When I decided to replace my aging heating system, I landed on the Weil-McLain CGA-6 Series 3 166,000 BTU Cast Iron Natural Gas Boiler. On paper, it seemed perfect: durable cast iron, enough BTUs to heat my 3,400 sq. ft. colonial in Pennsylvania, and a trusted brand name.

But here’s what I quickly discovered: buying the boiler is just step one. The real journey starts with the installation. Between permits, venting, zoning, and safety checks, I learned a lot—some of it the hard way.

This guide is my way of sharing what I wish I had known before and during the process, so you can walk into your own boiler upgrade with confidence.

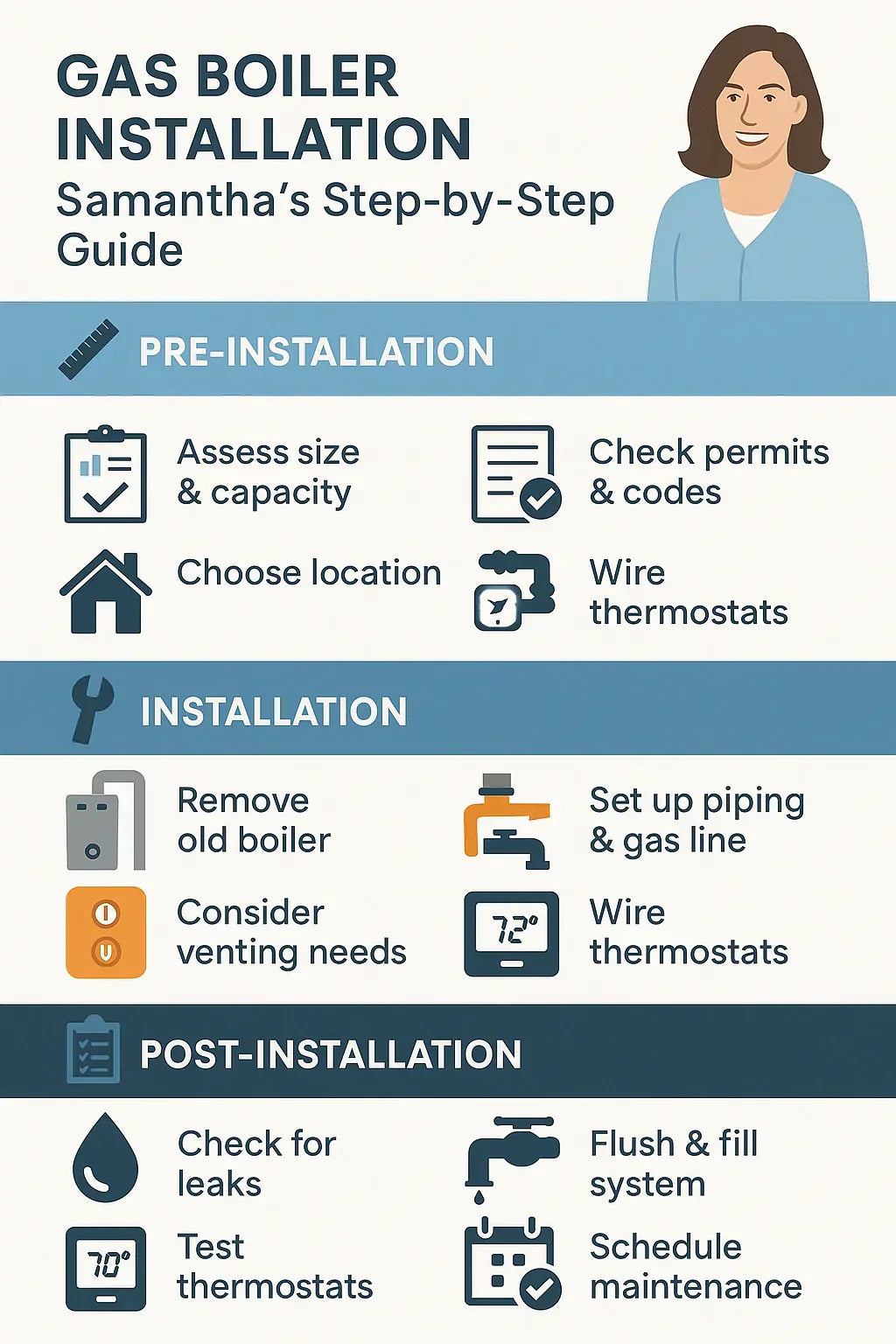

🏡 Step 1: Pre-Installation Prep

📏 Right-sizing the boiler

-

My contractor double-checked the sizing using a Manual J calculation (a professional load calculation).

