Most PTAC failures don’t happen on the inside of the building—they start outside, where water, wind, insects, and temperature swings attack the sleeve. A PTAC sleeve that isn’t properly graded, sealed, and fortified will leak, rot, sweat, whistle, or allow conditioned air to escape.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

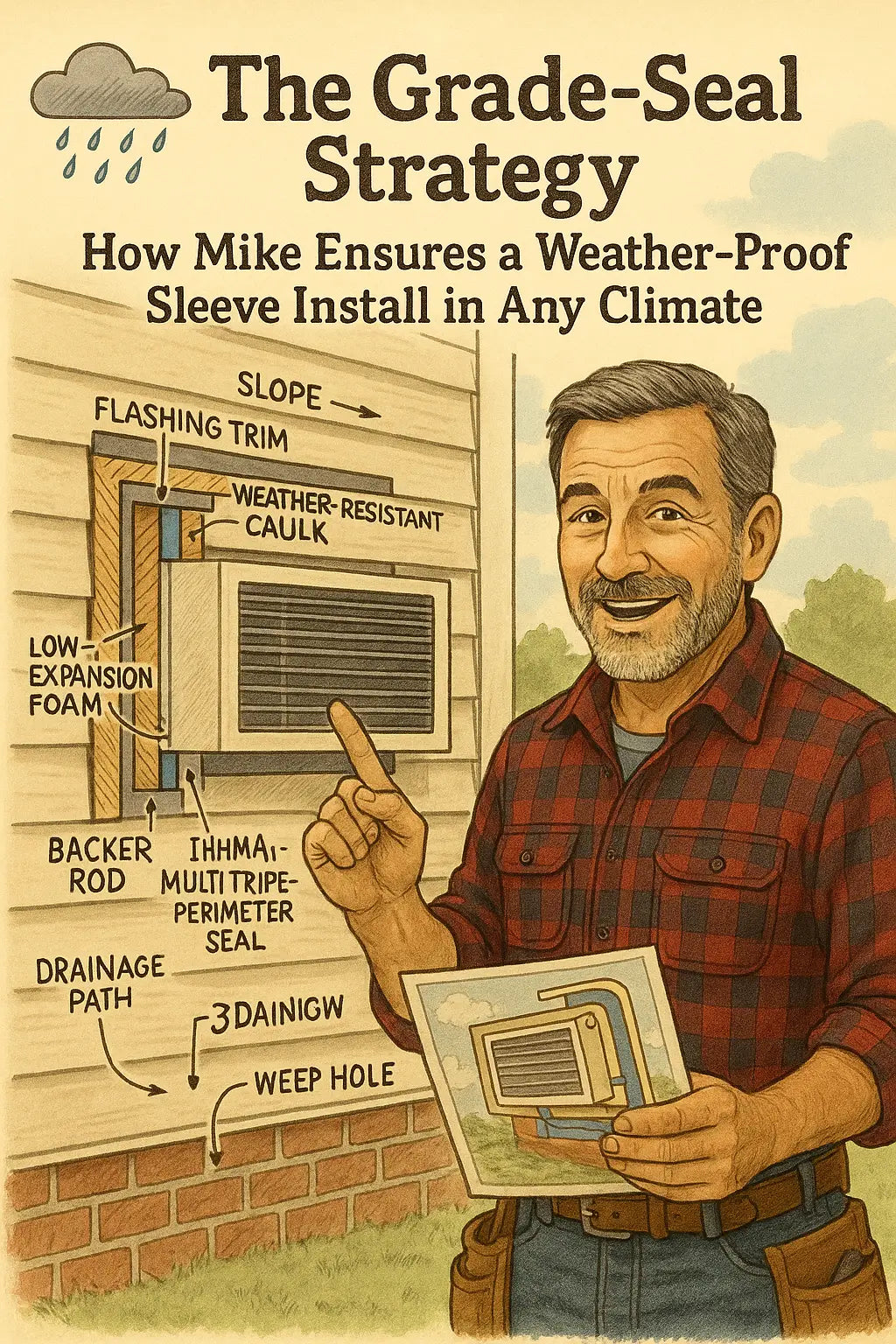

That’s why Mike developed The Grade-Seal Strategy, a complete exterior-to-interior weatherproofing system that ensures any PTAC sleeve—from economical hotel units to premium 15,000 BTU Amana J-Series installs—remains watertight, airtight, and climate-resilient for over a decade.

This method is engineered for:

-

Hot & humid climates

-

Cold northern regions

-

Coastal and salt-air zones

-

High-wind areas

-

Desert climates with sand intrusion

-

Mixed climates with freeze/thaw cycles

If the sleeve survives the outside, the system inside will last.

🧭 1. Why Weather-Proofing Matters More Than Most Installers Realize

Most installers follow manufacturer instructions for sliding the sleeve into the wall—but weather-proofing is often reduced to “foam it and caulk it.”

