When I installed my Weil-McLain CGA-6 Series 3 166,000 BTU Cast Iron Natural Gas Boiler, I assumed it would just run quietly in the basement for decades. After all, cast-iron boilers are known for durability. But what I quickly learned is that regular maintenance isn’t optional—it’s essential.

Think of your boiler like a car. You wouldn’t drive 100,000 miles without changing the oil. Similarly, you shouldn’t run a boiler year after year without flushing drains, checking valves, and cleaning critical components.

This guide is my step-by-step maintenance checklist for keeping your Weil-McLain CGA-6 running safely, efficiently, and reliably all year long.

📅 Why Boiler Maintenance Matters

-

Efficiency: A poorly maintained boiler can waste up to 10–20% more energy each year .

-

Longevity: Cast-iron boilers like the CGA-6 can last 20–30 years with proper care.

-

Safety: Testing safety valves and low-water cutoffs helps prevent dangerous malfunctions.

-

Comfort: Regular checks ensure even heating across all zones.

🔗 DOE – Boiler Maintenance Guide

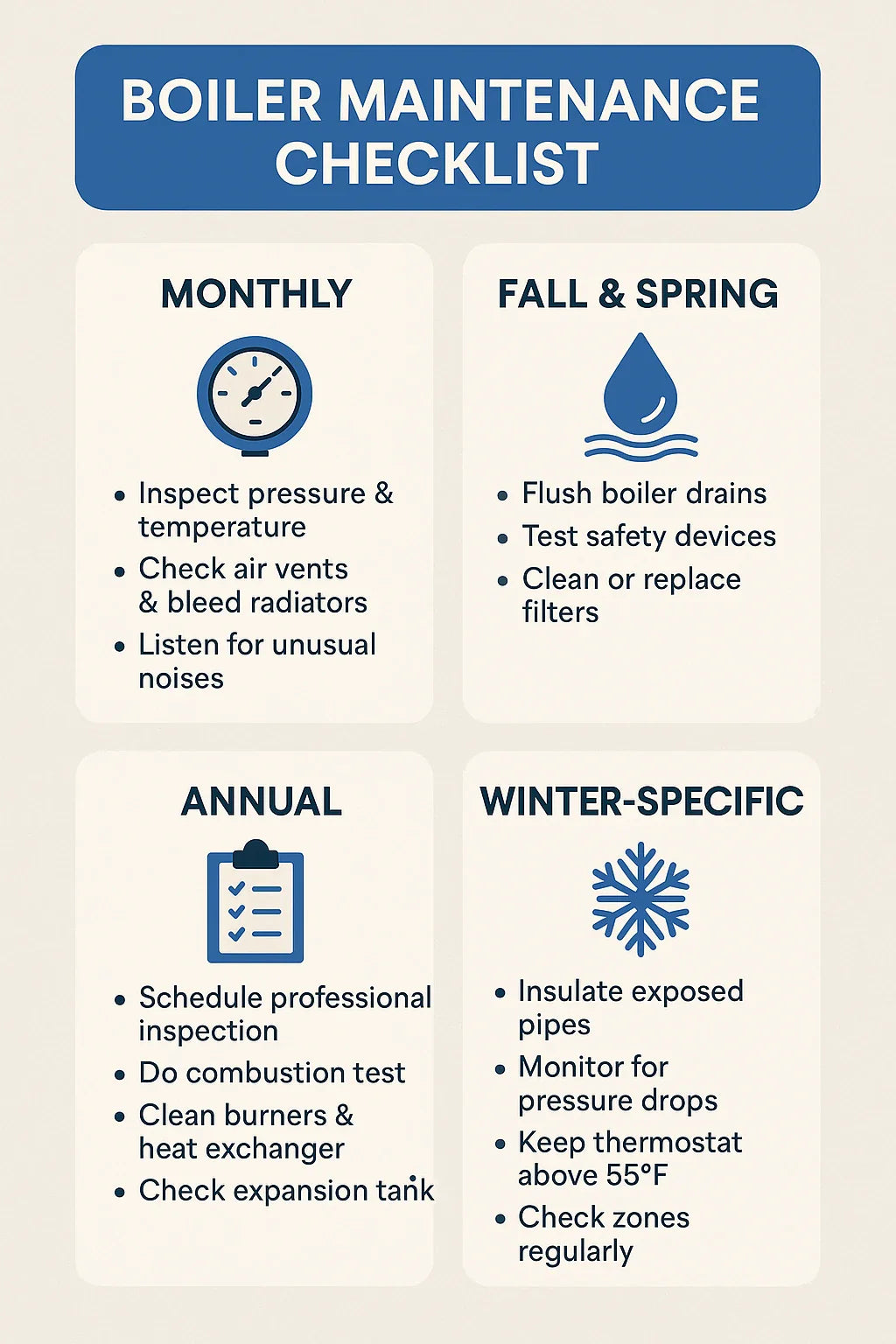

✅ Monthly Maintenance Checklist

1. Inspect pressure & temperature gauges

-

Normal boiler pressure: 12–15 psi (cold) and up to 20 psi (hot).

