Why Tony refuses to size, sell, or install equipment until the ductwork proves it deserves it.

🏗️ Introduction: The Hard Truth Tony Teaches Every Homeowner

Most people think HVAC planning goes like this:

-

Pick a furnace or heat pump

-

Pick a SEER rating

-

Pick a tonnage

-

THEN figure out ductwork

Tony laughs when he hears that.

“If the ducts can’t move air, the equipment is just an expensive noise machine.”

He’s installed thousands of systems over four decades. And the pattern is always the same:

-

Strong ducts = long equipment life

-

Weak ducts = short equipment life

Ductwork is the chassis.

Equipment is the engine.

You wouldn’t put a V8 in a lawn mower.

Same logic — bigger equipment cannot compensate for bad airflow.

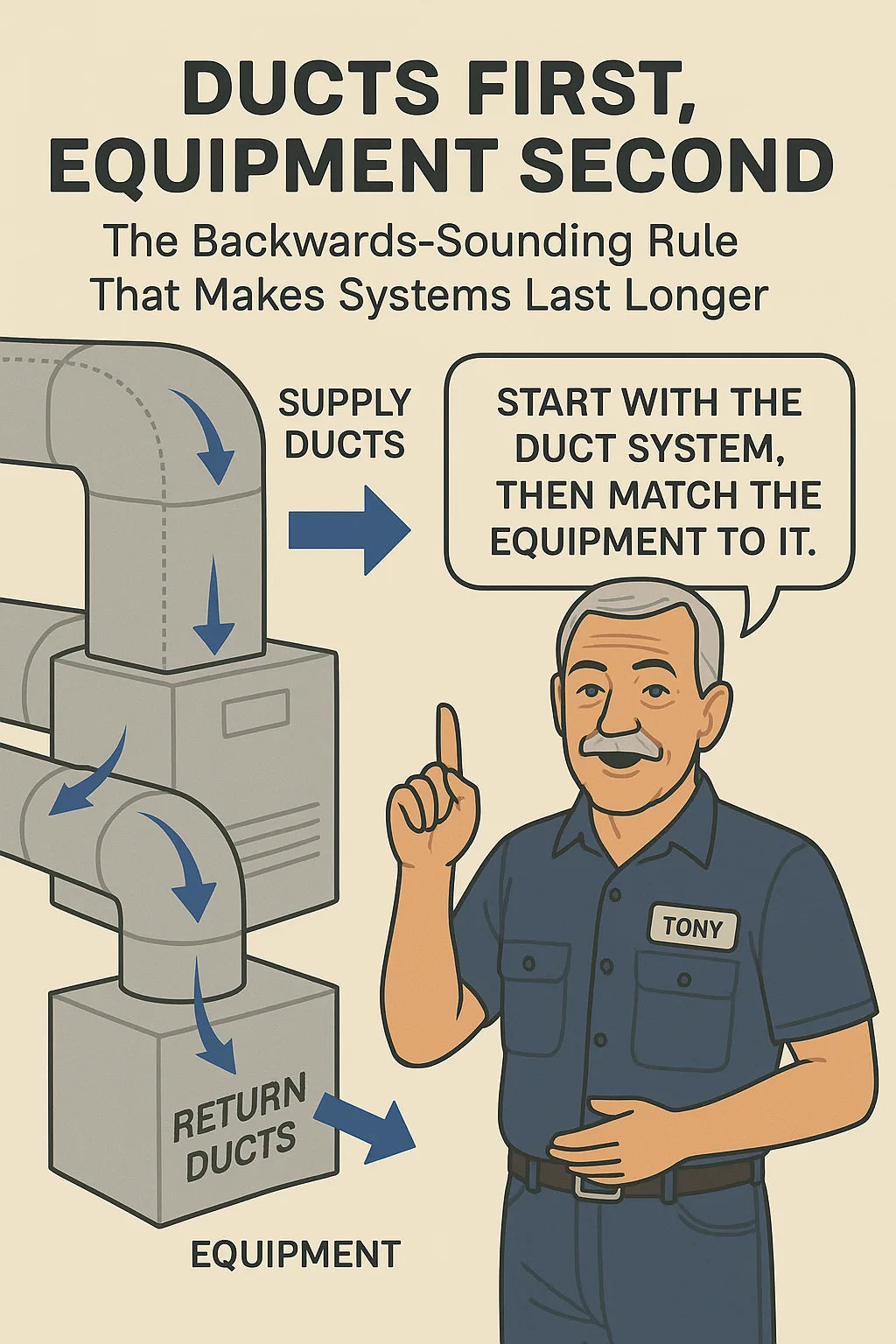

Tony’s rule sounds backwards… but it’s gospel:

Design the ducts FIRST.

Match the equipment SECOND.

That’s how you get systems that last 20+ years.

This article explains exactly why.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow

📦 1. The Biggest HVAC Mistake: Buying Equipment Before Checking Ducts

Tony sees this constantly:

-

Homeowner buys a 3.5-ton heat pump

-

Installer arrives

-

They realize the home has 2-ton ductwork

-

They hook it up anyway

And the outcome?

-

coil freezes

-

compressor struggles

-

heat strips overheat

-

blower runs hot

-

static pressure skyrockets

-

energy bills explode

-

equipment dies early

It’s not the equipment’s fault.

The DUCTS were never capable of feeding it the air it needed.

The Department of Energy warns that poor duct systems reduce HVAC performance by 20–30%:

👉 https://www.energy.gov/energysaver/ductwork-improvements

Tony says it better:

“Your ducts decide how big your system can be — not the other way around.”

🌬️ 2. Airflow Is the Foundation — Every System Lives or Dies by CFM

CFM = cubic feet per minute.

It’s the lifeblood of your HVAC system.

