Most PTAC performance problems—poor cooling, uneven heating, weak airflow, noisy operation, coil freeze-ups, or skyrocketing energy bills—don’t start with the compressor, the blower, or even the installation cutout.

They start with blocked indoor airflow.

Furniture. Drapes. Beds. Cabinets. Carpeting. TV stands. Wall décor. Luggage. Even a rug edge can alter airflow paths inside the room.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

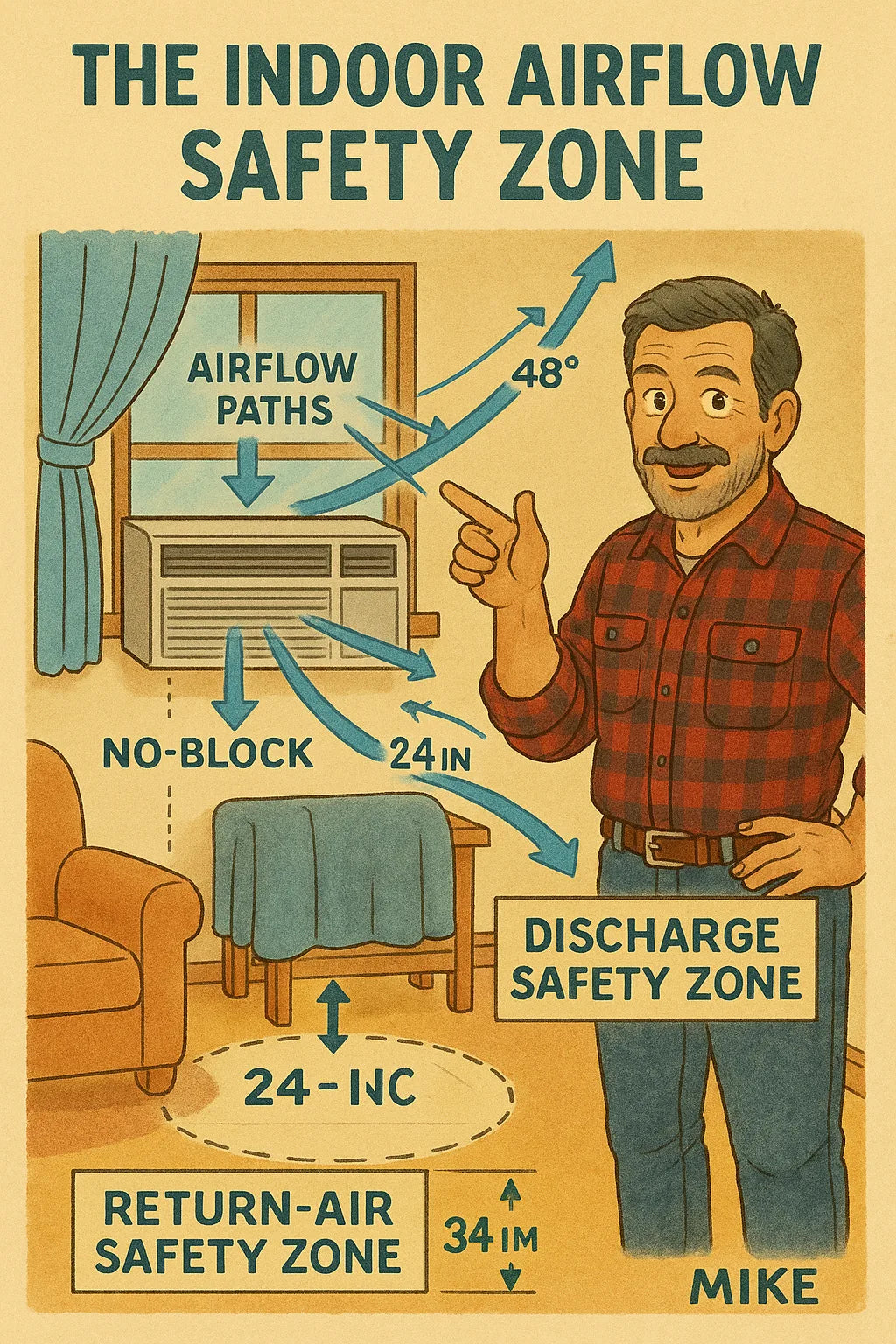

That’s why Mike created a defined method he calls The Indoor Airflow Safety Zone—a no-block perimeter around the PTAC’s return and discharge paths that ensures the machine breathes properly, circulates properly, and performs at its engineering capacity.

