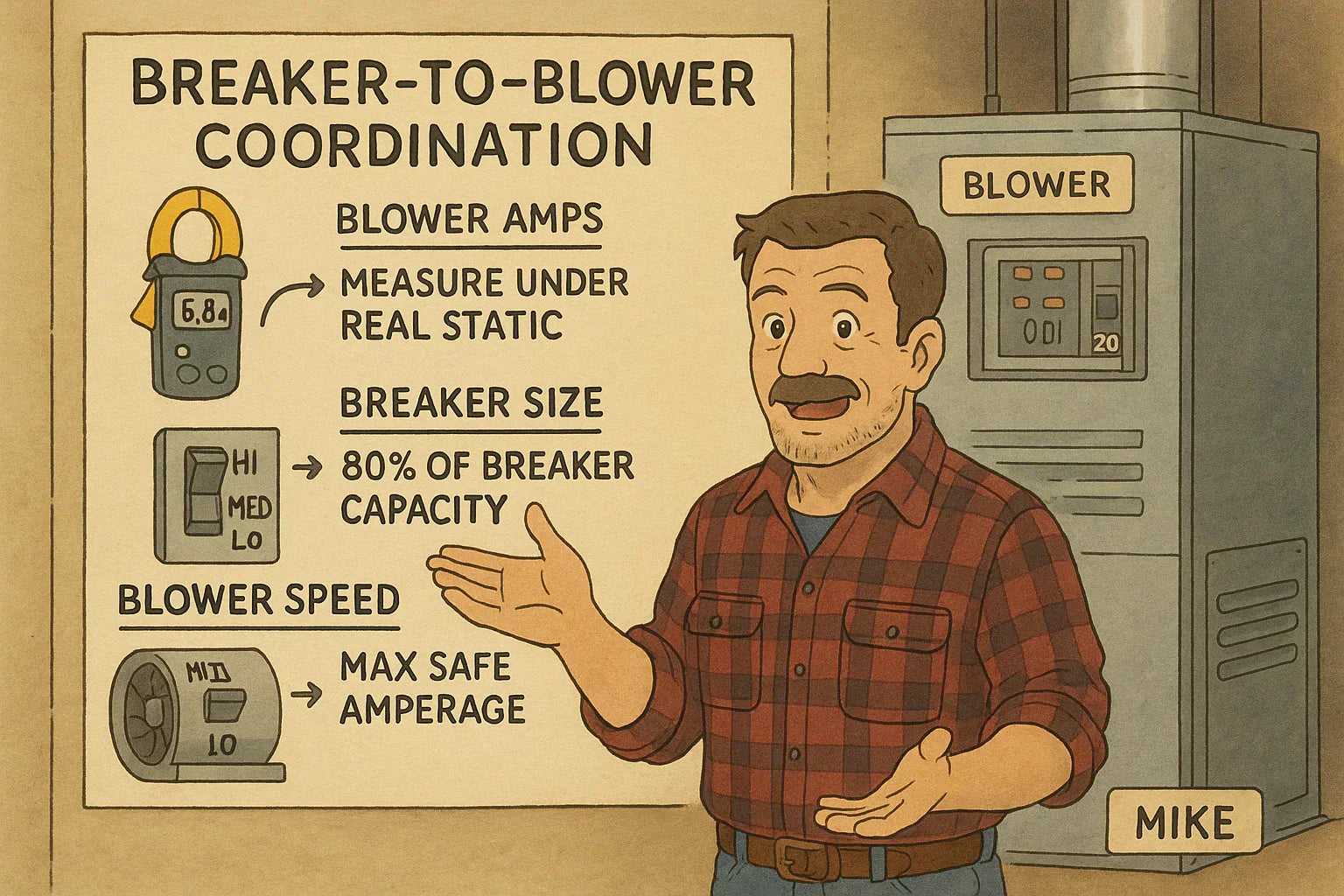

This article lays out Mike’s Breaker-to-Blower Coordination Plan — the method I use in the field to ensure a furnace’s airflow demand matches the electrical protection that feeds it.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow - MBVK20DP1X00, HKTAD201

If you want the blower to last, the heat strips to stay safe, and the system to deliver full CFM without electrical issues, this is the plan you follow.