Standard airflow requirements:

-

350–400 CFM per ton of AC

-

100 CFM per kW of electric heat

-

130 CFM per 10,000 BTU of gas furnace output

If your ducts can’t move enough CFM, the system:

-

overheats

-

freezes

-

short-cycles

-

loses capacity

-

wastes money

-

wears out early

Tony’s famous line:

“If air can’t move, nothing works. Doesn’t matter what brand is on the box.”

This aligns with ACCA airflow standards:

👉 https://www.acca.org

📉 3. Static Pressure — The Invisible Enemy that Kills New Equipment

Even perfectly installed equipment will fail if static pressure is too high.

Static pressure is the “back pressure” inside the duct system.

Tony explains it simply:

“High static = your blower is choking.”

Acceptable Total External Static Pressure (TESP):

-

0.3–0.5 in. w.c. → Ideal

-

0.6–0.7 → Restrictive

-

0.8–1.0+ → Equipment killer

Where high static comes from:

-

undersized returns

-

long duct runs

-

crushed flex duct

-

high-MERV filters

-

undersized trunks

-

dirty coils

-

narrow turns

-

poor transitions

If static pressure is too high, Tony will NOT install equipment until ducts are corrected.

📐 4. The Duct System Determines Your Maximum System Size

Tony sizes ducts FIRST because ducts determine:

-

CFM

-

pressure

-

capacity

-

blower speed

-

heat distribution

-

room comfort

-

equipment lifespan

Tony’s sizing values (REAL WORLD, not lab conditions):

| Ton | Required CFM | Minimum Return Size | Typical Return Setup |

|---|---|---|---|

| 2.0 | 700–800 CFM | 14"–16" | 1 large return |

| 2.5 | 875–1,000 CFM | 16" | 1–2 returns |

| 3.0 | 1,050–1,200 CFM | 18" | 2 returns |

| 3.5 | 1,225–1,400 CFM | 18"–20" | 2–3 returns |

| 4.0 | 1,400–1,600 CFM | 20" | 3 returns |

| 5.0 | 1,750–2,000 CFM | 22" | 3–4 returns |

Most homes Tony sees have HALF the return airflow needed.

So he doesn’t upsize equipment — he fixes ducts.