That shortcut leads to:

-

Mold around the interior frame

-

Water infiltration into studs

-

Rotting sheathing

-

Sleeve frost buildup

-

Exterior grille icing

-

Noise infiltration

-

Energy loss

-

Sleeve corrosion

The Department of Energy highlights the cost impact of poor air sealing:

🔗 https://www.energy.gov/energysaver/air-sealing-your-home

Mike’s view is simple:

“If the outside isn’t sealed right, the inside will always suffer.”

The Grade-Seal Strategy eliminates weak links from every climate angle.

📐 2. Climate Mapping: Mike’s First Step Before Any Exterior Sealants Come Out

Every climate introduces different threats:

🌧 Humid Southeast

-

Hydrostatic pressure

-

Heavy rain splash-back

-

Mold growth

-

Termite risk

❄️ Northern Freezing Zones

-

Freeze/thaw cycles

-

Ice damming

-

Frost expansion behind the sleeve

🌬 High-Wind Atlantic / Gulf

-

Lateral wind-driven rain

-

Salt intrusion

-

Grille pressure distortion

🌵 Desert Regions

-

Sand intrusion

-

UV-caulk degradation

-

Extreme temperature swings

🌦 Mixed Climates

-

Constant seasonal contraction/expansion

Mike tailors his Grade-Seal Strategy to these environmental battles.

📏 3. The Golden Rule of Sleeve Drainage: Always Downhill to the Outdoors

A PTAC sleeve must always slope downward ¼" per foot toward the exterior.

✔ Why this slope matters:

-

Prevents water from pooling inside the sleeve

-

Directs condensate outdoors, not into the wall cavity

-

Maintains proper drainage channel performance

-

Reduces mold risk

ASHRAE performance guidelines acknowledge the importance of drainage in HVAC equipment

Mike’s slope test:

Place a torpedo level inside the sleeve.

If the bubble touches the indoor line → slope is correct.

If centered → risky.

If touching the outdoor line → wrong direction entirely.

🧱 4. The “Dry-Run Exterior Audit”: Mike’s Exterior Surface Evaluation

Before sealing anything, Mike inspects the exterior plane.

✔ Check siding type

Some materials require specific sealants:

-

Vinyl → flexible, UV-safe caulk

-

Fiber cement → elastomeric sealant

-

Stucco → backer rod + polyurethane

-

Brick → freeze-tolerant mortar caulk

✔ Inspect for water paths

Mike looks for:

-

Drip caps

-

Existing rot

-

Water streaking

-

Soft wood

-

Prior repairs

-

Improper flash lines

✔ Confirm sleeve overhang

The sleeve should extend ⅛"–½" beyond the exterior wall face.

If it is recessed, wind-driven rain will infiltrate the sleeve.

🧵 5. The Triple-Perimeter Seal: Mike’s Three-Layer Weatherproofing System

This is the core of the Grade-Seal Strategy.

Mike applies weatherproofing in three independent zones, each doing a separate job.

🧱 Layer 1: Structural Seal (Backer Rod + Polyurethane)

This seal fills the large perimeter gaps around the sleeve.

✔ Why backer rod?

-

Controls caulk depth

-

Creates a flexible bond

-

Reduces cracking in freeze cycles

-

Allows expansion and contraction

✔ Why polyurethane sealant?

-

UV resistant

-

Fully waterproof

-

Stays elastic in heat and cold

-

Longer lifespan than silicone

This layer ensures bulk water can’t enter the wall.

🧊 Layer 2: Thermal/Moisture Seal (Low-Expansion Foam)

Inside the cavity, Mike uses low-expansion window-and-door foam.

NOT high-expansion foam.

✔ Why?

High-expansion foam can:

-

Bow the sleeve

-

Alter slope

-

Warp framing

-

Create pressure points

Low-expansion foam maintains:

-

True geometry

-

Consistent slope

-

Air-tightness

EPA indoor air quality guidelines emphasize using low-VOC, low-expansion products for enclosed spaces:

🔗 https://www.epa.gov/indoor-air-quality-iaq

💧 Layer 3: Exterior Weather Line (Skin Sealant + Flash Trim)

This is the visible protection layer.

Mike installs:

-

A heavy-duty exterior flashing trim

-

UV/weather-resistant caulk

-

A secondary drip edge

-

A wind break (if in high-wind zones)

This final coat ensures:

-

Rain hits the exterior face and sheds outward

-

UV doesn’t crack the caulk

-

Wind doesn’t lift the seal

-

The sleeve stays quiet under gusts

🪟 6. Drainage Engineering: How Mike Enhances the Factory Drain Path

Factory PTAC sleeves come with:

-

Drainage channels

-

Drain holes

-

Optional drain kits

However, real-world building materials often compromise drainage.

Mike inspects:

-

Channel slope

-

Burrs blocking water flow

-

Factory flash imperfections

-

Exterior grille splashback path

If needed, he lightly files the drain channel or adds a drain kit.

