Hey, it’s Tony here. If you’ve got a GE Zoneline PTAC installed in your home, apartment, or building, chances are you’ve come across the RAD10 condensate drain kit. It’s one of those small accessories that doesn’t get the spotlight but makes a huge difference in performance and long-term reliability.

I’ve installed these kits in homes, hotels, and even small office buildings. The truth is: improper condensate drainage is one of the top reasons PTACs fail early or cause expensive water damage. A simple kit like the GE RAD10 gives condensate a safe path out of your unit—no mess, no mold, no callbacks.

This guide will walk you through:

-

Tools and materials you need

-

Step-by-step instructions

-

Mistakes to avoid

-

Maintenance tips once it’s installed

By the end, you’ll know exactly how to attach the GE RAD10 drain kit and have the peace of mind that your PTAC is protected.

🔧 Section 1: Why You Need the GE RAD10 Kit

Before we dive into the install, let’s quickly cover why this kit matters:

-

Controls the water path: Without a drain kit, condensate can overflow into your wall or floor.

-

Prevents mold and mildew: Standing water = bad smells and air quality problems.

-

Protects your building: Stops hidden leaks that ruin drywall and insulation.

-

Supports internal/external drainage: Gives you flexibility depending on your setup.

-

Required in many installs: Some building codes and GE’s own guidelines recommend or mandate it.

👉 According to PTAC Central, drain kits are required on all new PTAC installations because they prevent callbacks and protect building interiors.

For me, I installed mine after spotting water stains and a musty smell. If I’d used the RAD10 from the start, I would’ve saved myself a repair job.

🛠️ Section 2: Tools & Materials Checklist

Before you roll up your sleeves, gather everything you need. Here’s my go-to checklist:

-

GE RAD10 kit (includes drain fittings, gaskets, screws, and plates)

-

Screwdriver (Phillips and flathead)

-

Adjustable wrench (for tightening fittings if needed)

-

Drain tubing (½" ID, if tying into a plumbing line)

-

Tube clamps (optional, for secure connections)

-

Level (to ensure slope for drainage)

-

Bucket of water (for testing flow)

-

Towels or drop cloth (to protect flooring during install)

Tony’s Tip: Lay out all the kit parts on a workbench first—knowing what’s what saves you confusion once you’re mid-install.

