When people look at a finished PTAC installation, they rarely notice when the sleeve is perfectly level, square, and centered—but they always notice when it’s not.

A PTAC sleeve that’s even ⅛ inch off can cause:

-

Compressor vibration

-

Water backflow

-

Loud chassis hum

-

Condensate leaks

-

Premature sleeve wear

-

Poor airflow

-

Visible crookedness from inside or outside

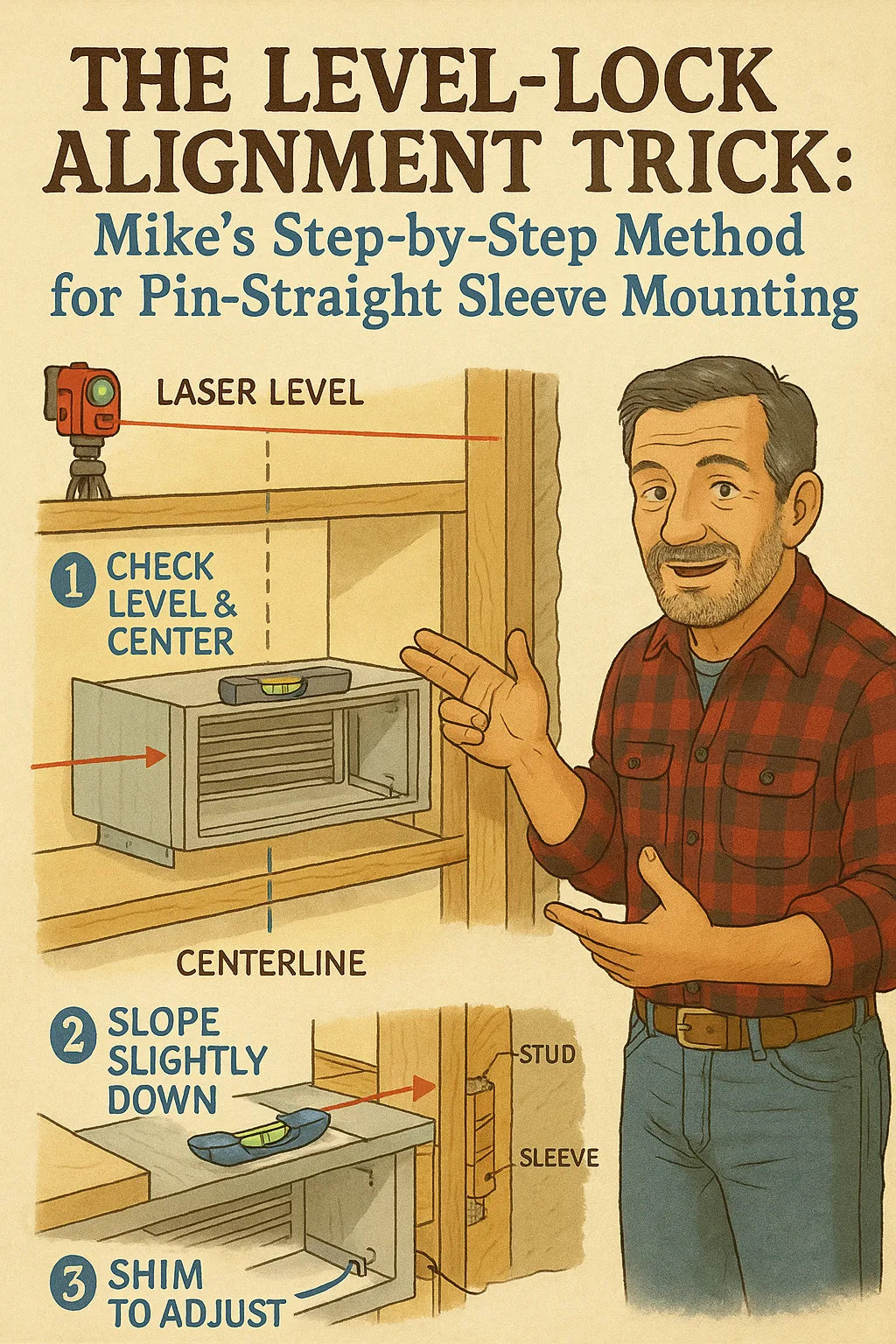

Mike has spent years perfecting a method he calls The Level-Lock Alignment Trick—a precision alignment sequence that guarantees every sleeve sits perfectly straight, perfectly sloped, perfectly centered, and permanently stable.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

This isn’t just leveling.