DOE guidance confirms active drainage greatly increases AC efficiency:

🔗 https://www.energy.gov/energysaver/room-air-conditioners

🧽 7. Wind-Tight vs. Air-Tight: Mike’s Differentiation Strategy

Most installers think “airtight is best,” but Mike warns against sealing every molecule of air.

❌ Airtight + No Pressure Relief = Whistling & Rattles

The sleeve must allow:

-

Micro-venting

-

Grille pressure equalization

-

Drain evaporation airflow

Mike creates a wind-tight but not vacuum-tight seal.

Wind-tight = no drafts

Airtight = sometimes too tight

🧰 8. Freeze-Proofing for Northern Installs

In freezing climates, the biggest enemy is ice expansion behind the sleeve.

Mike adds:

-

A hydrophobic barrier membrane

-

A foam compression buffer

-

A backer-rod relief zone

-

Flexible exterior caulk that holds elasticity down to -20°F

This prevents:

-

Sleeve displacement

-

Water freeze pressure

-

Interior frost blooms

-

Noise caused by temperature contraction

🧂 9. Salt-Air Reinforcement for Coastal & Gulf Regions

Coastal homes face:

-

Salt corrosion

-

Wind-driven rain

-

Constant humidity

-

UV beating down on caulk lines

Mike’s coastal modifications include:

-

Stainless screws only

-

Marine-grade polyurethane

-

Extra exterior flashing

-

Anti-corrosion spray on sleeve edges

-

Sand screen integration

If it protects a boat hull, it protects a PTAC.

🏜️ 10. Desert & High-Heat Adaptations

Desert climates damage caulk rapidly.

Mike uses:

-

Hybrid polymer sealants (superior UV resistance)

-

Light-colored exterior flashing to reduce heat load

-

Dust screens behind the grille

-

High-temperature foam

This prevents:

-

Cracked sealant

-

Sand infiltration

-

Sleeve warping under heat expansion

🌀 11. High-Wind Region Reinforcement: The Storm Seal

In hurricane-prone regions:

-

Negative pressure

-

Windborne debris

-

Horizontal rain

-

Pressure waves

All attack the sleeve opening.

Mike reinforces with:

-

A secondary interior sill block

-

Exterior screw anchors

-

Metal flashing with hemmed edges

-

Storm-rated caulk beads

-

A reinforced grille with deeper louvers

NFPA exterior building standards emphasize securing mechanical openings:

🔗 https://www.nfpa.org/codes-and-standards

🪛 12. The 360° Sleeve Perimeter Inspection

Before installing the PTAC chassis, Mike completes a full inspection.

He checks for:

✔ Uniform caulk bead

✔ No bridging between sleeve & trim

✔ No voids beneath flashing

✔ Correct outward slope

✔ Level horizontal alignment

✔ Zero foam bulging inside

If the sleeve passes the 360° exam, only then does Mike install the chassis.

💨 13. Airflow Integrity: The Hidden Factor Most Installers Forget

A weatherproof sleeve is worthless if airflow can’t move properly.

Mike verifies:

-

Exterior grille doesn’t block drain paths

-

No foam intruding into airflow channels

-

No pressure hot spots

-

No air recirculation behind the sleeve

DOE efficiency studies show airflow blockages dramatically reduce AC performance:

🔗 https://www.energy.gov/energysaver/room-air-conditioners

🧊 14. Condensate Mastery: Why Mike Tests Drainage Under Full Load

Mike pours two cups of water into the sleeve and watches.

✔ Does it drain out immediately?

✔ Does any water backflow?

✔ Does water ride along the wall?

✔ Does wind push water inward during gusts?

This simple test identifies:

-

Bad grading

-

Blocked channels

-

Incorrect foam placement

-

Poor flashing integration

🧼 15. Final Weather-Seal Test: Mike’s Three-Condition Validation

Mike tests the sleeve under:

🌧 Simulated Rainfall

Sprays exterior trim from above at a downward angle to imitate real rainfall.

🌬 High-Pressure Wind Simulation

Uses a leaf blower or airflow machine to simulate gusts.

❄️ Cold-Edge Inspection

Chills the exterior grille to detect:

-

Drafts

-

Cold bridging

-

Caulk failure

Only when all three pass does Mike sign off.

🧠 16. Why the Grade-Seal Strategy Works in Every Climate

This method works because it combines:

-

Drainage engineering

-

Material science

-

Building envelope knowledge

-

Climate adaptation

-

Airflow pressure principles

-

Expansion/contraction physics

Mike summarizes the philosophy like this:

“Water follows weakness. Seal the weakness, and you seal the home.”

Homes survive longer. Sleeves stay cleaner. Units run quieter. And there are no callbacks.

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know more about: The Level-Lock Alignment Trick: Mike’s Step-by-Step Method for Pin-Straight Sleeve Mounting