🏢 Introduction: The Space Challenge

One of the biggest mistakes I’ve seen in commercial HVAC planning isn’t choosing the wrong tonnage—it’s not planning for space.

A 10 ton multi-positional system like the Daikin light commercial unit is a serious piece of equipment. It’s not something you tuck into a corner of a closet or wedge into a cramped basement. If your mechanical room isn’t properly sized and laid out, you’ll run into:

-

Delivery headaches (can’t fit the unit through doorways).

-

Installation delays (ducts, drains, and wiring not accessible).

-

Safety hazards (no room for service or airflow).

I’ve had to stop projects halfway through because someone assumed “if it’s 10 tons, it’ll just fit.” Believe me—it doesn’t work that way.

This guide explains what you need to know about dimensions, clearance requirements, and space planning so your 10 ton system fits right the first time.

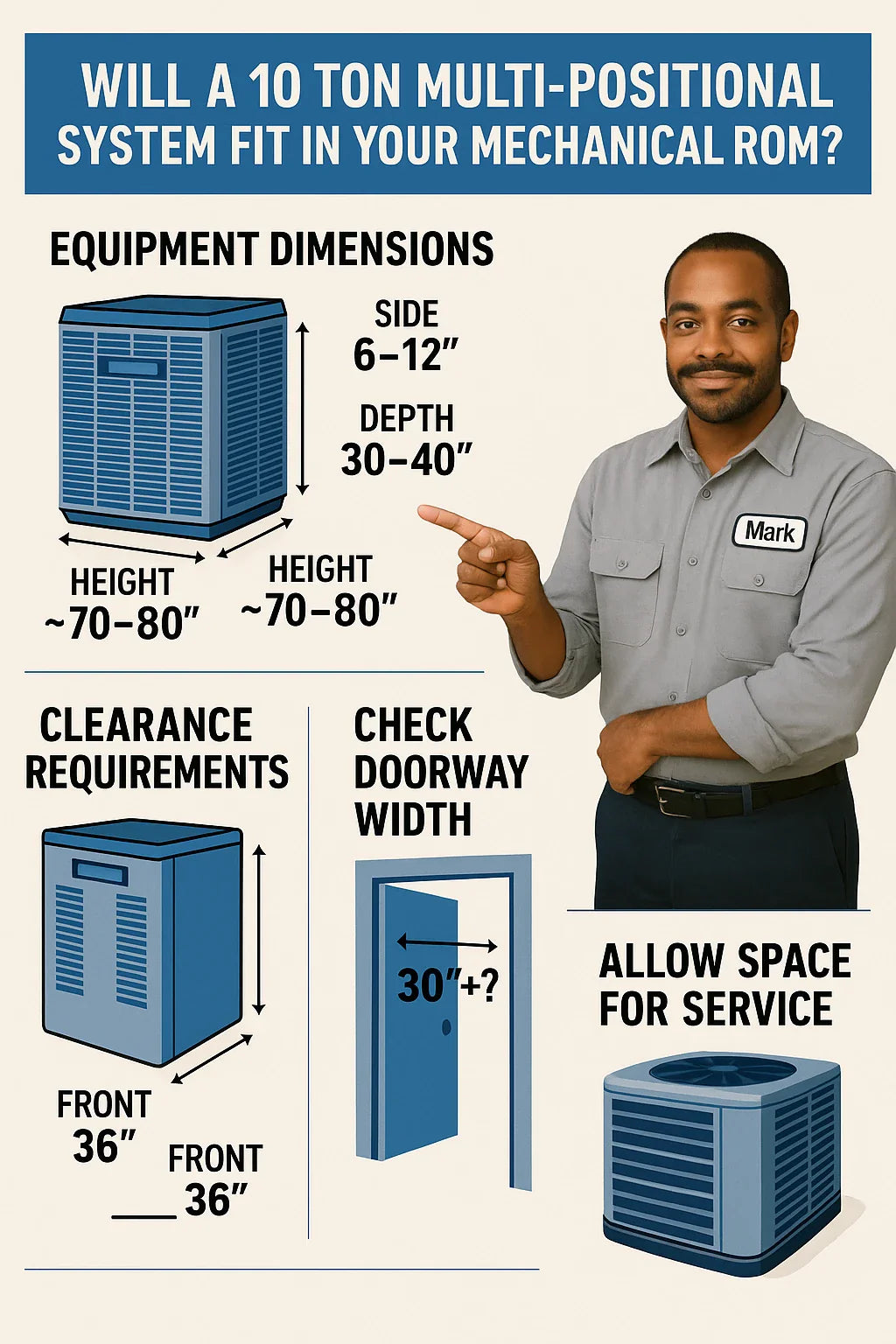

📐 Equipment Dimensions: How Big Is a 10 Ton System?

Let’s start with size.

Air Handler Dimensions (Typical Daikin 10 Ton Unit)

-

Height: ~55–65 inches (about 5 feet).

-

Width: 25–35 inches.

-

Depth: 30–40 inches.

-

Weight: 350–500 pounds.

Outdoor Condenser Dimensions

-

Height: ~55–65 inches.

-

Width: 40–55 inches.

-

Depth: 40–55 inches.

