Clearances are the most misunderstood part of electric furnace installation. Most installers think “clearance” just means fire code spacing or keeping combustibles away.

But with a modern high-airflow electric furnace — especially 10–20 kW units like the Goodman MBVK20DP1X00 series — clearances aren’t just safety requirements.

They control:

-

🔧 serviceability

-

🔥 temperature rise

-

🌬️ airflow stability

-

🎧 noise performance

-

🔌 electrical access

-

🧱 vibration behavior

-

🛠️ lifespan of the unit

Get clearances wrong, and the furnace becomes loud, hard to service, starved for air, overheating, and aging twice as fast.

Get clearances right, and the furnace becomes a quiet, cool-running, high-efficiency system that technicians can service easily for decades.

This is Mike’s Clearance Confidence Guide — my complete process for designing the space around an electric furnace before installation begins.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow - MBVK20DP1X00, HKTAD201

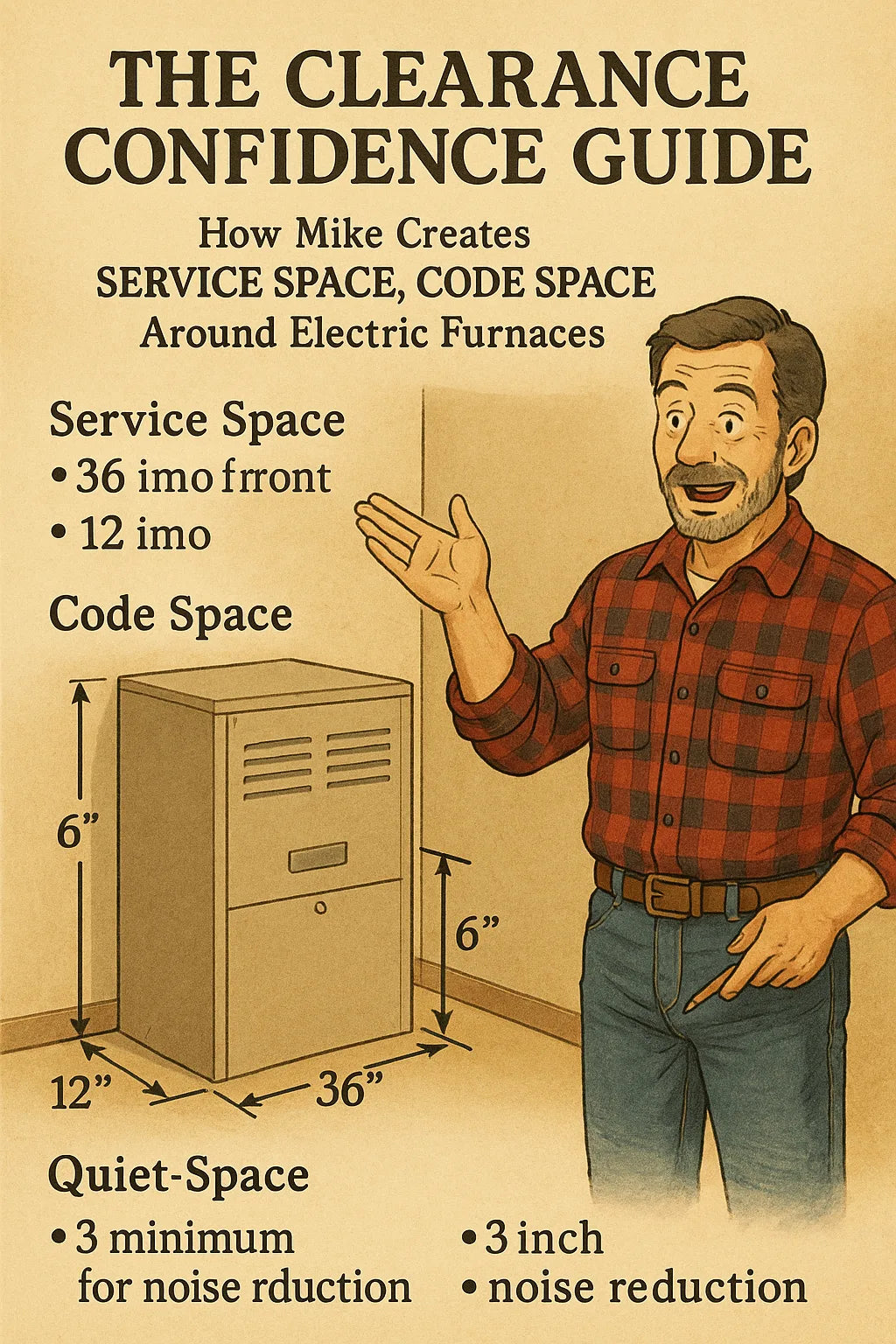

🧭 1. The Three Clearance Zones Every Furnace Needs

Most installers treat furnace clearances as a simple rectangle around the cabinet.