It’s locking the geometry of the sleeve into the wall so it never shifts, sags, or tilts over time.

🧭 1. Why Sleeve Alignment Matters More Than Most Installers Think

Mike explains it like this:

“The sleeve is the backbone of the PTAC. If the backbone is crooked, everything built on it will fail.”

Improper alignment causes:

Mechanical Problems

-

The chassis creates high-frequency vibration noise

-

The fan becomes unbalanced

-

The compressor resonates against the enclosure

Water Problems

-

Condensate drains incorrectly

-

Water drips inside the room

-

Mold forms inside the sleeve

Energy Loss

-

Air bypasses the coils

-

Negative pressure pulls outdoor air indoors

Department of Energy studies show that improper window and wall AC installation can significantly increase infiltration and energy loss:

🔗 https://www.energy.gov/energysaver/room-air-conditioners

Aesthetics & Customer Satisfaction

A crooked unit is instantly noticeable—especially with a wall sleeve where trim lines emphasize misalignment.

🛠️ 2. The Tools Mike Uses to Guarantee Pin-Straight Geometry

Mike never starts alignment without the right tools. His alignment kit includes:

Core Tools

-

Cross-line laser level

-

24" torpedo level

-

48" carpenter’s level

-

Shim assortment (wood + composite)

-

Deep-scan stud finder

-

Self-tapping framing screws

-

Angle square

Precision-Assist Tools

-

Laser tripod

-

Chalk line or pencil grid

-

Rubber mallet

-

Vacuum (for cleanup during adjustments)

📐 3. The Level-Lock Geometry Grid: Mike’s Alignment Blueprint

Before the sleeve enters the wall, Mike lays out a wall geometry grid—a mapping system that guarantees a perfect final orientation.

This grid consists of:

A. Horizontal Level Line (Top Reference)

Laser line projected across the wall marking:

-

Sleeve top height

-

Interior trim alignment

-

Visual symmetry line

B. Vertical Centerline

Runs floor to ceiling, marking:

-

Center of sleeve

-

Alignment with room layout

-

Equal distance from obstacles

C. Stud Edge Lines

Reveal where sleeve anchors must be placed.

D. Projection Depth Mark

Shows where the sleeve must stop so the grille sits flush with exterior trim.

Mike’s rule:

“If the grid is perfect, the sleeve must be perfect.”

🧱 4. The Structural Bracing Pass: How Mike Prepares a Wall So the Sleeve Doesn’t Drift

Sleeves shift when the wall cavity is unstable.

Before setting the sleeve, Mike checks for:

-

Stud flex

-

Missing blocking

-

Weak drywall edges

-

Oversized cavity gaps

✔ Mike reinforces the cavity with:

-

Horizontal blocking (2×4 or 2×6)

-

Side stud stiffeners

-

Micro-shims compressed between framing members

-

Backer rod where insulation or gaps appear

This prevents the sleeve from rotating, bowing, or tilting during sealing and long-term usage.

NFPA building guidelines reinforce proper framing support around mechanical penetrations

🔧 5. The Sleeve Reality Check: Measuring the Sleeve Before Alignment

Even brand-new sleeves can be off by:

-

⅛" in height

-

¼" in width

-

Slight twisting due to shipping

-

Interior lip variations

Mike measures:

1. Exterior flange height

2. Interior flange depth

3. Left/right interior wall thickness

4. Straightness across all four surfaces

5. Factory slope

If the sleeve is warped:

-

Mike gently re-squares with hand pressure

-

Or compensates with a shim pattern

You never install a sleeve without knowing its actual geometry.

📥 6. The Soft-Set Method: Positioning the Sleeve Before Final Anchoring

Instead of pushing the sleeve straight into place, Mike uses a technique he calls soft-set positioning:

Step 1 – Insert the sleeve halfway

This allows free left/right and up/down movement.

Step 2 – Align to the geometry grid

Mike adjusts:

-

Height

-

Centerline

-

Slope

-

Rotation

Step 3 – Gently tap into place

Using a mallet, he nudges—not forces—the sleeve until it sits nearly perfect.

At this stage, the sleeve must:

-

Float

-

Adjust

-

Move easily

This prevents “locked-in crookedness.”

