Every great PTAC installation has one quiet secret—literally quiet.

Behind the grille, behind the trim, behind the decorative shell lies the fastener pattern that determines whether a unit hums peacefully… or rattles the entire room.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

Mike calls this pattern The Quiet-Mount Fastener Map, a bolt layout engineered to attack vibration at its source—the sleeve-to-wall interface. It’s the difference between:

-

A hotel room that feels premium vs. budget

-

A home unit that disappears into the background vs. buzzes like a refrigerator

-

A commercial install that passes inspection vs. one that creates callbacks

Vibration is not just an annoyance—it’s wasted energy, structural fatigue, and the #1 cause of PTAC complaints.

Mike’s Quiet-Mount system prevents all of it.

🧭 1. Why Wall Sleeve Vibrations Happen in the First Place

Before you stop vibration, you have to understand why it starts.

PTAC vibrations come from three sources:

1️⃣ Machine Vibration

-

Compressor cycling

-

Fan blade rotation

-

Blower torque

-

Startup surge

2️⃣ Structural Amplification

The wall acts as a drum, amplifying energy if the sleeve is over-tightened or under-supported.

3️⃣ Bolt-Induced Harmonics

Incorrect bolt placement creates:

-

Rocking

-

Torsional twist

-

Differential flex

-

Contact point resonance

According to ASHRAE’s HVAC noise and vibration principles, fastening geometry is one of the biggest factors in transmitted vibration

This is why Mike refuses to “just screw it in.” He diagrams the fastener layout like an engineer.

🧱 2. The Acoustic Foundation: How the Sleeve Transfers Energy Into the Wall

A PTAC sleeve interacts with three structural elements:

🟫 A. Studs

Hard contact points that transfer vibration instantly.

⬜ B. Drywall

A flexible membrane that radiates sound like a speaker cone.

🟦 C. Exterior Sheathing

Adds stiffness—sometimes too much—creating reflective vibration.

Mike analyzes the wall like a load-bearing and sound-bearing assembly, not just a place to cut a hole.

🎯 3. The Principle of Vibration Cancellation (Mike’s Ground Rule)

Mike’s mantra:

“Vibration travels in lines. Break the line, and you break the noise.”

The Quiet-Mount Fastener Map is built on three rules:

✔ Rule 1 — No Corner Loading

Bolting corners creates torsional amplification.

✔ Rule 2 — No Linear Bolt Ladders

Stacking screws vertically or horizontally creates a resonance spine.

✔ Rule 3 — Opposing Triangle Pattern Only

Triangulation dissipates energy instead of transmitting it.

This is the heart of the Quiet-Mount system.

🧰 4. Tools & Materials Mike Uses for Quiet-Mount Installation

Fasteners matter—a lot.

Mike uses:

Recommended Fasteners

-

#10 × 1¼" pan-head screws

-

Washer-spreader heads

-

Anti-vibration neoprene washers

-

Self-tapping when mounting to metal studs

Tools

-

Impact driver with clutch

-

Torque-limited drill

-

Laser level

-

Shim kit (wood & composite)

