A PTAC system can heat, cool, dehumidify, and ventilate—but none of that matters if the electrical connection isn’t right.

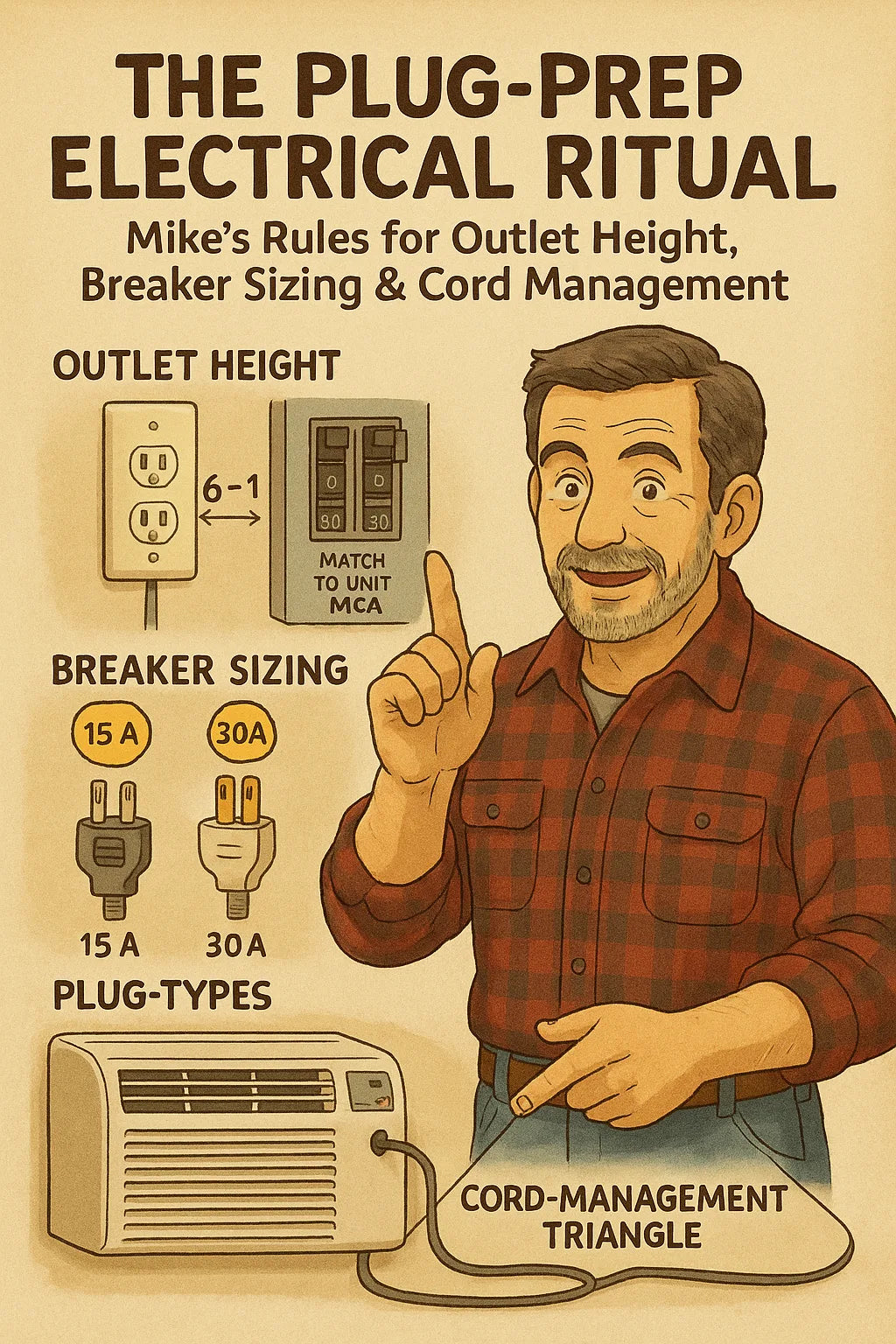

Mike calls the PTAC power setup “The Plug-Prep Electrical Ritual” because he follows it the same way on every installation. Why? Because electrical mistakes don’t just cause poor performance—they cause:

-

Tripped breakers

-

Melted plugs

-

Burnt receptacles

-

Fire hazards

-

Warranty voids

-

Noise and compressor hard-starting

-

Low voltage and overheating

A PTAC is a heavy electrical appliance. Treating the power setup casually is how things go wrong.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

This guide reveals Mike’s complete electrical ritual—from outlet height to breaker sizing to cord routing—engineered for safety, longevity, and code-conscious installation.

