🏢 Introduction: Why Maintenance Matters

When I walk into a building with a brand-new 10 ton commercial AC system, I can already predict what will happen if the owner skips maintenance: higher bills, uneven cooling, unexpected breakdowns, and eventually, a replacement years before it should be needed.

These systems aren’t cheap. A Daikin 10 Ton Multi-Positional Split System with a 20kW heat kit is designed to last 15–20 years—but only if you take care of it. Without regular upkeep, you could be looking at a system lifespan closer to 8–12 years.

The truth is simple: maintenance is cheaper than repairs. In fact, the U.S. Department of Energy estimates that proper maintenance can reduce HVAC energy use by 10–20% annually .

I’ve pulled together the most important maintenance tips I’ve learned as a facilities manager, so your Daikin 10 ton system runs smooth, efficient, and problem-free.

🧹 Tip 1: Stay on Top of Filter Changes

One of the easiest—and most overlooked—maintenance tasks is air filter replacement.

-

How often?

-

Office or retail: every 2–3 months.

-

Restaurants or dusty workshops: every 1 month.

-

Community centers with moderate use: every 3 months.

-

-

Why it matters:

-

Dirty filters restrict airflow, forcing your 10 ton blower to work harder.

-

That means higher energy bills and shorter equipment life.

-

Clean filters also improve indoor air quality, which employees and customers notice.

-

-

Pro tip: Keep a box of spare filters on site, and train staff to swap them out.

📖 ENERGY STAR’s filter maintenance guide confirms this is the #1 step to keeping efficiency high.

❄️ Tip 2: Clean Coils Regularly

Your Daikin system has two main sets of coils:

-

Evaporator coil (inside the air handler).

-

Condenser coil (outside unit).

Over time, dirt, grease, and pollen coat the fins. This insulation layer blocks heat transfer, making the system run longer to achieve the same cooling.

-

When to clean: Twice a year (spring and fall).

-

How to clean:

-

Turn off power.

-

Spray with coil cleaner (non-corrosive, foaming).

-

Rinse gently with water.

-

-

Warning signs: Longer runtimes, uneven cooling, ice buildup on coils.

📖 Energy.gov HVAC maintenance page explains coil cleaning as a must-do task.

🌬️ Tip 3: Inspect & Seal Ductwork

Even the most efficient Daikin unit can’t perform if your ductwork leaks. The U.S. DOE estimates up to 30% of conditioned air is lost through leaky ducts in commercial systems .

-

Annual inspection checklist:

-

Look for disconnected joints.

-

Check for visible holes, crushed sections, or missing insulation.

-

Test airflow in rooms—weak airflow could signal leaks.

-

-

Fixing leaks:

-

Seal with mastic sealant or foil-backed tape (never duct tape).

-

Add insulation to ducts in unconditioned spaces.

-

📖 ASHRAE commercial maintenance standards emphasize duct integrity for efficiency.

⚡ Tip 4: Monitor Electrical Components

A 10 ton system draws serious electrical load—especially with a 20kW heat kit. Ignoring electrical maintenance is a recipe for tripped breakers or worse.

-

What to check annually:

-

Breakers, relays, and fuses.

-

Contactors (they wear out faster under heavy use).

-

Wiring connections for tightness and corrosion.

-

-

Signs of trouble:

-

Frequent breaker trips.

-

Burning smell from panels.

-

Heat kit shutting off unexpectedly.

-

🧊 Tip 5: Maintain Refrigerant Charge

Your Daikin system relies on refrigerant to move heat. Too little refrigerant = your system works overtime and risks compressor failure. Too much = reduced efficiency and higher pressures.

-

Annual tasks for pros:

-

Check refrigerant pressures.

-

Inspect for leaks.

-

Top off or recover refrigerant as needed.

-

-

Signs of refrigerant issues:

-

Ice on evaporator coil.

-

Warm supply air.

-

Higher-than-normal utility bills.

-

📖 HVAC.com’s refrigerant guide outlines best practices.

🛠️ Tip 6: Schedule Professional Tune-Ups

Even with regular in-house checks, a licensed HVAC contractor should inspect your system twice a year:

-

Spring tune-up (before cooling season):

-

Refrigerant charge.

-

Coil condition.

-

Filter replacement.

-

Blower motor amperage.

-

-

Fall tune-up (before heating season):

-

Heat kit wiring and operation.

-

Electrical load test.

-

Thermostat calibration.

-

Safety controls.

-

Pro tune-ups cost $300–$600 annually but prevent thousands in repairs.

📖 ACHR News – Commercial HVAC maintenance tips.

