Why your system is only as good as its ability to breathe — and why return air is the most overlooked part of HVAC design.

🌀 Introduction: Your System Has a LUNG — and It’s Probably Undersized

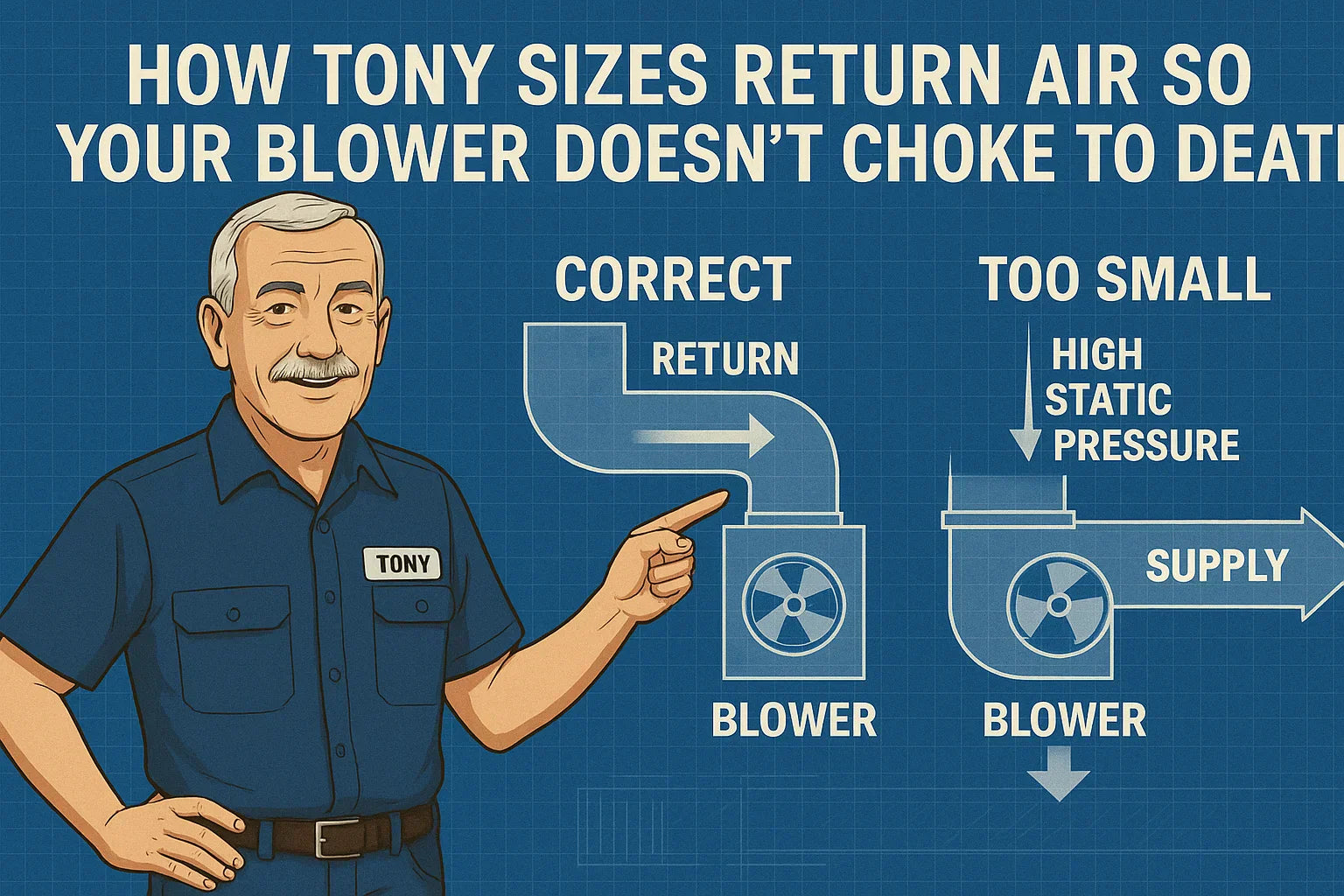

Tony tells homeowners the same thing every week:

“Your HVAC system has two jobs: push air out, and suck air back.

If the return side can’t breathe, the blower chokes to death.”

Most people obsess over:

-

BTUs

-

tonnage

-

coil size

-

heat strips

-

SEER2 ratings

…but NONE of that matters if the return air is undersized.

Tony has walked into homes with:

-

brand-new 4-ton heat pumps

-

20 kW electric furnaces

-

high-end ECM blowers

…and the return air was sized for a 1.5-ton system.