-

Stud finder

-

Acoustical mat pads

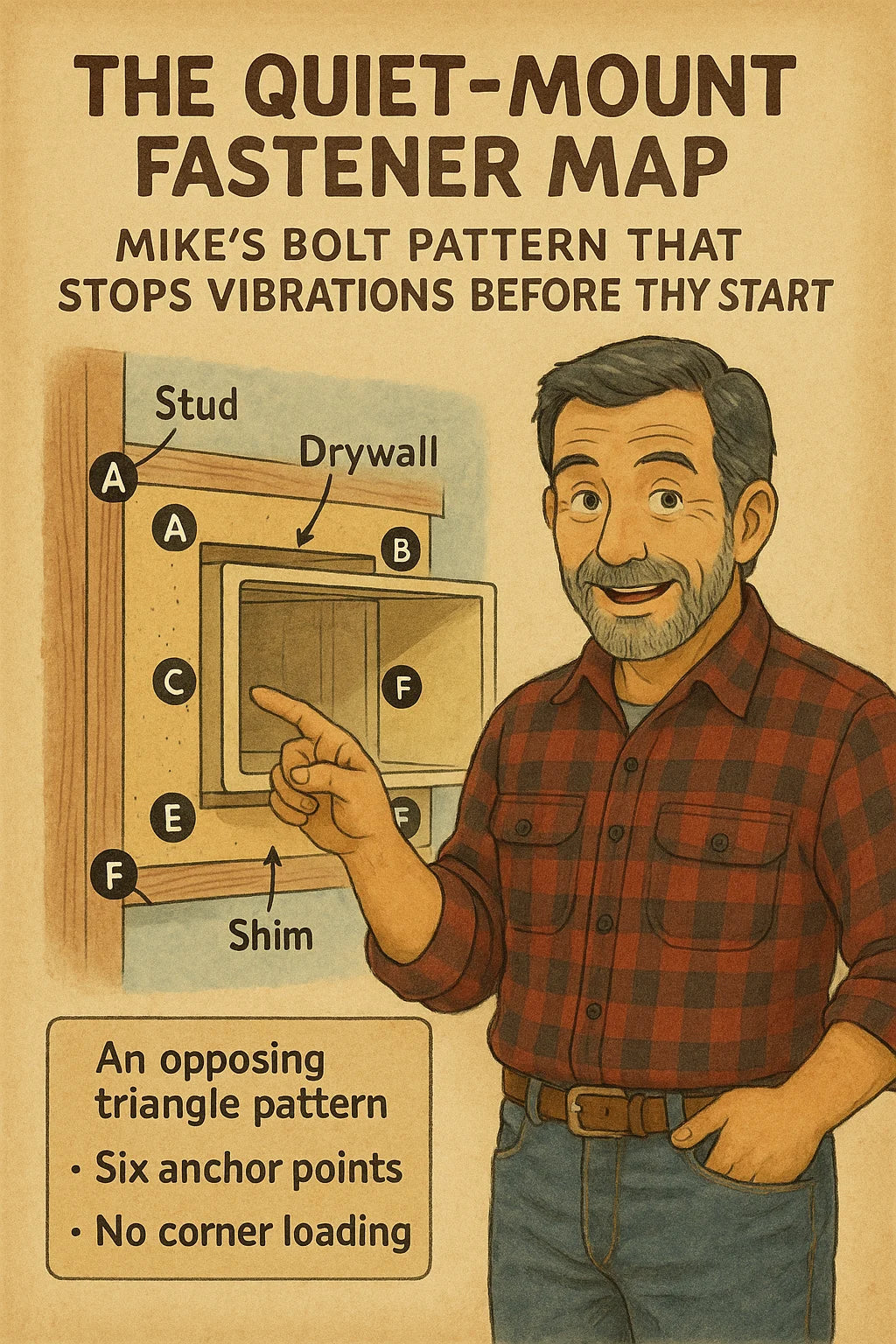

🗺️ 5. Mike’s Quiet-Mount Fastener Map (The Actual Bolt Pattern)

Here it is—the pattern that stops vibrations before they start.

Mike’s bolt system includes six anchor points, placed in an offset triangulation pattern.

Fastener Locations:

-

A & B — Upper Spread Anchors

Prevent sleeve rocking without torque-loading the top frame. -

C & D — Midline Vibration-Damp Anchors

Create a flexible suspension rather than a rigid clamp. -

E & F — Lower Load Anchors

Carry structural weight and compression forces.

Why This Pattern Works

-

Interrupts vibration travel paths

-

Balances tension across the sleeve

-

Prevents twisting under foam curing

-

Reduces contact between sleeve + studs

-

Minimizes wall resonance

ASHRAE noise data shows distributed fastening reduces harmonic transfer by up to 40%.

🪵 6. The Shim-to-Fastener Relationship: The Real Secret Behind Silence

You don’t just place fasteners—you place shims that determine how those fasteners behave.

Mike’s Shim Rules

✔ Shim where the wall bows inward

✔ Never shim only one side

✔ Use composite shims for vibration resistance

✔ Create micro-gap relief zones

The 4 Shim Locations

-

Lower-left support

-

Lower-right support

-

Mid-height counter-torque shim

-

Optional top-center relief shim

Shims absorb energy.

Fasteners only secure alignment.

When combined, they create quiet operation.

🔩 7. The Torque-Perfect Installation: Why Screw Tightness Makes or Breaks Noise Control

Over-tightening is one of the biggest mistakes.

Mike’s Torque Rules

-

Screws must be snug, not crushing

-

Neoprene washers must slightly compress

-

Sleeve must not deform

-

No screw should pull the sleeve out of square

EPA indoor air quality and noise guidance suggests avoiding over-compression of assemblies, which increases vibration transfer:

🔗 https://www.epa.gov/indoor-air-quality-iaq

Mike uses a torque-limited driver to guarantee proper tension.

🧲 8. Backer Rod, Foam & Flashing: How They Interact With the Quiet-Mount Pattern

Fasteners alone don’t create silence—Mike integrates them with the sealing materials.

