A PTAC installation is only as good as the hole you cut in the wall.

Get the opening wrong—off-center, out-of-square, unstable, or dust-loaded—and the entire job becomes harder, louder, weaker, and far more expensive to fix.

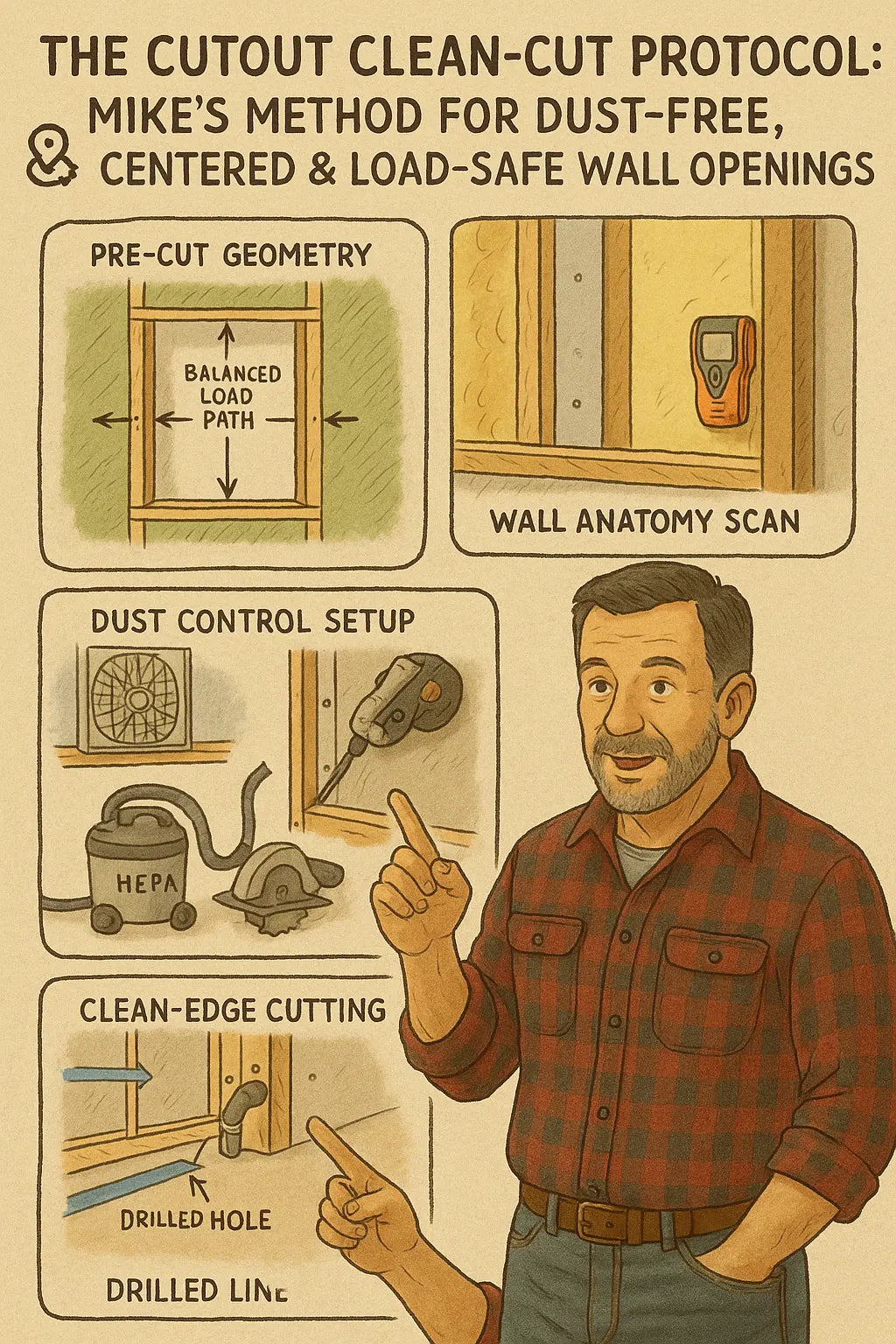

That’s why Mike teaches a system he calls The Cutout Clean-Cut Protocol, a start-to-finish method for making a centered, square, structurally safe, dust-controlled, inspection-ready opening for a PTAC sleeve.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

This guide reveals every step of the method—geometry, structural load paths, dust capture, wall biology, and real-world field lessons earned over 25 years of cutting open walls.

📦 1. Why the Clean-Cut Protocol Exists: Most Wall Openings Fail Before the Saw Starts

Bad wall openings almost always trace back to:

-

Cutting before mapping the load path

-

Cutting without knowing the interior cavity

-

Cutting in the wrong order

-

Using the wrong blade for the wall materials

-

Forgetting to control dust

-

Assuming the wall is plumb or unbowed

-

Misreading the sleeve projection

-

Underestimating how drywall fractures

Mike’s rule:

“If the measurement is perfect but the cutout is sloppy, the install will fail and the callbacks will follow.”

