When a PTAC goes wrong, the damage rarely starts with the compressor, the fan, or the thermostat—it starts with water.

A single cup of improperly drained condensate can become:

-

Wall rot

-

Mold inside insulation

-

Bubble-paint and crumbling drywall

-

Exterior sheathing decay

-

Backflow flooding

-

Chassis corrosion

-

Sleeves full of algae and odor

-

Structural damage from freeze-thaw expansion

Mike has seen it all. That’s why he created a moisture-control system called The Drip-Lock Moisture Plan—a methodical approach to drainage, sealing, slope control, and water-path engineering that ensures every PTAC drains safely outward and never allows moisture to invade the building envelope.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

This plan doesn’t just protect the PTAC—it protects the house.

🚰 1. Why Moisture Is the #1 PTAC Failure Point (and Why Most Installers Ignore It)

Air conditioners are water machines.

Every BTU of cooling removes humidity from the air, condenses it on the coil, and sends that water somewhere.

If the water doesn’t go outside, it goes into:

-

The wall

-

The sill

-

The insulation

-

The flooring

-

The electrical system

-

Or the PTAC itself

According to DOE guidance, improper drainage can severely reduce AC performance and damage structural components:

🔗 https://www.energy.gov/energysaver/room-air-conditioners

Mike says it plainly:

“Cooling is optional. Draining is mandatory.”

The Drip-Lock Plan ensures drainage paths are reliable in every climate.

📐 2. The Three Forces That Control Water (Mike’s Field Hydrodynamics)

Mike bases his system on three water behaviors:

1️⃣ Gravity Flow

Water always finds the lowest point—unless something traps it.

2️⃣ Capillary Action

Water can travel upward through wood, concrete, or drywall fibers.

3️⃣ Pressure Differential

Wind, negative pressure, and blocked drain paths can push water backward.

ASHRAE’s building science standards confirm these moisture transport mechanisms

A PTAC installer must control all three.

📦 3. The Drip-Lock Moisture Triangle

The entire system rests on three components:

🔻 1. Sleeve Slope (Primary Drain Path)

Ensures condensate flows outward.

🔻 2. Moisture Barriers (Stop Wall Intrusion)

Blocks water from ever touching bare building materials.

🔻 3. Exterior Drain Management (Guide Water Away)

Ensures water exits cleanly, without backflow risk.

Each leg of the triangle is necessary.

If even one is wrong, moisture finds its way into the wall.

📏 4. Perfect Sleeve Slope: Mike’s Most Inspected Measurement

The PTAC sleeve must slope ¼ inch per foot toward the exterior.

Why This Slope Matters:

-

Moves water away from interior

-

Reduces backflow

-

Ensures condensate exits drain ports

-

Prevents pooling inside the sleeve

-

Ensures ice melt in winter moves outward, not inward

Mike checks slope five times during install:

-

Before insertion

-

Midway into wall

-

Fully inserted, before shimming

-

After shimming

-

After foam cures

He uses a torpedo level, not eyeballing.

Slope errors cause 80% of moisture callbacks.

🧼 5. The Sleeve Interior: Mike’s “Water Highway” Inspection

Once the sleeve is in place, Mike inspects the interior channel:

✔ No debris

✔ No foam intrusion

✔ No burrs blocking drain path

✔ No factory defects

✔ No insulation touching internal walls

A rough seam or misplaced insulation slows drainage and creates algae growth.

🛡️ 6. The Moisture Barrier Layer: Mike’s Wall-Protecting Shield

Mike installs multiple layers to protect the building envelope.

A. Backer Rod Perimeter

Fills large voids without sealing them rigidly.

-

Prevents foam from expanding into the sleeve

-

Creates a compressible moisture buffer

-

Reduces capillary water transport

B. Closed-Cell Low-Expansion Foam

Mike only uses low-expansion foam for PTAC installs.

Why?

High-expansion foam:

-

Bows the sleeve

-

Changes the slope

-

Breaks the water path

-

Blocks drainage ports

C. Air/Water Membrane Flashing

A thin membrane tape around the exterior opening:

-

Prevents wind-driven rain intrusion

-

Stops capillary absorption into sheathing

-

Adds an exterior-grade waterproof seal

This step aligns with DOE recommendations for sealing building penetrations:

🔗 https://www.energy.gov/energysaver/air-sealing-your-home

🪟 7. The Exterior Drip Strategy: Where Mike Directs the Water

Once water exits the sleeve, it must go somewhere safe.

Mike uses:

✔ Drip Edge Flashing

Ensures water drips outward, not downward into siding.

✔ Splash Guard

Redirects water away from foundation or walkway.

✔ Insect/Mesh Screen

Keeps bugs out without blocking flow.

✔ Downward Grille Angle

Pushes water away from the wall even during heavy wind.

🔁 8. Backflow Prevention: Mike’s Answer to Wind-Driven Rain

Wind can push water:

-

Back into the sleeve

-

Into drain ports

-

Into insulation

-

Behind flashing

Mike prevents this by:

✔ Creating a positive outward slope

✔ Using exterior grilles with directional louvers

✔ Installing a backflow barrier ridge inside sleeve

✔ Using drain ports with downward flare

ASHRAE references wind-driven moisture as a cause of envelope failures

🧊 9. Freeze-Lock Protection: How Mike Prepares for Winter

In cold climates, water freezes in the sleeve and expands.

