Why your system’s supply-to-return temperature difference tells the truth about ductwork, airflow, design, and whether the system is even safe to run.

🌡️ Introduction: The One Number Tony Trusts More Than Any Manual or Sales Brochure

Homeowners ask Tony all the time:

“How do you KNOW my system is sized right?”

He doesn’t start by looking at:

-

BTUs

-

tonnage

-

heat strip wattage

-

furnace rating

-

coil tonnage

-

SEER2 or HSPF

Nope.

Tony goes straight to heat rise — the temperature difference between:

Return air (what the system breathes in)

and

Supply air (what the system blows out).

That difference — called ΔT (delta-T or temperature split) — tells him:

-

if the airflow is correct

-

if the ducts are sized right

-

if the coil is matched

-

if the blower is undersized or choking

-

if heat strips are overheating

-

if a furnace is firing correctly

-

if a heat pump is performing to spec

-

if the system was designed right in the first place

Tony says:

“Heat rise doesn’t lie.

Fancy equipment CAN lie, but heat rise never does.”

This article breaks down exactly how Tony uses ΔT to verify proper design, safe operation, and long-term system reliability.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow

🧰 1. What Heat Rise Actually Is — And Why It Matters More Than Most Techs Realize

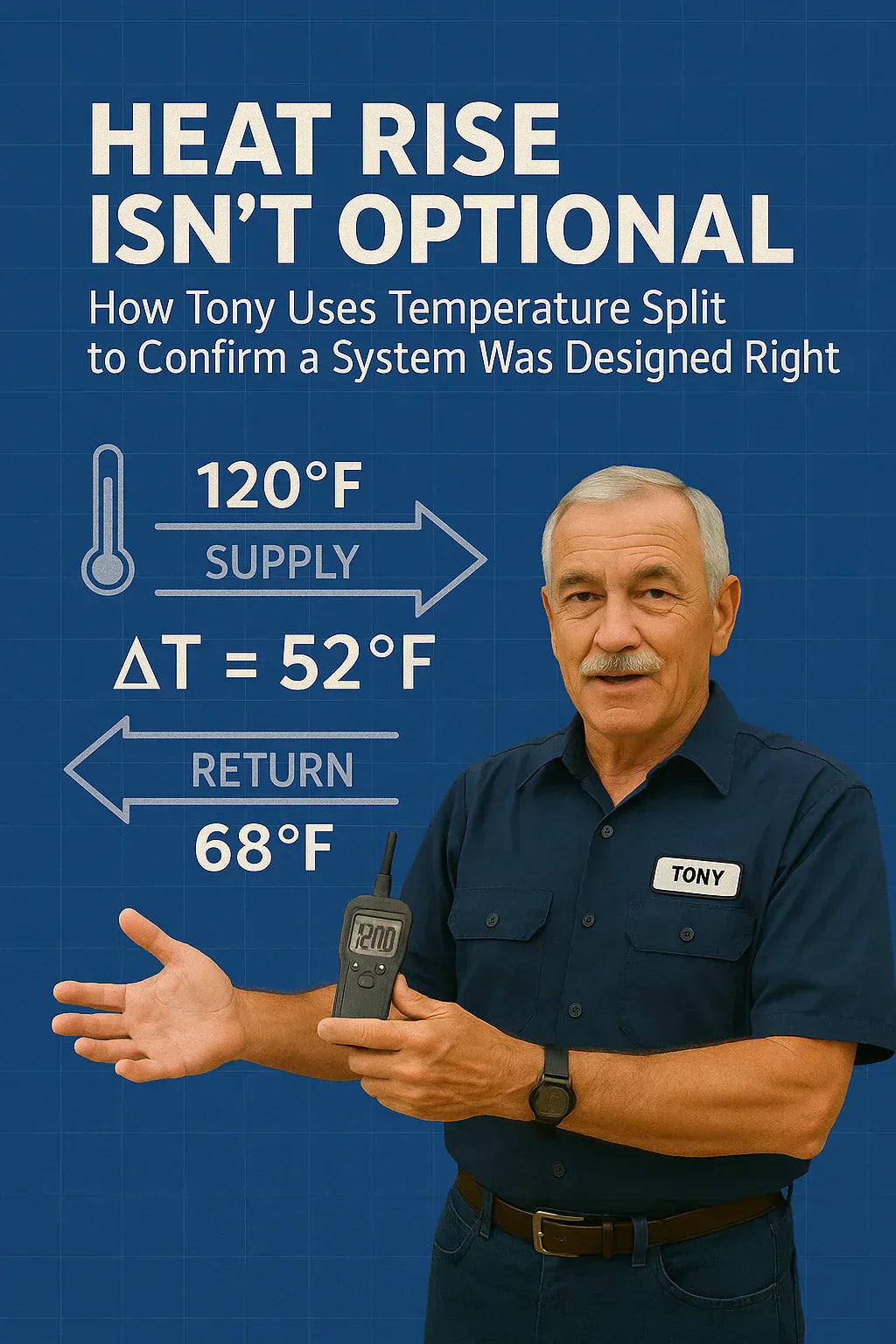

Heat rise (or temperature split) uses a simple formula:

ΔT = Supply Air Temperature – Return Air Temperature

For example:

Return = 68°F

Supply = 120°F

ΔT = 52°F

That 52°F tells Tony ALL of this:

-

Is airflow right?