Result?

-

screaming blower

-

hot limit trips

-

reduced airflow

-

frozen AC coils

-

overheated heat strips

-

sky-high static pressure

-

short cycling

-

poor comfort

-

premature motor failure

This article breaks down exactly how Tony sizes return air — using physics, standards, field testing, and a lifetime of blower autopsies.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow

📦 1. Return Air Is More Important Than Supply — Tony Learned This the Hard Way

Most installers look at the SUPPLY duct first.

Tony doesn’t.

“The blower doesn’t care how much air you WANT to push out.

It cares how much air it can pull IN.”

Return air problems account for 70–80% of airflow issues, and Tony sees it constantly:

-

Multiple supply runs feeding one tiny return

-

Long, restrictive return trunks

-

Filter grilles too small

-

High-MERV filters choking airflow

-

Return air leaking from attics or crawlspaces

-

Single return for a multi-story home

-

Undersized return plenums

-

Flex duct crushed behind a closet return

The EPA warns that restricting return airflow severely harms system performance:

👉 https://www.epa.gov/indoor-air-quality-iaq

Tony’s approach:

Design the return BEFORE the supply.

⚙️ 2. The Magic Ratio: Returns Must Be 20–30% Larger Than Supply

This is Tony’s golden rule:

Supply air is the muscle.

Return air is the throat.

The throat must be bigger than the muscle.

Tony always sizes return air at:

-

20–30% MORE CFM capacity than the total supply CFM.

Why?

Because return air:

-

pulls against filter restriction

-

pulls against duct friction

-

pulls against home leakage

-

pulls against coil restriction

-

pulls through longer duct runs

-

pulls through grilles, elbows, transitions

Supply ducts push into open space.

Return ducts pull through obstacles.

This is why Tony oversizes return every time.

📉 3. Static Pressure Goes Through the Roof When Return Is Undersized

Return air is the #1 cause of high static pressure.

Tony defines static pressure simply:

“Static pressure is back-pressure inside your ducts.

High static = your blower is suffocating.”

Acceptable Total External Static Pressure (TESP)

-

0.3 – 0.5 in. w.c. → Ideal

-

0.6 – 0.7 in. w.c. → Restrictive

-

0.8 – 1.0+ → System choking

Tony tests static pressure on EVERY system he touches.

If return static is over 0.2–0.25, he already knows:

-

the return duct is undersized

-

the filter grille is choking

-

or the return path is poorly designed

📐 4. Tony’s Return Air Sizing Table (The One He Uses in the Field)

Here’s what Tony uses for quick duct sizing:

Return Air CFM by Duct Diameter (flex or metal)

| Return Size | Max Return CFM (Real World) |

|---|---|

| 10" | ~300 CFM |

| 12" | ~450 CFM |

| 14" | ~650 CFM |

| 16" | ~900 CFM |

| 18" | ~1200 CFM |

| 20" | ~1600 CFM |

So a 3-ton system needing ~1,200 CFM should have:

-

one 18" return, OR

-

two 14" returns, OR

-

multiple strategically placed smaller returns

But most homes have:

-

one 14" return for a 3.5-ton system

-

or one 12" return for a 3-ton system

-

or one 10" return trying to feed a 2.5-ton unit

Tony sees this every week.

🧮 5. The Real Return Air Formula — Simple, Fast, Accurate

Tony doesn’t need software.

He uses one fast calculation:

Return Duct Area (sq in) = Total System CFM ÷ 2

Why divide by two?

Because duct sizing charts assume:

-

ideal static

-

ideal flex stretch

-

ideal transitions

-

ideal filter airflow

Reality is worse.

So Tony doubles capacity by doubling duct area.

Example:

1,600 CFM system →

1,600 ÷ 2 = 800 sq inches of duct area needed

That’s:

-

one 20" round return (314 sq in × π-ish friction factors), OR

-

two 16" returns, OR

-

three 14" returns

Most homes have HALF this area.

🧵 6. Flex Return Duct — The Silent Killer of Blower Motors

Tony hates flex duct for return air.

He calls it:

“A straw for your HVAC system.”

Problems:

-

20–40% more friction than metal

-

compresses easily

-

often poorly stretched

-

sags, droops, pinches

-

insulation gaps lose temp

-

easily kinked behind closets

Flex duct rated for:

-

400 CFM in a lab

…delivers 250–300 CFM in a real attic.

This aligns with DOE ductwork performance research

Tony NEVER sizes return air assuming perfect flex duct.