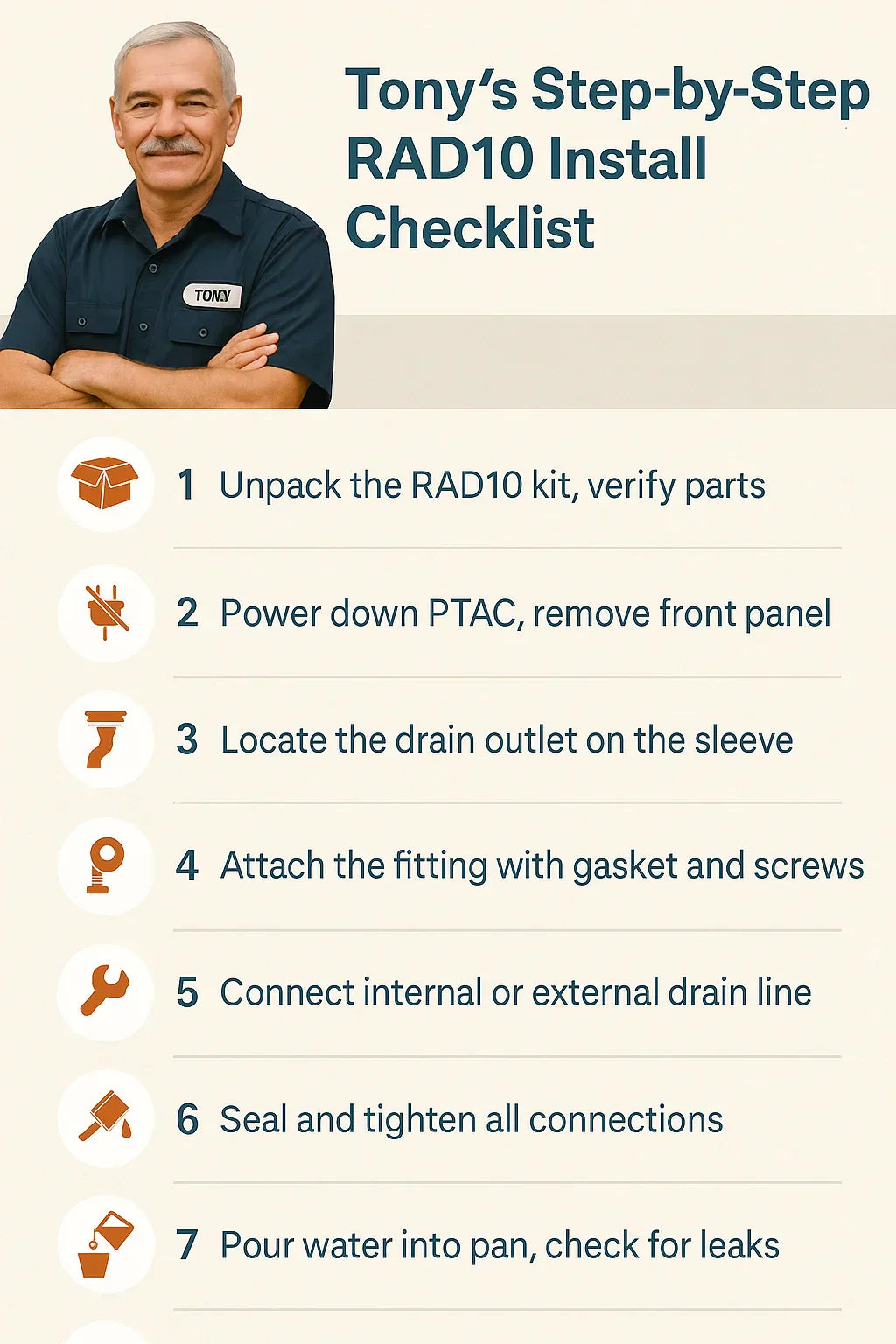

📋 Section 3: Step-by-Step Installation Guide

Let’s break this down step by step.

Step 1: Unpack the RAD10 Kit

-

Open the box and confirm you have:

-

Drain fitting(s)

-

Rubber gasket(s)

-

Screws and mounting plate(s)

-

Optional blank-off plate

-

-

Read through the included GE installation sheet once—it’ll help you visualize the process.

Step 2: Power Down & Prep the Unit

-

Turn off power to your PTAC unit (unplug if possible).

-

Remove the front panel of the PTAC. This gives you access to the sleeve and chassis area.

Tony’s Tip: Never work on your PTAC while it’s running. Safety first.

Step 3: Locate the Drain Outlet

-

Look inside the wall sleeve base pan.

-

You should see the pre-marked drain knockout or outlet where the RAD10 will attach.

-

If your sleeve has multiple drain locations, decide whether you’ll route internally (into plumbing) or externally (out the wall).

Step 4: Attach the RAD10 Fitting

-

Insert the gasket into place against the sleeve wall.

-

Position the RAD10 fitting through the sleeve opening.

-

Secure with screws using the included plate.

👉 Ensure the gasket seals tightly—this prevents leaks around the joint.

Step 5: Connect Drain Line

-

If using internal drainage:

-

Attach ½" tubing to the fitting.

-

Route tubing to an approved plumbing drain line.

-

Use clamps to secure.

-

-

If using external drainage:

-

Position the outlet to discharge outside.

-

Ensure water runs away from the building foundation.

-

Tony’s Tip: Always slope the drain line downward. Even a slight uphill run will cause backups.

Step 6: Seal & Tighten

-

Double-check all connections.

-

Apply a small bead of HVAC-safe sealant if needed around fittings (optional but recommended in high-humidity areas).

Step 7: Test the Setup

-

Pour a cup of water into the PTAC’s condensate pan.

-

Watch closely: the water should flow smoothly through the RAD10 fitting and out the drain line.

-

Check for leaks around the gasket or fittings.

Tony’s Tip: If water pools or backs up, your drain line slope is wrong or there’s an obstruction—fix it now, not later.

Step 8: Reassemble & Power On

-

Replace the PTAC’s front cover.

-

Restore power and run the unit in cooling mode for a few minutes.

-

Watch for proper drainage during operation.

⚠️ Section 4: Common Mistakes to Avoid

I’ve seen plenty of DIYers trip up on small things. Here’s what to watch out for:

-

Overtightening screws → Can warp the gasket and cause leaks.

-

Ignoring slope → Drain line must tilt downward for gravity to work.

-

Forgetting to test with water → Always simulate condensate before calling it done.

-

Using the wrong tubing size → If it’s too small, it’ll clog fast.

-

Letting line exit near foundation → Always route away from building to prevent seepage.

👉 Beckett warns that improper slope and clogged drains are the leading causes of condensate overflows.

🔄 Section 5: Tony’s Post-Install Maintenance Tips

Once the kit is in place, you’re not done forever—maintenance keeps it working.

-

Monthly: Pour a cup of water into the pan to confirm flow.

-

Every 3–6 months: Flush tubing with a vinegar + water mix to clear algae.

-

Yearly: Inspect gaskets and replace if brittle.

-

After storms: Check external drains for debris blockages.

👉 Quality Home Air Care suggests flushing drain lines regularly to prevent algae and mold buildup.

💵 Section 6: Is Installing the RAD10 Worth It?

Here’s how I break it down:

-

RAD10 cost: $50–$75

-

Average drywall repair from leaks: $500–$1,500

-

Mold remediation cost: $2,000+

👉 The Furnace Outlet notes that drainage issues are one of the most expensive PTAC mistakes you can make.

For me, a one-hour install and a small investment is a no-brainer.

✅ Section 7: Final Wrap-Up

So there you have it—a complete installation guide for the GE RAD10 Drain Kit.

-

It’s simple enough for most DIYers.

-

Takes under an hour with the right tools.

-

Prevents mold, leaks, and costly repairs.

I’ll put it this way: if you’re installing a PTAC without a drain kit, you’re leaving your walls and wallet at risk. With the RAD10 in place, you know condensate is always under control.

Now that you know how to do it, grab your tools, follow the steps, and get that kit installed. Future you will thank you.

In the next topic we will know more about: Internal vs. External Drain Setup: Which One Is Right for You?