But in my system, there are three zones, each with its own purpose:

1️⃣ Service Space — for humans and tools

Clear area reserved for:

-

door removal

-

filter changes

-

blower extraction

-

electric cabinet access

-

manometer probes

-

heat strip replacement

2️⃣ Code Space — for fire, electrical & safety clearance

This includes:

-

minimum side/back/top distances

-

NEC-required electrical working space

-

return/supply opening distances

-

temperature clearance around wiring

3️⃣ Quiet-Space — for airflow, vibration & acoustic damping

This is where comfort truly happens:

-

preventing wall resonance

-

absorbing blower vibration

-

eliminating duct booming

-

keeping noise out of living spaces

Most installations only account for the second one — code.

But service space and quiet-space are what make a system excellent.

🔥 2. Code Clearances: The Minimum You Must Never Violate

Electric furnaces don’t require the flame clearances of gas units, but they are still governed by NEC (National Electrical Code) and manufacturer minimums.

Typical minimum clearances:

-

1 inch from sides

-

1 inch from back

-

0 inches from supply plenum (if metal)

-

1–2 feet front service access

But don’t rely on “typicals”—always check the manual for your model.

Verified NEC resource:

National Fire Protection Association — NEC

https://www.nfpa.org

Mike’s Rule:

You should never design around the minimum clearance —

you should design around the comfort and service clearance, which always exceeds code.

🧰 3. Service Space: Designing for Real Technicians, Not Hypothetical Ones

Serviceability defines system lifespan.

If a unit is crammed in a corner:

-

blower won’t be cleaned

-

filters won’t be changed

-

heat strips won’t be inspected

-

sequencers won’t be replaced

-

electrical lugs won’t be tightened

In other words:

bad clearances equal bad maintenance equal bad comfort.

Mike’s Service Space Standards

Front clearance: 36 inches minimum

This allows:

-

blower removal

-

panel removal

-

filter swaps

-

multimeter work

Side clearance (service side): 12–18 inches

This is required for:

-

wiring access

-

conduit routing

-

low-voltage connections

Top clearance: 6 inches minimum

Even when code says 0", top clearance improves:

-

wire routing

-

duct transition quality

-

cabinet cooling

Back clearance: 3–6 inches

For:

-

vibration isolation

-

airflow behind cabinet

-

wall protection

These spaces prevent service callbacks and technician frustration.

🎧 4. Quiet-Space: The Secret Clearance Zone Nobody Talks About

This is where Mike’s method stands apart.

Even if a furnace meets code and service requirements, it can still:

-

rattle

-

hum

-

resonate

-

transmit vibration into walls

-

boom through ducts

Why?

Because there isn’t enough quiet-space.

Quiet-Space Is Needed For:

-

vibration dissipation

-

airflow smoothing

-

transition geometry

-

noise buffering

Mike’s Quiet-Space Minimums:

-

1" minimum gap between furnace and any wall

-

2–4" gap between return plenum and wall

-

never mount furnace directly to stud wall

-

use neoprene pads under furnace

-

keep return drop off the ground 1–2 inches

Sound travels through structures, not air.

Quiet-space prevents structure-borne noise.

Verified acoustic engineering concept:

ASHRAE Applications Handbook — Noise & Vibration Control

https://www.ashrae.org

🌬️ 5. Designing Supply & Return Clearance for Maximum Airflow

Airflow around the cabinet matters just as much as airflow through the ducts.

If the cabinet is too close to walls or obstructions, air entering or leaving internal plenums becomes turbulent.

