Key Takeaways

-

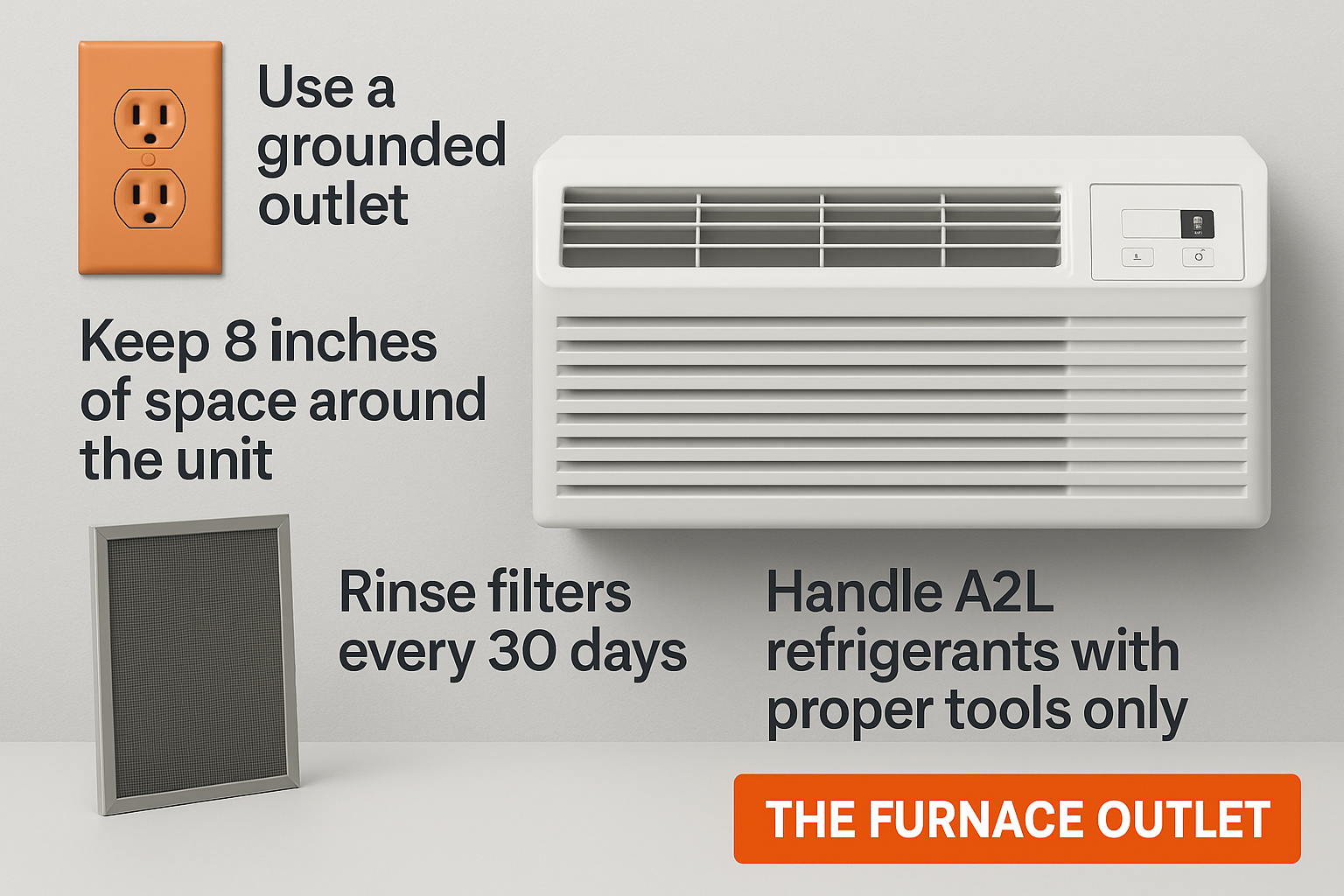

Use a grounded outlet—loose or two-prong plugs are dangerous.

-

Keep 8 inches of space around the unit for safe airflow.

-

Rinse filters every 30 days to save energy and cut fire risk.

-

Handle A2L refrigerants with proper tools only.

-

Do lock-out/tag-out before maintenance to avoid shocks.

Why PTAC Safety Matters in Busy U.S. Buildings

A single PTAC cools a hotel room, senior-living suite, or college dorm without ductwork. That convenience hides real hazards: electric shock, coil fires, mold, and now mildly flammable A2L refrigerants. The Consumer Product Safety Commission logs over 2,000 PTAC-related incidents each year—half involve power cords and blocked grilles. In this guide you’ll learn practical rules that protect guests and staff, meet U.S. codes, and keep units running longer. We’ll link to deeper dives—such as the PTAC Maintenance Guide—so you can act fast when questions pop up. By the end, even a 12-year-old will grasp why “plug, air, clean, cool” is the golden safety mantra.

Don’t forget the basics—get your HVAC filters and tools here.

Electrical Safety: Grounding, Cords, and Breakers

Electricity is the first line of defense. Always match the plug to a properly grounded receptacle—check the label for 208/230 V or 265 V before sliding the chassis into the wall sleeve. If you’re unsure, the PTAC Sizing Chart explains voltage and plug face codes in plain English. Never file down the grounding pin; it’s the path that saves lives when a hot wire touches the metal frame. Inspect cords every quarter: look for brittle insulation, burn marks near the prongs, or bent blades. Unplug (or lock out at the breaker) before you remove the grille—arcing behind the control board can hit 2,000 °F in milliseconds. National Electrical Code (NEC-2023) calls for an all-pole disconnect within sight; many property managers mount a handle-operated breaker above the headboard for this reason.