🧠 1. Why the Breaker and the Blower Must Be Engineered Together

Electric furnaces rely on:

-

heat strips for heating load

-

blower motors for airflow distribution

Heat strips draw massive wattage.

But the blower determines whether those strips overheat or run safely.

Airflow depends on:

-

blower RPM

-

blower motor amperage

-

static pressure

-

supply/return geometry

-

duct resistance

And blower amperage depends on:

-

breaker size

-

wire gauge

-

voltage stability

-

load balance

If either side is mismatched, the system:

-

overheats

-

short-cycles

-

trips breakers

-

delivers low CFM

-

runs loud

-

pulls too many watts

-

reduces heat strip life

This is why breaker and blower decisions must be made simultaneously, not separately.

Supporting NEC electrical safety guidance:

🔌 2. Step One: Identify the Blower’s True Electrical Demand

Every blower motor has two different current ratings:

1. Nameplate FLA (Full Load Amps)

This is the maximum current the motor can draw safely.

2. Real-World Running Amps

This depends on actual static pressure and chosen blower speed.

A blower on “High” under 0.1 in.wc of static might pull 3.5 amps.

The same blower under 0.7 in.wc might pull 7.5 amps.

That’s a 2× increase — without changing anything except airflow resistance.

Mike’s Rule:

Never size a breaker from the nameplate.

Always measure blower amperage under the real static pressure of the installed duct system.

This is the only accurate method.

🌬️ 3. Step Two: Measure the Static Pressure Before Selecting the Breaker

High static pressure = high blower amp draw.

Low static pressure = lower amp draw.

Typically:

-

PSC blowers double amperage as static increases.

-

ECM blowers maintain RPM by pulling more wattage (and more amps).

Meaning ECMs must be electrically protected properly.

Mike’s Target Static:

-

0.30–0.50 in.wc total external static pressure

-

Anything above 0.60 → amps rise fast

-

Anything above 0.80 → blower and heat strips are at risk

Reference for duct pressure standards:

https://www.acca.org (Manual D Air Distribution Design)

🔧 4. Step Three: Match Breaker Size to the Blower Circuit — Not the Heat Strip Circuit

Most installers get this wrong.

Heat strips have their own breaker (60–120A depending on kW).

But the blower requires its own breaker, usually:

-

15A for small PSC motors

-

20A for large PSC motors

-

15–20A for ECM motors

Never run the blower from the heat circuit breaker unless the manufacturer specifically designed it that way.

Why?

Because:

-

blower amps change with static

-

breaker sizes for heat strips cannot protect small-gauge blower wires

-

heat strip overload trips kill airflow

NEC Load & Breaker Requirements for Motors

https://www.nfpa.org

(Motor circuits have special rules for ampacity and protection.)

🔩 5. Step Four: Wire Gauge Must Match Both Breaker AND Blower Load

If wire gauge is wrong, you get:

-

voltage drop

-

conductor heating

-

blower strain

-

extra amp draw

-

breaker trips

-

motor burnout

Mike’s Wire Gauge Rules:

-

14 AWG → max 15A

-

12 AWG → max 20A

-

10 AWG → max 30A

Most blower circuits need 12 AWG copper on a 20A breaker.

Never use aluminum for blower circuits.

🏗️ 6. Step Five: Choose Blower Speed Tap According to Breaker Capacity + Airflow Demand

This is where airflow and electrical coordination meet.

Blower speed taps change:

-

CFM output

-

amp draw

-

noise

-

heat strip safety margin

Example:

Heating Mode:

-

Medium speed may draw 4.1 amps

-

High speed may draw 6.8 amps

If your breaker is only 5A above the medium setting, high-speed may overload it under high static.