Mike’s Airflow Clearance Rules

Return Drop Clearance

-

2–4" behind return box

-

3–6" on sides if possible

-

Keep return drop centered to avoid wall noise

Supply Plenum Clearance

-

1–2" clearance from ceiling for heat dissipation

-

6–12" before first branch takeoff

-

Never compress a transition against framing

This creates smooth laminar airflow rather than chaotic turbulence.

📐 6. The Geometry of Working Space — Mike’s “Technician Triangle”

Whenever I design a furnace closet or mechanical room, I draw what I call the Technician Triangle.

It ensures enough room for:

-

tool access

-

blower removal

-

part replacement

-

cleaning

-

testing

The Technician Triangle Points:

-

Front access (3 ft minimum)

-

Side access (1 ft minimum)

-

Door swing or panel removal path

If any of these are blocked, the installation will cost more to service every year.

🔌 7. Electrical Working Clearance: NEC Rules That Most Installers Forget

Electric furnaces include:

-

240V heat circuits

-

blower circuits

-

transformer & control circuits

-

sequencers & relays

NEC requires:

30 inches width × 36 inches depth × 78 inches height

for electrical working space in front of energized equipment.

This applies even in residential applications.

Verified NEC working clearance reference:

Many furnace closets violate this — causing dangerous service conditions.

🛠️ 8. Clearances for Duct Transitions & Filter Access

A furnace can be installed perfectly…

…and then ruined by a cramped duct transition.

Duct Transition Clearance

-

Allow at least 10–12 inches above furnace for a smooth transition

-

Avoid “shoebox transitions” caused by low clearance

-

Angle restriction = airflow restriction

Filter Access Clearance

Filters must be easy to remove or they won’t get changed.

Ideal filter door clearance:

-

12–24 inches in front

-

Nothing blocking slide-out path

-

No water heaters or pipes obstructing access

A neglected filter can double external static pressure — killing blower performance.

🧱 9. Wall Material Clearance Considerations

Not all walls are equal.

Against drywall?

Keep 1 inch for airflow.

Against concrete?

Use insulation or moisture barrier.

Against exterior wall?

Avoid condensation by adding thermal break spacing.

Against metal studs?

Use vibration pads or neoprene wall buffers.

🧲 10. How Clearance Affects Furnace Noise

Noise increases in tight spaces because:

-

air accelerates when squeezed

-

air becomes turbulent near surfaces

-

vibration transfers into framing

-

resonance chambers form behind units

Mike’s Silence Formula:

More clearance = less noise.

Less clearance = more complaints.

Give the furnace room to breathe and it becomes silent.

🧪 11. Clearance Testing: Mike’s “Mock Install” Method

Before installing anything, I do this:

1. Draw furnace footprint with tape on floor

Mark clearances around the outline.

2. Place cardboard “plenum” above furnace footprint

Simulate real duct transition height.

3. Position camera/phone in front of unit

Ensure service tech can see screws, lugs, and filters.

4. Open imaginary service door

Ensure swing path is clear.

5. Install imaginary return drop

Check spacing, noise isolation, and wall-breaks.

6. Add imaginary conduit & whip

Check NEC working space.

If anything feels tight now, it’ll be a nightmare later.

🧰 12. Mike’s Clearance Confidence Checklist

Before finalizing any installation, I check:

Service Space

-

36" front

-

12–18" side

-

6" top

-

3–6" back

Code Space

-

NEC electrical workspace correct

-

Manufacturer minimums met

-

Combustibles clear

Quiet-Space

-

Furnace not touching walls

-

Return drop isolated

-

Plenum spaced from framing

-

Neoprene pads used

Airflow Clearance

-

Return openings unblocked

-

Supply transition smooth

-

Filter door accessible

Environmental Clearance

-

No moisture source nearby

-

No obstructions in duct path

When all boxes are checked, the furnace runs quieter, cooler, and longer.

🎉 Conclusion: Clearance Isn’t Empty Space — It’s Performance Space

A furnace doesn’t just need power, airflow, and ductwork.

It needs room to live.

When you apply Mike’s Clearance Confidence Guide, you get:

✔ a quiet furnace

✔ a safer furnace

✔ a cleaner-running furnace

✔ an easy-to-service furnace

✔ a system that outlives its expected lifespan

Clearance isn’t wasted space.

It’s the secret to premium performance, safety, and silence.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know more about: The First-Fire Calibration: Mike’s Post-Install Ritual That Sets Blowers, Heat Strips & Safety Limits for Real Homes