Bad installs cause:

-

Sleeve cracking

-

Sill splitting

-

Ice dams inside the wall

-

Frost blowing into the room

Mike includes:

✔ Thermal gap around drain area

✔ Downward flare on exterior grille

✔ Foam buffer zones to allow ice expansion

✔ Sealed drain ports to prevent upward airflow

These prevent freeze-thaw damage.

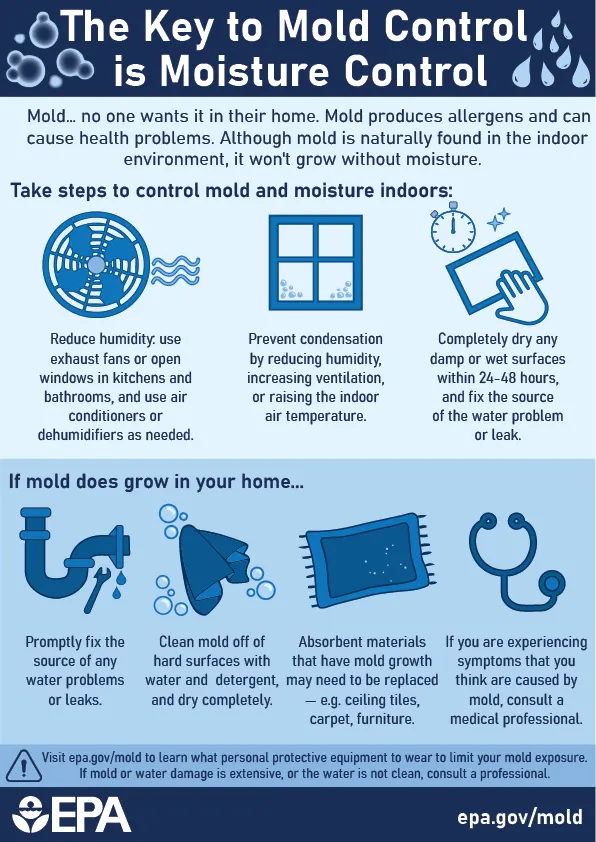

🧽 10. Mold Prevention: The Drip-Lock Anti-Mold Checklist

Mike eliminates mold risks by controlling temperature, moisture, and organic materials.

Mike’s Mold-Prevention Steps

-

Keep insulation fully intact

-

Seal all raw wood edges

-

Maintain slope for no standing water

-

Flush sleeve interior annually

-

Use antimicrobial cleaner during service

-

Keep return airflow unblocked

-

Replace filters monthly in humid climates

EPA IAQ guidelines emphasize controlling moisture at its source:

🔗 https://www.epa.gov/indoor-air-quality-iaq

🧪 11. Mike’s Water-Test Ritual: The Proof That Drip-Lock Works

Mike performs a controlled water test:

Step 1 — Pour one cup of water into interior sleeve.

Should instantly travel outward.

Step 2 — Spray exterior grille with hose at downward angle.

Simulates wind-driven rain.

Step 3 — Run PTAC in cooling mode for 10 minutes.

Confirms normal condensate flow.

Step 4 — Inspect interior wall for moisture meter readings.

0–5% is acceptable; above 10% indicates failure.

Step 5 — Inspect foam and membrane seals.

Only after passing all steps does he consider the job complete.

🌀 12. Why Some PTAC Installs “Smell Musty” After 6 Months

Mike has diagnosed dozens of cases where:

-

The slope was wrong

-

The sleeve pooled water

-

The wall insulation absorbed moisture

-

Mold began inside the sill

-

Air passed across moldy insulation and into the room

Bad drainage—even a little—is enough to begin microbial growth.

Proper Drip-Lock execution eliminates this entirely.

🧰 13. The Annual Drip-Lock Maintenance Plan

Mike trains homeowners and hotels to perform:

✔ Annual sleeve rinse

✔ Drain-port clearing

✔ Exterior grille inspection

✔ Mold check with flashlight

✔ Check for rust or pooling

✔ Verify slope hasn’t shifted due to building settling

DOE maintenance guidance backs regular cleaning of drainage components

🏠 14. Drip-Lock for Different Climates

🌧 Humid South

-

Larger drain-port openings

-

Anti-algae coating

-

Quarterly cleaning

❄️ Cold North

-

Increased freeze gap

-

Heavier flashing

-

Low-permeance membrane

🌬 Windy Coastal Zones

-

Extended drip edge

-

Louvered grille

-

Salt-resistant coating

🏜 Dry Desert

-

UV-resistant sealants

-

Dust screens

Drip-Lock adapts to every climate.

🔍 15. The Drip-Lock Inspection Checklist (Mike’s Final Pass)

Mike confirms:

✔ Correct outward slope

✔ Clean, unobstructed drain path

✔ Backer rod installed properly

✔ Foam sealed but not load-bearing

✔ Exterior flashing is watertight

✔ No risk of backflow

✔ No wall moisture intrusion

✔ No insulation exposure

✔ No signs of mold

If a single item fails, he reworks the install.

🧠 16. Why The Drip-Lock Moisture Plan Works

Because it respects:

-

Building science

-

Water behavior

-

HVAC physics

-

Real-world climate conditions

-

Material limitations

-

Human behavior (curtains, furniture, neglect)

Mike sums it up:

“Water always wins—unless you plan for it.”

The Drip-Lock Moisture Plan ensures:

-

No wall rot

-

No mold

-

No backflow

-

No odors

-

No callbacks

-

Maximum PTAC lifespan

This is what separates a basic install from a professional one.

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know more about: The Thermal-Balance Placement Method: Where Mike Puts PTACs So They Heat & Cool Rooms Evenly