The Clean-Cut Protocol is built to eliminate these mistakes entirely.

📐 2. Pre-Cut Geometry: Establishing the Centerline & Balanced Load Path

Before touching a saw, Mike finishes what he calls the geometry pass.

🎯 A. The True Centerline

The cutout should align with:

-

Natural room symmetry

-

Airflow paths

-

Furniture clearances

-

Exterior façade aesthetics

-

Electrical reach

The centerline should never be chosen based only on stud spacing.

Studs are moved—not airflow.

🏗 B. Load Path Verification

PTAC openings remove drywall and sometimes framing.

Mike checks:

-

Is the wall load-bearing?

-

Do the studs create a safe window for the opening?

-

Do we need a micro-header?

-

Is there a plumbing or electrical path intersecting the cut?

He uses NEC and building guidelines for spacing and electrical protection:

🔗 https://www.nfpa.org/codes-and-standards

If anything looks questionable, the cut moves—not the structure.

🔍 3. Wall Anatomy Scan: The “Science Before Sawdust” Phase

Mike’s Clean-Cut Protocol includes a total wall survey.

🧲 A. Deep-Scan Stud Detection

He uses both:

-

An electronic deep stud finder

-

A magnetic screw-locator

Combined, these expose:

-

True stud center

-

False positives from metal lath

-

Horizontal blocking

-

Old patched openings

-

Double studs

-

Fire stops

🛠 B. Cavity Depth Measurement

A pilot hole gives:

-

Interior cavity depth

-

Insulation density

-

Vapor barrier presence

-

Drywall-to-siding offset

This prevents cutting into utilities, avoiding the “why is water spraying into the room?” moment.

🎧 C. Sound Signature Test

Mike taps the wall lightly.

He can tell if the cavity contains:

-

Ducting

-

Copper piping

-

Electrical conduit

-

Brick or concrete backing

It's the old-school version of an inspection camera.

🧽 4. Dust Control Setup: Why Mike Treats Dust Like a System, Not a Mess

PTAC cutouts generate:

-

Drywall dust

-

Wood dust

-

Fiberglass insulation flakes

-

Potential silica particulates

Uncontrolled, these contaminate:

-

HVAC return air

-

Electronics

-

Carpeting

-

Resident breathing zones

🧰 Mike’s Dust Control System

-

Painter’s tape perimeter seal

-

Drop cloths under the cut zone

-

Masking film over nearby furniture

-

A HEPA vacuum tethered to the saw

-

Low-speed cutting to prevent powder burst

-

Negative-pressure room setup (box fan + window)

Environmental and health guidance supports dust control:

🔗 https://www.epa.gov/indoor-air-quality-iaq

Mike never cuts without this system in place.

✏️ 5. Marking the Opening: Mike’s 4-Corner, 6-Line Method

Once the wall has been surveyed, Mike begins marking the cut.

🧭 A. Vertical Lines (Centerline + Stud Edge Lines)

-

Draw the main centerline.

-

Draw two parallel lines marking where the studs sit.

-

Confirm these lines are plumb with a laser.

📏 B. Horizontal Lines (Top + Bottom of Opening)

These are set based on:

-

Sleeve height

-

Minimum 3" clearance above sleeve top for airflow

-

ADA or hotel design guidelines

-

Convection height relative to the floor

📐 C. Diagonal Verification Lines

Mike draws corner-to-corner diagonals.

When the diagonals measure the same:

The cutout is square.

If they differ by more than ⅛":

-

Redraw

-

Re-level

-

Re-mark

This step eliminates crooked openings before the saw wastes drywall.

🪵 6. Material Recognition: Cutting Different Walls the Right Way

PTAC installers often discover too late that the wall they're cutting isn’t standard drywall.

Mike checks for:

✔ Drywall over lumber

Use oscillating saw + vacuum attachment.

✔ Drywall + OSB sheathing

Use carbide blade, slow passes.

✔ Plaster & lath

Use multi-tool—never a reciprocating saw.

(Recip saws destroy plaster keys instantly.)

✔ Brick or CMU backer

Stop. Reassess structural options.

✔ Vinyl siding exterior

Plan for fine-blade oscillation.

Keep siding expansion gaps intact.

🪜 7. The Relief Cut Technique: Why Mike Never Cuts the Outline First

Most installers draw a rectangle then plunge the saw into a corner.

This guarantees:

-

Wall blowout

-

Cracked drywall edges

-

Ragged corners

-

Stress fractures

-

Shattered plaster

Mike’s technique:

1️⃣ Step One — Drill Corner Pilot Holes

Gives clean radius transitions.