-

Weight: 500–650 pounds.

That’s just the unit itself. You also need space for:

-

Duct connections (supply + return).

-

Electrical panels and disconnects.

-

Condensate drains/pumps.

-

Service access panels (front and sides).

📖 HVAC.com’s installation guide notes that mechanical rooms often fail not because of unit size, but because of poor allowance for service access.

🔄 Multi-Positional Flexibility

Here’s one advantage of Daikin’s multi-positional design: you can configure the air handler in three orientations.

-

Upflow – Air blows upward into ducts above the unit.

-

Best for: ceiling-mounted ducts in offices and retail.

-

-

Downflow – Air blows downward into floor ducts.

-

Best for: slab-on-grade buildings with ducts below.

-

-

Horizontal (left or right) – Air blows sideways.

-

Best for: tight crawlspaces, mechanical rooms with limited height.

-

This flexibility can make the difference between a system that fits and one that requires major construction.

📏 Clearance Requirements

Even if you can squeeze the equipment into a space, you also need to meet clearance requirements.

Air Handler Service Clearances

-

Front: 36 inches minimum (for filter access and coil cleaning).

-

Sides: 12–18 inches.

-

Top/Bottom: Varies by orientation, but allow at least 12 inches.

Outdoor Condenser Clearances

-

Sides: At least 24–36 inches for airflow.

-

Top: 5 feet clear above the fan discharge.

-

Front (service access): 36 inches minimum.

Why It Matters

-

Poor clearance makes it hard to service coils, fans, and electrical components.

-

OSHA requires safe working space around electrical panels and equipment.

-

Tight spaces trap heat, reducing efficiency.

🚪 Mechanical Room Access

This is one of the most overlooked factors in installation planning: getting the unit into the mechanical room.

Doorways & Pathways

-

Check door width—many 10 ton units are 30–35 inches wide. If your door is only 32 inches, it’ll be a tight squeeze.

-

Clear hallways and corners—no tight turns during delivery.

-

If the unit can’t fit, walls may need to be temporarily removed.

Floor Space

-

A 10 ton system often requires a dedicated mechanical room, not just a closet.

-

Floor must support 500+ pounds (for the indoor unit) and more if stacked with accessories.

📖 ASHRAE installation standards stress pre-checking mechanical room design before ordering equipment.

🔧 Supporting Systems That Take Space

The unit itself isn’t the only thing demanding room. Your mechanical room also needs to accommodate:

-

Electrical panels and disconnects (per NEC and OSHA code).

-

Condensate drainage systems (gravity-fed or pump).

-

Duct transitions to connect to supply and return.

-

Fresh air intake systems for ventilation if required.

-

Heat kit wiring and breakers (for systems with 20kW kits).

Too often I’ve seen units shoved into small rooms with no space left for drains, breakers, or duct transitions—a recipe for maintenance nightmares.

📖 DOE guidelines explain that poorly designed mechanical rooms lead to long-term efficiency losses.

🛠️ Modifications If Space Is Tight

So what if your mechanical room feels too small? Don’t panic—there are options.

Solutions I’ve Used

-

Switch orientation – Use horizontal instead of upflow.

-

Resize ductwork – Move or reroute ducts to free clearance.

-

Outdoor pad install – Relocate air handler outdoors in mild climates.

-

Rooftop placement – Install condenser or even full unit on the roof with crane.

-

Knockout wall panel – Add a removable wall panel for future replacements.

Sometimes the fix is simple—other times, it requires rethinking where the system goes altogether.

📖 Modernize HVAC cost guide lists duct and structural modifications as common hidden costs.

🧾 Mark’s Real-World Example

A few years ago, I was helping replace a failed 10 ton system in a 3,800 sq. ft. retail store.

The new Daikin unit arrived on site—and we hit a wall. Literally. The mechanical room door was 32 inches wide, but the air handler was 34 inches.

Our solution: remove part of the door frame and temporarily widen the entry. We also switched the air handler to horizontal orientation to fit the ceiling height.

Lesson learned: always measure pathways and room clearance before ordering equipment.

✅ Checklist Before Ordering a 10 Ton Unit

Here’s my go-to checklist to avoid installation disasters:

-

📏 Measure mechanical room dimensions (length, width, height).

-

🚪 Measure doorways and hallways—include turns.

-

🔧 Verify service clearance (36 inches in front).

-

⚡ Plan for electrical disconnects and panels.

-

💧 Check for condensate drain access.

-

🛠️ Review duct layout—are trunks large enough for 10 tons of airflow?

-

🏗️ Confirm structural support for equipment weight.

-

📖 Consult manufacturer’s installation manual.

📈 Conclusion: Fit First, Buy Second

Buying the right AC system is only half the battle. If it doesn’t fit in your mechanical room, you’ll waste time, money, and patience.

From my perspective as a facilities manager:

-

Measure twice, order once.

-

Don’t assume flexibility = unlimited fit.

-

Always account for clearance, access, and service space.

Mark’s takeaway: “The best system won’t help you if it can’t fit through the door.”

In the next topic we will know more about: Do 10 Ton Commercial AC Systems Qualify for Rebates or Tax Credits in 2025?