🏢 Introduction: The Big Budget Question

If you manage a commercial property or run a small-to-mid-sized business, you already know HVAC isn’t just about comfort—it’s about dollars. A poorly sized or outdated system can spike your energy bills, cut into profits, and frustrate employees and customers.

When it comes to light commercial spaces in the 3,000–4,000 sq. ft. range, a 10 ton AC system (like the Daikin Multi-Positional Split System with 20kW heat kit) is often the go-to choice.

But here’s the million-dollar (or maybe $20,000) question:

👉 “How much does a 10 ton AC system really cost, from equipment to installation, and how do long-term savings factor in?”

Having overseen a few installations myself, I can tell you that costs aren’t just about the equipment sitting on the truck. They include labor, permits, ductwork, and ongoing efficiency. Let’s break it down piece by piece.

💵 Equipment Costs: What You’re Paying For

A 10 ton commercial split system is a serious investment. You’re not looking at residential-grade pricing anymore.

Typical Equipment Cost Range

-

$8,000–$14,000 for the main unit (condenser + air handler).

-

Add-ons push that number higher.

Add-Ons That Impact Cost

-

20kW heat kit: $400–$900.

-

Smart thermostat / control system: $300–$800.

-

Zoning equipment: $1,000–$3,000 depending on building design.

-

Upgraded filtration (MERV 13 or higher): $200–$500.

Brand Differences

-

Daikin: Known for balanced cost and efficiency (14.8 IEER2 rating).

-

Trane/Carrier: Premium pricing, often +10–20%.

-

Goodman: More budget-friendly, but lower efficiency in some models.

📖 For context, see Modernize HVAC Cost Guide.

🔧 Installation & Labor Costs

This is where a lot of building owners get sticker shock. Labor can sometimes rival or exceed equipment costs.

Typical Labor Cost Range

-

$5,000–$10,000+ depending on complexity.

What Drives Labor Costs Up

-

Electrical setup: 3-phase wiring, breakers, and disconnects can run $1,500–$3,000.

-

Ductwork modifications: Upgrading undersized ducts may cost $2,000–$6,000.

-

Mechanical room adjustments: Clearing space, drainage, vibration pads.

-

Rooftop installs: Crane rental alone can cost $1,000–$3,000.

-

Local labor rates: Urban areas cost more than rural towns.

My Real-World Example

On one office install I managed:

-

Equipment: $10,500.

-

Labor: $7,800 (included duct upgrades + crane).

-

Total: $18,300 installed.

📖 See HVAC.com’s commercial installation overview.

🛠️ Additional Costs to Budget For

Even beyond equipment and labor, there are hidden or often-overlooked costs:

-

Permits & inspections: $500–$1,500 depending on jurisdiction.

-

Commissioning & testing: $500–$1,000, often required for warranty.

-

Future duct sealing/insulation: If your ductwork isn’t tight, you’ll lose efficiency.

-

Maintenance contracts: $500–$1,200 annually for professional upkeep.

📖 ASHRAE outlines these requirements in HVAC installation standards.

⚡ Operating Costs & Efficiency (Why IEER2 Matters)

Here’s where smart business owners separate cheap upfront costs from long-term smart investments.

A Daikin 10 Ton with 14.8 IEER2 rating is significantly more efficient than older systems with IEER in the 11–12 range.

Example Energy Cost Comparison

-

Old 12 IEER system: $9,500/year cooling costs.

-

New 14.8 IEER2 system: $8,000/year cooling costs.

-

Annual savings: ~$1,500/year.

Over a 15-year lifespan, that’s $22,500 in savings—more than covering the upfront difference.

📖 Check the ENERGY STAR light commercial HVAC efficiency page.

📈 ROI & Payback Period

I often tell colleagues: “Don’t look at sticker price—look at payback.”

-

Extra cost of high-efficiency system: $2,000.

-

Annual savings: $1,200–$1,500.

-

Payback period: 2–3 years.

-

After that: pure profit in reduced utility bills.

📖 For more analysis, see ACEEE’s commercial energy efficiency research.

✅ Long-Term Savings Strategies

A 10 ton AC is a big investment. To make sure you’re getting every dollar back:

1. Use Smart Thermostats

-

Set occupied/unoccupied schedules.

-

Prevents wasted energy nights and weekends.

📖 ENERGY STAR: Smart Thermostats.

2. Stay on Top of Maintenance

-

Change filters quarterly.

-

Clean coils annually.

-

Schedule pro tune-ups twice a year.

📖 ACHR News on commercial HVAC maintenance.

3. Research Rebates & Incentives

-

Utility rebates for high IEER2 systems.

-

Federal tax deductions for energy-efficient commercial upgrades.

📖 ENERGY STAR Rebate Finder.