-

Even though the CGA-6 is 166,000 BTUs, my home’s load was closer to 155,000 BTUs, making it a near-perfect match.

-

Oversizing = wasted money and short cycling. Undersizing = not enough heat in the dead of winter.

🔗 Manual J load calculation basics – Energy Vanguard

📝 Permits and codes

-

I had to apply for a mechanical permit through my township, which cost about $200.

-

Local code required a licensed contractor to handle the gas connection.

-

In some areas, even replacing “like for like” requires inspection.

👉 Lesson: Call your local building office before ordering the boiler.

📍 Choosing the location

-

My old boiler sat in the basement near the chimney.

-

Clearances around the new CGA-6 were crucial: Weil-McLain recommends 24" in front and at least 6" from combustible surfaces.

-

I also had to make space for circulator pumps and an expansion tank.

💡 Samantha’s tip: Sketch your mechanical room layout before installation day.

🔧 Step 2: Day-of Installation

🧹 Removing the old boiler

-

Contractors disconnected gas, water, and electrical lines.

-

The old cast-iron beast weighed nearly 500 lbs—it took two men with a dolly and some creative maneuvering.

-

Disposal fee: $150 at a local scrap yard.

🔩 Setting up piping and gas lines

-

The installer ran new black iron pipe for the gas line, sized for proper flow.

-

All connections were sealed and pressure-tested with soap solution.

-

Copper supply and return lines were sweat-soldered into place.

👉 Important: The CGA-6 requires 1" minimum gas piping depending on length.

🔗 NFPA 54 National Fuel Gas Code

🌬️ Venting and chimney considerations

-

My old chimney wasn’t properly lined for modern efficiency levels.

-

A stainless steel chimney liner was required ($1,200 extra).

-

This prevented condensation damage and ensured safe venting.

🔗 Chimney Safety Institute of America

🎛️ Wiring thermostats and zoning

-

I opted for 4 heating zones (basement, first floor, second floor, attic office).

-

Each zone got its own circulator pump and thermostat.

-

The wiring panel tied them all into the boiler’s control board.

👉 Added cost: $2,000 for pumps, valves, and thermostats, but worth it for comfort.

🔗 HeatingHelp: Zone valves vs. circulators

✅ Step 3: Post-Installation Checklist

🔍 Leak and pressure testing

-

System was filled with water, then pressure-tested at 30 psi.

-

All joints were inspected for leaks.

💦 Flushing and bleeding

-

The installer flushed the system to remove solder flux and debris.

-

Air bleeders on each loop ensured no trapped air would cause gurgling.

🌡️ First fire-up

-

Gas was turned on, and the boiler fired smoothly.

-

Thermostats were checked zone by zone.

-

The relief valve and low-water cutoff were tested for safety.

📅 Scheduling maintenance

-

I booked a one-year follow-up to re-check venting, gas pressure, and efficiency.

-

Recommended maintenance:

-

Annual flue and vent inspection.

-

Check circulators and valves.

-

Flush system every 3–5 years.

-

🔗 DOE – Boiler maintenance guide

💵 Cost and Timeline Expectations

-

Equipment (CGA-6): $4,300

-

Installation labor: $5,200

-

Accessories (pumps, expansion tank, thermostat): $2,000

-

Chimney liner: $1,200

-

Permits & disposal: $350

👉 Total: $13,050 (minus rebates = $12,200 net).

Timeline: 2 days (old removal + new install + wiring + testing).

📝 Samantha’s Key Takeaways

-

Don’t underestimate prep. Permits and chimney liners can delay things.

-

Budget extra. I thought it would cost $10k, but accessories pushed it up by $3k.

-

Hire a pro. Gas lines and venting are not DIY-friendly.

-

Zoning pays off. My heating bills dropped 18% after splitting into four zones.

-

Plan for downtime. We were without heat for a day in January—keep space heaters handy.

✅ Final Word

Installing a Weil-McLain CGA-6 gas boiler isn’t a weekend DIY project—it’s a major investment that requires planning, permits, and professional expertise. But done right, it can transform your home’s comfort and efficiency for decades.

If I had to do it again, I’d budget more, plan further ahead, and still choose the same boiler.

In the next topic we will know more about: Maintenance Checklist: Filters, Drains & Seasonal Care for Your Weil-McLain CGA-6