⚡ 1. Why PTACs Need a Dedicated Electrical Ritual—Not Just “A Plug”

Mike explains the electrical risks plainly:

“A PTAC draws more power than most appliances in a bedroom. Treat it like a toaster on steroids.”

A PTAC’s power demand is unique because:

➡️ It supports heating & cooling loads simultaneously

Models with electric heat strips draw massive amperage—often 20A, 30A, or even more.

➡️ Compressor startup creates voltage dip

If the outlet or wiring is subpar, the compressor struggles, causing:

-

Clicking

-

Buzzing

-

Hard starts

-

Loud vibration

➡️ Combined fan, compressor, and heater loads stress circuits

This is why breaker sizing and dedicated circuits are critical.

➡️ Power interruptions cause system short-cycling

Which damages electronics and increases wear.

The U.S. Department of Energy emphasizes proper electrical setup for AC systems to operate safely and efficiently:

🔗 https://www.energy.gov/energysaver/room-air-conditioners

📏 2. Outlet Height: Why Mike Never Mounts a PTAC Outlet “Wherever It Fits”

Most DIYers install the outlet:

-

Too low

-

Too high

-

Too far off to the side

But PTAC cords are short on purpose—to prevent unsafe extensions.

🧠 Mike’s Rule: The outlet must be within the cord’s natural fall line.

This means:

📐 Outlet Center Height:

6–10 inches above the finished floor (based on PTAC model & cord length)

📐 Horizontal Offset from Sleeve:

0–6 inches from the sleeve’s power cord exit side

🎯 Why the height matters:

-

Prevents cord tension

-

Avoids cords touching heating elements

-

Keeps cord accessible for service

-

Prevents entanglement with furniture

🔥 Safety Reason:

Placing the outlet too low increases the chance of:

-

Water intrusion

-

Cleaning equipment snagging the cord

-

Furniture compressing the plug

-

Accidental unplugging

Proper height allows a smooth “gravity loop” in the cord—safe, tidy, and strain-free.

⚙️ 3. Breaker Sizing: How Mike Selects the Right Amperage Every Time

Breaker sizing is where most installations fail.

🧠 Mike’s Core Breaker Rule:

“Match the breaker to the PTAC’s MCA, not the plug type.”

MCA = Minimum Circuit Ampacity

This value appears on the PTAC nameplate.

📘 Typical PTAC Breaker Recommendations:

| PTAC Type | Cooling Only | Heat Pump | Heat Strip + Cooling |

|---|---|---|---|

| 7,000–9,000 BTU | 15A | 15A | 20A |

| 12,000–15,000 BTU | 20A | 20A | 20A–30A |

| 3.5–5 kW Heat Strip Models | — | — | 30A dedicated |

Never guess breaker size.

Never copy from older units.

Never use a breaker to “fix” a tripping issue.

Breaker oversizing is dangerous—and the Department of Energy stresses proper circuit sizing for all high-powered equipment:

🔗 https://www.energy.gov/energysaver/air-sealing-your-home

🧵 4. Outlet Type: Mike’s Two-Plug System for PTAC Safety

There are two types of PTAC plugs:

1️⃣ Perpendicular blades (15A & 20A)

Look like T-type or standard appliance plugs.

2️⃣ Parallel + offset blades (30A & larger)

Used for high-wattage heat strips.

Mike matches outlet type exactly to:

-

Manufacturer recommendations

-

Cord configuration

-

Breaker amperage

Never mix & match plug/outlet types.

Incorrect outlets lead to:

-

Melted receptacles

-

Overheated plugs

-

Arc faults

-

Warranty failures

The National Fire Protection Association (NFPA) emphasizes correct receptacle and circuit pairing for appliance safety:

🔗 https://www.nfpa.org/for-professionals/codes-and-standards

🧰 5. Wire Gauge Selection: Mike’s Secret Weapon Against Overheating

Mike never relies solely on breaker size; he cross-matches wire gauge.