Mike’s Rule:

Select the blower speed tap that delivers required CFM without pushing blower amps above 80% of breaker capacity.

That leaves margin for static shifts, filter loading, and duct aging.

🌡️ 7. Step Six: Verify Heat Strip and Blower Coordination

Heat strips must have enough airflow to stay under temperature limits.

If airflow is too low:

-

heat strips overheat

-

high-limit switches trip

-

electrical resistance increases

-

wiring overheats

-

breakers trip

The Heat-to-Airflow Formula:

Heat strips require 350–400 CFM per 5 kW of heat.

Example:

20 kW heat → 20/5 × 350 = 1,400 CFM minimum

If the blower can’t provide this CFM:

-

it pulls more amps

-

may exceed breaker capacity

-

heat strips exceed temperature rise limits

DOE HVAC airflow guidance:

https://www.energy.gov/energysaver/energy-saver

🧯 8. Step Seven: Avoid Shared Breaker Problems

Some furnaces combine:

-

blower

-

control transformer

-

board

-

outdoor unit call circuitry

on a shared circuit.

This may exceed breaker thresholds during:

-

high static

-

cold starts

-

heat strip staging

-

emergency heat

Mike’s Configuration:

-

Dedicated breaker for blower/control circuit

-

Separate breaker(s) for heat strips

-

Outdoor unit ALWAYS on its own breaker

This prevents nuisance trips and protects low-voltage circuitry.

🔍 9. Step Eight: Measure Real Amps After Installation — Not Before

Blower amp draw can only be known after:

-

ductwork is installed

-

filters are in place

-

return drops are sealed

-

registers are installed

-

dampers are opened

-

transitions are completed

Before installation: airflow is theoretical.

After installation: airflow is real.

Mike’s Commissioning Test:

-

Set blower to target speed

-

Close filter door

-

Measure static pressure

-

Measure blower amps on each speed

-

Ensure measured amps ≤ 80% of breaker rating

-

Verify full heat mode without breaker trip

If amps exceed safe limits → reduce static or adjust blower tap.

🛠️ 10. Troubleshooting Breaker-to-Blower Mismatch

If a blower is tripping breakers, these are the likely causes:

| Symptom | Cause | Fix |

|---|---|---|

| Breaker trips after filter change | higher-speed tap + high static | lower speed / reduce static |

| Breaker hot to touch | undersized wire / loose lug | tighten + rewire |

| Blower loud | high RPM due to ECM compensation | reduce static pressure |

| Uneven airflow | blower starving for return air | increase return duct size |

| Trips during heat | heat strips + blower share breaker | separate circuits |

Most blower electrical failures are airflow problems in disguise.

🧰 11. Mike’s Breaker-to-Blower Coordination Checklist

Before calling any job complete, I run through this list:

ELECTRICAL

-

Breaker matches blower amp draw

-

Wire gauge correct for breaker

-

Lugs torqued

-

Voltage between 228–240V

AIRFLOW

-

Static pressure ≤ 0.5

-

Blower speed chosen for safe amperage

-

Returns sized correctly

-

Supply branches balanced

HEAT

-

Heat strip staging verified

-

Temperature rise within spec

-

No high-limit trips

PERFORMANCE

-

Real-world blower amperage tested

-

Full heat mode tested

-

Emergency heat tested

If any item fails, the system is not ready.

🎉 Conclusion: Electrical Protection and Airflow Aren’t Separate — They Are One System

When the blower and the breakers are coordinated properly, you get:

✔ stable airflow

✔ safe heat strip operation

✔ lower energy consumption

✔ longer blower life

✔ quieter performance

✔ no nuisance trips

✔ no overheated wiring

When they aren’t coordinated, the system becomes unpredictable, unsafe, and inefficient.

The Breaker-to-Blower Coordination Plan is how you keep an electric furnace running at peak performance — and protect every component it powers.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know more about: The Clearance Confidence Guide: How Mike Creates Service Space, Code Space & Quiet-Space Around Electric Furnaces