Check plug types and match voltage fast—use our PTAC Sizing Guide.

Fire Prevention Starts with Airflow and Correct Placement

PTACs reject heat straight back into the room; starve that path and the internal temperature soars past 212 °F. Keep eight inches of clearance in front and two inches on the sides. Heavy drapes, luggage stands, and even tall mulch outside the vented wall sleeve trap heat. A recent hotel audit found that blocked sleeves caused half of all PTAC fires. Before installation, read our quick guide on PTAC Energy Rebates—it explains why utility programs insist on clear return airflow. Newer units using R-32 or R-454B (both A2L) need spark-free service valves and no open flames nearby. Always post a “No Smoking or Vaping” decal within three feet of the grille—ASHRAE 15.2-2024 makes this a best practice in hospitality spaces.

Cleaning and Filter Care Without Breaking the Unit

Dirt acts like a blanket on the indoor coil. When air can’t move, the compressor runs longer, wires heat up, and the fire risk jumps. Slide out the filter monthly—run it under warm water, shake dry, and reinstall. For a visual step-by-step, bookmark Save 20 % Energy with Simple Maintenance. Wipe the front grille with a damp microfiber cloth—harsh sprays can pit plastic and expose sharp edges. Vacuum the vent screen outside; spider webs are flammable. Always unplug first. A soft-bristle coil brush loosens debris without bending aluminum fins—bent fins cut airflow like a closed door. Finish by dropping a mold-control tablet in the base pan; it fizzes for 30 days and keeps the condensate drain clear.

Deep Maintenance: Coils, Drain Pans, and Wall Sleeves

Seasonal maintenance dives deeper. Remove the chassis and set it on a trolley—two people minimum. Spray a foaming coil cleaner, wait ten minutes, and rinse with low-pressure water. Check the drain pan slope; water pooling near the heater strip can flash-boil when the unit switches to heat. Re-seal gaps around the wall sleeve with exterior-grade silicone; gaps invite rain and insects. The PTAC Maintenance Guide lists monthly, quarterly, and annual tasks. Always let the chassis dry 24 hours before restoring power—hidden moisture tracks electricity straight to metal parts. Finally, check airflow with a simple tissue test: if the tissue flutters steadily away from the grille, you have good draw.

Refrigerant Safety: From R-410A to Modern A2L Blends

Most PTACs sold after 2024 use A2L refrigerants like R-32 or R-454B to meet U.S. EPA GWP limits. These blends are low in flammability but still ignite around 1,000 °F. Use hoses, recovery tanks, and vacuum pumps stamped “A2L-compatible.” Never mix hoses between refrigerants—cross-contamination can form acids that weaken copper tubing. Purge with dry nitrogen, not oxygen. If you smell sweet, solvent-like odors, evacuate and ventilate; A2L gases are heavier than air and linger near the floor. Keep a handheld leak detector rated for A2Ls—older R-410A sensors won’t pick them up. Store cylinders below 125 °F and upright; a tipped bottle can spit liquid refrigerant into the gauge manifold, causing frostbite.

Need safe accessories? Shop A2L-rated tools and line sets.

Training, Tools, and PPE for Maintenance Staff

Safety plans only work when people know and follow them. Hold a 30-minute refresher each quarter covering lock-out/tag-out, PPE, and spill response. Arc-rated gloves (Class 00, 500 V) stop most PTAC shock events; leather protectors go over them for cuts. Clear, ANSI-Z87.1 eye protection guards against coil cleaner splash. A2L compatible leak detectors and vacuum pumps reduce mishandling. Post the unit’s wiring diagram on the inside of every access door so new techs aren’t guessing. For more step-by-step fault finding, share the PTAC Troubleshooting Cheat Sheet with your team. Finally, log each service task—dated notes prove compliance when insurers ask.

Quick Reference Safety Checklist for Owners and Managers

-

Confirm correct voltage and grounded plug.

-

Keep eight-inch clearance around intake and discharge grilles.

-

Rinse or replace filter every 30 days.

-

Inspect cord, plug, and chassis for damage each quarter.

-

Clean coils and drain pan every six months.

-

Use A2L-rated gauges and tanks for R-32 or R-454B units.

-

Lock out power before service; verify with a meter.

-

Document all work in a maintenance log.

Pin this list next to your housekeeping checklist or share it company-wide through the HVAC Tips hub so no one forgets the basics.

Ready for Safer, Smarter PTACs?

Explore R-32 PTACs, hotel units, and A2L-compatible tools built for 2025 safety codes.

📸 Need sizing help? Snap a photo for a quote.

📞 Contact us if you're unsure what to order—we're here to help.

Frequently Asked Questions

Q: Can I run a PTAC on an extension cord?

A: No. Extension cords overheat and void warranties. Always use a dedicated, grounded outlet.

Q: How often should I change the filter in a hotel setting?

A: Every 30 days during heavy use, or sooner if guests smoke.

Q: Is R-32 dangerous?

A: It’s slightly flammable (A2L) but safe when handled with A2L-rated tools and good ventilation.

Q: What’s the best cleaner for coils?

A: A non-acid, foaming coil cleaner labeled for aluminum fins. Rinse thoroughly.

Q: My PTAC trips the breaker—what now?

A: Unplug it, inspect for cord damage, and check the plug type against the breaker size. See the Troubleshooting Cheat Sheet for step-by-step tests.