2️⃣ Step Two — Relief Cuts at the Center

Short 4–6" vertical cuts relieve tension before cutting the perimeter.

3️⃣ Step Three — Inside-Out Cut Order

Work from the panel’s center outward.

Drywall breaks outward—this cuts with the grain, not against it.

🧹 8. Dust-Free Cutting: Mike’s 4-Speed Method

Mike adjusts saw speed depending on debris type:

| Material | Speed | Reason |

|---|---|---|

| Drywall | Low | Prevents powder explosions |

| OSB / Plywood | Medium | Cleaner edges |

| Stud lumber | Medium-high | Faster plunge |

| Metal lath | Low | Reduces spark risk |

A HEPA vacuum sits 1–2" from the blade, attached with a clamp-on nozzle.

EPA guidelines reinforce the value of HEPA filtration for particulates

🧱 9. Structural Integrity: When to Add Cripple Studs, Reinforcement & Micro-Headers

If your cut removes a significant portion of the stud or compromises the load-bearing layout, Mike strengthens the opening.

🪵 A. Cripple Studs

Installed under headers to distribute load.

🪚 B. Micro-Header

A small 2×4 or 2×6 boxed header above the sleeve.

🪛 C. Jack Stud Reinforcement

Adds strength when removing more than 2" of a stud flange.

📐 D. Backer Support

For drywall stability and noise reduction.

🧊 10. Insulation Handling: Mike’s “No-Loose-Fibers” Protocol

Randomly cutting insulation causes:

-

Fiberglass drift

-

Air leaks

-

Sound leaks

-

Moisture pathways

Mike uses:

✔ Light misting (prevents airborne fibers)

✔ A breadknife motion to cut clean

✔ Stapled back foil (restores thermal barrier)

✔ Backer rod perimeter to prepare for sealing

This step is often skipped—and always regretted later.

🧰 11. Final Pass: The “Finger Test” and Edge Calibration

Once the opening is cut, Mike performs his tactile inspection.

🔍 He checks for:

-

Hollow gaps

-

Paper tears

-

Crumbly corners

-

Stud splintering

-

Out-of-square edges

-

Dust residue on cavity surfaces

Anything loose is trimmed or reinforced before the sleeve enters the wall.

🧼 12. Clean-Edge Finishing: Foam, Flashing & Air Barrier Prep

A proper cutout needs a proper perimeter.

✔ Backer Rod

Inserted into large voids.

✔ Low-Expansion Foam

Used sparingly—not as structural support.

✔ Exterior Flashing

Prevents water infiltration.

✔ Interior Tape Line

Keeps vapor barrier consistent.

Department of Energy recommendations for air sealing support these practices:

🔗 https://www.energy.gov/energysaver/air-sealing-your-home

🧪 13. The Dry-Fit Verification: Mike’s “Truth Moment”

Before installing the sleeve, Mike dry-fits it without:

-

Foam

-

Screws

-

Sealant

-

Trim

He checks:

✔ Projection depth

✔ Square seating

✔ Stud contact points

✔ Airflow clearance

✔ No binding or tilt

If the sleeve doesn’t slide in smoothly?

The cutout isn’t ready.

He fixes the cutout—never forces the sleeve.

🧯 14. Dust-Off Protocol: Returning the Home to Pre-Cut Condition

Mike’s cleanup method ensures the homeowner never sees evidence of the demolition.

🧼 Full Cleanup Checklist

-

Vacuum cavity

-

Vacuum edges

-

Wipe studs with damp cloth

-

Mop floor under opening

-

Remove masking gently

-

Clean tool paths

-

Wipe wall surfaces

EPA and IAQ guidance confirm surface cleaning after construction reduces airborne particulates:

🔗 https://www.epa.gov/indoor-air-quality-iaq

🎓 15. Final Inspection: The Clean-Cut Certification

Mike ends with a 6-point inspection:

✔ Is the opening square to within ⅛"?

✔ Are the edges smooth and fracture-free?

✔ Is the dust fully contained?

✔ Is the load path unchanged or reinforced?

✔ Is the cavity clean and insulation controlled?

✔ Does the sleeve dry-fit perfectly?

If all six pass, the wall is ready for the PTAC sleeve installation.

🧠 Final Thoughts: Why the Clean-Cut Protocol Matters

Anyone can cut a hole in a wall.

But a clean, centered, dust-free, load-safe opening is what separates a beginner from a seasoned HVAC pro.

Mike’s closing philosophy:

“A PTAC opening is surgery. If you respect the wall, it will respect the install.”

The Clean-Cut Protocol produces:

-

Stronger installs

-

Quieter operation

-

Fewer air leaks

-

Better weatherproofing

-

Longer equipment life

-

Zero callbacks

It’s the foundation of every good PTAC installation.

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know more about: The Grade-Seal Strategy: How Mike Ensures a Weather-Proof Sleeve Install in Any Climate