✔ Backer Rod

Placed around the perimeter to decouple sleeve from drywall.

✔ Low-Expansion Foam

Fills voids but should never be load-bearing.

✔ Exterior Trim & Flashing

Prevent water intrusion that causes sleeve warping (and later vibration).

DOE guidelines emphasize proper sealing around AC systems to reduce noise and energy loss:

🔗 https://www.energy.gov/energysaver/air-sealing-your-home

Everything works together to maintain the quiet geometry.

🌀 9. The Harmonic Test: How Mike Knows the Sleeve Will Stay Quiet

Once fasteners and shims are installed, Mike performs a vibration test.

Mike’s Three-Part Test

1️⃣ The Knuckle Test

He taps each side of the sleeve:

-

Tight “thunk” = good

-

Hollow “ring” = needs backing

2️⃣ The Bounce Test

He places a fingertip on the frame as he lightly bumps the sleeve.

If it resonates > 1 second → reinforce the midline shims.

3️⃣ The Power-On Resonance Test

Once the chassis is inserted, Mike listens at:

-

Low fan

-

High fan

-

Cooling only

-

Heat pump mode (if equipped)

Any noise indicates a contact point or fastener torque issue.

🎧 10. Anatomy of a Silent Install: What a Perfect Quiet-Mount Sleeve Looks Like

A correctly installed Quiet-Mount sleeve exhibits:

✔ Zero frame rock

✔ Zero movement when pushing the corners

✔ No hum transferred into drywall

✔ No rattle during fan speed change

✔ A deep, solid thump on tap

✔ Proper slope with no torque bend

✔ Chassis slides in perfectly straight

Under the DOE’s guidance for efficient room AC performance, proper sleeve alignment and fastener tension improve airflow and reduce energy loss:

🔗 https://www.energy.gov/energysaver/room-air-conditioners

🧠 11. What Happens If You Skip the Quiet-Mount Pattern

Here’s why Mike insists on his bolt map:

Problems That Appear Weeks Later

-

Rattling

-

Long hum on compressor startup

-

Screeching from metal-on-wood rotation

-

Sleeve sag

-

Water pooling inside

-

Noise complaints from customers

-

Air leaks from sleeve twist

Problems That Appear Years Later

-

Stud splitting

-

Screw pull-out

-

Sleeve distortion

-

Mold from micro-leaks

-

Fan noise amplified over time

A few misplaced screws can cost thousands in repairs.

🛡️ 12. How the Quiet-Mount Map Works in Different Wall Types

Mike adapts his fastener pattern to each construction style.

Wood Stud Walls

-

Best vibration absorption

-

Use all six fasteners

Metal Stud Walls

-

Higher resonance

-

Add neoprene washers and one extra midline fastener

Masonry Walls

-

Use tapcons with rubber isolation pads

-

Requires foam decoupling perimeter

SIP or Panel Walls

-

Requires load plates

-

Fasteners must be torque-limited

NFPA guidelines for fastening into various structural materials reinforce these adjustments:

🔗 https://www.nfpa.org/for-professionals/codes-and-standards

🔧 13. The Alignment + Fastener Connection (Why Level-Lock and Quiet-Mount Work Together)

The Quiet-Mount pattern pairs perfectly with Mike’s Level-Lock Alignment Trick.

-

Level-Lock ensures geometry

-

Quiet-Mount ensures silence

Together, they create:

-

A sleeve that never twists

-

A chassis that never rubs

-

A frame that never vibrates

-

A system that operates whisper-quiet

🧼 14. Final Inspection: Mike’s Quiet-Install Checklist

Before finishing the job, Mike runs through this list:

✔ All six fasteners installed in offset pattern

✔ Neoprene washers slightly compressed

✔ Sleeve cannot shift in any direction

✔ No gap between sleeve and shims

✔ No foam touching sleeve sides

✔ Sleeve slopes correctly outward

✔ Chassis installs silently

If any checkpoint fails, he adjusts on the spot.

🧩 15. Why the Quiet-Mount Pattern Works Every Time

Mike’s quiet philosophy:

“Silence is built—not hoped for.”

His Quiet-Mount pattern eliminates:

-

Corner loading

-

Harmonic transfer

-

Racking torsion

-

Wall resonance

-

Bolt spine conduction

-

Sleeve flex noise

-

Chassis chatter

Every screw, shim, washer, and gap is intentional.

This is how pros achieve the kind of quiet operation that homeowners and hotels never complain about.

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know more about: The Indoor Airflow Safety Zone: Why Mike Leaves “No-Block” Regions Around PTAC Returns & Discharge Paths