-

Overpressure may indicate expansion tank issues.

2. Check air vents & bleed radiators

-

Air trapped in radiators causes “cold spots.”

-

Use bleed valves to release air until water flows steadily.

3. Listen for unusual noises

-

A knocking or banging sound = trapped air or water hammer.

-

Whistling may point to scale buildup inside heat exchangers.

💡 Samantha’s note: I caught a circulator pump problem early just by listening for a “grinding” noise one evening.

🍂 Seasonal Care (Fall & Spring)

1. Flush boiler drains

-

Sediment builds up in cast-iron boilers, reducing heat transfer.

-

Attach a hose to the drain valve, flush until water runs clear.

🔗 HeatingHelp – Boiler Sediment Issues

2. Test safety devices

-

Pressure relief valve: Lift lever slightly—water should discharge.

-

Low-water cutoff: Drain water until the cutoff activates and shuts the burner off.

3. Clean or replace filters

-

If your system uses a hydronic air handler or indirect water heater, filters should be checked every season.

-

Clogged filters reduce airflow and stress pumps.

4. Inspect venting & chimney

-

Look for corrosion, leaks, or blockages.

-

Birds’ nests and leaves are surprisingly common.

🔗 CSIA – Chimney Maintenance Basics

🗓️ Annual Care

Every year, schedule a professional technician to perform these deeper tasks:

1. Combustion efficiency test

-

Uses a combustion analyzer to measure CO₂, O₂, and flue gas temperature.

-

Ensures safe burning and maximum efficiency.

2. Clean burners & heat exchanger

-

Soot and scale buildup reduce heat transfer.

-

A pro will brush and vacuum these surfaces.

3. Inspect expansion tank

-

Test for proper pressure (12 psi standard).

-

Replace if waterlogged.

4. Check circulator pumps

-

Inspect for leaks around seals.

-

Lubricate if required (most modern pumps are sealed, but older ones aren’t).

5. Review wiring & controls

-

Loose thermostat wires or faulty zone valves cause uneven heating.

-

Control board should be inspected for wear or corrosion.

🔗 Gas Boiler Maintenance Costs

❄️ Winter-Specific Maintenance Tips

1. Insulate exposed pipes

-

Especially in basements or crawlspaces.

-

Prevents frozen pipes during cold snaps.

2. Monitor pressure drops

-

If your system loses pressure frequently, it could mean a hidden leak.

3. Keep thermostat above 55°F

-

When away for holidays, never let the house get too cold—frozen pipes = costly repairs.

4. Check zones regularly

-

Walk through the house once a week to ensure all zones are heating evenly.

🧑🔧 Samantha’s Real-World Maintenance Lessons

-

The clogged drain incident: One fall, I skipped flushing the drain. By January, I noticed “gurgling” sounds—turns out sediment was restricting water flow. A quick flush fixed it.

-

Zoning made troubleshooting easier: With 4 thermostats, I could immediately tell when just the attic office zone wasn’t heating properly.

-

Professional inspection pays off: My tech found a cracked relief valve gasket before it became a leak. The $150 inspection likely saved me $1,000 in water damage.

🧾 Maintenance Cost Breakdown

| Task | DIY Cost | Pro Cost |

|---|---|---|

| Flush drains | Free | $100–$150 |

| Test relief valve | Free | Included in annual service |

| Bleed radiators | Free | $100+ if hired |

| Annual inspection | — | $150–$300 |

| Combustion efficiency test | — | $100–$200 |

| Chimney inspection | — | $100–$250 |

👉 Samantha’s total: about $250/year in professional care, plus 1–2 hours of DIY seasonal work.

📊 How Maintenance Extends Boiler Life

-

No maintenance: 10–15 years before major issues.

-

Basic seasonal care: 20 years of reliable service.

-

Consistent pro + DIY care: 25–30 years possible for cast iron boilers like the CGA-6.

🔗 EnergyStar – Boiler Life Expectancy

✅ Key Takeaways

-

The Weil-McLain CGA-6 is built for decades of comfort—but only if you maintain it.

-

Monthly: check gauges, bleed radiators, listen for noises.

-

Seasonally: flush drains, test valves, inspect venting.

-

Annually: book a pro for deep cleaning and combustion testing.

-

Winter: insulate pipes, check zones, and keep thermostats above 55°F.

💡 Samantha’s advice: Make maintenance part of your seasonal routine. A couple of hours now saves thousands later.

In the next topic we will know more about: Do Weil-McLain Gas Boilers Qualify for Energy Rebates or Tax Credits in 2025?