-

Are filters restricting?

-

Are ducts undersized?

-

Are returns suffocating the blower?

-

Are heat strips overheating?

-

Is the coil dirty?

-

Is the furnace firing properly?

-

Is static pressure within limits?

-

Is the blower speed correct?

The U.S. DOE stresses proper airflow and temperature rise as key to correct HVAC performance:

👉 https://www.energy.gov/energysaver/home-heating-systems

Heat rise is the system’s truth serum.

🔥 2. Heat Rise Values Tony Expects for Every Type of System

Tony has specific targets for each heating method.

Gas Furnace (Typical)

-

Acceptable heat rise: 30°F–60°F

-

Listed on every furnace data plate

-

Too low = high airflow or firing issues

-

Too high = low airflow (VERY dangerous)

If heat rise exceeds the listed range?

Tony shuts the furnace down until corrected.

Electric Heat Strips

-

Typical heat rise: 20°F–35°F per stage

-

Too high = overheating

-

Too low = not enough airflow or failed strip

DOE warns that electric resistance heat is extremely sensitive to airflow:

👉 https://www.energy.gov/energysaver/electric-resistance-heating

Heat Pump (Heating Mode)

-

Typical temperature split: 15°F–30°F

-

Lower in colder weather

-

Too low = low charge, low airflow, or defrost problems

-

Too high = airflow restriction

Air Conditioning (Cooling Mode)

-

Typical ΔT: 16°F–22°F

-

Lower = airflow too high, low charge

-

Higher = airflow too low, dirty coil

ACCA’s Manual S and Manual D documents confirm these ranges:

Tony uses these ΔT values as his “diagnostic compass.”

🧊 3. Why High Heat Rise = The Blower Is Suffocating

Tony always checks for one thing first:

Is heat rise above the equipment’s rated limit?

Because high ΔT means:

-

not enough air is moving across the heat source

-

heat has nowhere to go

-

components are overheating

-

safety switches are working overtime

-

blower motors are stressed

-

strips and exchangers suffer damage

Common causes Tony sees:

-

undersized return ducts

-

1-inch restrictive filters

-

dirty blower wheel

-

dirty coil

-

closed registers

-

long, restrictive duct runs

-

kinks in flex duct

-

static pressure above 0.7 in.w.c.

Tony has seen gas furnaces hit 160°F supply temps simply because of one small, clogged 16x20 filter grille.

💨 4. Why Low Heat Rise = Airflow Is Too High or Heat Output Is Wrong

Low ΔT means:

-

TOO MUCH airflow

or -

NOT ENOUGH heating capacity

Tony checks:

✔ Blower speed (might be on “high” when it should be “medium”)

✔ Heat strips (a failed 5 kW strip cuts ΔT dramatically)

✔ Gas pressure (incorrect manifold pressure lowers output)

✔ Refrigerant charge (for heat pumps)

✔ Oversized return air

✔ Leaky return ducts pulling in cold air

Tony once saw a 15°F heat rise on a gas furnace that should be at 45°F.

Guess what?

Return ducts were leaking 400 CFM of 35°F crawlspace air.

ΔT told the truth.

🧼 5. Dirty Coils & Filters Destroy Heat Rise — Even on Brand-New Systems

Tony says this constantly:

“If a filter can’t breathe, the equipment can’t heat.”

Dirty filters reduce airflow → heat rise goes UP.

Dirty evaporator coils increase resistance → heat rise goes UP.

Dirty blower wheels move less air → heat rise goes UP.

DOE documentation warns that poor maintenance reduces HVAC performance exactly this way:

👉 https://www.energy.gov/energysaver/maintaining-your-air-conditioner

Tony often finds:

-

coil matted with dust

-

blower wheel caked with debris

-

filter clogged months ago

-

return grille blocked by furniture

Heat rise instantly exposes all of these.

📉 6. Why Heat Rise Reveals Duct Design Problems Better Than Any Other Test

Tony uses ΔT as his duct competence test.

If ΔT is too high?

Ducts can’t remove heat → static pressure too high.

If ΔT is too low?

Ducts leak return air → reducing temperature difference.

If ΔT varies between rooms?

Duct runs are unbalanced or too long.

If ΔT changes throughout the cycle?

Return duct leaks air from an attic or crawlspace.