🧊 7. Filter Grilles — The Most Undersized Component in the Entire System

Tony sees more wrong filter grilles than anything else.

Most homes have:

-

12"x12"

-

14"x14"

-

16"x20"

A 16x20 grille passes only:

~500 CFM with a normal filter

At MERV 11 or MERV 13?

Drop that to ~350–400 CFM.

For a 1,200–1,400 CFM system, you would need:

-

two 16x25 grilles, or

-

one 20x25 + one 16x25, or

-

one 24"x24" high-flow grille

Tony sizes filter grilles based on EPA airflow guidance:

👉 https://www.epa.gov/indoor-air-quality-iaq

If he sees:

“One tiny hallway return grille for the whole house…”

He already knows the blower is dying.

🔥 8. Why Electric Furnaces NEED Massive Returns

Electric heat strips require 100 CFM per kW to avoid overheating.

Example

20 kW heat requires:

-

2,000 CFM of return air

-

PLUS the return must be larger than supply

If return air is even slightly undersized:

-

heat strips overheat

-

limit switches trip

-

blower overheats

-

system short cycles

-

breakers trip

-

wire insulation cooks

-

system lifespan drops

DOE resistance heating documentation echoes this airflow requirement:

👉 https://www.energy.gov/energysaver/electric-resistance-heating

Tony has seen dozens of heat strips fail because the return was too small.

🧊 9. Heat Pumps Are Just as Sensitive — Even a Small Return Restriction Breaks Them

Heat pumps work with lower supply air temperatures:

-

85–105°F typical

-

75–95°F in cold weather

If return air is undersized:

-

pressure rises

-

airflow drops

-

coil gets too cold

-

system enters defrost

-

capacity drops

-

supplemental heat kicks on

-

energy bills skyrocket

DOE heat pump guidance warns about airflow issues just like Tony does:

👉 https://www.energy.gov/energysaver/heat-pump-systems

Return air issues cripple heat pump performance faster than any other system.

📉 10. Tony’s Static Pressure Audit — The Secret to Knowing Return Size

Tony checks static pressure in three spots:

✔ Across the filter

High = grille or filter too restrictive.

✔ Return plenum

High = duct too small or kinked.

✔ Blower inlet

High = system starved for air.

If Tony sees:

-

supply static: 0.2

-

return static: 0.4

-

total: 0.6

He knows the return is the bottleneck.

🛠️ 11. How Tony Fixes Return Air Problems (The Exact Methods)

Tony applies one or more of these depending on the home:

1. Add additional return grilles

Easiest way to relieve the blower.

2. Install larger return trunks

From 12" → 16"

From 14" → 18"

3. Replace flex with rigid metal

Huge airflow improvement.

4. Use 2" or 4" media filters

Much lower pressure drop.

5. Add return in every major zone

Especially two-story homes.

6. Seal duct leakage

Stops air from being pulled from attics/crawlspaces.

7. Open blocked return paths

Undercut doors

Transfer grilles

Jump ducts

🏡 12. Real Case Study: Tony Saves a Blower From Self-Destruction

Home:

2,000 sq ft

3.5-ton heat pump (1,400 CFM)

One 14"x20" return grille

14" flex return duct

Symptoms:

-

loud blower

-

poor heating

-

cold bedrooms

-

tripped heat strip limits

-

static pressure = 0.9" (!!)

Tony’s Findings:

-

return grille delivering 480 CFM

-

duct delivering 520 CFM

-

blower designed for 1,400 CFM

-

coil freezing

-

strips overheating

Tony’s Fix:

-

added second 16"x25" return

-

upgraded flex to 18" metal

-

installed low-restriction media filter

-

sealed return plenum

Final Results:

-

1,410 CFM delivered

-

Static pressure = 0.48"

-

Heat strips stable

-

No more cold rooms

-

Blower amperage dropped by 30%

-

System efficiency increased

Tony’s verdict?

“This blower wasn’t broken — it was suffocating.”

🏁 Conclusion: Return Air Is the Lifeline — And Tony Sizes It Like Your System’s Life Depends On It

Tony’s final word on return air:

“Your blower isn’t weak. It’s starving.

Feed it more return air, and everything gets better.”

When return air is properly sized:

-

static pressure drops

-

airflow increases

-

coil performance improves

-

electric heat runs safely

-

heat pumps gain capacity

-

blower amps decrease

-

rooms heat evenly

-

equipment lasts longer

Return air isn’t a detail.

It’s the foundation of system design.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know mmore about: Ducts First, Equipment Second — The Backwards-Sounding Rule That Makes Systems Last Longer