📏 Electrical Wire Size Guide:

| Breaker | Wire Gauge |

|---|---|

| 15A | 14 AWG |

| 20A | 12 AWG |

| 30A | 10 AWG |

Undersized wire causes:

-

Voltage drop

-

Compressor stutter

-

Heat-strip overheating

-

Fire risk

Even if you “don’t touch wiring,” Mike checks existing gauge during site evaluation.

🔄 6. The Cord Management Triangle: Mike’s Tidy, Safe, Repeatable Layout

A PTAC’s power cord must:

-

Hang naturally

-

Avoid sharp bends

-

Stay away from the return grille

-

Avoid resting against the heater deck

Mike calls this path the Cord Management Triangle.

📐 Triangle Points:

-

Plug

-

Cord slack loop

-

Entry point into PTAC chassis

🎯 Mike’s Cord Rules:

-

Leave at least 2–4 inches of slack

-

Never coil excess cord on the floor

-

Never let cords touch hot surfaces

-

Route cords away from water-prone areas

-

Use cord clips only if manufacturer-approved

This prevents:

-

Plug tension

-

Cord abrasion

-

Overheating

-

Fire hazards

🧊 7. The Heat Strip Clearance Check

Heat strip PTACs can reach internal temps of 200–400°F during heating cycles.

If the cord touches the heater deck or sits too close to airflow discharge, risk increases sharply:

-

Melted insulation

-

Arcing

-

Plug deformation

-

Circuit overload

Mike ensures:

-

Cord runs on cool side of unit

-

No slack near the discharge

-

Minimum 2 in distance from hot surfaces

DOE safety notes on heating equipment reinforce this practice:

🔗 https://www.energy.gov/energysaver/home-heating-systems

🛡️ 8. Surge Protection: Mike’s Silent Insurance Policy

A PTAC should never be plugged into:

-

Power strips

-

Extension cords

-

Cheap surge protectors

Mike uses:

✔ Hardwired surge suppressors

✔ Breaker-integrated surge modules

Because PTACs contain:

-

Control boards

-

Thermistors

-

Electronic expansion valves

-

Fan-speed controllers

A voltage spike can destroy them instantly.

EPA indoor equipment guidelines also recommend isolated surge protection for sensitive electronics:

🔗 https://www.epa.gov/indoor-air-quality-iaq

📋 9. The Three-Point Electrical Inspection (Performed Before Mike Ever Powers On the Unit)

Mike verifies:

1️⃣ Ground Integrity

PTACs need a true, bonded ground.

2️⃣ Tight Receptacle Grip

Loose outlets cause plug arcing.

3️⃣ No Heat Damage on the Plug

Brown spots = resistance = heat = hazard.

🔧 10. The First-Fire Electrical Calibration

Before the PTAC runs for the first time, Mike monitors:

-

Voltage under load

-

Breaker temperature

-

Cord temperature

-

Plug firmness

-

Fan startup current

-

Refrigerant noise indicators

If the electrical system is stressed, Mike fixes that before looking at the PTAC.

🧠 11. Why Mike Calls It a “Ritual”

Because it saves:

-

Time

-

Money

-

Callbacks

-

Energy

-

Equipment lifespan

Most electrical issues start small and end expensive.

Mike’s ritual prevents:

-

Trips

-

Burnouts

-

Melted plugs

-

Cord failures

-

Chassis overheating

-

Bad compressor behavior

Everything in the ritual is deliberate.

“A PTAC is only as smart as the power you give it.”

📘 12. Mike’s Plug-Prep Checklist

Before signing off an install, Mike verifies:

✔ Outlet mounted at correct height

✔ Correct receptacle type

✔ Correct breaker size

✔ Proper wire gauge

✔ Ground confirmed

✔ No cord tension

✔ Cord protected from heat

✔ No obstruction to plug area

✔ Circuit dedicated

✔ Surge protection optional

✔ Voltage confirmed under load

If any box fails, the job isn’t complete.

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know more about: The Drip-Lock Moisture Plan: How Mike Prevents Wall Rot, Mold & Backflow in PTAC Installs