🧱 5. Why Big Equipment + Small Ducts = Death Sentence

Tony has removed dozens of systems under 10 years old because of one problem:

Equipment was too big for the ductwork.

Symptoms include:

-

blower wheel dust baked on from overheating

-

ECM motors burned out from over-amp conditions

-

iced evaporator coils

-

cracked heat exchangers (gas furnace)

-

melted terminal connections on heat strips

-

sweating ducts

-

severe short cycling

-

loud airflow noise

-

uneven rooms

Tony’s signature saying:

“Oversizing equipment on undersized ducts is like trying to jog while breathing through a coffee stirrer.”

He refuses to do it.

🪠 6. Flex Duct: Tony’s “Silent Killer” of Good Equipment

Tony has a love/hate relationship with flex duct:

-

He loves it for short, straight runs

-

He hates it for everything else

Flex duct problems:

-

too much friction

-

easily crushed

-

installed without stretching

-

long runs sag like hammocks

-

kinks behind attic trusses

-

insulation gaps leak heat

A run of flex duct that should move 400 CFM will often move 250–300 CFM in real homes.

The DOE has documented these losses extensively

This is why Tony often removes:

-

6" flex

-

8" flex

-

10" flex

…and replaces them with steel ducts or oversized flex with proper supports.

🧊 7. Heat Pumps and Electric Furnaces Amplify Duct Problems

Heat pumps run with lower supply temperatures:

-

85–105°F in heating

-

lower in cold weather

Electric heat strips require enormous airflow:

-

100 CFM per kW of heat

So when ductwork is undersized:

-

heat strips overheat

-

defrost cycles run constantly

-

rooms stay cold

-

backup heat runs too often

-

utility bills spike

DOE heat pump guidance explains why airflow is critical:

👉 https://www.energy.gov/energysaver/heat-pump-systems

Tony’s perspective:

“Heat pumps and electric heat are unforgiving. Ducts must be right or the system fights itself.”

🔍 8. Tony’s Duct Inspection Checklist Before He Touches Equipment

Tony inspects:

✔ Supply trunks

for size, length, and airflow capacity

✔ Return trunks

most systems fail here

✔ Filter grilles

usually too restrictive

✔ Flex duct compression

a universal problem

✔ Coil cleanliness

a dirty coil fakes undersized ducts

✔ Blower wheel

dust adds major static

✔ Static pressure readings

the truth meter

✔ Leaks & gaps

every duct leaks until proven otherwise

EPA airflow guidelines support all of these checks:

👉 https://www.epa.gov/indoor-air-quality-iaq

If ductwork fails his tests, he designs a duct-first renovation, not an equipment-first quote.

🛠️ 9. How Tony Fixes Duct Systems BEFORE Installing Equipment

Tony uses a set of proven corrections:

1. Add more return air

Solves 80% of airflow problems.

2. Enlarge returns

14" → 16"

16" → 18"

18" → 20"

3. Upgrade filter grilles

Low-restriction models dramatically help airflow.

4. Replace flex with metal

Especially for long trunk lines.

5. Add proper duct supports

Fixes sagging flex.

6. Reroute bad elbows

Short 90° bends are airflow killers.

7. Install balancing dampers

Fine-tunes the system.

8. Seal duct leaks

Massive energy savings and better comfort.

Tony won’t size equipment until these are right.

🏁 Conclusion: Good Equipment Needs Good Ductwork — Period.

Tony’s final message?

“Bad equipment on good ductwork can still work.

Good equipment on bad ductwork will NEVER work.”

It sounds backwards.

But it’s how systems survive decades instead of dying in eight years.

Ducts FIRST.

Equipment SECOND.

Always.

When the duct system is right:

-

airflow increases

-

static drops

-

blower amps fall

-

coils perform better

-

strip heat is stable

-

heat pumps hold capacity

-

rooms feel even

-

equipment lasts FAR longer

This rule is simple but powerful:

**Fix the air path. Then install the equipment.

Not the other way around.**

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know mmore about: Heat Rise Isn’t Optional — How Tony Uses Temperature Split to Confirm a System Was Designed Right