This article breaks down how the airflow zone works, why it matters, and how Mike calculates exact distances for every install.

🌀 1. Why Airflow Matters More Than Most Homeowners Realize

Airflow is the bloodstream of HVAC.

Block it, and the machine suffocates.

When indoor airflow is restricted, PTAC systems experience:

❌ Reduced heat transfer

Coils cannot absorb or reject heat efficiently.

❌ Compressor overwork

The system runs longer, louder, and hotter.

❌ Temperature imbalance

Cold spots, hot corners, drafts, and stratification.

❌ Higher energy consumption

DOE research confirms restricted airflow dramatically increases AC energy use:

🔗 https://www.energy.gov/energysaver/room-air-conditioners

❌ Ice formation on cooling coils

Low airflow → low refrigerant pressure → coil icing.

❌ Premature equipment failure

Motors overheat, compressors cycle excessively, and sensors read falsely.

Mike summarizes it simply:

“A PTAC is only as good as the air it can move. Give it space, and it’ll give you comfort.”

🧭 2. Mike’s Two Critical Airflow Zones

Mike defines airflow safety regions as two independent “no-block” zones:

Zone A — Return-Air Safety Zone (Breathing Area)

This is where the PTAC inhales room air.

Zone B — Discharge-Air Safety Zone (Throw Path)

This is where the PTAC throws conditioned air across the room.

Both zones must be protected for the system to work correctly.

🫁 3. Zone A: The Return-Air Safety Zone

The return path is the most commonly blocked region—usually because it’s at floor level and behind furniture.

📥 What the Return Does

-

Pulls in room air

-

Passes it through the filter

-

Sends it across the evaporator or heater

-

Balances room pressure

ASHRAE IAQ guidelines emphasize the importance of unobstructed air pathways to maintain system efficiency and indoor comfort:

🚫 What Blocks the Return

-

Beds

-

Sofas

-

Carpeting curled up

-

Curtains

-

Cabinets

-

Luggage

-

Storage bins

-

Laundry piles

📏 Mike’s Return-Air Clearance Rule

Mike keeps a minimum 24-inch open radius around the return grille.

Specifically:

| Obstruction | Minimum Clearance |

|---|---|

| Furniture front | 24 in |

| Side objects | 12–18 in |

| Curtains | 6 in minimum (but never resting on grille) |

| Floor objects | 3 in vertical clearance |

If airflow slows by more than 20%, the PTAC begins to overheat or overcool internally.

🎯 4. Zone B: The Discharge-Air Safety Zone

This is the path the PTAC uses to send conditioned air across the room.

When blocked, conditioned air loops back into the return, creating a short-cycle loop.

Short-cycling prevents the room from ever reaching set temperature.

🚫 Common Discharge Blockers

-

Bed frames or mattresses

-

TV stands

-

Side tables

-

Couch arms

-

Curtains blowing downward during cooling

-

Wall art placed too close above discharge

🔥 Heat Mode Is Most Sensitive

Blocking discharge air in heat mode causes:

-

Sensor misreads

-

Temperature overshoot

-

Burnt heat-strip smell

-

Short cycling

📏 Mike’s Discharge Clearance Rule

| Direction | Clearance Needed |

|---|---|

| Upward | 36 in |

| Forward | 48 in |

| Sides | 12–18 in |

Cool air needs room to "throw" and mix. Warm air needs room to rise and circulate.

📐 5. Airflow Physics: Why These Safety Zones Work

Most installers know to "keep space clear," but Mike understands why.

PTAC airflow is built on:

A. Throw Distance

Cold air travels horizontally 4–10 ft before dropping.

Warm air rises 2–6 ft before circulating.

B. Induction

Discharge air pulls surrounding room air into its stream.

Blocking induction collapses airflow.

C. Pressure Differential

The return and discharge must remain pressure-balanced.

If discharge is blocked, return airflow drops by up to 40%.

D. Thermal Stratification

Without proper discharge, warm air gets trapped near the ceiling while cold air pools near the floor.

These principles are supported by DOE HVAC airflow studies:

🔗 https://www.energy.gov/energysaver/air-sealing-your-home

🛠️ 6. Mike’s “Airflow Hazard Scan” — Performed Before Every Install

Before he installs a PTAC—or reinstalls one after servicing—Mike performs a three-part room scan.