🧾 Real-World Example: Mark’s Office

When we replaced our outdated 8.5 ton system with a Daikin 10 ton 14.8 IEER2 unit, here’s what it looked like:

-

Equipment: $10,500.

-

Labor: $7,800.

-

Permits/Commissioning: $1,000.

-

Total: ~$19,300.

Annual savings:

-

Old bills: ~$9,500/year.

-

New system: ~$8,200/year.

-

Savings: $1,300/year.

Payback:

-

Reached in under 4 years.

-

Net savings after 15 years: ~$15,000–$18,000.

That’s why I always stress: lowest upfront bid isn’t always the cheapest long-term.

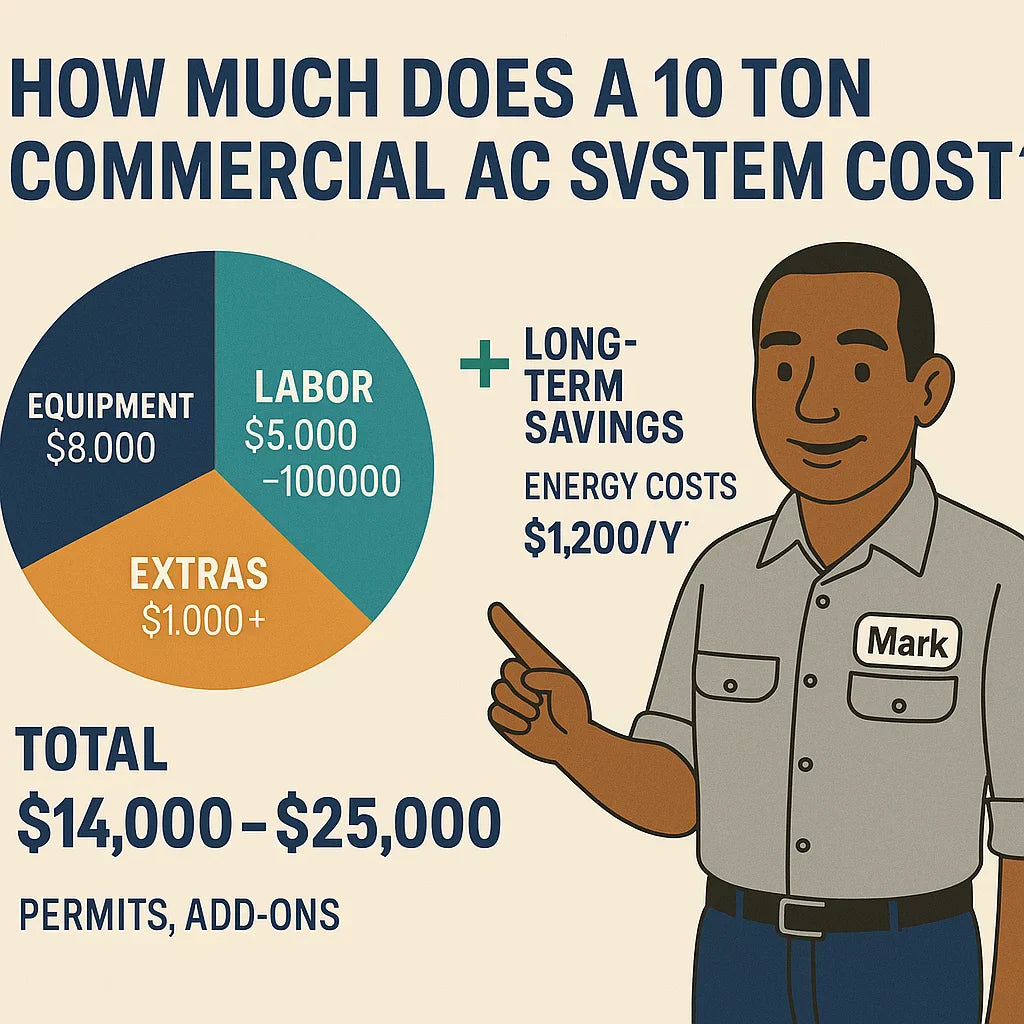

📊 Conclusion: Budgeting Smart for a 10 Ton System

So, how much should you budget for a 10 ton commercial AC system?

-

Equipment: $8,000–$14,000.

-

Labor: $5,000–$10,000.

-

Total installed cost: $13,000–$24,000.

And here’s the real key:

-

A high-efficiency system like Daikin’s 14.8 IEER2 unit pays for itself in 2–5 years.

-

Long-term, it saves tens of thousands on energy bills.

-

Mark’s takeaway: “The cheapest system often costs the most in the long run. Budget for efficiency, not just installation.”

In the next topic we will know more about: Maintenance Tips to Keep Your Daikin 10 Ton System Running Smooth