📏 7. The 3-Axis Level Test: Mike’s Alignment Triangle

The Level-Lock Trick uses three independent level checks:

🟦 Axis 1: Horizontal Level (Interior Lip)

Ensures visual symmetry inside the room.

🟩 Axis 2: Vertical Plumb (Left & Right Interior Surfaces)

Ensures chassis slides properly without friction.

🟥 Axis 3: Exterior-To-Interior Slope

Ensures water drains outward.

ASHRAE building science guidelines emphasize proper drainage slope for HVAC wall installs

Mike requires all three axes to align within 1⁄16".

🔩 8. The Shim-Lock Pattern: How Mike Locks the Sleeve Into Perfect Geometry

This is the heart of the Level-Lock Trick.

Instead of stuffing shims randomly, Mike uses a balanced shim pattern that prevents torque, twist, and vibration.

Shim Locations:

-

Bottom left

-

Bottom right

-

Mid-height left

-

Mid-height right

-

Top center (optional, when needed)

Shim Rules:

-

Never shim only one corner

-

Never wedge shims too tightly

-

Never use high-expansion foam as structural support

Mike leaves micro-gaps for expansion and movement.

EPA guidance supports allowing airflow and preventing overly tight assemblies that trap moisture:

🔗 https://www.epa.gov/indoor-air-quality-iaq

When shims are properly balanced, the sleeve becomes completely motionless.

🔧 9. The Micro-Anchor Technique: Permanently Locking the Sleeve Without Warping It

Once the sleeve is aligned and shimmed, Mike permanently locks it with a method called micro-anchoring:

✔ Uses small pilot holes

Prevents splitting studs or bowing sleeve edges.

✔ Anchors only after confirming all three axes

Never before.

✔ Alternates left-right-left-right tightening

Prevents torque build-up on the sleeve.

✔ Uses 1¼"–1½" screws so they don’t penetrate too deep

Protects wiring and insulation.

NFPA mechanical fastening guidelines emphasize safe anchoring practices

Once anchored, the sleeve is locked in perfectly.

🧊 10. The Foam-Freeze Test: Ensuring the Sleeve Doesn’t Warp During Sealing

Foam can undo perfect alignment if improperly applied.

Mike prevents this with:

Low-Expansion Foam Only

High expansion pushes the sleeve off level.

Two-Stage Application

-

Fill 30–40% and allow curing

-

Top off remaining voids without pressure

Constant re-leveling during curing

Mike checks level every 10 minutes.

Perimeter Inspection After Full Cure

If foam expanded unevenly, he trims the interior before installing trim.

🔍 11. The Pin-Straight Verification Sequence

Before installing the PTAC chassis, Mike verifies:

✔ Sleeve bottom is straight against level

✔ Sleeve inner shell is plumb

✔ Sleeve slopes ¼" per foot outward

✔ Exterior grille opening is uniform

✔ No shim compression after the anchor screws

✔ Sleeve didn’t warp due to foam curing

He repeats the 3-axis test from Section 7.

If everything passes, the sleeve is now Level-Locked.

📦 12. Chassis Fit & Glide Test: The Ultimate Proof

Mike inserts the PTAC chassis without power, checking:

-

Smooth glide from inside to full seating

-

No side rubbing

-

No top/bottom contact

-

Level visible through chassis gap lines

-

Straight airflow discharge alignment

If the chassis glides perfectly, the sleeve geometry is perfect.

If it catches or scrapes:

-

Sleeve alignment is off

-

Foam shifted the frame

-

Shims are imbalanced

-

Sleeve is twisted

Mike fixes these before the PTAC ever runs.

📘 13. Why the Level-Lock Trick Works Every Time

Mike’s philosophy:

“Perfect alignment isn’t luck—it’s a sequence.”

The Level-Lock Trick succeeds because it:

**1. Aligns the wall cavity

-

Aligns the sleeve’s geometry

-

Aligns the slope

-

Locks the sleeve in balanced tension

-

Prevents foam warping

-

Verifies alignment under chassis load**

This creates:

-

Quieter operation

-

Longer equipment life

-

Better condensate drainage

-

No callbacks

-

No crooked installs

-

A professional, symmetrical look inside and out

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know more about: The Quiet-Mount Fastener Map: Mike’s Bolt Pattern That Stops Vibrations Before They Start