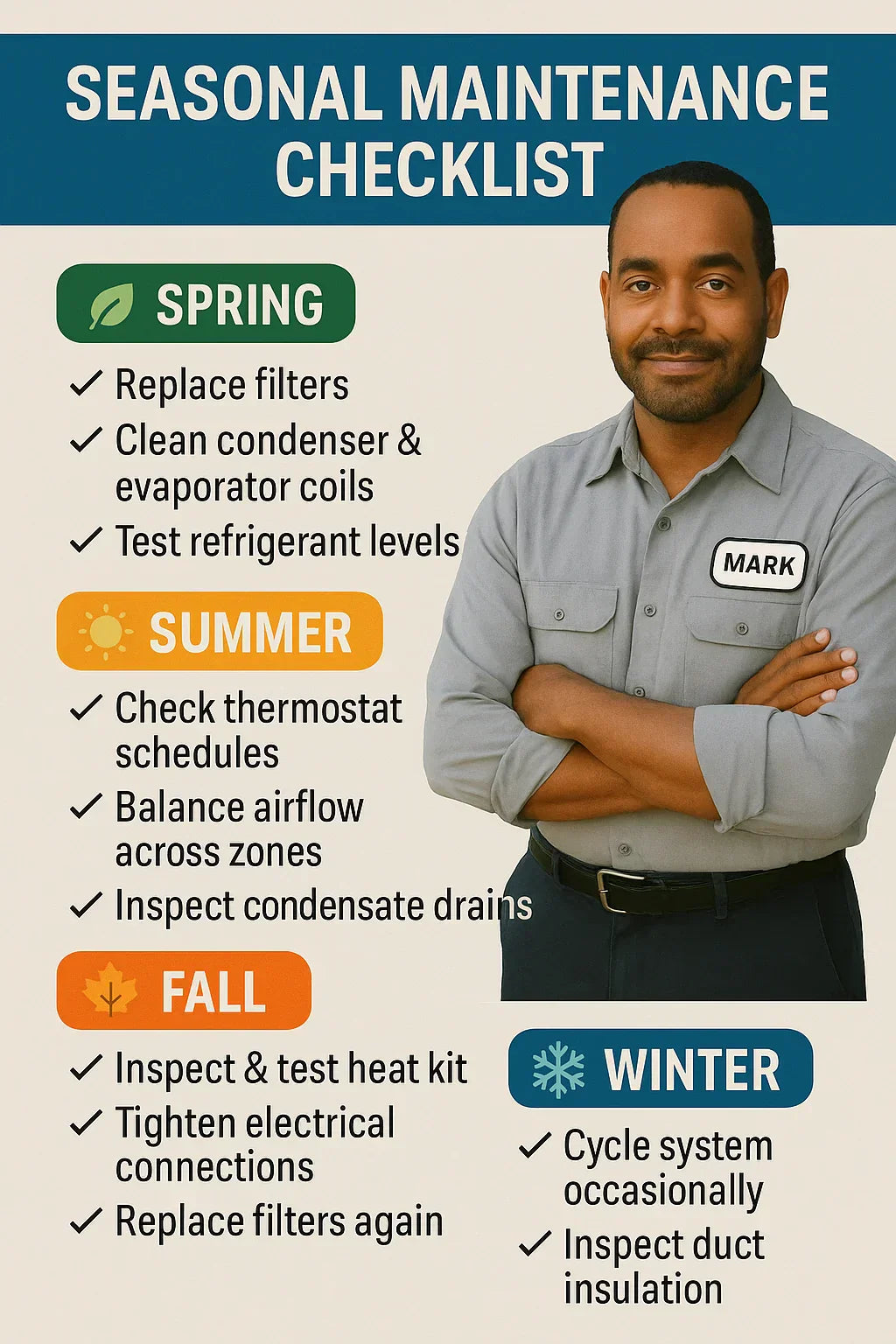

🕒 Tip 7: Set Up Seasonal Checklists

Here’s the seasonal checklist I use in my facility.

🌱 Spring

-

Replace filters.

-

Clean condenser and evaporator coils.

-

Test refrigerant levels.

☀️ Summer

-

Check thermostat schedules.

-

Balance airflow across zones.

-

Inspect condensate drains.

🍂 Fall

-

Inspect and test the 20kW heat kit.

-

Tighten electrical connections.

-

Replace filters again.

❄️ Winter

-

Cycle the system occasionally (even in mild weather).

-

Inspect duct insulation.

-

Check for unusual noises during heating operation.

📖 ENERGY STAR HVAC seasonal guide.

✅ Mark’s Pro Advice

Here are a few lessons I’ve learned firsthand:

-

Don’t procrastinate. A clogged filter or dirty coil today becomes a $2,000 compressor repair tomorrow.

-

Log every service call. Having a record saves time when troubleshooting or filing a warranty claim.

-

Train staff. Empower employees to report hot/cold spots, strange noises, or rising energy bills early.

-

Invest in a service contract. Contractors prioritize customers with contracts during peak season breakdowns.

📈 Conclusion: A Smooth System Pays You Back

A Daikin 10 ton commercial system is built for durability, but like any machine, it only performs as well as you maintain it.

By sticking to filter changes, coil cleaning, duct inspections, electrical monitoring, refrigerant checks, and seasonal tune-ups, you’ll:

-

Extend lifespan from 10–12 years to 15–20 years.

-

Save 10–20% on annual energy costs.

-

Avoid costly mid-season breakdowns.

My bottom line as a facilities manager: “Maintenance isn’t an expense—it’s insurance for your comfort and your wallet.”

In the next topic we will know more about: Daikin vs. Trane vs. Goodman: Which 10 Ton Light Commercial AC Is Right for You?