This aligns with EPA duct leakage warnings:

👉 https://www.epa.gov/indoor-air-quality-iaq

Heat rise is Tony’s proof that the duct system is either:

-

correctly designed

or -

slowly killing the equipment

🧪 7. Tony’s Field Method: How He Measures Heat Rise Like a Pro

Tony uses the same method every time:

Step 1 — Measure Return Temperature

He places a probe:

-

two feet upstream of the filter

-

away from outside air influence

-

in the return plenum

Step 2 — Measure Supply Temperature

He places a probe:

-

two feet past the heat source

-

before duct splitting

-

never at a register (too much loss)

Step 3 — Let System Stabilize

He waits:

-

10–12 minutes for gas furnace

-

7–9 minutes for heat strips

-

12–15 minutes for heat pump

Step 4 — Calculate ΔT

Simple math.

Step 5 — Compare to Rated Nameplate

Every furnace lists allowed heat rise.

If ΔT is out of range → design issue.

No guesswork.

No assumptions.

Heat rise tells the truth.

🔥 8. Gas Furnace Heat Rise — Where Safety Truly Hinges on Airflow

Gas furnaces are the most dangerous to get wrong.

Signs the furnace is overheating:

-

ΔT too high

-

supply air over 150°F

-

limit switch clicking

-

metal expansion noises

-

blower ramping hard

-

burning dust smell

High ΔT = high exchanger temperature = metal stress = premature cracking.

Tony has condemned cracked heat exchangers in systems less than 6 years old…

all because the returns were choking the blower.

He follows manufacturer-recommended heat rise ranges and NEC safety guidelines

⚡ 9. Electric Heat: Heat Rise Is the Only Thing Preventing Melted Wires & Burnouts

Electric heat strips need MASSIVE airflow:

-

100 CFM per kW, minimum

Example:

10 kW → 1,000 CFM

20 kW → 2,000 CFM

Tony has seen:

-

overheated cabinets

-

melted high-temp wire insulation

-

scorched heat strip frames

-

blown high-limit switches

All because airflow was low → heat rise too high.

DOE explicitly warns about electric heat airflow requirements:

👉 https://www.energy.gov/energysaver/electric-resistance-heating

ΔT tells Tony immediately if strip heat is safe.

❄️ 10. Heat Pumps: ΔT Is Lower — But Even More Informative

Heat pumps don’t produce 120°F air.

They produce:

-

85°F–100°F normally

-

lower in very cold weather

Tony uses ΔT to check:

-

refrigerant charge

-

staging and ramping issues

-

defrost cycle behavior

-

duct leakage

-

return temperature integrity

-

airflow correctness

-

whether auxiliary heat is masking performance problems

A heat pump with ΔT below 10°F (while defrost is OFF) is always a problem.

DOE confirms the temperature split is tied directly to airflow and charge:

👉 https://www.energy.gov/energysaver/heat-pump-systems

🧠 11. Tony’s Rule: “The System Doesn’t Care What You Paid — It Cares if the Air Moves.”

Tony proves equipment sizing correctness with ΔT.

If ΔT is good →

System was designed right.

If ΔT is wrong →

System was poorly designed, or is being choked by:

-

bad duct sizing

-

wrong blower tap

-

dirty components

-

wrong heat strip staging

-

bad gas pressure

-

coil mismatch

-

airflow restriction

Heat rise is the “performance verdict.”

🏗️ 12. Real Case Study: Tony Fixes a System Using Only ΔT

Home

2,100 sq ft

3.5-ton heat pump

10 kW heat strips

Symptoms

-

house cold in winter

-

strips constantly tripping

-

high power bills

Tony’s ΔT Tests

Return: 67°F

Supply: 102°F

ΔT = 35°F ← way too high for heat pump alone

Heat strips kicked in:

Return: 67°F

Supply: 138°F

ΔT = 71°F ← EXTREMELY dangerous

Tony’s Findings

-

return duct undersized

-

flex return kinked behind closet

-

filter grille too small

-

blower wheel dirty

Tony’s Fix

-

replaced 14" return with 18"

-

new high-flow grille

-

cleaned blower

-

raised blower speed one tap

-

rebalanced ductwork

Final ΔT

Heat pump: 22°F (perfect)

Aux heat: 28°F (safe)

Problem solved.

ΔT saved the system.

🏁 Conclusion: Heat Rise Isn’t Optional — It’s the System’s Report Card

Tony puts it plainly:

“Heat rise tells me if your system is healthy, sick, or dying.”

It proves:

-

airflow correctness

-

duct sizing

-

coil condition

-

blower performance

-

gas firing accuracy

-

heat strip safety

-

heat pump capacity

-

refrigerant charge

-

static pressure impact

Every perfect HVAC system has one thing in common:

A perfect ΔT.

If ΔT is right, everything else will be right.

If ΔT is wrong, NOTHING else will be right.

Heat rise never lies.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know mmore about: When an Electric Furnace Beats a Heat Pump — System Design for Homes Too Cold (or Too Tight) for Anything Else