1️⃣ The Furniture Scan

He checks for:

-

Bed placement

-

Sofa proximity

-

Desk overhangs

-

TV stand depth

-

Cabinet blocking

2️⃣ The Fabric Scan

Soft materials cause hidden problems.

Mike examines:

-

Curtain length

-

Drapery thickness

-

Bed skirts

-

Area rugs that curl up near returns

EPA guidance confirms fabrics can hinder ventilation pathways and alter indoor air quality:

🔗 https://www.epa.gov/indoor-air-quality-iaq

3️⃣ The Room Geometry Scan

He checks:

-

Room width

-

Room depth

-

Ceiling height

-

Shape (rectangular vs. L-shape)

This determines how far discharge air must travel.

📏 7. Mike’s 4 Airflow Safety Zones for Different Room Layouts

A. Standard Bedroom (10×12 to 12×14)

PTAC is usually installed below a window.

Safety Zone:

-

24" return clearance

-

48" discharge clearance

-

Keep bed at least 30" away from airflow path

B. Hotel Room Layout

Common issue: curtains covering the unit.

Safety Zone Add-Ons:

-

Curtain standoff arms

-

Weighted curtain bottoms

-

Minimum 6" distance from PTAC

Hotels often violate airflow safety, reducing PTAC efficiency by 20–30%.

C. Studio Apartment

Open layout, but more furniture near the PTAC.

Safety Consideration:

-

Leave 4 ft of open space forward

-

No tall furniture blocking lateral induction

D. Assisted Living / Senior Rooms

Includes more soft furnishings.

Mike’s Adjustment:

-

Increase discharge clearance to 60 in

-

Raise return-air zone if possible

🧊 8. The "Cold Loop" & "Hot Loop" Problems: What Happens When Discharge Air is Blocked

Cold Loop

Occurs in cooling mode.

Cold air loops back into the return before mixing → coil freezes.

Hot Loop

Occurs in heating mode.

Discharge heat rises straight into the return → thermometer shuts system off too early.

Both loops result in:

-

Poor temperature control

-

Excess runtime

-

Higher energy bills

-

Short equipment lifespan

DOE data supports the importance of proper airflow separation to prevent cycling issues:

🔗 https://www.energy.gov/energysaver/room-air-conditioners

🧲 9. Mike’s Airflow Security Add-Ons

When a room layout forces furniture near the unit, Mike reinforces the safety zone using:

✔ Deflection Louvers

Redirect discharge upward or sideways.

✔ Curtain Air Standoff Brackets

Push curtains away from return airflow.

✔ Furniture Bump Stops

Prevent beds or sofas from creeping into the zone.

✔ Auxiliary Return Grilles (Advanced)

Allows supplemental intake when main return is partially restricted.

🧩 10. The Safety Zone + Efficiency Connection

Mike emphasizes that airflow isn’t just comfort—

It’s system efficiency, durability, and safety.

Proper airflow reduces:

-

Compressor strain

-

Heat-strip consumption

-

Fan amperage

-

System run-time

EPA and ASHRAE ventilation standards confirm that unrestricted airflow directly improves HVAC efficiency

📘 11. Mike’s Indoor Airflow Safety Zone Checklist

Before signing off an install, Mike verifies:

✔ Nothing within 24" of the return

✔ Nothing within 48" of discharge path

✔ Curtains fully clear of airflow

✔ Furniture not “drifting” into zone

✔ Adequate induction space

✔ Balanced return/discharge pressures

✔ No cold-loop or hot-loop pathways

✔ Filters fully exposed

He treats airflow space like “equipment real estate.”

🧠 12. Why Mike Says: “Air Needs Living Space Too.”

Homeowners often don't think of air like a physical object.

But Mike does.

“Air is like a person—it needs a path to walk, a place to breathe, and room to move.”

Blocked airflow cripples performance, increases costs, and damages equipment.

Clear airflow transforms PTAC behavior:

-

Quieter

-

Cooler

-

Stronger airflow

-

Better temperature accuracy

-

Longer lifespan

It’s one of the simplest upgrades—and the most overlooked.

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know more about: The Plug-Prep Electrical Ritual: Mike’s Rules for Outlet Height, Breaker Sizing & Cord Management